Effects of Machining Velocity on Ultra-Fine Grained Al 7075 Alloy Produced by Cryogenic Temperature Large Strain Extrusion Machining

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

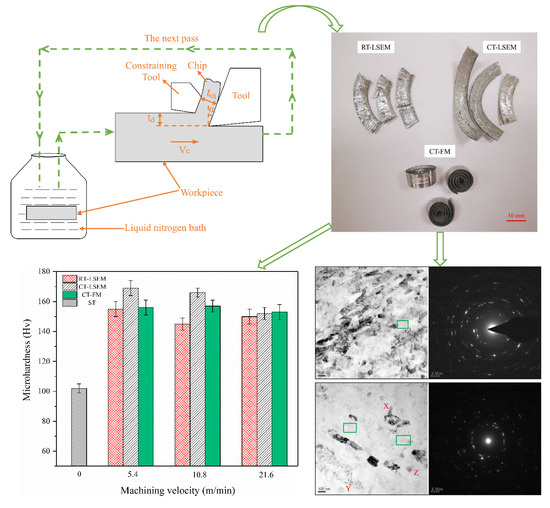

3.1. Chip Thickness and Morphology

3.2. DSC Analysis

3.3. SEM and TEM Analysis

3.4. Micro-Hardness

4. Summary

- The machining velocity and processing temperature have great influences on the chip thickness and chip morphology. In addition, the constraining tool is the key factor that controls the chip formation process. The chip thickness decreases with the machining velocity. The chip is fully extruded and reaches the value as expected when the machining velocity is 5.4 m/min. The chip morphology of CT-LSEM is featured with better integrity than that by RT-LSEM and CT-FM. Deformation at CT can suppress the crack localization and improve the ductility and work-hardening capacity of alloys.

- DSC and TEM analysis reveal that many defects exist within the samples created by LSEM especially under CT, due to which the aging kinetics is accelerated. SAED analysis reveals that most of grain boundaries in RT-LSEM sample are LABs, while the volume fraction of HABs increases for the CT-LSEM sample. A higher dislocation density emerges in the CT-LSEM sample, while dynamic recovery occurs in the RT-LSEM sample owing to the heat generated through deformation, resulting in the annihilation of dislocations. The solutes can get sufficient energy to precipitate out from the matrix under CT, therefore, some coarse-grained E phases are present in the RT-LSEM sample.

- The hardness of chip decreases with the machining velocity for all conditions except for RT-LSEM at 21.6 m/min. On the one hand, much more heat produced at higher machining velocity softens the alloys due to the dynamic recovery. On the other hand, the hardening effect via precipitation strengthening works, which eventually compensates the softening. Additionally, the chip thickness and the shear strain cannot reach the predefined value at higher velocities, so the degree of grain refinement is not enough. The dislocation strengthening contributes more to the hardness of CT-LSEM samples.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moscoso, W.; Shankar, M.R.; Mann, J.B.; Compton, D.W.; Chandrasekar, S. Bulk nanostructured materials by large strain extrusion machining. J. Mater. Res. 2006, 22, 201–205. [Google Scholar] [CrossRef]

- Cai, S.L.; Chen, Y.; Ye, G.G.; Jiang, M.Q.; Wang, H.Y.; Dai, L.H. Characterization of the deformation field in large-strain extrusion machining. J. Mater. Process. Technol. 2015, 216, 48–58. [Google Scholar] [CrossRef]

- Efe, M.; Moscoso, W.; Trumble, K.P.; Compton, W.D.; Chandrasekar, S. Mechanics of large strain extrusion machining and application to deformation processing of magnesium alloys. Acta Mater. 2012, 51, 2031–2042. [Google Scholar] [CrossRef]

- Deng, W.J.; He, Y.T.; Lin, P.; Xia, W.; Tang, Y. Investigation of the effect of rake angle on large strain extrusion machining. Mater. Manuf. Process. 2014, 29, 621–626. [Google Scholar] [CrossRef]

- Deng, W.J.; Lin, P.; Xie, Z.C.; Li, Q. Analysis of large-strain extrusion machining with different chip compression ratios. J. Nanomater. 2012, 2012, 1–12. [Google Scholar] [CrossRef]

- Deng, W.J.; Lin, P.; Li, Q.; Xia, W. Effect of constraining tool corner radius on large strain extrusion machining. Mater. Manuf. Process. 2013, 28, 1090–1094. [Google Scholar] [CrossRef]

- Guo, Y.; Efe, M.; Moscoso, W.; Sagapuram, D.; Trumbleb, K.P.; Chandrasekara, S. Deformation field in large-strain extrusion machining and implications for deformation processing. Scr. Mater. 2012, 66, 235–238. [Google Scholar] [CrossRef]

- Palaniappan, K.; Murthy, H.; Rao, B.C. Production of fine-grained foils by large strain extrusion-machining of textured Ti–6Al–4V. J. Mater. Res. 2018, 33, 108–120. [Google Scholar] [CrossRef]

- Wang, Y.M.; Jiao, T.; Ma, E. Dynamic processes for nanostructure development in Cu after severe cryogenic rolling deformation. Mater. Trans. 2003, 10, 1926–1934. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Cheng, S.; Ma, E.; Zhu, Y.T. Simultaneously increasing the ductility and strength of nanostructured alloys. Adv. Mater. 2006, 18, 2280–2283. [Google Scholar] [CrossRef]

- Huang, F.; Tao, N.R.; Lu, K. Effects of strain rate and deformation temperature on microstructures and hardness in plastically deformed pure aluminum. J. Mater. Sci. Technol. 2011, 27, 1–7. [Google Scholar] [CrossRef]

- Panigrahi, S.K.; Jayaganthan, R. Effect of ageing on microstructure and mechanical properties of bulk, cryorolled, and room temperature rolled Al 7075 alloy. J. Alloy. Compd. 2011, 509, 9609–9616. [Google Scholar] [CrossRef]

- Yu, H.L.; Lu, C.; Tieu, K.; Li, H.; Godbole, A.; Liu, X.; Kong, C. Enhanced materials performance of Al/Ti/Al laminate sheets subjected to cryogenic roll bonding. J. Mater. Res. 2017, 32, 3761. [Google Scholar] [CrossRef]

- Panigrahi, S.K.; Jayaganthan, R. Development of ultrafine grained high strength age hardenable Al 7075 alloy by cryorolling. Mater. Des. 2011, 32, 3150–3160. [Google Scholar] [CrossRef]

- Weiss, M.; Taylor, A.S.; Hodgson, P.D.; Stanford, N. Strength and biaxial formability of cryo-rolled 2024 aluminium subject to concurrent recovery and precipitation. Acta Mater. 2013, 61, 5278–5289. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Lin, D.; Liao, Y.L.; Cheng, G.J. Cryogenic ultrahigh strain rate deformation induced hybrid nanotwinned microstructure for high strength and high ductility. J. Appl. Phys. 2014, 115, 231519. [Google Scholar] [CrossRef]

- Park, D.H.; Choi, S.W.; Kim, J.H.; Lee, J.M. Cryogenic mechanical behavior of 5000- and 6000-series aluminum alloys: Issues on application to offshore plants. Cryogenics 2015, 68, 44–58. [Google Scholar] [CrossRef]

- Lu, J.; Yin, J.G.; He, Y.; Ding, B.F. Microstructural evolution of ultrafine-grained Al-Zn-Mg Alloy during high speed and large plastic deformation at cryogenic temperature. Rare Met. Mater. Eng. 2005, 34, 742–745. [Google Scholar] [CrossRef]

- Magalhães, D.C.C.; Hupalo, M.F.; Cintho, O.M. Natural aging behavior of AA7050 Al alloy after cryogenic rolling. Mater. Sci. Eng. A 2014, 593, 1–7. [Google Scholar] [CrossRef]

- Huo, W.G.; Hou, L.G.; Cui, H.; Zhuang, L.Z.; Zhang, J.S. Fine-grained AA 7075 processed by different thermomechanical processings. Mater. Sci. Eng. A 2014, 618, 244–253. [Google Scholar] [CrossRef]

- Huang, Y.C.; Yan, X.Y.; Qiu, T. Microstructure and mechanical properties of cryo-rolled AA6061 Al alloy. Trans. Nonferrous Met. Soc. 2016, 26, 12–18. [Google Scholar] [CrossRef]

- Panigrahi, S.K.; Jayaganthan, R. Effect of Annealing on Thermal Stability, Precipitate Evolution, and Mechanical Properties of Cryorolled Al 7075 Alloy. Metall. Mater. Trans. A 2011, 42, 3208–3217. [Google Scholar] [CrossRef]

- Tang, J.G.; Chen, H.; Zhang, X.M.; Liu, S.D.; Liu, W.J.; Ouyang, H.; Li, H.P. Influence of quench-induced precipitation on aging behavior of Al-Zn-Mg-Cu alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 1255–1263. [Google Scholar] [CrossRef]

- Rokni, M.R.; Zarei-Hanzaki, A.; Abedi, H.R. Microstructure evolution and mechanical properties of back extruded 7075 aluminum alloy at elevated temperatures. Mater. Sci. Eng. A 2012, 532, 593–600. [Google Scholar] [CrossRef]

- Chayong, S.; Atkinson, H.V.; Kapranos, P. Thixoforming 7075 aluminium alloys. Mater. Sci. Eng. A 2009, 390, 3–12. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Shaeri, M.; Salehi, M.T.; Seyyedein, S.H.; Abutalebi, M.R. Effect of equal channel angular pressing on aging treatment of Al-7075 alloy. Prog. Nat. Sci. Mater. 2015, 25, 159–168. [Google Scholar] [CrossRef] [Green Version]

- Salamci, E.; Cochrane, R.F. Investigation of secondary phase particles in spray deposited 7000 series aluminium alloys. Mater. Sci. Technol. 2002, 18, 1445–1452. [Google Scholar] [CrossRef]

- Ayer, R.; KOO, J.Y.; Steeds, J.W.; Park, B.K. Microanalytical study of the heterogeneous phases in commercial AI-Zn-Mg-Cu alloys. Metall. Mater. Trans. A 1985, 16, 1925–1936. [Google Scholar] [CrossRef]

- Kim, W.J.; Sa, Y.K. Micro-extrusion of ECAP processed magnesium alloy for production of high strength magnesium micro-gears. Scr. Mater. 2006, 54, 1391–1395. [Google Scholar] [CrossRef]

- Su, Q.; Xu, J.; Li, Y.Q.; Yoon, J.I.; Shan, D.B.; Guo, B.; Kim, H.S. Microstructural evolution and mechanical properties in superlight Mg-Li alloy processed by high-pressure torsion. Materials 2018, 11, 598. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, X.; Chen, H.; Deng, W. Effects of Machining Velocity on Ultra-Fine Grained Al 7075 Alloy Produced by Cryogenic Temperature Large Strain Extrusion Machining. Materials 2019, 12, 1656. https://doi.org/10.3390/ma12101656

Yin X, Chen H, Deng W. Effects of Machining Velocity on Ultra-Fine Grained Al 7075 Alloy Produced by Cryogenic Temperature Large Strain Extrusion Machining. Materials. 2019; 12(10):1656. https://doi.org/10.3390/ma12101656

Chicago/Turabian StyleYin, Xiaolong, Haitao Chen, and Wenjun Deng. 2019. "Effects of Machining Velocity on Ultra-Fine Grained Al 7075 Alloy Produced by Cryogenic Temperature Large Strain Extrusion Machining" Materials 12, no. 10: 1656. https://doi.org/10.3390/ma12101656

APA StyleYin, X., Chen, H., & Deng, W. (2019). Effects of Machining Velocity on Ultra-Fine Grained Al 7075 Alloy Produced by Cryogenic Temperature Large Strain Extrusion Machining. Materials, 12(10), 1656. https://doi.org/10.3390/ma12101656