Variation of Mechanical Characteristics of Polyurethane Foam: Effect of Test Method

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Overview

2.1.1. Tensile Test

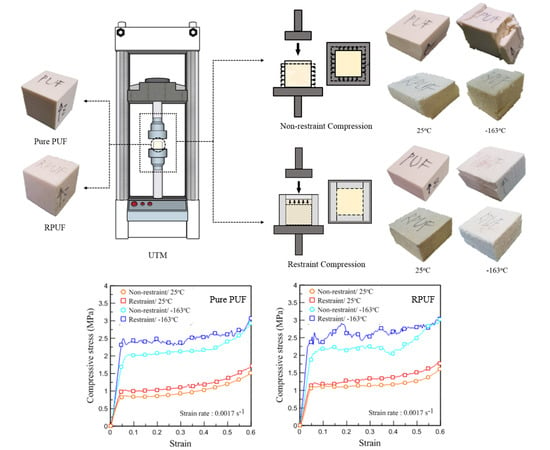

2.1.2. Compressive Test

2.1.3. Shear Test

2.2. Material Properties

2.3. Experimental Preparation

2.4. Experimental Scenarios

3. Results and Discussion

3.1. Shape Structure Analysis

3.1.1. Conventional Compressive Test

3.1.2. Restraint Compressive Test

3.2. Mechanical Performance Analysis

3.3. Scanning Electron Microscope Analysis

3.4. Microstructural Analysis

4. Conclusions

- The rigid PUF properties that depend on environmental variables were detailed under restraint conditions. The results of the restraining compression tests conducted considering the effects of room and cryogenic temperature were shown to exhibit a mechanical performance that is distinctly different from that of the conventional compression tests.

- In the case of restraint experiments, there was a significant change between the two temperature environments compared to the existing compression test. Even at the same cryogenic temperature, it was found that the cell structure, as well as the shape of the specimens, was maintained, and the intensity of the rigid PUF showed a difference of up to 0.47 MPa compared to that of the previous test.

- The microstructure internally observed in the test specimens (pure PUF and RPUF) confirmed that the breaking characteristics of rigid PUF, which depend on temperature, were derived from the segments that comprise the inside of the material, and also showed that the restraint condition proposed in this study was significantly involved in these properties.

- In the experiments conducted under conventional compressive conditions, the difference in the strength performance between the pure PUF and RPUF was clear depending on the addition of glass fibers. In the restraint test, however, the difference was greatly reduced. This confirmed the reactionary action supporting the closed-cell structure against expansion from external loads.

Author Contributions

Funding

Conflicts of Interest

References

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed]

- Dhaliwal, G.S.; Anandan, S.; Chandrashekhara, K.; Lees, J.; Nam, P. Development and characterization of polyurethane foams with substitution of polyether polyol with soy-based polyol. Eur. Polym. J. 2018, 107, 105–117. [Google Scholar] [CrossRef]

- Su, B.Y.; Huang, C.M.; Sheng, H.; Jang, W.Y. The effect of cell-size dispersity on the mechanical properties of closed-cell aluminum foam. Mater. Charact. 2018, 135, 203–213. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Zhao, L.; Luo, J. Dynamic crushing behavior of 3D closed-cell foams based on Voronoi random model. Mater. Des. 2010, 31, 4281–4289. [Google Scholar] [CrossRef]

- Verdolotti, L.; Di Caprio, M.R.; Lavorgna, M.; Buonocore, G.G. Polyurethane nanocomposite foams: Correlation between nanofillers, porous morphology, and structural and functional properties. Polyurethane Polym. 2017, 31, 277–310. [Google Scholar]

- Shoaib, M.; Bahadur, A.; Iqbal, S.; Rahman, M.S.U.; Ahmed, S.; Shabir, G.; Javaid, M.A. Relationship of hard segment concentration in polyurethane-urea elastomers with mechanical, thermal and drug release properties. J. Drug Deliv. Sci. Technol. 2017, 37, 88–96. [Google Scholar] [CrossRef]

- Bernardini, J.; Licursi, D.; Anguillesi, I.; Cinelli, P.; Coltelli, M.B.; Antonetti, C.; Galletti, A.M.R.; Lazzeri, A. Exploitation of Arundo donax L. Hydrolysis Residue for the Green Synthesis of Flexible Polyurethane Foams. Bioresources 2017, 12, 3630–3655. [Google Scholar] [CrossRef]

- Heijkants, R.G.J.C.; Van Calck, R.V.; De Groot, J.H.; Pennings, A.J.; Schouten, A.J.; Van Tienen, T.G.; Ramrattan, N.; Buma, P.; Veth, R.P.H. Design, synthesis and properties of a degradable polyurethane scaffold for meniscus regeneration. J. Mater. Sci. Mater. Electron. 2004, 15, 423–427. [Google Scholar] [CrossRef] [Green Version]

- Cady, C.; Gray, G.; Liu, C.; Lovato, M.; Mukai, T. Compressive properties of a closed-cell aluminum foam as a function of strain rate and temperature. Mater. Sci. Eng. A 2009, 525, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Xu, S.; Li, Z.; Yang, J.; Zheng, H.; Hu, S. Temperature effects on the mechanical behavior of aluminum foam under dynamic loading. Mater. Sci. Eng. A 2014, 599, 174–179. [Google Scholar] [CrossRef]

- Mondal, D.; Jha, N.; Badkul, A.; Das, S.; Khedle, R. High temperature compressive deformation behaviour of aluminum syntactic foam. Mater. Sci. Eng. A 2012, 534, 521–529. [Google Scholar] [CrossRef]

- Li, L.; Xue, P.; Chen, Y.; Butt, H. Insight into cell size effects on quasi-static and dynamic compressive properties of 3D foams. Mater. Sci. Eng. A 2015, 636, 60–69. [Google Scholar] [CrossRef]

- Shi, X.; Liu, S.; Nie, H.; Lu, G.; Li, Y. Study of cell irregularity effects on the compression of closed-cell foams. Int. J. Mech. Sci. 2018, 135, 215–225. [Google Scholar] [CrossRef]

- Chen, Y.; Das, R.; Battley, M. Effects of cell size and cell wall thickness variations on the stiffness of closed-cell foams. Int. J. Solids Struct. 2015, 52, 150–164. [Google Scholar] [CrossRef]

- Ferkl, P.; Kršková, I.; Kosek, J. Evolution of mass distribution in walls of rigid polyurethane foams. Chem. Eng. Sci. 2018, 176, 50–58. [Google Scholar] [CrossRef]

- Köll, J.; Hallström, S. Elastic properties of equilibrium foams. Acta Mater. 2016, 113, 11–18. [Google Scholar] [CrossRef]

- Şerban, D.A.; Weissenborn, O.; Geller, S.; Marşavina, L.; Gude, M. Evaluation of the mechanical and morphological properties of long fibre reinforced polyurethane rigid foams. Polym. Test. 2016, 49, 121–127. [Google Scholar] [CrossRef]

- Xie, H.; Yang, W.; Yuen, A.C.Y.; Xie, C.; Xie, J.; Lu, H.; Yeoh, G.H. Study on flame retarded flexible polyurethane foam/alumina aerogel composites with improved fire safety. Chem. Eng. J. 2017, 311, 310–317. [Google Scholar] [CrossRef]

- Hamilton, A.R.; Thomsen, O.T.; Madaleno, L.A.; Jensen, L.R.; Rauhe, J.C.M.; Pyrz, R. Evaluation of the anisotropic mechanical properties of reinforced polyurethane foams. Compos. Sci. Technol. 2013, 87, 210–217. [Google Scholar] [CrossRef] [Green Version]

- Zhao, C.; Yan, Y.; Hu, Z.; Li, L.; Fan, X. Preparation and characterization of granular silica aerogel/polyisocyanurate rigid foam composites. Constr. Build. Mater. 2015, 93, 309–316. [Google Scholar] [CrossRef]

- Maleki, H.; Durães, L.; Portugal, A. Synthesis of lightweight polymer-reinforced silica aerogels with improved mechanical and thermal insulation properties for space applications. Microporous Mesoporous Mater. 2014, 197, 116–129. [Google Scholar] [CrossRef] [Green Version]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G.; Zhang, M. Synergistic effect of expandable graphite, diethyl ethylphosphonate and organically-modified layered double hydroxide on flame retardancy and fire behavior of polyisocyanurate-polyurethane foam nanocomposite. Polym. Degrad. Stab. 2014, 101, 92–101. [Google Scholar] [CrossRef]

- Hebda, E.; Ozimek, J.; Raftopoulos, K.N.; Michałowski, S.; Pielichowski, J.; Jancia, M.; Pielichowski, K. Synthesis and morphology of rigid polyurethane foams with POSS as pendant groups or chemical crosslinks. Polym. Adv. Technol. 2015, 26, 932–940. [Google Scholar] [CrossRef]

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Gloc, M.; Kulesza, M.; Krauze, S.; Lewandowska, M.; Kowalski, M. Flammability, mechanical properties and structure of rigid polyurethane foams with different types of carbon reinforcing materials. Compos. Struct. 2016, 140, 67–76. [Google Scholar] [CrossRef]

- Li, Z.; Gong, L.; Li, C.; Pan, Y.; Huang, Y.; Cheng, X. Silica aerogel/aramid pulp composites with improved mechanical and thermal properties. J. Non Cryst. Solids 2016, 454, 1–7. [Google Scholar] [CrossRef]

- Dong, L.; Hou, F.; Li, Y.; Wang, L.; Gao, H.; Tang, Y. Preparation of continuous carbon nanotube networks in carbon fiber/epoxy composite. Compos. Part A Appl. Sci. Manuf. 2014, 56, 248–255. [Google Scholar] [CrossRef]

- Nikje, M.M.A.; Noruzian, M.; Moghaddam, S.T. Investigation of Fe3O4/AEAP supermagnetic nanoparticles on the morphological, thermal and magnetite behavior of polyurethane rigid foam nanocomposites. Polimery 2015, 60. [Google Scholar] [CrossRef]

- Pikhurov, D.V.; Sakhatskii, A.S.; Zuev, V.V. Rigid polyurethane foams with infused hydrophilic/hydrophobic nanoparticles: Relationship between cellular structure and physical properties. Eur. Polym. J. 2018, 99, 403–414. [Google Scholar] [CrossRef]

- Estravís, S.; Tirado-Mediavilla, J.; Santiago-Calvo, M.; Ruiz-Herrero, J.L.; Villafañe, F.; Rodríguez-Pérez, M.Á. Rigid polyurethane foams with infused nanoclays: Relationship between cellular structure and thermal conductivity. Eur. Polym. J. 2016, 80, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.M.; Kim, J.H.; Ahn, J.H.; Kim, J.D.; Park, S.; Park, K.H.; Lee, J.M. Synthesis of nanoparticle-enhanced polyurethane foams and evaluation of mechanical characteristics. Compos. Part B Eng. 2018, 136, 28–38. [Google Scholar] [CrossRef]

- Santiago-Calvo, M.; Blasco, V.; Ruiz, C.; París, R.; Villafañe, F.; Rodríguez-Pérez, M.Á. Synthesis, characterization and physical properties of rigid polyurethane foams prepared with poly (propylene oxide) polyols containing graphene oxide. Eur. Polym. J. 2017, 97, 230–240. [Google Scholar] [CrossRef]

- Nazeran, N.; Moghaddas, J. Synthesis and characterization of silica aerogel reinforced rigid polyurethane foam for thermal insulation application. J. Non Cryst. Solids 2017, 461, 1–11. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, J.; Lu, G.; Zhao, L. Compressive behavior of closed-cell aluminum alloy foams at medium strain rates. Mater. Sci. Eng. A 2011, 528, 2326–2330. [Google Scholar] [CrossRef]

- Wang, P.; Xu, S.; Li, Z.; Yang, J.; Zhang, C.; Zheng, H.; Hu, S. Experimental investigation on the strain-rate effect and inertia effect of closed-cell aluminum foam subjected to dynamic loading. Mater. Sci. Eng. A 2015, 620, 253–261. [Google Scholar] [CrossRef]

- Shen, J.; Lu, G.; Ruan, D. Compressive behaviour of closed-cell aluminium foams at high strain rates. Compos. Part B Eng. 2010, 41, 678–685. [Google Scholar] [CrossRef]

- Chen, Y.; Das, R.; Battley, M. Finite element analysis of the compressive and shear responses of structural foams using computed tomography. Compos. Struct. 2017, 159, 784–799. [Google Scholar] [CrossRef]

- Nammi, S.; Myler, P.; Edwards, G. Finite element analysis of closed-cell aluminium foam under quasi-static loading. Mater. Des. 2010, 31, 712–722. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q.; Lowe, T.; McDonald, S.; Withers, P. Investigation of strain-rate effect on the compressive behaviour of closed-cell aluminium foam by 3D image-based modelling. Mater. Des. 2016, 89, 215–224. [Google Scholar] [CrossRef]

- Fahlbusch, N.C.; Grenestedt, J.L.; Becker, W. Effective failure behavior of an analytical and a numerical model for closed-cell foams. Int. J. Solids Struct. 2016, 97, 417–430. [Google Scholar] [CrossRef]

- Kadkhodapour, J.; Raeisi, S. Micro–macro investigation of deformation and failure in closed-cell aluminum foams. Comput. Mater. Sci. 2014, 83, 137–148. [Google Scholar] [CrossRef]

- Saadatfar, M.; Mukherjee, M.; Madadi, M.; Schröder-Turk, G.; García-Moreno, F.; Schaller, F.; Hutzler, S.; Sheppard, A.; Banhart, J.; Ramamurty, U. Structure and deformation correlation of closed-cell aluminium foam subject to uniaxial compression. Acta Mater. 2012, 60, 3604–3615. [Google Scholar] [CrossRef]

- Veyhl, C.; Belova, I.; Murch, G.; Fiedler, T. Finite element analysis of the mechanical properties of cellular aluminium based on micro-computed tomography. Mater. Sci. Eng. A 2011, 528, 4550–4555. [Google Scholar] [CrossRef]

- Design against Accidental Loads. Available online: https://rules.dnvgl.com/docs/pdf/DNV/codes/docs/2010-10/RP-C204.pdf (accessed on 1 October 2010).

- Nho, I.S.; Yun, Y.M.; Park, M.J.; Oh, Y.T.; Kim, S.C. Structural Safety Assessment of Mark III Membrane Type Liquid Natural Gas Cargo Containment System under Ice Collision. J. Ocean Eng. Technol. 2014, 28, 126–132. [Google Scholar] [CrossRef]

- Cantat, I.; Cohen-Addad, S.; Elias, F.; Graner, F.; Höhler, R.; Pitois, O.; Rouyer, F.; Saint-Jalmes, A.; Cox, S. Foams: Structure and Dynamics; Oxford University: Oxford, UK, 2013. [Google Scholar]

- Gibson, L. The mechanical behaviour of cancellous bone. J. Biomech. 1985, 18, 317–328. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Saint-Michel, F.; Chazeau, L.; Cavaillé, J.Y.; Chabert, E. Mechanical properties of high density polyurethane foams: I. Effect of the density. Compos. Sci. Technol. 2006, 66, 2700–2708. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, Z.; Yu, J.; Yang, J.; Lu, F. Spherical indentation of closed-cell aluminum foams: An empirical force–depth relation. Mater. Sci. Eng. A 2014, 618, 433–437. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, Z.; Yu, J.; Tang, L. Effect of temperature on the indentation behavior of closed-cell aluminum foam. Mater. Sci. Eng. A 2012, 550, 222–226. [Google Scholar] [CrossRef]

- Idris, M.; Vodenitcharova, T.; Hoffman, M. Mechanical behaviour and energy absorption of closed-cell aluminium foam panels in uniaxial compression. Mater. Sci. Eng. A 2009, 517, 37–45. [Google Scholar] [CrossRef]

- International Organization for Standardization. 2014. Rigid Cellular Plastics-Determination of Compression Properties. ISO. Available online: https://www.iso.org/standard/45078.html; https://www.sis.se/api/document/preview/917631/ (accessed on 1 August 2014).

- Manujesh, B.J.; Vijayalakshmi, R. Fatigue Behavior and Failure Mechanism of PU Foam Core E-glass Reinforced Vinyl Ester Sandwich Composites. Int. J. Mater. Eng. 2013, 3, 66–81. [Google Scholar]

- Park, S.B.; Choi, S.W.; Kim, J.H.; Bang, C.S.; Lee, J.M. Effect of the blowing agent on the low-temperature mechanical properties of CO2- and HFC-245fa-blown glass-fiber-reinforced polyurethane foams. Compos. Part B Eng. 2016, 93, 317–327. [Google Scholar] [CrossRef]

- Lu, G.; Yu, T. Energy Absorption of Structures and Materials, 1st ed.; Woodhead Publishing: Cambridge, UK, 2003. [Google Scholar]

- Daphalapurkar, N.P.; Hanan, J.C.; Phelps, N.B.; Bale, H.; Lu, H. Tomography and Simulation of Microstructure Evolution of a Closed-Cell Polymer Foam in Compression. Mech. Adv. Mater. Struct. 2008, 15, 594–611. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, C.S.; Choi, S.W.; Kim, J.H.; Bang, C.S.; Lee, J.M. Polymeric foams for cryogenic temperature application: Temperature range for non-recovery and brittle-fracture of microstructure. Compos. Struct. 2016, 136, 258–269. [Google Scholar] [CrossRef]

- Kang, S.M.; Lee, S.J.; Kim, B.K. Shape memory polyurethane foams. Express Polym. Lett. 2012, 6, 63–69. [Google Scholar] [CrossRef]

- Sonnenschein, M.F. Polyurethanes: Science, Technology, Markets, and Trends; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Kader, M.; Islam, M.; Saadatfar, M.; Hazell, P.; Brown, A.; Ahmed, S.; Escobedo, J. Macro and micro collapse mechanisms of closed-cell aluminium foams during quasi-static compression. Mater. Des. 2017, 118, 11–21. [Google Scholar] [CrossRef]

- Christensen, R. A comparison of open cell and closed cell properties for low-density materials. J. Mech. Mater. Struct. 2007, 2, 1299–1307. [Google Scholar] [CrossRef] [Green Version]

- Sadot, O.; Ram, O.; Anteby, I.; Gruntman, S.; Ben-Dor, G. The trapped gas effect on the dynamic compressive strength of light aluminum foams. Mater. Sci. Eng. A 2016, 659, 278–286. [Google Scholar] [CrossRef]

- Mu, Y.; Yao, G.; Liang, L.; Luo, H.; Zu, G. Deformation mechanisms of closed-cell aluminum foam in compression. Scr. Mater. 2010, 63, 629–632. [Google Scholar] [CrossRef]

| Test Method | Dimension | mm | Inches (in) | Note |

|---|---|---|---|---|

| Tensile test (ASTM D 1623) | Gauge length | 25.4 | 1 | >0.5 in |

| Diameter | 28.7 | 1.13 | 0.13 | |

| Cross-section | - | - | 1 in2 | |

| Radius of curvature | 11.9 | 0.47 | 18° to the center line. | |

| Compressive test (ASTM D 1621) | Height | 25.4 | 1 | Less than width or diameter |

| Cross-section | - | - | >4 in2, <6 in2 | |

| Shear test (ASTM C 273) | Thickness | - | - | = core specimen |

| Length | - | - | >12 times thickness | |

| Width | - | - | >2 in |

| Material | Dimension (mm) | Mass (g) | Density (g/cm3) |

|---|---|---|---|

| Pure PUF | 50 × 50 × 50 | 12.63 | 0.11 |

| RPUF | 15.88 | 0.13 |

| Material | Conventional | Restraint | ||||

|---|---|---|---|---|---|---|

| Temperature (°C) | Strain Rate (s−1) | Temperature (°C) | Strain Rate (s−1) | |||

| Room | Cryogenic (1 h) | Room | Cryogenic (1 h) | |||

| 25 | −163 | 0.0017 | 25 | −163 | 0.0017 | |

| Pure PUF | √ | √ | √ | √ | √ | √ |

| RPUF | √ | √ | √ | √ | √ | √ |

| Material | Pure PUF | RPUF | |||

|---|---|---|---|---|---|

| Temperature (°C) | 25 | −163 | 25 | −163 | |

| Cross-section | A (mm2) | 2585.5 | 2590.3 | 2565.8 | 2561 |

| A (%) | 3.4 | 3.6 | 2.6 | 2.4 | |

| Material | Pure PUF | RPUF | |||

|---|---|---|---|---|---|

| Temperature (°C) | 25 | −163 | 25 | −163 | |

| Cross-section | A (mm2) | 2558.3 | 2528.3 | 2545.5 | 2522.8 |

| A (%) | 2.3 | 1.1 | 1.8 | 0.9 | |

| Material | Property (MPa) | 25 °C | −163 °C | ||

|---|---|---|---|---|---|

| Non-Restraint | Restraint | Non-Restraint | Restraint | ||

| Pure PUF | Compressive strength, | 0.83 | 1.02 | 2.02 | 2.49 |

| Elastic modulus, | 16.636 | 20.817 | 33.777 | 51.271 | |

| RPUF | Compressive strength, | 1.12 | 1.22 | 2.18 | 2.53 |

| Elastic modulus, | 22.129 | 24.439 | 38.363 | 52.254 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, K.-B.; Kim, H.-T.; Her, N.-Y.; Lee, J.-M. Variation of Mechanical Characteristics of Polyurethane Foam: Effect of Test Method. Materials 2019, 12, 2672. https://doi.org/10.3390/ma12172672

Park K-B, Kim H-T, Her N-Y, Lee J-M. Variation of Mechanical Characteristics of Polyurethane Foam: Effect of Test Method. Materials. 2019; 12(17):2672. https://doi.org/10.3390/ma12172672

Chicago/Turabian StylePark, Ki-Beom, Hee-Tae Kim, Nam-Yong Her, and Jae-Myung Lee. 2019. "Variation of Mechanical Characteristics of Polyurethane Foam: Effect of Test Method" Materials 12, no. 17: 2672. https://doi.org/10.3390/ma12172672

APA StylePark, K. -B., Kim, H. -T., Her, N. -Y., & Lee, J. -M. (2019). Variation of Mechanical Characteristics of Polyurethane Foam: Effect of Test Method. Materials, 12(17), 2672. https://doi.org/10.3390/ma12172672