Properties of Two-Variety Natural Luffa Sponge Columns as Potential Mattress Filling Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Morphology Observation of Luffa Sponge Fiber Bundles with Scanning Electron Microscopy

2.3. Fourier Transform Infrared Spectroscopy Analysis

2.4. Quasi-Static Uniaxial Compression and Repetitive Loading Test of Luffa Sponge Column

2.5. Dimensional Stability of Luffa Sponge Columns

2.6. Water Absorption and Desorption Testing

3. Results and Discussion

3.1. Basic Mechanical Properties of Two Types of Luffa Sponge Columns

3.2. Fourier Transform Infrared Spectroscopy Analysis

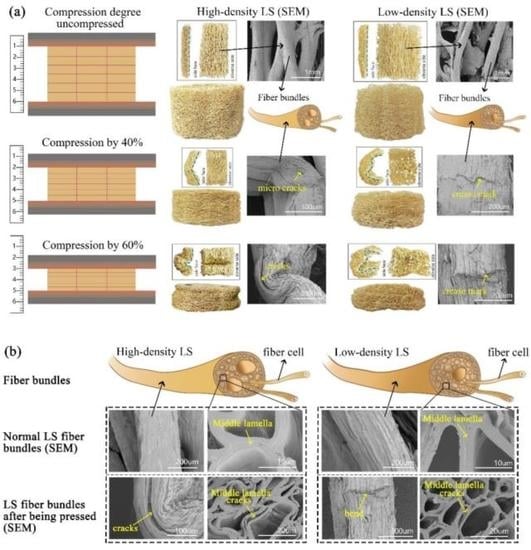

3.3. Morphology Characteristics of Fiber Bundles from Compressed Luffa Sponge Columns

3.4. Dimensional Stability of Compressed Luffa Sponge Columns

3.5. Water Absorption and Desorption Properties of Luffa Sponge

4. Conclusions

- (1)

- The stress–strain curves of high-density and low-density LS columns are similar; both of them have a long plateau stage. However, the high-density LS column has an obvious initial stress peak point in the elastic stage, and the energy absorption structure of its hoop wall belongs to the typical type II structure. The low-density LS column has no initial stress peak point in the elastic stage, and the energy absorption structure of its hoop wall belongs to type I. The compressive strength of the high-density LS columns is almost 10 times that of the low-density LS columns. However, the densification strain of the two types of LS columns is similar; both of them mainly range from 0.6 to 0.7. Therefore, the two types of LS columns can be batch-made into mattress filling material by grading the densities of LS columns. Moreover, the collapse of high-density and low-density LS columns is determined by the coupling of axial yielding and bending of the LS fibers.

- (2)

- The high-density LS fibers contain relatively more methylene and a lower amount of lignin, which contributes to its good flexiblility and resilience to the macromolecule chain and microfibril of high-density LS fiber. The low-density LS fiber contains more lignin, which indicates that the microfibril structure of low-density LS fiber exhibits more rigidity. Even so, in the process of bending deformation of high-density LS fiber bundles, the debonding of fiber cells and surface cracking of fiber bundles occur easily due to the fiber bundles’ relatively large diameter, low tensile strength, low elastic modulus, low elongation at break, thick middle lamella, and high proportion of substance in fiber cells. However, the low-density LS fibers show more rigidity. There is also debonding between the fiber cells and crushing of the waxy layer on the surface of fiber bundles when the low-density LS columns are compressed to the initial densification stage; however, no cracks occur in the bent position—that is, fiber bundles of compressed low-density LS columns can maintain a relatively intact surface morphology.

- (3)

- After compression treatment, high-density LS columns show good dimensional stability. Their height recovery is not more than 5% under constant temperature and humidity conditions for 24 h. However, the amount of compression significantly affects the dimensional stability of low-density LS columns. Low-density columns compressed by 40% (compressed to the platform stage) show a height recovery of no more than 1.62%, while those compressed by 60% (compressed to the initial densification stage) exhibit a height recovery up to 15.62%.

- (4)

- Low-density and high-density LS filling materials can absorb 3.45 and 2.07 times their own weight of water, respectively. At the same time, the two types of LS filling material show good water desorption. The water desorption rates of low-density and high-density LS filling materials are over 91.44 and 76.86%, respectively, which are significantly greater than those of the other three commonly used plant fiber fillers for mattress. Therefore, the use of LS filling material to prepare mattresses is conducive to ensuring a dry bed during sleep.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, Y.; Su, N.; Zhang, K.; Zhu, S.; Zhao, L.; Fang, F.; Ren, L.; Guo, Y. In-Depth Analysis of the Structure and Properties of Two Varieties of Natural Luffa Sponge Fibers. Materials 2017, 10, 479. [Google Scholar] [CrossRef] [PubMed]

- Saeed, A.; Iqbal, M. Loofa (Luffa cylindrica) sponge: Review of development of the biomatrix as a tool for biotechnological applications. Biotechnol. Progress 2013, 29, 573–600. [Google Scholar] [CrossRef] [PubMed]

- Li, L. Antifungal Finishing and Research of Modified Luffa Spong Composite Insocks; Shanxi University of Sciences and Technology: Shanxi, China, 2013. [Google Scholar]

- Shen, J.; Min Xie, Y.; Huang, X.; Zhou, S.; Ruan, D. Mechanical properties of luffa sponge. J. Mech. Behav. Biomed. Mater. 2012, 15, 141–152. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.-S.; Kim, Y.-H.; Kim, S.-O.; Shin, K.-O.; Chung, K.-H. Effect of intake of sponge gourd (Luffa cylindrica) seed oil and yukdomok (Chionanthus retusa L.) seed oil on lipid levels of blood and organs of a mice. Food Sci. Biotechnol. 2013, 22, 757–763. [Google Scholar] [CrossRef]

- Keiichi, W.; Yuji, M.; Gunki, F. Isolation and Partial Characterization of Three Protein synthesis Inhibitory Proteins from the Seeds of Luffa of Three Protein synthesis Inhibitory Proteins from the Seeds of Luffa cylindrica. Agric. Biol. Chem. 1990, 54, 2085–2092. [Google Scholar]

- Demir, H.; Top, A.; Balköse, D.; Ülkü, S. Dye adsorption behavior of Luffa cylindrica fibers. J. Hazard. Mater. 2008, 153, 389–394. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, M.; Vahabzadeh, F.; Bonakdarpour, B.; Mehranian, M.; Mofarrah, E. Phenolic removal in olive oil mill wastewater using loofah-immobilized Phanerochaete chrysosporium. World J. Microbiol. Biotechnol. 2006, 22, 119–127. [Google Scholar] [CrossRef]

- Ahmadi, M.; Vahabzadeh, F.; Bonakdarpour, B.; Mehranian, M. Empirical modeling of olive oil mill wastewater treatment using loofa-immobilized Phanerochaete chrysosporium. Process Biochem. 2006, 41, 1148–1154. [Google Scholar] [CrossRef]

- Akhtar, N.; Saeed, A.; Iqbal, M. Chlorella sorokiniana immobilized on the biomatrix of vegetable sponge of Luffa cylindrica: A new system to remove cadmium from contaminated aqueous medium. Bioresour. Technol. 2003, 88, 163–165. [Google Scholar] [CrossRef]

- Chen, J.P.; Lin, T.C. Loofa sponge as a scaffold for culture of rat hepatocytes. Biotechnol. Progress 2005, 21, 315–319. [Google Scholar] [CrossRef] [PubMed]

- Roble, N.; Ogbonna, J.; Tanaka, H. A novel circulating loop bioreactor with cells immobilized in loofa (Luffa cylindrica) sponge for the bioconversion of raw cassava starch to ethanol. Appl. Microbiol. Biotechnol. 2003, 60, 671–678. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.P.; Yu, S.C.; Hsu, B.R.S.; Fu, S.H.; Liu, H.S. Loofa sponge as a scaffold for the culture of human hepatocyte cell line. Biotechnol. Progress 2003, 19, 522–527. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Xie, Y.M.; Huang, X.; Zhou, S.; Ruan, D. Behaviour of luffa sponge material under dynamic loading. Int. J. Impact Eng. 2013, 57, 17–26. [Google Scholar] [CrossRef]

- Siqueira, G.; Bras, J.; Dufresne, A. Luffa cylindrica as a lignocellulosic source of fiber, microfibrillated cellulose and cellulose nanocrystals. BioResources 2010, 5, 727–740. [Google Scholar]

- Demir, H.; Atikler, U.; Balköse, D.; Tıhmınlıoğlu, F. The effect of fiber surface treatments on the tensile and water sorption properties of polypropylene–luffa fiber composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 447–456. [Google Scholar] [CrossRef]

- Ajiwe, V.; Ndukwe, G.; Anyadiegwu, I. Vegetable diesel fuels from Luffa cylindrica oil, its methylester and ester-diesel blends. Chem. Class J. 2005, 2, 1–4. [Google Scholar]

- Haex, B. Back and Bed: Ergonomic Aspects of Sleeping; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Yang, Y.; Zhang, N.; Xie, J.; Xu, W.; Liu, K.; Chen, Y.; Fan, S. A study on the fruit growth of loofah. Acta Agric. Univ. Jiangxiensis 2000, 22, 66–69. [Google Scholar]

- Chen, Q.; Shi, Q.; Gorb, S.N.; Li, Z. A multiscale study on the structural and mechanical properties of the luffa sponge from Luffa cylindrica plant. J. Biomech. 2014, 47, 1332–1339. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Lu, G.; Ruan, D. Compressive behaviour of closed-cell aluminium foams at high strain rates. Compos. Part B Eng. 2010, 41, 678–685. [Google Scholar] [CrossRef]

- Zhao, L. Study on the Properties of the Luffa Sponge-Mattress; Anhui Agricutural University: Hefei, China, 2015. [Google Scholar]

- Scarfato, P.; Di Maio, L.; Incarnato, L. Structure and physical-mechanical properties related to comfort of flexible polyurethane foams for mattress and effects of artificial weathering. Compos. Part B Eng. 2017, 109, 45–52. [Google Scholar] [CrossRef]

- Zhou, J.; Shrotriya, P.; Soboyejo, W. Mechanisms and mechanics of compressive deformation in open-cell Al foams. Mech. Mater. 2004, 36, 781–797. [Google Scholar] [CrossRef]

- Li, Q.M.; Magkiriadis, I.; Harrigan, J.J. Compressive Strain at the Onset of Densification of Cellular Solids. J. Cell. Plasti. 2016, 42, 371–392. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Li, X.; Zhang, T. Resilience properties of mountain palm fiber. Tech. Text. 2012, 10, 40–44. [Google Scholar]

- Liu, W.; Mohanty, A.; Drzal, L.; Askel, P.; Misra, M. Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J. Mater. Sci. 2004, 39, 1051–1054. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Indran, S.; Raj, R.E.; Sreenivasan, V. Characterization of new natural cellulosic fiber from Cissus quadrangularis root. Carbohydr. Polym. 2014, 110, 423–429. [Google Scholar] [CrossRef] [PubMed]

- Su, X.Y.; Yu, T.; Reid, S.R. Inertia-sensitive impact energy-absorbing structures part II: Effect of strain rate. Int. J. Impact Eng. 1995, 16, 673–689. [Google Scholar] [CrossRef]

- Shen, J.; Xie, Y.M.; Zhou, S.; Huang, X.; Ruan, D. Water-responsive rapid recovery of natural cellular material. J. Mech. Behav. Biomed. Mater. 2014, 34, 283–293. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Tang, A.; Zhang, H.; Chen, G.; Xie, G. Studies on Hydrophilization Modification and Dispersion Behavior of Polyester Fibers. China Synthetic Fiber Industry. 2002, 25, 4–7. [Google Scholar]

- Mazali, I.O.; Alves, O.L. Morphosynthesis: High fidelity inorganic replica of the fibrous network of loofa sponge (Luffa cylindrica). Anais da Academia Brasileira de Ciências 2005, 77, 25–31. [Google Scholar] [CrossRef] [PubMed]

| Factors | Types | Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|---|

| Compressive strength of luffa sponge (LS) columns (high-density–low-density; HD–LD) | Between Groups | 0.224 | 1 | 0.224 | 77.580 | 0.000 |

| Within Groups | 0.104 | 36 | 0.003 | - | - | |

| Total | 0.328 | 37 | - | - | ||

| Densification strain of LS columns (HD–LD) | Between Groups | 0.000 | 1 | 0.000 | 0.005 | 0.947 |

| Within Groups | 0.053 | 36 | 0.001 | - | - | |

| Total | 0.053 | 37 | - | - |

| LS Columns | The Amount Compressed | Mean of Height Recovery (%) | SD (n = 5) |

|---|---|---|---|

| A | 40% | 0.92 | 0.56 |

| B1 | 40% | 1.62 | 0.96 |

| B2 | 40% | 3.5 | 1.4 |

| B3 | 40% | 3.58 | 0.9 |

| A | 60% | 15.62 | 1.84 |

| B1 | 60% | 3.3 | 1.68 |

| B2 | 60% | 3.88 | 1.26 |

| B3 | 60% | 4.2 | 1.22 |

| Factors | Types | Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|---|

| HD LS columns compressed by 40% and 60% | Between Groups | 5.985 | 1 | 5.985 | 3.177 | 0.086 |

| Within Groups | 52.748 | 28 | 1.884 | - | - | |

| Total | 58.734 | 29 | - | - | - | |

| LD LS columns compressed by 40% and 60% | Between Groups | 540.225 | 1 | 540.225 | 291.643 | 0.000 |

| Within Groups | 14.819 | 8 | 1.852 | - | - | |

| Total | 555.044 | 9 | - | - | - | |

| HD and LD LS columns compressed by 40% | Between Groups | 14.702 | 1 | 14.702 | 9.338 | 0.007 |

| Within Groups | 28.338 | 18 | 1.574 | - | - | |

| Total | 43.039 | 19 | - | - | - | |

| HD and LD LS columns compressed by 60% | Between Groups | 524.513 | 1 | 524.513 | 240.668 | 0.000 |

| Within Groups | 39.229 | 18 | 2.179 | - | - | |

| Total | 563.742 | 19 | - | - | - |

| Materials | Water Absorption Ratio (%) | Water Desorption Ratio after 13h (%) | ||

|---|---|---|---|---|

| Mean Value | SD (n = 3) | Mean Value | SD (n = 3) | |

| Low-Density LS | 345 | 13 | 91.44 | 6.13 |

| High-Density LS | 207 | 4 | 76.86 | 4.56 |

| 3D Jute Mat | 653 | 34 | 18.06 | 1.20 |

| Carvel Jute Mat | 811 | 6 | 35.61 | 1.19 |

| Palm Mat | 511 | 9 | 35.77 | 1.28 |

| Factors | Types | Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|---|

| LS Columns and 3D Jute Mat | Between Groups | 8736.66 | 1 | 8736.66 | 139.46 | 0.000 |

| Within Groups | 438.51 | 7 | 62.64 | - | - | |

| Total | 9175.17 | 8 | - | - | - | |

| LS Columns and Carvel Jute Mat | Between Groups | 4712.26 | 1 | 4712.26 | 75.23 | 0.000 |

| Within Groups | 438.44 | 7 | 62.63 | - | - | |

| Total | 5150.70 | 8 | - | - | - | |

| LS Columns and Palm Mat | Between Groups | 4681.25 | 1 | 4681.25 | 74.66 | 0.000 |

| Within Groups | 438.88 | 7 | 62.70 | - | - | |

| Total | 5120.13 | 8 | - | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zhang, K.; Yuan, F.; Zhang, T.; Weng, B.; Wu, S.; Huang, A.; Su, N.; Guo, Y. Properties of Two-Variety Natural Luffa Sponge Columns as Potential Mattress Filling Materials. Materials 2018, 11, 541. https://doi.org/10.3390/ma11040541

Chen Y, Zhang K, Yuan F, Zhang T, Weng B, Wu S, Huang A, Su N, Guo Y. Properties of Two-Variety Natural Luffa Sponge Columns as Potential Mattress Filling Materials. Materials. 2018; 11(4):541. https://doi.org/10.3390/ma11040541

Chicago/Turabian StyleChen, Yuxia, Kaiting Zhang, Fangcheng Yuan, Tingting Zhang, Beibei Weng, Shanshan Wu, Aiyue Huang, Na Su, and Yong Guo. 2018. "Properties of Two-Variety Natural Luffa Sponge Columns as Potential Mattress Filling Materials" Materials 11, no. 4: 541. https://doi.org/10.3390/ma11040541

APA StyleChen, Y., Zhang, K., Yuan, F., Zhang, T., Weng, B., Wu, S., Huang, A., Su, N., & Guo, Y. (2018). Properties of Two-Variety Natural Luffa Sponge Columns as Potential Mattress Filling Materials. Materials, 11(4), 541. https://doi.org/10.3390/ma11040541