A Multi-Source Harvesting System Applied to Sensor-Based Smart Garments for Monitoring Workers’ Bio-Physical Parameters in Harsh Environments

Abstract

:1. Introduction

- a harvester, that transduces the energy supplied by the source into electric energy; typical harvesters are the photovoltaic cells, thermoelectric generators (TEGs), antennas for the radio-frequency (RF) energy, the piezoelectric, electromagnetic, magneto-electric, electrostatic, or triboelectric transducers for mechanical energy (Figure 1);

- a conditioning electronic unit, that converts the variable signal produced by the harvester into a DC voltage for the electric load; the conditioning section includes a voltage regulator and complex control circuit able to manage the generated power as a function of the power load requirements and available power from the harvester (Figure 1). Also, this section has an impedance matching function for ensuring the maximum transfer of the harvested power;

- the energy storage device, a battery or super-capacitor (SC); it stores energy gathered by the harvesting unit in order to feed the electronic load in any operating condition (Figure 1).

1.1. Analysis of Wearable Technologies for Energy Harvesting and Health Monitoring

1.2. Description of the Proposed Energetically-Autonomous Wearable Device for Health and Environmental Monitoring Applications in the Workplace.

2. Materials and Methods

Description of Employed Energy Harvesters and Sensors

- Size 1: 197 mm × 97 mm × 0.8 mm dimensions, 1 W maximum electrical power, operating current up to 666 mA, 1.5 V operating voltage, 800 mA short-circuit current and 2 V open-circuit voltage (Figure 4a,b).

- Size 2: 190 mm × 130 mm × 0.8 mm dimensions, 1.5 W maximum electrical power, operating current up to 1000 mA, 1.5 V operating voltage, 1200 mA short-circuit current and 2 V open-circuit voltage (Figure 4c).

- Electro-Mechanical Conversion: (direction-1) 23 × 10−12 m/V, 700 × 10−6 N/V, (direction-3) −33 × 10−12 m/V;

- Mechano-Electrical Conversion: (direction-1) 12 mV per microstrain, 400 mV/µm, 14.4 V/N;

- Pyro-electrical Conversion: (direction 3) 13 mV/N, 8 V/K (@ 25 °C);

- Capacitance: 1.36 nF; Dissipation Factor of 0.018 @ 10 kHz; Impedance of 12 KΩ @ 10 kHz;

- Maximum Operating Voltage: DC) 280 V that yields a 7 µm displacement in the direction-1; AC) 840 V that yields a 21 µm displacement in the direction-1;

- Maximum applied Force (at the break, direction-1): 6–9Kg (yield voltage output: 830 V–1275 V).

3. Results

3.1. Estimation of Solar Cells’ Power Efficiency for Different Light Sources and Luminous Intensities

3.2. Characterization of the Developed Piezoelectric Harvesters Applied to the Human Body

3.3. Characterization of the Selected Thermo-Electric Generators and Relative Conditioning Section.

4. Discussion

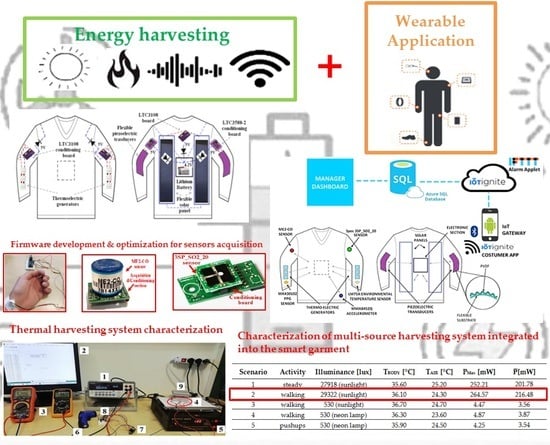

- Scenario 1: a stationary user with a body temperature of 35.6 °C exposed to direct sunlight;

- Scenario 2: a user walking quickly (5 km/h) and exposed to direct sunlight with a body temperature of 36.1 °C;

- Scenario 3: a user walking quickly (5 km/h) and exposed to diffused sunlight with a body temperature of 36.3 °C;

- Scenario 4: a user walking quickly (5 km/h) and exposed to artificial light (neon lamp) with a body temperature of 36.3 °C;

- Scenario 5: a user performing pushups (0.5 Hz) and exposed to artificial light (neon lamp) with a body temperature of 35.9 °C.

Testing and Characterization of the Sensors Included in the Smart Garment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mathias, D.N.; Kim, S.-I.; Park, J.; Joung, Y.-H. Real Time ECG Monitoring Through a Wearable Smart T-shirt. Trans. Electr. Electron. Mater. 2015, 16, 16–19. [Google Scholar] [CrossRef] [Green Version]

- Kamišalić, A.; Fister, I.; Turkanović, M.; Karakatič, S. Sensors and Functionalities of Non-Invasive Wrist-Wearable Devices: A Review. Sensors 2018, 18, 1714. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eskofier, B.M.; Lee, S.I.; Baron, M.; Simon, A.L.; Martindale, C.F.; Gassner, H.; Klucken, J. An Overview of Smart Shoes in the Internet of Health Things: Gait and Mobility Assessment in Health Promotion and Disease Monitoring. Appl. Sci. 2017, 7, 986. [Google Scholar] [CrossRef] [Green Version]

- Prauzek, M.; Konecny, J.; Borova, M.; Janosova, K.; Hlavica, J.; Musilek, P. Energy Harvesting Sources, Storage Devices and System Topologies for Environmental Wireless Sensor Networks: A Review. Sensors (Basel) 2018, 18, 2446. [Google Scholar] [CrossRef] [Green Version]

- Munir, B.; Dyo, V. On the Impact of Mobility on Battery-Less RF Energy Harvesting System Performance. Sensors (Basel) 2018, 18, 3597. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.G.; Chang, N. Powering the IoT: Storage-less and converter-less energy harvesting. In Proceedings of the 20th IEEE Asia and South Pacific Design Automation Conference, Chiba, Japan, 19–22 January 2015; pp. 124–129. [Google Scholar]

- Tang, X.; Wang, X.; Cattley, R.; Gu, F.; Ball, A.D. Energy Harvesting Technologies for Achieving Self-Powered Wireless Sensor Networks in Machine Condition Monitoring: A Review. Sensors (Basel) 2018, 18, 4113. [Google Scholar] [CrossRef] [Green Version]

- Eren, H.; Webster, J.G. Telemedicine and Electronic Medicine; CRC Press: Boca Raton, FL, USA, 2018; ISBN 978-1-351-23147-3. [Google Scholar]

- Dimitrov, D.V. Medical Internet of Things and Big Data in Healthcare. Healthc. Inform. Res. 2016, 22, 156–163. [Google Scholar] [CrossRef]

- Zeinab, K.A.M.; Elmustafa, S.A.A. Internet of Things Applications, Challenges and Related Future Technologies. World Sci. News 2017, 67, 126–148. [Google Scholar]

- Visconti, P.; de Fazio, R.; Primiceri, P.; Cafagna, D.; Strazzella, S.; Giannoccarro, I.N. A Solar-Powered Fertigation System based on Low-Cost Wireless Sensor Network Remotely Controlled by Farmer for Irrigation Cycles and Crops Growth Optimization. Int. J. Electron. Telecommun. 2020, 66, 59–68. [Google Scholar]

- Jokic, P.; Magno, M. Powering smart wearable systems with flexible solar energy harvesting. In Proceedings of the 2017 IEEE International Symposium on Circuits and Systems (ISCAS), Baltimore, MD, USA, 28–31 May 2017; pp. 1–4. [Google Scholar]

- Haghi, M.; Thurow, K.; Stoll, R. Wearable Devices in Medical Internet of Things: Scientific Research and Commercially Available Devices. Healthc. Inform. Res. 2017, 23, 4–15. [Google Scholar] [CrossRef]

- Abraham, K.M. Prospects and Limits of Energy Storage in Batteries. J. Phys. Chem. Lett. 2015, 6, 830–844. [Google Scholar] [CrossRef] [PubMed]

- Visconti, P.; Primiceri, P.; Orlando, C. Solar Powered Wireless Monitoring System of Environmental Conditions for Early Flood Prediction or Optimized Irrigation in Agriculture. ARPN J. Eng. Appl. Sci. 2016, 11, 4623–4632. [Google Scholar]

- Visconti, P.; Ferri, R.; Pucciarelli, M.; Venere, E. Development and Characterization of a solar-based energy harvesting and power management system for a WSN node applied to optimized goods transport and storage. Int. J. Smart Sens. Intell. Syst. 2016, 9, 1637–1667. [Google Scholar]

- Visconti, P.; Primiceri, P.; Ferri, R.; Pucciarelli, M.; Venere, E. An Overview On State-of-Art Energy Harvesting Techniques and Choice Criteria: A WSN Node for Goods Transport and Storage Powered by a Smart Solar- Based EH System. Int. J. Renew. Energy Res. 2017, 7, 1281–1295. [Google Scholar]

- Loncar-Turukalo, T.; Zdravevski, E.; da Silva, J.M.; Chouvarda, I.; Trajkovik, V. Literature on Wearable Technology for Connected Health: Scoping Review of Research Trends, Advances, and Barriers. J. Med. Internet Res. 2019, 21, 1–23. [Google Scholar] [CrossRef]

- Iqbal, M.H.; Aydin, A.; Brunckhorst, O.; Dasgupta, P.; Ahmed, K. A review of wearable technology in medicine. J. R. Soc. Med. 2016, 109, 372–380. [Google Scholar] [CrossRef]

- Al-Eidan, R.M.; Al-Khalifa, H.; Al-Salman, A.M. A Review of Wrist-Worn Wearable: Sensors, Models, and Challenges. J. Sens. 2018, 2018, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Ramadass, Y.K.; Chandrakasan, A.P. A Battery-Less Thermoelectric Energy Harvesting Interface Circuit With 35 mV Startup Voltage. IEEE J. Solid-State Circuits 2011, 46, 333–341. [Google Scholar] [CrossRef]

- Kim, S.; Vyas, R.; Bito, J.; Niotaki, K.; Collado, A.; Georgiadis, A.; Tentzeris, M.M. Ambient RF Energy-Harvesting Technologies for Self-Sustainable Standalone Wireless Sensor Platforms. Proc. IEEE 2014, 102, 1649–1666. [Google Scholar] [CrossRef]

- Thielen, M.; Sigrist, L.; Magno, M.; Hierold, C.; Benini, L. Human body heat for powering wearable devices: From thermal energy to application. Energy Convers. Manag. 2017, 131, 44–54. [Google Scholar] [CrossRef] [Green Version]

- de Fazio, R.; Cafagna, D.; Marcuccio, G.; Visconti, P. Limitations and Characterization of Energy Storage Devices for Harvesting Applications. Energies 2020, 13, 783. [Google Scholar] [CrossRef] [Green Version]

- Silva, F.A. Handbook of Energy Harvesting Power Supplies and Applications [Book News]. IEEE Ind. Electron. Mag. 2016, 10, 67–68. [Google Scholar] [CrossRef]

- Cai, Y.; Deng, F.; Zhao, J.; Qiu, H.; Fan, X.; Liang, Z. The Distributed System of Smart Wearable Energy Harvesting Based on Human Body. In Proceedings of the 2018 IEEE 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 7450–7454. [Google Scholar]

- Alhawari, M.; Tekeste, T.; Mohammad, B.; Saleh, H.; Ismail, M. Power management unit for multi-source energy harvesting in wearable electronics. In Proceedings of the 2016 IEEE 59th International Midwest Symposium on Circuits and Systems (MWSCAS), Abu Dhabi, UAE, 16–19 October 2016; pp. 1–4. [Google Scholar]

- Kim, S.-E.; Kang, T.; Oh, K.-I.; Park, M.J.; Park, H.-I.; Lim, I.G.; Lee, J.-J. Energy Management Integrated Circuit for Multi-Source Energy Harvesters in WBAN Applications. Appl. Sci. 2018, 8, 1262. [Google Scholar] [CrossRef] [Green Version]

- Visconti, P.; de Fazio, R.; Costantini, P.; Miccoli, S.; Cafagna, D. Arduino-Based Solution for In-Car- Abandoned Infants’ Controlling Remotely Managed by Smartphone Application. JCOMSS 2019, 15, 89–100. [Google Scholar] [CrossRef] [Green Version]

- Gaetani, F.; Primiceri, P.; Antonio Zappatore, G.; Visconti, P. Hardware design and software development of a motion control and driving system for transradial prosthesis based on a wireless myoelectric armband. IET Sci. Meas. Technol. 2019, 13, 354–362. [Google Scholar] [CrossRef]

- Osswald, S.; Weiss, A.; Tscheligi, M. Designing wearable devices for the factory: Rapid contextual experience prototyping. In Proceedings of the 2013 IEEE International Conference on Collaboration Technologies and Systems (CTS), San Diego, CA, USA, 20–24 May 2013; pp. 517–521. [Google Scholar]

- Alam, M.M.; Hamida, E.B. Surveying Wearable Human Assistive Technology for Life and Safety Critical Applications: Standards, Challenges and Opportunities. Sensors 2014, 14, 9153–9209. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Takei, K.; Honda, W.; Harada, S.; Arie, T.; Akita, S. Toward Flexible and Wearable Human-Interactive Health-Monitoring Devices. Adv. Healthc. Mater. 2015, 4, 487–500. [Google Scholar] [CrossRef]

- Mantua, J.; Gravel, N.; Spencer, R.M.C. Reliability of Sleep Measures from Four Personal Health Monitoring Devices Compared to Research-Based Actigraphy and Polysomnography. Sensors 2016, 16, 646. [Google Scholar] [CrossRef] [Green Version]

- Bio-Monitor: Keeping an Eye on Astronauts’ Vital Signs. Available online: https://www.asc-csa.gc.ca/eng/sciences/bio-monitor.asp (accessed on 12 April 2020).

- Qaosar, M.; Ahmed, S.; Li, C.; Morimoto, Y. Hybrid Sensing and Wearable Smart Device for Health Monitoring and Medication: Opportunities and Challenges. In Proceedings of the AAAI Spring Symposium Series; Association for the Advancement of Artificial Intelligence, Palo Alto, CA, USA, 26–28 March 2018; Volume 1, pp. 269–274. [Google Scholar]

- Al-khafajiy, M.; Baker, T.; Chalmers, C.; Asim, M.; Kolivand, H.; Fahim, M.; Waraich, A. Remote health monitoring of elderly through wearable sensors. Multimed. Tools Appl. 2019, 78, 24681–24706. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, Y.; Matsuda, Y.; Arakawa, Y.; Yasumoto, K. WaistonBelt X: A Belt-Type Wearable Device with Sensing and Intervention Toward Health Behavior Change. Sensors 2019, 19, 4600. [Google Scholar] [CrossRef] [Green Version]

- Kyriakopoulos, G.; Ntanos, S.; Anagnostopoulos, T.; Tsotsolas, N.; Salmon, I.; Ntalianis, K. Internet of Things (IoT)-Enabled Elderly Fall Verification, Exploiting Temporal Inference Models in Smart Homes. Int. J. Environ. Res. Public Health 2020, 17, 408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stetter, B.J.; Ringhof, S.; Krafft, F.C.; Sell, S.; Stein, T. Estimation of Knee Joint Forces in Sport Movements Using Wearable Sensors and Machine Learning. Sensors 2019, 19, 690. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lapinski, M.; Brum Medeiros, C.; Moxley Scarborough, D.; Berkson, E.; Gill, T.J.; Kepple, T.; Paradiso, J.A. A Wide-Range, Wireless Wearable Inertial Motion Sensing System for Capturing Fast Athletic Biomechanics in Overhead Pitching. Sensors 2019, 19, 3637. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mamun, M.A.A.; Yuce, M.R. Sensors and Systems for Wearable Environmental Monitoring Toward IoT-Enabled Applications: A Review. IEEE Sens. J. 2019, 19, 7771–7788. [Google Scholar] [CrossRef]

- Haghi, M.; Stoll, R.; Thurow, K. A Low-Cost, Standalone, and Multi-Tasking Watch for Personalized Environmental Monitoring. IEEE Trans. Biomed. Circuits Syst. 2018, 12, 1144–1154. [Google Scholar] [CrossRef]

- Kim, S.; Paulos, E.; Gross, M.D. WearAir: Expressive t-shirts for air quality sensing. In Proceedings of the TEI ’10, Cambridge, MA, USA, 25–27 January 2010; pp. 295–296. [Google Scholar]

- Spirjakin, D.; Baranov, A.; Akbari, S. Wearable Wireless Sensor System With RF Remote Activation for Gas Monitoring Applications. IEEE Sens. J. 2018, 18, 2976–2982. [Google Scholar] [CrossRef]

- Pu, X.; Hu, W.; Wang, Z.L. Toward Wearable Self-Charging Power Systems: The Integration of Energy-Harvesting and Storage Devices. Small 2018, 14, 1–20. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, J.; Kim, T.Y.; Hossain, M.S.A.; Kim, S.-W.; Kim, J.H. All-in-one energy harvesting and storage devices. J. Mater. Chem. A 2016, 4, 7983–7999. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H.; Kim, S.-W.; Wang, Z.L. Preface for Special Topic: Nanogenerators. APL Mater. 2017, 5, 073701. [Google Scholar] [CrossRef] [Green Version]

- Varma, S.J.; Kumar, K.S.; Seal, S.; Rajaraman, S.; Thomas, J. Fiber-Type Solar Cells, Nanogenerators, Batteries, and Supercapacitors for Wearable Applications. Adv. Sci. 2018, 5, 1–32. [Google Scholar] [CrossRef]

- Yao, H.; Ye, L.; Zhang, H.; Li, S.; Zhang, S.; Hou, J. Molecular Design of Benzodithiophene-Based Organic Photovoltaic Materials. Chem. Rev. 2016, 116, 7397–7457. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Li, S.; Yao, H.; Zhang, S.; Zhang, Y.; Yang, B.; Hou, J. Molecular Optimization Enables over 13% Efficiency in Organic Solar Cells. J. Am. Chem. Soc. 2017, 139, 7148–7151. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Xu, G.; Cui, C.; Li, Y. Flexible and Semitransparent Organic Solar Cells. Adv. Energy Mater. 2018, 8, 1701791. [Google Scholar] [CrossRef]

- Shin, S.S.; Yeom, E.J.; Yang, W.S.; Hur, S.; Kim, M.G.; Im, J.; Seo, J.; Noh, J.H.; Seok, S.I. Colloidally prepared La-doped BaSnO3 electrodes for efficient, photostable perovskite solar cells. Science 2017, 356, 167–171. [Google Scholar] [CrossRef] [PubMed]

- Service, R.F. Perovskite solar cells gear up to go commercial. Science 2016, 354, 1214–1215. [Google Scholar] [CrossRef] [PubMed]

- Qiu, L.; He, S.; Yang, J.; Deng, J.; Peng, H. Fiber-Shaped Perovskite Solar Cells with High Power Conversion Efficiency. Small 2016, 12, 2419–2424. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Wu, F.; Redouté, J.; Yuce, M.R. An Autonomous Wireless Body Area Network Implementation Towards IoT Connected Healthcare Applications. IEEE Access 2017, 5, 11413–11422. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, C.; Liu, J.; Xiong, J.; Liu, J.; Zhang, K.; Liu, Y.; Peng, M.; Yu, A.; Zhang, A.; et al. Lattice Strain Induced Remarkable Enhancement in Piezoelectric Performance of ZnO-Based Flexible Nanogenerators. ACS Appl. Mater. Interfaces 2016, 8, 1381–1387. [Google Scholar] [CrossRef]

- Leoni, A.; Stornelli, V.; Ferri, G.; Errico, V.; Ricci, M.; Pallotti, A.; Saggio, G. A human body powered sensory glove system based on multisource energy harvester. In Proceedings of the 2018 IEEE 14th Conference on Ph.D. Research in Microelectronics and Electronics (PRIME), Prague, Czech Republic, 2–5 July 2018; pp. 113–116. [Google Scholar]

- Weddell, A.S.; Magno, M.; Merrett, G.V.; Brunelli, D.; Al-Hashimi, B.M.; Benini, L. A survey of multi-source energy harvesting systems. In Proceedings of the IEEE 2013 Design, Automation Test in Europe Conference Exhibition (DATE), Grenoble, France, 18–22 March 2013; pp. 905–908. [Google Scholar]

- Dąbrowska, A.; Greszta, A. Analysis of the Possibility of Using Energy Harvesters to Power Wearable Electronics in Clothing. Adv. Mater. Sci. Eng. 2019, 2019, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.-H.; Cho, H.-S.; Park, S.-H.; Song, S.-H.; Yun, K.-S.; Lee, J.H. Effect of garment design on piezoelectricity harvesting from joint movement. Smart Mater. Struct. 2016, 25, 1–15. [Google Scholar] [CrossRef]

- Cao, X.; Jie, Y.; Wang, N.; Wang, Z. Triboelectric Nanogenerators Driven Self-Powered Electrochemical Processes for Energy and Environmental Science. Adv. Energy Mater. 2016, 6, 1–20. [Google Scholar] [CrossRef]

- Ahmed, A.; Saadatnia, Z.; Hassan, I.; Zi, Y.; Xi, Y.; He, X.; Zu, J.; Wang, Z. Self-Powered Wireless Sensor Node Enabled by a Duck-Shaped Triboelectric Nanogenerator for Harvesting Water Wave Energy. Adv. Energy Mater. 2016, 1–10. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Z.L. Reviving Vibration Energy Harvesting and Self-Powered Sensing by a Triboelectric Nanogenerator. Joule 2017, 1, 480–521. [Google Scholar] [CrossRef]

- Li, Z.; Saadatnia, Z.; Yang, Z.; Naguib, H. A hybrid piezoelectric-triboelectric generator for low-frequency and broad-bandwidth energy harvesting. Energy Convers. Manag. 2018, 174, 188–197. [Google Scholar] [CrossRef]

- Ahmed, A.; Zhang, S.L.; Hassan, I.; Saadatnia, Z.; Zi, Y.; Zu, J.; Wang, Z.L. A washable, stretchable, and self-powered human-machine interfacing Triboelectric nanogenerator for wireless communications and soft robotics pressure sensor arrays. Extrem. Mech. Lett. 2017, 13, 25–35. [Google Scholar] [CrossRef]

- Chen, H.; Song, Y.; Cheng, X.; Zhang, H. Self-powered electronic skin based on the triboelectric generator. Nano Energy 2019, 56, 252–268. [Google Scholar] [CrossRef]

- Hua, Q.; Sun, J.; Liu, H.; Bao, R.; Yu, R.; Zhai, J.; Pan, C.; Wang, Z.L. Skin-inspired highly stretchable and conformable matrix networks for multifunctional sensing. Nat. Commun. 2018, 9, 1–11. [Google Scholar] [CrossRef]

- Chen, H.; Su, Z.; Song, Y.; Cheng, X.; Chen, X.; Meng, B.; Song, Z.; Chen, D.; Zhang, H. Omnidirectional Bending and Pressure Sensor Based on Stretchable CNT-PU Sponge. Adv. Funct. Mater. 2017, 27, 1–9. [Google Scholar] [CrossRef]

- Moravčík, M.; Schmid, M.; Burch, N.; Lisý, V.; Morrill, D.; Bard, N.; Davis, T.; Waugh, K.; Johanson, M.; Bowling, M. DeepStack: Expert-level artificial intelligence in heads-up no-limit poker. Science 2017, 356, 508–513. [Google Scholar] [CrossRef] [Green Version]

- Yu, X.; Mahajan, B.K.; Shou, W.; Pan, H. Materials, Mechanics, and Patterning Techniques for Elastomer-Based Stretchable Conductors. Micromachines 2017, 8, 7. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Guo, H.; He, X.; Liu, G.; Xi, Y.; Shi, H.; Hu, C. Enhancing Performance of Triboelectric Nanogenerator by Filling High Dielectric Nanoparticles into Sponge PDMS Film. ACS Appl. Mater. Interfaces 2016, 8, 736–744. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.-S.; Brugger, J.; Kim, B. A silk-fibroin-based transparent triboelectric generator suitable for autonomous sensor network. Nano Energy 2016, 20, 37–47. [Google Scholar] [CrossRef]

- Wang, J. Special Issue for Wearable Electrochemical Sensors. Electroanalysis 2016, 28, 1148. [Google Scholar] [CrossRef] [Green Version]

- Gross, A.J.; Holzinger, M.; Cosnier, S. Buckypaper bioelectrodes: Emerging materials for implantable and wearable biofuel cells. Energy Environ. Sci. 2018, 11, 1670–1687. [Google Scholar] [CrossRef]

- Lv, J.; Jeerapan, I.; Tehrani, F.; Yin, L.; Silva-Lopez, C.A.; Jang, J.-H.; Joshuia, D.; Shah, R.; Liang, Y.; Xie, L.; et al. Sweat-based wearable energy harvesting-storage hybrid textile devices. Energy Environ. Sci. 2018, 11, 3431–3442. [Google Scholar] [CrossRef]

- Kanimba, E.; Tian, Z. Modeling of a Thermoelectric Generator Device, 1st ed.; IntechOpen: London, UK, 2016; Volume 1. [Google Scholar] [CrossRef] [Green Version]

- Yan, J.; Liao, X.; Yan, D.; Chen, Y. Review of Micro Thermoelectric Generator. J. Microelectromech. Syst. 2018, 27, 1–18. [Google Scholar] [CrossRef]

- Rojas, J.P.; Singh, D.; Inayat, S.B.; Sevilla, G.A.T.; Fahad, H.M.; Hussain, M.M. Review—Micro and Nano-Engineering Enabled New Generation of Thermoelectric Generator Devices and Applications. ECS J. Solid State Sci. Technol. 2017, 6, 3036–3044. [Google Scholar] [CrossRef] [Green Version]

- Leonov, V. Thermoelectric Energy Harvesting of Human Body Heat for Wearable Sensors. IEEE Sens. J. 2013, 13, 2284–2291. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, F.; Shakhsheer, Y.; Silver, J.D.; Klinefelter, A.; Nagaraju, M.; Boley, J.; Pandey, J.; Shrivastava, A.; Carlson, E.J.; et al. A Batteryless 19μW MICS/ISM-Band Energy Harvesting Body Sensor Node SoC for ExG Applications. IEEE J. Solid-State Circuits 2013, 48, 199–213. [Google Scholar] [CrossRef]

- Proto, A.; Bibbo, D.; Cerny, M.; Vala, D.; Kasik, V.; Peter, L.; Conforto, S.; Schmid, M.; Penhaker, M. Thermal Energy Harvesting on the Bodily Surfaces of Arms and Legs through a Wearable Thermo-Electric Generator. Sensors 2018, 18, 1927. [Google Scholar] [CrossRef] [Green Version]

- Minnaert, B.; Veelaert, P. A Proposal for Typical Artificial Light Sources for the Characterization of Indoor Photovoltaic Applications. Energies 2014, 7, 1500–1516. [Google Scholar] [CrossRef] [Green Version]

- Virtuani, A.; Lotter, E.; Powalla, M. Influence of the light source on the low-irradiance performance of Cu(In,Ga)Se2 solar cells. Sol. Energy Mater. Sol. Cells 2006, 90, 2141–2149. [Google Scholar] [CrossRef]

- Benghanem, M.S.; Alamri, S.N. Modeling of photovoltaic module and experimental determination of serial resistance. J. Taibah Univ. Sci. 2009, 2, 94–105. [Google Scholar] [CrossRef]

- Özdemir, A.T. An Analysis on Sensor Locations of the Human Body for Wearable Fall Detection Devices: Principles and Practice. Sensors (Basel) 2016, 16, 1161. [Google Scholar] [CrossRef] [PubMed]

| Source | Operating Conditions | Harvested Power |

|---|---|---|

| Light | Indoor | 4 μW/cm2 |

| Outdoor | 4100 μW/cm2 | |

| Thermal | Human (small temperature gradient) | 25 μW/cm2 |

| Industrial (high temperature gradient) | 1–10 μW/cm2 | |

| RF signals | Communication signals | 0.1 μW/cm2 |

| Industrial RF signals | 1 μW/cm2 | |

| Mechanical Vibrations | Human (Hz range) | 40 μW/cm2 |

| Industrial (kHz range) | 800 μW/cm2 |

| Illuminance [lux] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 560 | 640 | 1512 | 3000 | 5150 | 10,230 | 17,170 | 33,800 | 87,100 | ||

| Sunlight | VIN [mV] | 45.44 | 51.26 | 112.92 | 150.50 | 340.23 | 500.12 | 695.49 | 1570.89 | 2850.45 |

| IIN [mA] | 7.18 | 7.98 | 16.50 | 27.98 | 50.71 | 93.45 | 182.90 | 390.37 | 672.67 | |

| Ne lamp | VIN [mV] | 30.23 | 33.52 | 46.56 | 72.67 | |||||

| IIN [mA] | 3.81 | 4.05 | 7.57 | 10.42 | ||||||

| Movements | Description | VOC,Max [V] | VOC,RMS [V] | PMax [µW] |

|---|---|---|---|---|

| 1 | Arm bending, transducer placed outside the elbow | 31.25 | 6.87 | 256.12 |

| 2 | Arm bending, transducer placed inside the elbow | 27.57 | 5.98 | 234.83 |

| 3 | Arm lifting, transducer placed outside the shoulder | 28.61 | 6.26 | 245.39 |

| 4 | Arm lifting, transducer placed inside the shoulder | 26.78 | 5.97 | 238.65 |

| Scenario | Activity | Illuminance [lux] | TBODY [°C] | TAIR [°C] | PMax [mW] | [mW] |

|---|---|---|---|---|---|---|

| 1 | steady | 27,918 (sunlight) | 35.60 | 25.20 | 252.21 | 201.78 |

| 2 | walking | 29,322 (sunlight) | 36.10 | 24.30 | 264.57 | 216.48 |

| 3 | walking | 530 (sunlight) | 36.70 | 24.70 | 4.47 | 3.56 |

| 4 | walking | 530 (neon lamp) | 36.30 | 23.60 | 4.87 | 3.87 |

| 5 | pushups | 530 (neon lamp) | 35.90 | 24.50 | 4.25 | 3.54 |

| Heart-Rate CocoBear (BPM) | Heart-Rate MAX30102 (BPM) | SpO2 CocoBear (%) | SpO2 MAX30102 (%) | Δ HR Coco Bear (BPM) | Δ SpO2 Coco Bear (%) | Temperature (°C) |

|---|---|---|---|---|---|---|

| 78 | 75 | 97 | 98 | 3 | 1 | 34.7 |

| 79 | 76 | 97 | 97 | 3 | 0 | 34.6 |

| 83 | 81 | 96 | 95 | 2 | 1 | 33.7 |

| 84 | 83 | 95 | 96 | 1 | -1 | 34.7 |

| 85 | 84 | 96 | 97 | 1 | -1 | 34.8 |

| 86 | 85 | 98 | 98 | 1 | 0 | 34.8 |

| 87 | 86 | 97 | 98 | 1 | -1 | 34.7 |

| 88 | 87 | 98 | 98 | 1 | 0 | 34.7 |

| 89 | 89 | 98 | 98 | 0 | 0 | 34.6 |

| 100 | 100 | 97 | 97 | 0 | 0 | 34.7 |

| 110 | 110 | 99 | 99 | 0 | 0 | 35.0 |

| 120 | 121 | 99 | 100 | -1 | -1 | 35.1 |

| 122 | 122 | 99 | 99 | 0 | 0 | 35.4 |

| Test | Threshold Value (1 LSB) | Manually Counted Steps | Counted Steps by MMA8452Q Pedometer |

|---|---|---|---|

| 1 | 150 | 50 | 70 |

| 2 | 150 | 100 | 127 |

| 3 | 200 | 100 | 109 |

| 4 | 200 | 110 | 118 |

| 5 | 200 | 125 | 137 |

| 6 | 220 | 70 | 72 |

| 7 | 220 | 100 | 101 |

| 8 | 220 | 110 | 112 |

| 9 | 225 | 100 | 102 |

| 10 | 225 | 110 | 112 |

| 11 | 230 | 100 | 98 |

| 12 | 230 | 105 | 102 |

| 13 | 230 | 108 | 105 |

| 14 | 240 | 110 | 103 |

| 15 | 240 | 125 | 115 |

| 16 | 250 | 100 | 86 |

| 17 | 250 | 108 | 96 |

| 18 | 300 | 115 | 100 |

| 19 | 300 | 136 | 116 |

| 20 | 350 | 125 | 100 |

| 21 | 400 | 125 | 95 |

| 22 | 500 | 125 | 90 |

| Threshold Value | Number of Performed Falls | Number of Detected Falls | Number of False Falls |

|---|---|---|---|

| 1 | 5 | 0 | 0 |

| 2 | 6 | 1 | 0 |

| 3 | 6 | 4 | 0 |

| 4 | 8 | 7 | 0 |

| 5 | 4 | 4 | 1 |

| 6 | 4 | 6 | 2 |

| 7 | 3 | 6 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Fazio, R.; Cafagna, D.; Marcuccio, G.; Minerba, A.; Visconti, P. A Multi-Source Harvesting System Applied to Sensor-Based Smart Garments for Monitoring Workers’ Bio-Physical Parameters in Harsh Environments. Energies 2020, 13, 2161. https://doi.org/10.3390/en13092161

de Fazio R, Cafagna D, Marcuccio G, Minerba A, Visconti P. A Multi-Source Harvesting System Applied to Sensor-Based Smart Garments for Monitoring Workers’ Bio-Physical Parameters in Harsh Environments. Energies. 2020; 13(9):2161. https://doi.org/10.3390/en13092161

Chicago/Turabian Stylede Fazio, Roberto, Donato Cafagna, Giorgio Marcuccio, Alessandro Minerba, and Paolo Visconti. 2020. "A Multi-Source Harvesting System Applied to Sensor-Based Smart Garments for Monitoring Workers’ Bio-Physical Parameters in Harsh Environments" Energies 13, no. 9: 2161. https://doi.org/10.3390/en13092161

APA Stylede Fazio, R., Cafagna, D., Marcuccio, G., Minerba, A., & Visconti, P. (2020). A Multi-Source Harvesting System Applied to Sensor-Based Smart Garments for Monitoring Workers’ Bio-Physical Parameters in Harsh Environments. Energies, 13(9), 2161. https://doi.org/10.3390/en13092161