Mechanical Alloying and Electrical Current-Assisted Sintering Adopted for In Situ Ti-TiB Metal Matrix Composite Processing

Abstract

:1. Introduction

2. Materials and Methods

- Ti(α) (COD 9008517),

- TiB (COD 9008946)

- Rwp—weighted pattern residual indicator

- Rexp—expected residual indicator

- GOD—goodness of fit

3. Results

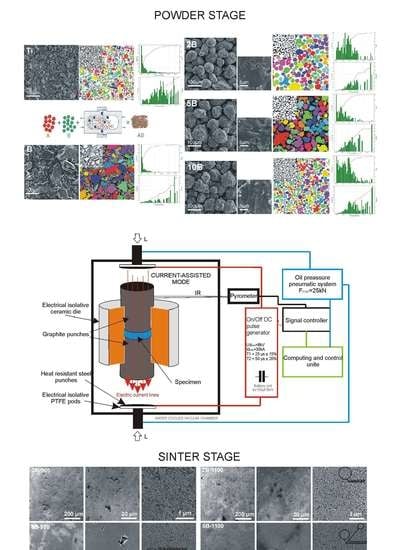

3.1. Precursor Powder Blend Stadium

3.2. Sintered Composite Material Stadium

4. Discussion

5. Conclusions

- the mechanical alloying approach allows a homogeneous distribution of the elements in the prepared precursor powder blends;

- the mechanical alloying approach allows obtaining the nanoscale range in the prepared precursor powder blends;

- the sinters obtained after PPS processing of the MA precursor powders are characterized by a composite microstructure with a highly dispersed reinforcement phase, whose size falls in the submicron to nanoscale range;

- the obtained in situ metal matrix composite sinters are characterized by low porosity, yet heavily dependent on the starting material composition characteristics and the proposed processing variants; and

- the final material properties can be adjusted not only by the composition, the processing approach or the temperature dependence but also by the starting material morphology, its size ratio, and proper distribution of the components.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saito, T. The automotive application of discontinuously reinforced TiB-Ti composites. JOM 2004, 56, 33–36. [Google Scholar] [CrossRef]

- Kainer, K.U. Basics of Metal Matrix Composites; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Geramny, 2006; ISBN 3527313605. [Google Scholar]

- Montgomery, J.S.; Wells, M.G.H.; Roopchand, B.; Ogilvy, J.W. Low-cost titanium armors for combat vehicles. JOM 1997, 49, 45–47. [Google Scholar] [CrossRef]

- Miklaszewski, A.; Jurczyk, M.U.; Kaczmarek, M.; Paszel-Jaworska, A.; Romaniuk, A.; Lipińska, N.; Żurawski, J.; Urbaniak, P.; Jurczyk, M. Nanoscale size effect in in situ titanium based composites with cell viability and cytocompatibility studies. Mater. Sci. Eng. C 2017, 73, 525–536. [Google Scholar] [CrossRef]

- Selvakumar, M.; Chandrasekar, P.; Mohanraj, M.; Ravisankar, B.; Balaraju, J.N. Role of powder metallurgical processing and TiB reinforcement on mechanical response of Ti-TiB composites. Mater. Lett. 2015, 144, 58–61. [Google Scholar] [CrossRef]

- Tjong, S.C.; Mai, Y.W. Processing-structure-property aspects of particulate- and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Effects of boron additions and solutionizing treatments on microstructures and ductility of forged Ti-6Al-4V alloys. J. Alloys Compd. 2015, 624, 170–178. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q. Microstructure and mechanical properties of in situ TiB reinforced titanium matrix composites based on Ti-FeMo-B prepared by spark plasma sintering. Compos. Sci. Technol. 2004, 64, 2495–2500. [Google Scholar] [CrossRef]

- Zhang, Z.; Shen, X.-B.; Wen, S.; Luo, J.; Lee, S.; Wang, F. In situ reaction synthesis of Ti–TiB composites containing high volume fraction of TiB by spark plasma sintering process. J. Alloys Compd. 2010, 503, 145–150. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium: Engineering Materials and Processes; Springer: New York, NY, USA, 2007. [Google Scholar]

- Gil, F.J.; Aparicio, C.; Planell, J.A. Effect of Oxygen Content on Grain Growth Kinetics of Titanium. J. Mater. Synth. Process. 2002, 10, 263–266. [Google Scholar] [CrossRef]

- Gorsse, S.; Chaminade, J.P.; Le Petitcorps, Y. In situ preparation of titanium base composites reinforced by TiB single crystals using a powder metallurgy technique. Compos. Part A Appl. Sci. Manuf. 1998, 29, 1229–1234. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Wang, B.; Xu, H.Y.; Kaveendran, B. Effects of extrusion and heat treatment on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composite with a network architecture. Compos. Part A Appl. Sci. Manuf. 2012, 43, 486–491. [Google Scholar] [CrossRef]

- Zhang, J.; Ke, W.; Ji, W.; Fan, Z.; Wang, W.; Fu, Z. Microstructure and properties of in situ titanium boride (TiB)/titanium (TI) composites. Mater. Sci. Eng. A 2015, 648, 158–163. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, Z.H.; Wang, F.C.; Shen, X.B.; Cai, H.N.; Lee, S.K.; Wang, L. Effect of Ti content and sintering temperature on the microstructures and mechanical properties of TiB reinforced titanium composites synthesized by SPS process. Mater. Sci. Eng. A 2013, 560, 249–255. [Google Scholar] [CrossRef]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium-titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Sahay, S.S.; Ravichandran, K.S.; Atri, R.; Chen, B.; Rubin, J. Evolution of microstructure and phases in in situ processed Ti-TiB composites containing high volume fractions of TiB whiskers. J. Mater. Res. 1999, 14, 4214–4223. [Google Scholar] [CrossRef]

- Miklaszewski, A. Ultrafast densification and microstructure evolution of in situ Ti/TiB metal matrix composite obtained by PPS approach. Int. J. Refract. Met. Hard Mater. 2017, 65, 34–38. [Google Scholar] [CrossRef]

- Miklaszewski, A. Effect of starting material character and its sintering temperature on microstructure and mechanical properties of super hard Ti/TiB metal matrix composites. Int. J. Refract. Met. Hard Mater. 2015, 53, 56–60. [Google Scholar] [CrossRef]

- Zadra, M. Mechanical alloying of titanium. Mater. Sci. Eng. A 2013, 583, 105–113. [Google Scholar] [CrossRef]

- Yurlova, M.S.; Demenyuk, V.D.; Lebedeva, L.Y.; Dudina, D.V.; Grigoryev, E.G.; Olevsky, E.A. Electric pulse consolidation: An alternative to spark plasma sintering. J. Mater. Sci. 2014, 49, 952–985. [Google Scholar] [CrossRef]

- Groza, J.R.; Zavaliangos, A. Sintering activation by external electrical field. Mater. Sci. Eng. A 2000, 287, 171–177. [Google Scholar] [CrossRef] [Green Version]

- Suryanarayana, C.; Norton, M.G. Practical Aspects of X-ray Diffraction. In X-ray Diffraction: A Practical Approach; Springer Science + Buisness Media: New York, NY, USA, 1998; ISBN 978-1-4899-0148-4. [Google Scholar]

- Miklaszewski, A.; Garbiec, D.; Niespodziana, K. Sintering behavior and microstructure evolution in cp-titanium processed by spark plasma sintering. Adv. Powder Technol. 2017, 29, 50–57. [Google Scholar] [CrossRef]

- Kessler, H.D.; Rostoker, W.; Van Thyne, R.J. Titanium Phase Diagrams; WADC Tech. Rep. 52-335 Ti; Statement A: Approved for public release; Wright-Patterson Air Force Base: Dayton, OH, USA, 1953. [Google Scholar]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q.; Rao, J. Growth mechanism of in situ TiB whiskers in spark plasma sintered TiB/Ti metal matrix composites. Cryst. Growth Des. 2006, 6, 1626–1630. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q. Stacking faults formation mechanism of in situ synthesized TiB whiskers. Scr. Mater. 2006, 55, 667–670. [Google Scholar] [CrossRef]

| Element | Average Particle Size [µm] | Purity Level [%] | Blend Composition 1 [wt.%] | Blend Composition 2 [wt.%] | Blend Composition 3 [wt.%] |

|---|---|---|---|---|---|

| Titanium | 50 | 99.5 | 98 | 95 | 90 |

| Boron | 80 | 99.5 | 2 | 5 | 10 |

| Symbol of the obtained after the MA process precursor composition | 2% | 5% | 10% | ||

| Treatment Temperature | Sample | Ti(α) | TiB | Rexp [%] | Rwp [%] | GOD | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| a [Å] | c [Å] | PA [%] | a [Å] | b [Å] | c [Å] | PA [%] | |||||

| 900 | 2% | 2.9641(5) | 4.7134(8) | 89.96 | 4.5532(70) | 6.0850(11) | 3.0529(57) | 10.04 | 8.67 | 19.67 | 2.27 |

| 5% | 2.9629(7) | 4.7226(13) | 68.82 | 4.5510(23) | 6.0953(33) | 3.0581(18) | 31.18 | 7.04 | 19.73 | 2.80 | |

| 10% | 2.9608(5) | 4.7313(11) | 42.63 | 4.5524(9) | 6.1146(16) | 3.0487(7) | 57.36 | 9.06 | 14.10 | 1.56 | |

| 1100 | 2% | 2.9637(3) | 4.7137(5) | 90.65 | 4.5608(23) | 6.1161(34) | 3.0617(19) | 9.35 | 9.22 | 15.55 | 1.69 |

| 5% | 2.9663(6) | 4.7195(11) | 70.58 | 4.5557(22) | 6.1169(38) | 3.0481(18) | 29.42 | 7.29 | 19.18 | 2.63 | |

| 10% | 2.9692(6) | 4.7423(14) | 40.59 | 4.5586(8) | 6.1341(15) | 3.0488(6) | 59.41 | 9.57 | 16.66 | 1.74 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miklaszewski, A.; Jurczyk, M. Mechanical Alloying and Electrical Current-Assisted Sintering Adopted for In Situ Ti-TiB Metal Matrix Composite Processing. Materials 2019, 12, 653. https://doi.org/10.3390/ma12040653

Miklaszewski A, Jurczyk M. Mechanical Alloying and Electrical Current-Assisted Sintering Adopted for In Situ Ti-TiB Metal Matrix Composite Processing. Materials. 2019; 12(4):653. https://doi.org/10.3390/ma12040653

Chicago/Turabian StyleMiklaszewski, Andrzej, and Mieczyslaw Jurczyk. 2019. "Mechanical Alloying and Electrical Current-Assisted Sintering Adopted for In Situ Ti-TiB Metal Matrix Composite Processing" Materials 12, no. 4: 653. https://doi.org/10.3390/ma12040653

APA StyleMiklaszewski, A., & Jurczyk, M. (2019). Mechanical Alloying and Electrical Current-Assisted Sintering Adopted for In Situ Ti-TiB Metal Matrix Composite Processing. Materials, 12(4), 653. https://doi.org/10.3390/ma12040653