The Study on Mechanical Strength of Titanium-Aluminum Dissimilar Butt Joints by Laser Welding-Brazing Process

Abstract

:1. Introduction

2. Experimental Details

2.1. Material Properties

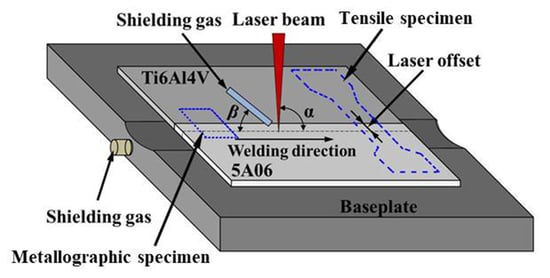

2.2. Set-Up of the Welding System

2.3. Experiment Plan

3. Weld Metallurgy and Fracture

3.1. Weld Structure and Composition

3.2. Fracture Properties

4. Discussion

4.1. Effects of Laser Offset

4.2. Effects of Welding Speed

4.3. Effects of Laser Power

5. Conclusions

- The Ti6Al4V titanium plate and 5A06 aluminum plate were successfully jointed by a laser welding–brazing process. A dissimilar butt joint with an IMC thickness of 2.79 μm was obtained by adjusting the laser offset, welding speed, and laser power to 500 μm, 11 mm/s, and 1130W, respectively. The maximum tensile strength of the joint was up to 183 MPa, which is equivalent to 83% of the tensile strength of the 5A06 aluminum alloy.

- The spreading length of both the topside and the backside increased first, then decreased with the increase in laser offset and laser power, and decreased with the increase in welding speed. The IFZW increased with the increase in laser offset and welding speed, and decreased with the increase in laser power. The fracture roughness decreased first, then increased with the increase in laser offset and laser power, and decreased with the increase in welding speed. The IMC thickness decreased with the increase in laser offset and welding speed, and increased with the increase in laser power.

- The tensile strength of the joint was influenced not only by the thickness and type of IMC, but also by the spreading ability of the aluminum liquid, the fracture area broken at the Ti/FZ interface, the relative area of the brittle, and the ductile fracture in FZ.

Author Contributions

Funding

Conflicts of Interest

References

- Woizeschke, P.; Vollertsen, F. A strength-model for laser joined hybrid aluminum–titanium transition structures. CIRP Annals-Manuf. Technol. 2016, 65, 241–244. [Google Scholar] [CrossRef]

- Miyagi, M.; Wang, H.; Yoshida, R.; Kawahito, Y.; Kawakami, H.; Shoubu, T. Effect of alloy element on weld pool dynamics in laser welding of aluminum alloys. Sci. Rep. 2018, 8, 12944. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.Z.; Li, Y.J.; Wang, J.; Liu, K. Improving of interfacial microstructure of Ti/Al joint during GTA welding by adopting pulsed current. Int. J. Adv. Manuf. Technol. 2014, 73, 1307–1312. [Google Scholar]

- Vaidya, W.V.; Horstmann, M.; Ventzke, V.; Petrovski, B.; Koçak, M.; Kocik, R.; Tempus, G. Improving interfacial properties of a laser beam welded dissimilar joint of aluminium AA6056 and titanium Ti6Al4V for aeronautical applications. J. Mater. Sci. 2010, 45, 6242–6254. [Google Scholar] [CrossRef]

- Ohnuma, I.; Fujita, Y.; Mitsui, H.; Ishikawa, K.; Kainuma, R.; Ishida, K. Phase equilibria in the Ti-Al binary system. Acta Mater. 2000, 48, 3113–3123. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Cicala, E.; Peyre, P.; Grevey, D. Direct keyhole laser welding of aluminum alloy AA5754 to titanium alloy Ti6Al4V. J. Mater. Processing Technol. 2015, 217, 96–104. [Google Scholar] [CrossRef]

- Karpov, M.I.; Korzhov, V.P.; Zheltyakova, I.S. Layer structure of a refractory multilayer Ti/Al composite after pressure diffusion welding. Met. Sci. Heat Treat. 2016, 58, 3–6. [Google Scholar] [CrossRef]

- Rajakumar, S.; Balasubramanian, V. Diffusion bonding of titanium and AA7075 aluminum alloy dissimilar joints-process modeling and optimization using desirability approach. Int. J. Adv. Manuf. Technol. 2016, 86, 1095–1112. [Google Scholar] [CrossRef]

- Bazarnik, P.; Adamczyk-Cieślak, B.; Gałka, A.; Płonka, B.; Snieżek, L.; Cantoni, M.; Lewandowska, M. Mechanical and microstructural characteristics of Ti6Al4V/AA2519 and Ti6Al4V/AA1050/AA2519 laminates manufactured by explosive welding. Mater. Des. 2016, 111, 146–157. [Google Scholar] [CrossRef]

- Fan, M.Y.; Yu, W.; Wang, W.; Guo, X.; Jin, K.; Miao, R.; Hou, W.; Kim, N.; Tao, J. Microstructure and mechanical properties of thin-multilayer Ti/Al laminates prepared by one-step explosive bonding. J. Mater. Eng. Perform. 2017, 26, 1–8. [Google Scholar] [CrossRef]

- Fronczek, D.M.; Chulist, R.; Szulc, Z.; Wojewoda-Budka, J. Growth kinetics of TiAl3, phase in annealed Al/Ti/Al explosively welded clads. Mater. Lett. 2017, 198, 160–163. [Google Scholar] [CrossRef]

- Xia, H.B.; Wang, S.G.; Ben, H.F. Microstructure and mechanical properties of Ti/Al explosive cladding. Mater. Des. 2014, 56, 1014–1019. [Google Scholar] [CrossRef]

- Plaine, A.H.; Suhuddin, U.F.H.; Afonso, C.R.M.; Alcantara, N.G.; Dos Santos, J.F. Interface formation and properties of friction spot welded joints of AA5754 and Ti6Al4V alloys. Mater. Des. 2016, 93, 224–231. [Google Scholar] [CrossRef]

- Choi, J.W.; Liu, H.H.; FujiI, H. Dissimilar friction stir welding of pure Ti and pure Al. Mater. Sci. Eng. A 2018, 730, 168–176. [Google Scholar] [CrossRef]

- Huang, Y.X.; Lv, Z.L.; Wan, L.; Shen, J.J.; Dos Santos, J.F. A new method of hybrid friction stir welding assisted by friction surfacing for joining dissimilar Ti/Al alloy. Mater. Lett. 2017, 207, 172–175. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Z.; Shen, Y.; Hu, W.; Luo, L. Dissimilar friction stir welding of Ti–6Al–4V alloy and aluminum alloy employing a modified butt joint configuration: Influences of process variables on the weld interfaces and tensile properties. Mater. Des. 2014, 53, 838–848. [Google Scholar] [CrossRef]

- Song, Z.; Nakata, K.; Wu, A.; Liao, J.; Zhou, L. Influence of probe offset distance on interfacial microstructure and mechanical properties of friction stir butt welded joint of Ti6Al4V and A6061 dissimilar alloys. Mater. Des. 2014, 57, 269–278. [Google Scholar] [CrossRef]

- Mohammadpour, M.; Yazdian, N.; Yang, G.; Wang, H.P.; Carlson, B.; Kovacevic, R. Effect of dual laser beam on dissimilar welding-brazing of aluminum to galvanized steel. Opt. Laser Technol. 2018, 98, 214–228. [Google Scholar] [CrossRef]

- Taban, E.; Gould, J.E.; Lippold, J.C. Characterization of 6061-T6 aluminum alloy to AISI 1018 steel interfaces during joining and thermo-mechanical conditioning. Mater. Sci. Eng. A 2010, 527, 1704–1708. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Gu, Y.Z.; Zeng, X.Y. Microstructure and tensile behavior of laser arc hybrid welded dissimilar Al and Ti Alloys. Materials 2014, 7, 1590–1602. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.F.; Chen, X.Z.; Pan, Q.H.; Madigan, B.; Long, J.Q. Laser welding dissimilar materials of aluminum to steel: An overview. Int. J. Adv. Manuf. Technol. 2016, 87, 3081–3090. [Google Scholar] [CrossRef]

- Wu, Y.; Cai, Y.; Wang, H.; Shi, S.; Hua, X.; Wu, Y. Investigation on microstructure and properties of dissimilar joint between SA553 and SUS304 made by laser welding with filler wire. Mater. Des. 2015, 87, 67–78. [Google Scholar] [CrossRef]

- Rong, Y.M.; Xu, J.; Cao, H.; Zheng, H.; Huang, Y.; Zhang, G. Influence of steady magnetic field on dynamic behavior mechanism in full penetration laser beam welding. J. Manuf. Process. 2017, 26, 399–406. [Google Scholar] [CrossRef]

- Ly, S.; Rubenchik, A.M.; Khairallah, S.A.; Guss, G.; Matthews, M.J. Metal vapor micro-jet controls material redistribution in laser powder bed fusion additive manufacturing. Sci. Rep. 2017, 7, 4085. [Google Scholar] [CrossRef] [PubMed]

- Casalino, G.; D’Ostuni, S.; Guglielmi, P.; Leo, P.; Mortello, M.; Palumbo, G.; Piccininni, A. Mechanical and microstructure analysis of AA6061 and Ti6Al4V fiber laser butt weld. Optik 2017, 148, 151–156. [Google Scholar] [CrossRef]

- Chen, S.H.; Yang, D.; Li, M.; Zhang, Y.; Huang, J.; Yang, J.; Zhao, X. Laser penetration welding of an overlap titanium-on-aluminum configuration. Int. J. Adv. Manuf. Technol. 2016, 87, 3069–3079. [Google Scholar] [CrossRef]

- Leo, P.; D’Ostuni, S.; Casalino, G. Low temperature heat treatments of AA5754-Ti6Al4V dissimilar laser welds: Microstructure evolution and mechanical properties. Opt. Laser Technol. 2018, 100, 109–118. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Méasson, A.; Cicala, E.; Duband, M.; Peyre, P. Aluminum to titanium laser welding-brazing in V-shaped groove. J. Mater. Process. Technol. 2017, 245, 24–36. [Google Scholar] [CrossRef]

- Peyre, P.; Berthe, L.; Dal, M.; Pouzet, S.; Sallamand, P.; Tomashchuk, I. Generation and characterization of T40/A5754 interfaces with lasers. J. Mater. Process. Technol. 2014, 214, 1946–1953. [Google Scholar] [CrossRef]

- Sahul, M.; Sahul, M.; Vyskoč, M.; Caplovic, L.; Pasak, M. Disk laser weld brazing of AW5083 aluminum alloy with titanium grade 2. J. Mater. Eng. Perform. 2017, 26, 1346–1357. [Google Scholar] [CrossRef]

- Chen, S.H.; Li, L.Q.; Chen, Y.B.; Dai, J.M.; Huang, J.H. Improving interfacial reaction nonhomogeneity during laser welding-brazing aluminum to titanium. Mater. Des. 2011, 32, 4408–4416. [Google Scholar] [CrossRef]

- Song, Z.H.; Nakata, K.; Wu, A.; Liao, J.S. Interfacial microstructure and mechanical property of Ti6Al4V/A6061 dissimilar joint by direct laser brazing without filler metal and groove. Mater. Sci. Eng. A 2013, 560, 111–120. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M. Modeling and experimental analysis of fiber laser offset welding of Al-Ti butt joints. Int. J. Adv. Manuf. Technol. 2016, 83, 89–98. [Google Scholar] [CrossRef]

- Sun, Q.J.; Li, J.Z.; Liu, Y.B.; Li, B.P.; Xu, P.W.; Feng, J.C. Microstructural characterization and mechanical properties of Al/Ti joint welded by CMT method-Assisted hybrid magnetic field. Mater. Des. 2017, 116, 316–324. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Metallic Materials–Tensile Testing–Part 1: Method of Test at Room Temperature; ISO 6892-1:2009; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Wei, S.Z.; Li, Y.J.; Wang, J.; Liu, K. Formation of brittle phases during pulsed current gas tungsten arc welding of titanium to aluminum alloys. J. Mater. Eng. Perform. 2014, 23, 1451–1457. [Google Scholar] [CrossRef]

- Kaplan, A.F.H.; Powell, J. Spatter in laser welding. J. Laser Appl. 2011, 23, 3337–3344. [Google Scholar] [CrossRef]

- Vacchi, G.S.; Plaine, A.H.; Silva, R.; Sordi, V.L.; Suhuddin, U.F.H.; Alcântara, N.G.; Kuri, S.E.; Rovere, C.A.D. Effect of friction spot welding (FSpW) on the surface corrosion behavior of overlapping AA6181/Ti-6Al-4V joints. Mater. Des. 2017, 131, 127–134. [Google Scholar] [CrossRef]

- Hao, X.H.; Dong, H.G.; Li, S.; Xu, X.X.; Li, P. Lap joining of TC4 titanium alloy to 304 stainless steel with fillet weld by GTAW using copper-based filler wire. J. Mater. Process. Technol. 2018, 257, 88–100. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J. Microstructure characteristics and mechanical property of aluminum alloy/stainless steel lap joints fabricated by MIG welding-brazing process. Mater. Sci. Eng. A 2011, 528, 6179–6185. [Google Scholar] [CrossRef]

- Huang, J.K.; He, J.; Yu, X.Q.; Li, C.L.; Ding, F. The study of mechanical strength for fusion-brazed butt joint between aluminum alloy and galvanized steel by arc-assisted laser welding. J. Manuf. Process. 2017, 25, 126–133. [Google Scholar] [CrossRef]

| Alloy | Elements (wt.%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | Ti | Mg | Si | Cu | Mn | Fe | Zn | V | C | N | H | O | |

| 5A06 | Bal. | 0.02 | 5.8–6.8 | 0.4 | 0.1 | 0.5–0.8 | 0.4 | 0.2 | – | – | – | – | – |

| Ti6Al4V | 5.5–6.8 | Bal. | – | – | – | – | 0.3 | – | 3.5–4.5 | 0.1 | 0.05 | 0.01 | 0.2 |

| Alloy | Density (g/cm3) | Thermal Conductivity (W/(m·K)) | Coefficient of Linear Expansion (K−1) | Tensile Strength (MPa) | Yield Strength (MPa) | Elasticity Modulus (GPa) |

|---|---|---|---|---|---|---|

| 5A06 | 2.64 | 117 | 24.7 × 10−6 | 325 | 160 | 68 |

| Ti6Al4V | 4.44 | 7.95 | 8.6 × 10−6 | 967 | 860 | 112 |

| Sample | Laser Power (W) | Welding Speed (mm/s) | Laser Offset (μm) | Shielding Gas Flow Rate (L/min) | |

|---|---|---|---|---|---|

| Top | Back | ||||

| 1 | 1130 | 9 | 300 | 20 | 15 |

| 2 | 1130 | 9 | 400 | 20 | 15 |

| 3 | 1130 | 9 | 500 | 20 | 15 |

| 4 | 1130 | 9 | 600 | 20 | 15 |

| 5 | 1130 | 9 | 700 | 20 | 15 |

| 6 | 1130 | 8 | 500 | 20 | 15 |

| 7 | 1130 | 9 | 500 | 20 | 15 |

| 8 | 1130 | 10 | 500 | 20 | 15 |

| 9 | 1130 | 11 | 500 | 20 | 15 |

| 10 | 1080 | 9 | 500 | 20 | 15 |

| 11 | 1130 | 9 | 500 | 20 | 15 |

| 12 | 1180 | 9 | 500 | 20 | 15 |

| 13 | 1230 | 9 | 500 | 20 | 15 |

| 14 | 1280 | 9 | 500 | 20 | 15 |

| Zones | Chemical Composition (at%) | Probable Phase | |||

|---|---|---|---|---|---|

| Ti | Al | V | Mg | ||

| P1 | 90.01 | 5.51 | 3.98 | 0.50 | Ti |

| P2 | 73.70 | 22.40 | 3.37 | 0.53 | Ti3Al |

| P3 | 52.09 | 44.64 | 2.87 | 0.39 | Ti3Al + TiAl |

| P4 | 36.34 | 61.42 | 1.17 | 1.06 | TiAl + TiAl2 |

| P5 | 29.99 | 66.79 | 1.59 | 1.63 | TiAl2 |

| P6 | 3.58 | 93.67 | 0.56 | 2.18 | Al |

| Z1 | 2.38 | 94.45 | 0.35 | 2.82 | Al |

| Z2 | 63.89 | 32.14 | 2.63 | 1.34 | Ti3Al |

| Z3 | 5.20 | 91.60 | 0.50 | 2.70 | Al |

| Z4 | 11.38 | 83.76 | 2.06 | 2.81 | TiAl3 |

| Z5 | 83.25 | 10.88 | 5.12 | 0.75 | Ti |

| Z6 | 27.49 | 67.41 | 3.05 | 2.05 | TiAl2 |

| Z7 | 82.14 | 10.76 | 6.39 | 0.72 | Ti |

| Z8 | 86.44 | 8.44 | 4.85 | 0.28 | Ti |

| Z9 | 76.39 | 19.59 | 3.70 | 0.33 | Ti + Ti3Al |

| Z10 | 63.28 | 31.61 | 3.68 | 1.42 | Ti3Al |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Duan, J.; Zhang, F.; Zhong, S. The Study on Mechanical Strength of Titanium-Aluminum Dissimilar Butt Joints by Laser Welding-Brazing Process. Materials 2019, 12, 712. https://doi.org/10.3390/ma12050712

Zhou X, Duan J, Zhang F, Zhong S. The Study on Mechanical Strength of Titanium-Aluminum Dissimilar Butt Joints by Laser Welding-Brazing Process. Materials. 2019; 12(5):712. https://doi.org/10.3390/ma12050712

Chicago/Turabian StyleZhou, Xiongfeng, Ji’an Duan, Fan Zhang, and Shunshun Zhong. 2019. "The Study on Mechanical Strength of Titanium-Aluminum Dissimilar Butt Joints by Laser Welding-Brazing Process" Materials 12, no. 5: 712. https://doi.org/10.3390/ma12050712

APA StyleZhou, X., Duan, J., Zhang, F., & Zhong, S. (2019). The Study on Mechanical Strength of Titanium-Aluminum Dissimilar Butt Joints by Laser Welding-Brazing Process. Materials, 12(5), 712. https://doi.org/10.3390/ma12050712