New Challenges in Tribology: Wear Assessment Using 3D Optical Scanners

Abstract

:1. Introduction

- Weighing [9]: according to this method, the components under study are weighed before and after a certain period of use to evaluate the mass wear rate. The difference of weight is useful also to assess the amount of the worn volume, when the exact density of the material is known and when the material is supposed to be homogenous. In this case, accurate mass balances should be used, as loss of material in wear applications is often very small, and thus little disturbances in mass can affect the test results. The advantage of weighing is that it is the simplest method for measuring wear rates. The disadvantages are due to the impossibility of using this method when the component under study cannot be dismounted or also when material is transferred on the components during the wear progress. Furthermore, this method does not enable evaluations of the wear distribution over the specimen’s surface.

- Surface activation: in surface activation, the target surface is activated with radioactive rays before wear. After the wear progression, the surface is examined with a radioactive-ray spectrometer and the change in activity shows the amount of wear. The advantage of surface activation is the possibility of performing simultaneous measurements of wear rates of various parts. The disadvantage is that this method is inaccurate and it is difficult to ensure safety during the procedure.

- Ultrasonic reflectometry and phase interference [10,11]: real time measurements of wear can be performed by these methods. Ultrasonic reflectometry is commonly used in the field of non-destructive testing (NDT) for crack detection, wall thickness monitoring, and medical imaging. A sound wave is emitted through the specimen under study using a piezoelectric transducer. This waveform travels through the host medium at a constant speed and is either partially or fully reflected at an interface. The reflected wave is picked up by the same sensor; the signal is then amplified and digitized. If the speed that sound travels through a host medium is known as well as the time this takes, the thickness of the material can be established [10]. Also, ultrasonic phase-comparison techniques can be used [11]. The advantage of these methods is the very high resolution. In-fact, up to 1 μm dimensional changes can be detected. The main disadvantage deals with the requirement of highly specialized personnel.

- 2D digital image processing [12,13,14,15,16]: this method is based on computer vision and statistical learning systems to estimate the wear level, for example in manufacturing tools, in order to identify the time for their replacement. Binary images for each worn specimen’s image can be obtained by applying several pre-processing and segmenting operations. Then every worn region can be described by means of some geometrical descriptors (as for example eccentricity, extent and solidity). Based on the results obtained using a finite mixture model approach, different levels of wear can be detected (for example low, medium, and high wear level). The estimate of the wear level enables replacement of the tool when the wear level is located at the end of the medium class, preventing the tool from falling into the high class. An estimation of wear can also be done by comparing 2D profiles, measured on the components during the wear progress, by processing those profiles using digital image processing techniques, as in [15,16]. The advantage of this method is the simplicity and the possibility of taking pictures without dismounting the component. On the other hand, the method is slow and not very accurate.

- Manual thickness measurements, contact microscopy, and profilometry and surface detection [17,18,19,20,21,22]: these methods imply the use of callipers, comparators, or devices called contact or stylus profilometers, coordinated measuring machines (CMM) and atomic force or friction force microscopes (AFM/FFM). Stylus profilometers and CMM are measuring instruments able to detect the 2D profile of a specific section of the specimen (in the case of profilometers) and the 3D topography of the target surface (in the case of CMMs) by contacting the specimen’s surface with a sensing probe (a diamond stylus or metal balls). AFM/FFM microscopes are particular kinds of scanning force microscopes (SFM) sensitive to mechanical properties down to the nanometre scale. In particular, the contact mode atomic force microscope (AFM) is more suitable for the study of morphology and tribological effects on the micro-nanometre scale [21]. Such a technique is customarily employed for the characterization of solid thin films and is able to provide absolute values of the local kinetic or sliding friction. For example, in [22] an AFM provided tribological information about the morphology and the kinetic friction at the micro-nanometre scale. That information is evidenced when the sharp probe of an AFM—supported on an elastic cantilever beam—is moved laterally while contacting the sample surface. Such technique, named ‘friction force microscopy’ (FFM), is accomplished in a standard AFM by detecting the twisting movement of the cantilever beam, due to the lateral force acting on the tip, and provides information on the amount of sliding friction between the AFM tip and a local portion of the sample surface. Using those contact methods, measurements are made before and after wear and the two obtained surfaces are compared by numerical techniques to compute the loss of material. The main advantages regard the high accuracy of these instruments that can also provide the distribution of wear. As a disadvantage, they are slow and the specimen must be dismounted most of the time; they require the use of very expensive equipment and most of all the contact with the specimen’s surface can alter the wear characteristics.

- Optical microscopy, 2D profilometry, and 3D scanning [23,24,25]: these methods imply the use of optical non-contact profilometers, 3D scanners, and microscopes. Optical 2D profilometers and 3D scanners can work according to the principles of optical range-finding techniques as, for example, confocal microscopy, time of flight, laser or structured light triangulation, photogrammetry, interferometry, etc. 3D optical microscopes can work according to the principles of confocal microscopy, focus variation microscopy, scanning electron microscopy, fluorescence microscopy. Those methods show many advantages versus the prior ones. For example, they are very accurate, simple, and fast, they are able to provide the distribution of wear over the entire surface of the components, even in real time and for objects with very complex shapes. When the scanning devices are portable, the specimen does not need to be dismounted; the absence of contact does not alter the surfaces. Equipment are relatively cheap with respect to the prior ones, thanks to technological progress, and they enable very fast wear assessments. The only disadvantage is related to the 2D profilometry that is not a good solution when the specimen has a complex shape.

2. Methods

2.1. Experimental Approach

- The nominal CAD model of the specimen as it results from the design phase.

- The digitized 3D model of the specimen at the beginning of its useful life. In this second case, the model can be reconstructed from the real specimen before its exercise or from another specimen, identical to the worn one, before use.

- (a)

- The worn and the reference models must be aligned and superimposed to evaluate the deviations.

- (b)

- The difference of volume between the worn and non-worn models can be calculated to evaluate the wear rates.

- (c)

- The color 3D map of deviations is built, representing the wear distribution over the specimen’s surface.

2.2. Limits of the Experimental Procedure

2.3. 3D Optical Scanning and Devices

3. Wear Characterization by Using 3D Optical Scanners

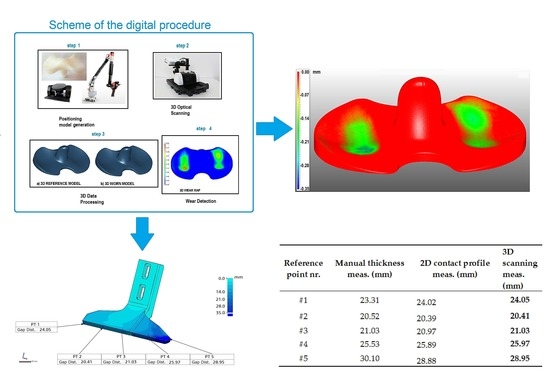

3.1. Test 1: Wear Characterization of Mixing Blades

- (a)

- The worn model was scanned by HandySCAN 700 and the full 3D model was automatically and real time reconstructed by the scanning software.

- (b)

- The worn model was superimposed and aligned to the CAD reference model with the mesh editing and modeling software Geomagic Control X (3D Systems, Rock Hill, SC, USA).

- (c)

- The 3D color map of the wear distribution was built.

- (d)

- The wear distribution was evaluated by comparison between the volumes calculated on the CAD and worn model and the reference points were checked to get the value of the gap distance, representing the material loss. The result is shown in Figure 4.

3.2. Test 2: Wear of a Knee Joint

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Grillini, L.; Affatato, S. How to measure wear following total hip arthroplasty. Hip Int. 2013, 23, 233–242. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Zhu, Z. Case study: Wear analysis of the middle plate of a heavy-load scraper conveyor chute under a range of operating conditions. Wear 2017, 380, 36–41. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, C.; Wang, X. The wear behavior of textured steel sliding against polymers. Materials 2017, 10, 330. [Google Scholar] [CrossRef]

- Polach, O.; Nicklisch, D. Wheel/rail contact geometry parameters in regard to vehicle behavior and their alteration with wear. Wear 2016, 366, 200–208. [Google Scholar] [CrossRef]

- Chang, S.; Pyun, Y.S.; Amanov, A. Wear enhancement of wheel-rail interaction by ultrasonic nanocrystalline surface modification technique. Materials 2017, 10, 188. [Google Scholar] [CrossRef]

- Heintze, S.D.; Ilie, N.; Hickel, R.; Reis, A.; Loguercio, A.; Rousson, V. Laboratory mechanical parameters of composite resins and their relation to fractures and wear in clinical trials—A systematic review. Dent. Mater. 2017, 33, 101–114. [Google Scholar] [CrossRef] [PubMed]

- Akkök, M.; Acar, B.; Açmaz, E. Experimental analysis and wear modeling for mechanical components of a typical rail launcher. Wear 2013, 306, 1–9. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W.; Stachowiak, G.B. Experimental Methods in Tribology. Tribol. Ser. 2004, 44, 27–29. [Google Scholar]

- Bills, P.; Blunt, L.; Jiang, X. Development of a technique for accurately determining clinical wear in explanted total hip replacements. Wear 2007, 263, 1133–1137. [Google Scholar] [CrossRef]

- Brunskill, H.; Harper, P.; Lewis, R. The real-time measurement of wear using ultrasonic reflectometry. Wear 2015, 332, 1129–1133. [Google Scholar] [CrossRef]

- Birring, A.S.; Kwun, H. Ultrasonic Measurement of Wear. Tribol. Int. 1989, 22, 33–37. [Google Scholar] [CrossRef]

- Castejòn, M.; Alegre, E.; Barreiro, J.; Hernàndez, L.K. On-line tool wear monitoring using geometric descriptors from digital images. Int. J. Mach. Tools Manuf. 2007, 47, 1847–1853. [Google Scholar] [CrossRef]

- Dutta, S.; Pal, S.K.; Mukhopadhyay, S.; Sen, R. Application of digital image processing in tool condition monitoring: A review. CIRP J. Manuf. Sci. Technol. 2013, 6, 212–232. [Google Scholar] [CrossRef]

- Hamed, A.M.; El-Ghandoor, H.; El-Diasty, F.; Saudy, M. Analysis of speckle images to assess surface roughness. Opt. Laser Technol. 2004, 36, 249–253. [Google Scholar] [CrossRef]

- Valigi, M.C.; Logozzo, S.; Rinchi, M. Wear resistance of blades in planetary concrete mixers. Design of a new improved blade shape and 2D validation. Tribol. Int. 2016, 96, 191–201. [Google Scholar] [CrossRef]

- Valigi, M.C.; Fabi, L.; Gasperini, I. Wear resistance of new blade for planetary concrete mixer. In Proceedings of the 5th World Tribology Congress, Torino, Italy, 8–13 September 2013. [Google Scholar]

- Carmignato, S.; Spinelli, M.; Affatato, S.; Savio, E. Uncertainty evaluation of volumetric wear assessment from coordinate measurements of ceramic hip joint prostheses. Wear 2011, 270, 584–590. [Google Scholar] [CrossRef]

- Bassani, R.; Ciulli, E.; Manfredi, E.; Manconi, S.; Polacco, A.; Pugliese, G. Experimental study on wear and fracture in aeronautical gear transmissions. In Proceedings of the 8th Biennial ASME Conference on Engineering Systems Design and Analysis, Torino, Italy, 4–7 July 2006. [Google Scholar]

- Uddin, M.S. Wear Measurement and Assessment of Explanted Cross-Linked PE Acetabular Cups Using a CMM. Tribol. Trans. 2014, 57, 767–777. [Google Scholar] [CrossRef]

- Uddin, M.S.; Mak, C.Y.; Callary, S.A. Evaluating hip implant wear measurements by CMM technique. Wear 2016, 364, 193–200. [Google Scholar] [CrossRef]

- Bhushan, B. Micro/Nanotribology: State of the art and its applications. In Proceedings of the NSF/AFOSR/ASME Workshop on Tribology Issues and Opportunities in MEMS, Columbus, OH, USA, 9–11 November 1997. [Google Scholar]

- Bassani, R.; Ciulli, E.; Labardi, M.; Allegrini, M. Wear analysis of journal bearing coatings by atomic force microscopy. Metall. Ital. 2002, 94, 37–44. [Google Scholar]

- Lingling, L.; Congbo, L.; Ying, T.; Yanbin, D. An integrated approach of reverse engineering aided remanufacturing process for worn components. Rob. Comput. Integr. Manuf. 2017, 48, 39–50. [Google Scholar] [CrossRef]

- Boyer, B.; Neri, T.; Di Iorio, A.; Geringer, J.; Philippot, R.; Farizon, F. The linear penetration rate is not relevant for evaluating wear of dual mobility cups: An explant study. Int. Orthop. 2017, 41, 599–603. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Ruggiero, A.; Merola, M.; Logozzo, S. Does metal transfer differ on retrieved Biolox® Delta composites femoral heads? Surface investigation on three Biolox® generations from a biotribological point of view. Compos. Part B Eng. 2017, 113, 164–173. [Google Scholar] [CrossRef]

- Valigi, M.C.; Logozzo, S.; Canella, G. A new automated 2 DOFs 3D desktop optical scanner. Mech. Mach. Sci. 2016, 47, 231–238. [Google Scholar] [CrossRef]

- Niola, V.; Rossi, C.; Savino, S. A New Real Time Shape Acquisition with a Laser Scanner: First Test Results. Rob. Comput. Integr. Manuf. 2010, 26, 543–550. [Google Scholar] [CrossRef]

- Pawley, J.B. Handbook of Biological Confocal Microscopy; Springer: New York, NY, USA, 2006; pp. 1–19. [Google Scholar]

- Austin, R.S.; Giusca, C.L.; Macaulay, G.; Moazzez, R.; Bartlett, D.W. Confocal laser scanning microscopy and area-scale analysis used to quantify enamel surface textural changes from citric acid demineralization and salivary remineralization in vitro. Dent. Mater. 2016, 32, 278–284. [Google Scholar] [CrossRef] [PubMed]

- El-Hakim, S.F.; Beraldin, J.A.; Blais, F. A Comparative evaluation of the performance of passive and active 3-D vision systems. In Proceedings of the SPIE, 2646-Conference on Digital Photogrammetry and Remote, St. Petersburg, VA, USA, 25–30 June 1995. [Google Scholar]

- Mada, S.K.; Smith, M.L.; Smith, L.N. An Overview of Passive and Active Vision Techniques for Hand-Held 3D Data Acquisition. In Proceedings of the SPIE 4877, Opto-Ireland 2002: Optical Metrology, Imaging, and Machine Vision, Galway, Ireland, 5–6 September 2002. [Google Scholar] [CrossRef]

- Kalova, I.; Lisztwan, M. Industrial Applications of Triangulation Technique. In Proceedings of the IFAC Workshop on Programmable Devices and Embedded Systems, Brno, Czech Republic, 14–16 February 2006. [Google Scholar]

- Valigi, M.C.; Logozzo, S.; Rinchi, M. Wear resistance of blades in planetary concrete mixers. Part II: 3D validation of a new mixing blade design and efficiency evaluation. Tribol. Int. 2016, 103, 37–44. [Google Scholar] [CrossRef]

- Valigi, M.C.; Logozzo, S.; Gasperini, I. Study of wear of planetary concrete mixer blades using a 3D optical scanner. Adv. Multidiscip. Eng. 2015, 15, 13–19. [Google Scholar] [CrossRef]

- Affatato, S.; Leardini, W.; Rocchi, M.; Toni, A.; Viceconti, M. Investigation on Wear of Knee Prostheses Under Fixed Kinematic Conditions. Artif. Organs 2007, 32, 13–18. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Valigi, M.C.; Logozzo, S. Wear Distribution Detection of Knee Joint Prostheses by Means of 3D Optical Scanners. Materials 2017, 10, 364. [Google Scholar] [CrossRef]

| Reference Point No. | Manual Thickness Meas. (mm) (Mean Value) | 2D Contact Profile Meas. (mm) (Mean Value) | 3D Scanning Meas. (mm) (Mean Value) |

|---|---|---|---|

| #1 | 23.31 | 24.02 | 24.05 |

| #2 | 20.52 | 20.39 | 20.41 |

| #3 | 21.03 | 20.97 | 21.03 |

| #4 | 25.53 | 25.89 | 25.97 |

| #5 | 30.10 | 28.88 | 28.95 |

| Sample No. | Mass Deviation From Gravimetric Tests (mg) | Mass Deviation From 3D Wear Maps (mg) |

|---|---|---|

| #1 | 13.05 | 12.30 |

| #2 | 6.10 | 6.30 |

| #3 | 7.50 | 8.80 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valigi, M.C.; Logozzo, S.; Affatato, S. New Challenges in Tribology: Wear Assessment Using 3D Optical Scanners. Materials 2017, 10, 548. https://doi.org/10.3390/ma10050548

Valigi MC, Logozzo S, Affatato S. New Challenges in Tribology: Wear Assessment Using 3D Optical Scanners. Materials. 2017; 10(5):548. https://doi.org/10.3390/ma10050548

Chicago/Turabian StyleValigi, Maria Cristina, Silvia Logozzo, and Saverio Affatato. 2017. "New Challenges in Tribology: Wear Assessment Using 3D Optical Scanners" Materials 10, no. 5: 548. https://doi.org/10.3390/ma10050548

APA StyleValigi, M. C., Logozzo, S., & Affatato, S. (2017). New Challenges in Tribology: Wear Assessment Using 3D Optical Scanners. Materials, 10(5), 548. https://doi.org/10.3390/ma10050548