Impacts of Defocusing Amount and Molten Pool Boundaries on Mechanical Properties and Microstructure of Selective Laser Melted AlSi10Mg

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

3.1. Crystalline Phases in the as-Printed AlSi10Mg

3.2. Effect of Laser Energy Density and Defocusing on Densification

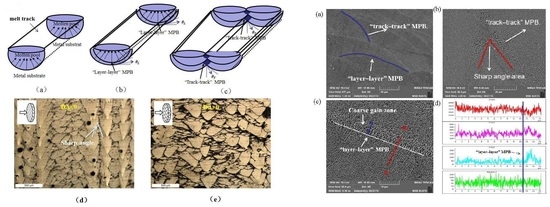

3.3. MPBs in the as-Printed AlSi10Mg

3.4. Tensile Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Berman, B. 3-D printing: the new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Stucker, B.; Rosen, D.W.; Gibson, I. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: Berlin, Germany, 2014. [Google Scholar]

- Yap, C.; Chua, C.; Dong, Z.; Liu, Z.; Zhang, D.; Loh, L.; Sing, S. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef] [Green Version]

- Gu, D. Laser Additive Manufacturing (AM): Classification, Processing Philosophy, and Metallurgical Mechanisms. In Laser Additive Manufacturing of High-Performance Materials; Springer: Berlin, Germany, 2015; pp. 15–71. [Google Scholar]

- AlMangour, B.; Grzesiak, D.; Borkar, T.; Yang, J.-M. Densification behavior, microstructural evolution, and mechanical properties of TiC/316L stainless steel nanocomposites fabricated by selective laser melting. Mater. Des. 2018, 138, 119–128. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Cheng, J.; Ertas, Y. Thermal behavior of the molten pool, microstructural evolution, and tribological performance during selective laser melting of TiC/316L stainless steel nanocomposites: Experimental and simulation methods. J. Mater. Process. Technol. 2018, 257, 288–301. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Wang, W.; Attallah, M.; Loretto, M. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Her-nandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of high-silicon steel parts produced using Selective Laser Melting. Acta Mater. 2016, 110, 207–216. [Google Scholar] [CrossRef]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.W.; Vleugels, J.; Van Humbeeck, J.; Kruth, J.P. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Eckert, J. Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 2017, 126, 25–35. [Google Scholar] [CrossRef]

- Ma, P.; Jia, Y.; Prashanth, K.G.; Scudino, S.; Yu, Z.; Eckert, J. Microstructure and phase formation in Al-20Si-5Fe-3Cu-1Mg synthesized by selective laser melting. J. Alloys Compd. 2016, 657, 430–435. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimization and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Humbeeck, J.V. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Abe, F.; Costa Santos, E.; Kitamura, Y.; Osakada, K.; Shiomi, M. Influence of forming conditions on the titanium model in rapid prototyping with the selective laser melting process. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2003, 217, 119–126. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Saunders, M.; Suvorova, A.; Zhang, L.; Liu, Y.; Fang, M.; Huang, Z.; Sercombe, T.B. A selective laser melting and solution heat treatment refined Al-12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility. Acta Mater. 2015, 95, 74–82. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by selective laser melting. Mater. Sci. Eng. A 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Lin, X.; Yang, H.O.; Chen, J.; Huang, W.D. Microstructure evolution of 316L stainless steel during laser rapid forming. Acta Metall. Sin. 2006, 42, 361–368. [Google Scholar]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloys Compds. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Wen, S.; Li, S.; Wei, Q.; Yan, C.; Sheng, Z.; Shi, Y. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 2014, 214, 2660–2667. [Google Scholar]

- Zhou, X.; Liu, X.; Zhang, D.; Shen, Z.; Liu, W. Balling phenomena in selective laser melted tungsten. J. Mater. Process. Technol. 2015, 222, 33–42. [Google Scholar] [CrossRef]

- Zhu, X.; Villeneuve, D.M.; Naumov, A. Experimental study of drilling sub-10 μm holes in thin metal foils with femtosecond laser pulses. Appl. Surf. Sci. 1999, 152, 138–148. [Google Scholar] [CrossRef]

- Ng, G.K.L.; Li, L. The effect of laser peak power and pulse width on the hole geometry repeatability in laser percussion drilling. Opt. Laser Technol. 2001, 33, 393–402. [Google Scholar] [CrossRef]

- Panwisawas, C.; Qiu, C.L.; Sovani, Y.; Brooks, J.W.; Attallah, M.M.; Basoalto, H.C. On the role of thermal fluid dynamics into the evolution of porosity during selective laser melting. Scr. Mater. 2015, 105, 14–17. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A. Mesoscopic simulation model of selective laser melting of stainless steel powder. J. Mater. Process. Technol. 2014, 214, 2627–2636. [Google Scholar] [CrossRef]

- Bauereiss, A.; Scharowsky, T.; Korner, C. Defect generation and propagation mechanism during additive manufacturing by selective beam melting. J. Mater. Process. Technol. 2014, 214, 2522–2528. [Google Scholar] [CrossRef]

- Townsend, A.; Racasan, R.; Leach, R.; Senin, N.; Thompson, A.; Ramsey, A.; Bate, D.; Woolliams, P.; Brown, S.; Blunt, L. An interlaboratory comparison of X-ray computed tomography measurement for texture and dimensional characterisation of additively manufactured parts. Addit. Manuf. 2018, 23, 422–432. [Google Scholar] [CrossRef]

- Alrbaey, K.; Wimpenny, D.; Tosi, R.; Manning, W.; Moroz, A. On optimization of surface roughness of selective laser melted stainless steel parts: A statistical study. J. Mater. Eng. Perform. 2014, 23, 2139–2148. [Google Scholar] [CrossRef]

| Weight (%) | Si | Fe | Zn | Mn | Mg | Ni | O | Cu | Al |

|---|---|---|---|---|---|---|---|---|---|

| AlSi10Mg | 9.0–11.0 | ≤0.55 | ≤0.10 | ≤0.45 | 0.2–0.45 | ≤0.05 | 0.02 | 0.03 | balance |

| Batch Number | Power (W) | Scan Speed (mm/s) | Defocusing Amount DA | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Microhardness (HV) | Young Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|---|---|---|---|

| P1 | 200 | 1400 | 0 | 390 ± 16 | 170 ± 3 | 112 ± 10 | 62.1 | 6.5 ± 1.3 |

| P2 | 260 | 1400 | 0 | 385 ± 18 | 165 ± 2 | 114 ± 6 | 63.7 | 6.8 ± 1.6 |

| P3 | 320 | 1400 | 0 | 429 ± 20 | 175 ± 6 | 121 ± 11 | 66.9 | 7.5 ± 1.5 |

| P4 | 370 | 1400 | 0 | 415 ± 12 | 178 ± 8 | 124 ± 8 | 70.6 | 6.9 ± 1.4 |

| P3D1 | 320 | 1400 | −2 | 370 ± 10 | 160 ± 6 | 117 ± 9 | 65.4 | 6.1 ± 1.3 |

| P3D2 | 320 | 1400 | −1.5 | 395 ± 12 | 177 ± 6 | 119 ± 6 | 63.7 | 7.3 ± 1.2 |

| P3D3 | 320 | 1400 | −1 | 390 ± 16 | 150 ± 6 | 120 ± 10 | 65.9 | 5.8 ± 1.3 |

| P3D4 | 320 | 1400 | −0.5 | 385 ± 17 | 182 ± 6 | 121 ± 10 | 62.3 | 7 ± 1.2 |

| P3D5 | 320 | 1400 | 0 | 429 ± 20 | 175 ± 6 | 121 ± 11 | 66.9 | 7.5 ± 1.5 |

| P3D6 | 320 | 1400 | 0.5 | 468 ± 14 | 191 ± 6 | 122 ± 12 | 71.2 | 9.5 ± 1.4 |

| P3D7 | 320 | 1400 | 1 | 430 ± 18 | 182 ± 6 | 116 ± 12 | 69.5 | 7.8 ± 1.2 |

| P3D8 | 320 | 1400 | 1.5 | 440 ± 15 | 177 ± 6 | 114 ± 16 | 63.5 | 8.2 ± 1.6 |

| P3D9 | 320 | 1400 | 2 | 425 ± 16 | 189 ± 6 | 119 ± 12 | 68.2 | 7.6 ± 1.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Su, Y.; Gu, R.; Wang, Z.; Zhou, Y.; Ma, Q.; Yan, M. Impacts of Defocusing Amount and Molten Pool Boundaries on Mechanical Properties and Microstructure of Selective Laser Melted AlSi10Mg. Materials 2019, 12, 73. https://doi.org/10.3390/ma12010073

Zhou S, Su Y, Gu R, Wang Z, Zhou Y, Ma Q, Yan M. Impacts of Defocusing Amount and Molten Pool Boundaries on Mechanical Properties and Microstructure of Selective Laser Melted AlSi10Mg. Materials. 2019; 12(1):73. https://doi.org/10.3390/ma12010073

Chicago/Turabian StyleZhou, Suyuan, Yang Su, Rui Gu, Zhenyu Wang, Yinghao Zhou, Qian Ma, and Ming Yan. 2019. "Impacts of Defocusing Amount and Molten Pool Boundaries on Mechanical Properties and Microstructure of Selective Laser Melted AlSi10Mg" Materials 12, no. 1: 73. https://doi.org/10.3390/ma12010073

APA StyleZhou, S., Su, Y., Gu, R., Wang, Z., Zhou, Y., Ma, Q., & Yan, M. (2019). Impacts of Defocusing Amount and Molten Pool Boundaries on Mechanical Properties and Microstructure of Selective Laser Melted AlSi10Mg. Materials, 12(1), 73. https://doi.org/10.3390/ma12010073