Microstructural and Thermo-Physical Characterization of a Water Hyacinth Petiole for Thermal Insulation Particle Board Manufacture

Abstract

:1. Introduction

2. Materials and Methods

2.1. WH Petiole Characterization

2.1.1. Microstructural Observations

2.1.2. Moisture Content

2.1.3. Water Absorption

2.1.4. Bulk Density

2.1.5. Chemical Characterization

2.2. WHP Board Characterization

2.2.1. Particle Board Manufacture

2.2.2. Microstructural Observations

2.2.3. Bulk Density of WHP Boards

2.2.4. Moisture Content of WHP Boards

2.2.5. Water Absorption of WHP Boards

2.2.6. Thickness Swelling of WHP Boards

2.2.7. Mechanical Testing of WHP Boards

2.2.8. Thermal Conductivity of WHP Boards

3. Results

3.1. WH Petiole Characterization

3.2. WHP-Panels Characterization

4. Discussion

5. Conclusions

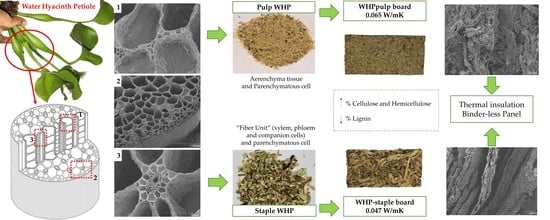

- The WHP low lignin content makes it possible to manufacture self-supporting binder-less WHP panels without requiring a heat energy procedure. The subsequent low energy involved in their manufacture makes them more sustainable, due to a reduced footprint.

- Their peculiar structure of larger aerenchymas encapsulates air more efficiently, compared to other plant fibres. This is one reason why the WHP is an excellent raw material for thermal insulation production. Thermal conductivities of 0.047–0.065 W/mK were achieved by using pulp and staples, respectively.

- The grinding process leads to particles of different size and microstructural composition. Pulp is mainly composed of aerenchyma tissue, while the staple is composed of “fibre units” and their surrounding aerenchymas. As a result, the physical, mechanical, and thermal properties of the boards are clearly affected by the particle size.

- In this sense, staple WHP panels are 1.21 times lighter than pulp WHP panels.

- In addition, pulp WHP panels have 2.5 times better Modulus of Rupture and 1.75 times better stability dimension behaviour than staple panels. Contrarily, staple WHP panels have 1.37 times better thermal insulation properties than pulp WHP panels, due to staple panels having a lower packing density, as was shown by SEM.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Asdrubali, F.; D’alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Li, H.; Lazzaretto, A.; Manente, G.; Tong, C.; Liu, Q.; Li, N. The development history and prospects of biomass-based insulation materials for buildings. Renew. Sustain. Energy Rev. 2017, 69, 912–932. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Holcroft, N.; Shea, A.; Walker, P. Determination of hygrothermal parameters of experimental and commercial bio-based insulation materials. Constr. Build. Mater. 2016, 124, 269–275. [Google Scholar] [CrossRef] [Green Version]

- Ali, M. Natural fibres as construction materials. J. Civ. Eng. Constr. Technol. 2012, 3, 80–89. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.P.; Sain, M. Biocomposites reinforced with natural fibres: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. A state-of-the-art review on soil reinforcement technology using natural plant fibre materials: Past findings, present trends and future directions. Materials 2018, 11, 553. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Bordoloi, S.; Kashyap, V.; Garg, A.; Sreedeep, S.; Wei, L.; Andriyas, S. Measurement of mechanical characteristics of fibre from a novel invasive weed: A comprehensive comparison with fibres from agricultural crops. Measurement 2018, 113, 62–70. [Google Scholar] [CrossRef]

- Bhuvaneshwari, M.; Sangeetha, K. Effect of Blending Ratio of Water Hyacinth Fibres on the Properties of Needle Punched Nonwoven Fabrics. Int. J. Tech. Res. Appl. 2017, 5, 90–94. [Google Scholar]

- Schiavoni, S.; D’alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Volf, M.; Diviš, J.; Havlík, F. Thermal, moisture and biological behaviour of natural insulating materials. Energy Procedia 2015, 78, 1599–1604. [Google Scholar] [CrossRef]

- Liuzzi, S.; Sanarica, S.; Stefanizzi, P. Use of agro-wastes in building materials in the Mediterranean area: A review. Energy Procedia 2017, 126, 242–249. [Google Scholar] [CrossRef]

- Pavelek, M.; Prajer, M.; Trgala, K.; Pavelek, M.; Prajer, M.; Trgala, K. Static and Dynamic Thermal Characterization of Timber Frame/Wheat (Triticum Aestivum) Chaff Thermal Insulation Panel for Sustainable Building Construction. Sustainability 2018, 10, 2363. [Google Scholar] [CrossRef]

- UNDP Senegal Technology transfer: Typha-based thermal insulation material production in senegal. UNDP Proj. Doc. 2016, 112.

- Krus, M.; Theuerkorn, W.; Großkinsky, T.; Künzel, H. New sustainable and insulating building material made of cattail. Nord. Symp. Build. Phys. 2014, 1252–1260. [Google Scholar]

- Vejeliene, J.; Gailius, A.; Vejelis, S.; Vaitkus, S.; Balciunas, G. Development of Thermal Insulation from Local Agricultural Waste. In Proceedings of the VIII International Conference Environmental Engineering, Vilnus, Lithuania, 19–20 May 2011. [Google Scholar]

- Luamkanchanaphan, T.; Chotikaprakhan, S.; Jarusombati, S. A Study of Physical, Mechanical and Thermal Properties for Thermal Insulation from Narrow-leaved Cattail Fibres. APCBEE Procedia 2012, 1, 46–52. [Google Scholar] [CrossRef]

- Téllez, T.R.; López, E.; Granado, G.; Pérez, E.; López, R.; Guzmán, J. The Water Hyacinth, Eichhornia crassipes: An invasive plant in the Guadiana River Basin (Spain). Aquat. Invasions 2008, 3, 42–53. [Google Scholar] [CrossRef]

- Coetzee, J.A.; Hill, M.P.; Ruiz-Téllez, T.; Starfinger, U.; Brunel, S. Monographs on invasive plants in Europe N° 2: Eichhornia crassipes (Mart.) Solms. Bot. Lett. 2017, 164, 303–326. [Google Scholar] [CrossRef]

- Ali, I.; Jayaraman, K.; Bhattacharyya, D. Implications of fibre characteristics and mat densification on permeability, compaction and properties of kenaf fibre panels. Ind. Crops Prod. 2014. [Google Scholar] [CrossRef]

- Regional Research Laboratory of Commonwealth Regional (Asia/Pacific) Rural Technology Programme Possibilities of utilization of water hyacinth for making water hyacinth-cement boards. In Report of the Second Review Meeting on Management of Water Hyacinth; International Atomic Energy Agency (IAEA) of United Kingdom: Colombo, Sri Lanka, 1981; Volume 39, pp. 93–94.

- Gosh, S.R.; Goswami, T.; Nombiar, M.K.C.; Chaliha, B.P.; Baruah, J.N. Investigation on water hyacinth (Eichhornia crassipes) for making water hyacinth-cement boards. In Proceedings of the International Conference on Water Hyacinth, Hyderabad, Assam, India, 7–11 February 1983; pp. 461–471. [Google Scholar]

- Xu, Y.; Xu, J.; Yang, H.; Pu, Q.; Jiang, L. Water Hyacinth Fibre Lightweight Concrete. CN 1025314863, 10 April 2013. [Google Scholar]

- Saleh, H.M.M. Stability of cemented dried water hyacinth used for biosorption of radionuclides under various circumstances. J. Nucl. Mater. 2014, 446, 124–133. [Google Scholar] [CrossRef]

- Na-Ayudhya, B.I. Comparison of compressive and splitting tensile strength of autoclaved aerated concrete (AAC) containing water hyacinth and polypropylene fibre subjected to elevated temperatures. Mater. Struct. 2016, 49, 1455–1468. [Google Scholar] [CrossRef]

- Marques, M.L.; Luzardo, F.H.M.; Velasco, F.G.; González, L.N.; Da Silva, E.J.; De Lima, W.G. Compatibility of vegetable fibres with Portland cement and its relationship with the physical properties. Bras. Eng. Agríc. Ambient. 2016, 2020, 466–472. [Google Scholar] [CrossRef]

- Viwatsakpol, S. Mortar Reinforced With Water Hyacinth Fibre; Kasestsart University: Bangkok, Thailand, 2014. [Google Scholar]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D.T. Properties and potential application of the selected natural fibres as limited life geotextiles. Carbohydr. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Bordoloi, S.; Yamsani, S.K.; Garg, A.; Sreedeep, S.; Borah, S. Study on the efficacy of harmful weed species Eicchornia crassipes for soil reinforcement. Ecol. Eng. 2015, 85, 218–222. [Google Scholar] [CrossRef]

- Vardhan, H.; Bordoloi, S.; Garg, A.; Sreedeep, S. Compressive strength analysis of soil reinforced with fibre extracted from water hyacinth. Eng. Comput. 2017, 34. [Google Scholar] [CrossRef]

- Saha, M. Mechanical Characterization of Water Hyacinth Reinforced Polypropylene Composites; Bangladesh University of Engineering and Technology: Dhaka, Bangladesh, 2011. [Google Scholar]

- Tumolva, T.; Ortenero, J.; Kubouchi, M. Characterization and Treatment of Water Hyacinth Fibres for NFRP Composites. In Proceedings of the XIX International Conference of Composite Materials, Canadian Asociation for Composite Structure and Materials. Montreal, QC, Canada, 28 July–2 August 2013; pp. 1–11. [Google Scholar]

- Jaktorn, C.; Jiajitsawat, S. Production of Thermal Insulator from Water Hyacinth Fibre and Natural Rubber Latex Energy Research & Promotion Center, Faculty of Sciences, Research Network & Innovation Development of Smart Materials for Energy, Sensors and Bio-resources. Int. J. Sci. 2014, 11, 31–41. [Google Scholar]

- Chimma, T. The Feasibility Study of Cement Board Made by Mixing Water Hyacinth with Cement; Mahidol University: Salaya, Thailand, 2001. [Google Scholar]

- Chatveera, B.; Nimityongskul, P.; Utyrt, Y. Use of Water Hyacinth Fibre as Randomly-Oriented Reinforcement in Roofing Sheets. Eng. Appl. Sci. Res. 2013, 21, 77–92. [Google Scholar]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- TAPPI 257 cm-02. Standard Test Method for Sampling and Preparing Wood for Analysis; Technical Association of Pulp and Paper Industry (TAPPI), TAPPI Press: Atlanta, GA, USA, 2012. [Google Scholar]

- TAPPI T 204 om-88. Standard Test Method for Solvent Extractives of Wood and Pulp; Technical Association of Pulp and Paper Industry (TAPPI), TAPPI Press: Atlanta, GA, USA, 2007. [Google Scholar]

- TAPPI T 207 cm-99. Standard Test Method for Water Solubility of Wood and Pulp; Technical Association of Pulp and Paper Industry (TAPPI), TAPPI Press: Atlanta, GA, USA, 1999. [Google Scholar]

- Wise, L.E.; Murphy, M.; D Adieco, A.A. A chlorite holocellulose, its fractionation and bearing on summative wood analysis and studies on the hemicellulloses. Pap. Trade J. 1946, 122, 35–43. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass: Laboratory Analytical Procedure (LAP) (Revised July 2011); National Renewable Energy Laboratory: Golden, CO, USA, 2008.

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fibre reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- EN 1602. European Standard Test Method for Thermal Insulating Products for Building Applications—Determination of the Apparent Density; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- EN 322. European Standard Test Method for Wood-Based Panels—Determination of Moisture Content; European Committee for Standardization: Brussels, Belgium, 1994. [Google Scholar]

- EN 12087. European Standard Test Method for Thermal Insulating Products for Building Applications—Determination of Long Term Water Absorption by Immersion; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- EN 317. European Standard Test Method for Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1994. [Google Scholar]

- EN 12089. European Standard Test Method for Thermal Insulating Products for Building Applications—Determination of Bending Behaviour; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- RILEM TC Test for the determination of modulus of rupture and limit of proportionality of thin fibre reinforced cement sections. In RILEM Recommendations for the Testing and Use of Constructions Materials; RILEM (Ed.) E & F SPON: London, UK, 1984; pp. 161–163. ISBN 2351580117. [Google Scholar]

- PHYWE Series of Publications P 3.6.03-00. Insulation House. In Laboratory Experiments; PHYWE SYSTEME GmbH & Co: Göttingen, Germany, 2012; p. 147. [Google Scholar]

- Herrero del Cura, S. Influencia de la Dosificación y Granulometría del Caucho de Neumático Fuera de uso (NFU) y de las Domensiones Físicas en las Propiedades Térmicas, Acústicas y Mecánicas de Placas de Mortero de yeso y Caucho; Universidad Politécnica de Madrid: Madrid, Spain, 2016. [Google Scholar]

- Barbero-Barrera, M.M.; Flores-Medina, N.; Pérez-Villar, V. Assessment of thermal performance of gypsum-based composites with revalorized graphite filler. Constr. Build. Mater. 2017, 142, 83–91. [Google Scholar] [CrossRef]

- Navacerrada, M.A.; Fernandez, P.; Díaz, C.; Pedrero, A. Thermal and Acoustic properties af aluminium foams manufactured by the infiltration process. Appl. Acoust. 2003, 74, 496–501. [Google Scholar] [CrossRef]

- Sundari, M.T.; Ramesh, A.; Thiripura Sundari, M.; Ramesh, A. Isolation and characterization of cellulose nanofibres from the aquatic weed water hyacinth-Eichhornia crassipes. Carbohydr. Polym. 2011, 87, 1701–1705. [Google Scholar] [CrossRef]

- Dantas-Santos, N.; Gomes, D.L.; Costa, L.S.; Cordeiro, S.L.; Costa, M.S.S.P.; Trindade, E.S.; Franco, C.R.C.; Scortecci, K.C.; Leite, E.L.; Rocha, H.A.O.; et al. Freshwater Plants Synthesize Sulfated Polysaccharides: Heterogalactans from Water Hyacinth (Eicchornia crassipes). Int. J. Mol. Sci. 2012, 13, 961–976. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bordoloi, S.; Hussain, R.; Garg, A.; Sreedeep, S.; Zhou, W.-H. Infiltration characteristics of natural fibre reinforced soil. Transp. Geotech. 2017, 12, 37–44. [Google Scholar] [CrossRef]

- Bordoloi, S.; Garg, A.; Sreedeep, S. Potential of Uncultivated, Harmful and Abundant Weed as a Natural Geo-Reinforcement Material. Adv. Civ. Eng. Mater. 2016, 5, 20160012. [Google Scholar] [CrossRef]

- Abdel-Fattah, A.F.; Abdel-Naby, M.A. Pretreatment and enzymic saccharification of water hyacinth cellulose. Carbohydr. Polym. 2012, 87, 2109–2113. [Google Scholar] [CrossRef]

- Hasan, M.R.; Chakrabarti, R. Floating aquatic macrophytes—Water hyacinths. In Use of Algae and Aquatic Macrophytes as Feed in Small-Scale Aquaculture—A Review; FAO Fisheries and Aquaculture Technical Paper 531; FAO: Roma, Italy, 2009; pp. 53–66. ISBN 978-92-5-106420-7. [Google Scholar]

- Zhou, W.; Zhu, D.; Langdon, A.; Li, L.; Liao, S.; Tan, L. The structure characterization of cellulose xanthogenate derived from the straw of Eichhornia crassipes. Bioresour. Technol. 2009, 100, 5366–5369. [Google Scholar] [CrossRef] [PubMed]

- Panyakaew, S.; Fotios, S. New thermal insulation boards made from coconut husk and bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Zheng, F.; Li, H.; Lu, C. An environment-friendly thermal insulation material from cotton stalk fibres. Energy Build. 2010, 42, 1070–1074. [Google Scholar] [CrossRef]

- Xu, J.; Sugawara, R.; Widyorini, R.; Han, G.; Kawai, S. Manufacture and properties of low-density binderless particleboard from kenaf core. J. Wood Sci. 2004, 50, 62–67. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Boukhattem, L.; Boumhaout, M.; Hamdi, H.; Benhamou, B.; Nouh, F.A. Moisture content influence on the thermal conductivity of insulating building materials made from date palm fibres mesh. Constr. Build. Mater. 2017, 148, 811–823. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Haldar, S.; Chatterjee, P.K. Geographical distribution and physiology of water hyacinth (Eichhornia crassipses)—the invasive hydrophyte and a biomass for producing xylitol. Int. J. ChemTech Res. 2015, 7, 1849–1861. [Google Scholar]

- Keegstra, K. Plant cell walls. Plant Physiol. 2010, 154, 483–486. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Chen, H. Chemical Composition and Structure of Natural Lignocellulose. In Biotechnology of Lignocellulose; Springer: Dordrecht, The Netherlands, 2014; pp. 25–71. [Google Scholar]

- Claramunt, J.; Ventura, H.; Fernández-Carrasco, L.; Ardanuy, M. Tensile and Flexural Properties of Cement Composites Reinforced with Flax Nonwoven Fabrics. Materials 2017, 10, 215. [Google Scholar] [CrossRef] [PubMed]

- Benfratello, S.; Capitano, C.; Peri, G.; Rizzo, G.; Scaccianoce, G.; Sorrentino, G. Thermal and structural properties of a hemp-lime biocomposite. Constr. Build. Mater. 2013, 48, 745–754. [Google Scholar] [CrossRef]

| WHP Size | Density (g/cm3) | Moisture Content (%) | Water Absorption (%) | |||

|---|---|---|---|---|---|---|

| Deviation | Deviation | Deviation | ||||

| Pulp | 0.625 | (±0.14) | 7.82 | (±1.87) | 540.82 | (±42.99) |

| Staple | 0.834 | (±0.17) | 7.94 | (±1.63) | 441.83 | (±64.74) |

| Sample | Holocellulose | Hot Water-Soluble | Pentosan | Lignin | Soluble in Neutral Organic Solvent |

|---|---|---|---|---|---|

| WHP | 37.95 wt.% | 36.11 wt.% | 5.9 wt.% | 5.84 wt.% | 4.34 wt.% |

| Sample | Density (g/cm3) | Moisture Content (%) | Water Absorption (%) | Thickness Swelling (%) | MOR (MPa) | Thermal Conductivity (W/mK) |

|---|---|---|---|---|---|---|

| pulp WHP | 305.25 (±22.08) | 8.63 (±0.79) | 555.20 (±0.08) | 57.68 (±10.34) | 0.548 (±0.125) | 0.065 (±0.00077) |

| staple WHP | 251.23 (±12.35) | 11.84 (±0.82) | 450.51 (±0.08) | 101.05 (±38.29) | 0.215 (±0.095) | 0.047 (±0.002474) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salas-Ruiz, A.; del Mar Barbero-Barrera, M.; Ruiz-Téllez, T. Microstructural and Thermo-Physical Characterization of a Water Hyacinth Petiole for Thermal Insulation Particle Board Manufacture. Materials 2019, 12, 560. https://doi.org/10.3390/ma12040560

Salas-Ruiz A, del Mar Barbero-Barrera M, Ruiz-Téllez T. Microstructural and Thermo-Physical Characterization of a Water Hyacinth Petiole for Thermal Insulation Particle Board Manufacture. Materials. 2019; 12(4):560. https://doi.org/10.3390/ma12040560

Chicago/Turabian StyleSalas-Ruiz, Adela, María del Mar Barbero-Barrera, and Trinidad Ruiz-Téllez. 2019. "Microstructural and Thermo-Physical Characterization of a Water Hyacinth Petiole for Thermal Insulation Particle Board Manufacture" Materials 12, no. 4: 560. https://doi.org/10.3390/ma12040560

APA StyleSalas-Ruiz, A., del Mar Barbero-Barrera, M., & Ruiz-Téllez, T. (2019). Microstructural and Thermo-Physical Characterization of a Water Hyacinth Petiole for Thermal Insulation Particle Board Manufacture. Materials, 12(4), 560. https://doi.org/10.3390/ma12040560