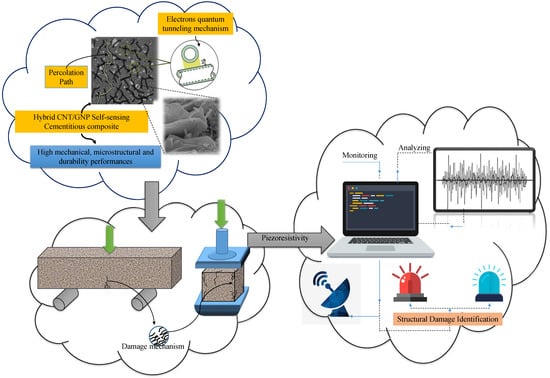

Ultra-Sensitive Affordable Cementitious Composite with High Mechanical and Microstructural Performances by Hybrid CNT/GNP

Abstract

:1. Introduction

2. Experimental Methods

2.1. Raw Materials and Characterization

2.2. Carbon Nanotube (CNT) + Graphene Nanoplatelet (GNP) Dispersion Method

2.3. Cementitious Composite Fabrication

2.4. Mechanical and Microstructural Characterization

2.5. Piezoresistivity Measurement

3. Results and Discussion

3.1. Mechanical and Microstructural Cementitious Composite Characterization

3.2. Microstructural Investigation

3.3. Durability of CNT + GNP Reinforced Cementitious Mortar

3.4. Piezoresistive Behavior

3.4.1. Electrical Resistance Results

3.4.2. Cyclic Compression Test Results

3.4.3. Cyclic Flexural Test Results

3.4.4. Gauge Factors

4. Conclusions

- An optimal concentration of CNT + GNP around 0.5% (1:1) shows the best performance in terms of durability (resistance against freeze–thaw cycles), microstructure and mechanical behaviour.

- Incorporating 0.5% CNT + GNP into the cementitious mortar led to increasing flexural strength by 37%, 41%, and 43% after 7, 28, and 90 days of curing respectively. These amounts for compressive strength were 28%, 36%, and 46% respectively.

- The improvement in flexural and compressive moduli was quite high reaching up to 123% and 168% respectively in the case of 0.5% reinforced samples after 90 days of curing.

- Scan electron microscopy, dry bulk density, apparent porosities, and ultrasonic wave passing time also showed the denser microstructure for reinforced mortar by 0.5% CNT + GNP.

- Evaluation of relative dynamic modules and weight loss of specimens after 180 freeze and thaw cycles also showed the best performance in terms of durability for the reinforced specimen by 0.5% CNT + GNP.

- Incorporating 0.5% CNT + GNP into the cementitious mortar led to the sharp change in electrical resistivity under cyclic loading which caused flexural and compression gauge factors by 398 and 460 respectively. This optimal percentage reveals significantly higher gauge factors when compared with the available results using individual nanoparticles.

- The results of this study provide proof of the concept that incorporating a low concentration of a hybrid combination of carbon nanotubes (CNTs) and graphene nanoplatelets (GNPs) in a cement mortar can provide self-sensing capabilities of the reinforced cementitious composite, enhancing microstructure, durability and mechanical performances.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Data Availability Statement

References

- Ozbulut, O.E.; Jiang, Z.; Harris, D.K. Exploring scalable fabrication of self-sensing cementitious composites with graphene nanoplatelets. Smart Mater. Struct. 2018, 27, 115029. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Alver, N.; Chai, H.K. Health Monitoring of Civil Infrastructure and Materials. Sci. World J. 2014, 2014, 2. [Google Scholar] [CrossRef]

- Le, J.-L.; Du, H.; Pang, S.D. Use of 2D Graphene Nanoplatelets (GNP) in cement composites for structural health evaluation. Compos. Part B Eng. 2014, 67, 555–563. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Shen, L.; Sun, Z.; Sheng, D. Piezoresistivity of smart carbon nanotubes (CNTs) reinforced cementitious composite under integrated cyclic compression and impact. Compos. Struct. 2020, 241, 112106. [Google Scholar] [CrossRef]

- Nazerigivi, A.; Najigivi, A. Study on mechanical properties of ternary blended concrete containing two different sizes of nano-SiO2. Compos. Part B Eng. 2019, 167, 20–24. [Google Scholar] [CrossRef]

- Nazerigivi, A.; Nejati, H.R.; Ghazvinian, A.; Najigivi, A. Effects of SiO2 nanoparticles dispersion on concrete fracture toughness. Constr. Build. Mater. 2018, 171, 672–679. [Google Scholar] [CrossRef]

- Rao, R.; Sindu, B.S.; Sasmal, S. Synthesis, design and piezo-resistive characteristics of cementitious smart nanocomposites with different types of functionalized MWCNTs under long cyclic loading. Cem. Concr. Compos. 2020, 108, 103517. [Google Scholar] [CrossRef]

- Nejati, H.R.; Nazerigivi, A.; Imani, M.; Karrech, A. Monotoring of fracture propagation in brittle materials using acoustic emission techniques-A review. Comput. Concr. 2020, 25, 15–27. [Google Scholar]

- Han, B.; Ding, S.; Yu, X. Intrinsic self-sensing concrete and structures: A review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Belli, A.; Mobili, A.; Bellezze, T.; Tittarelli, F.; Cachim, P. Evaluating the Self-Sensing Ability of Cement Mortars Manufactured with Graphene Nanoplatelets, Virgin or Recycled Carbon Fibers through Piezoresistivity Tests. Sustainability 2018, 10, 4013. [Google Scholar] [CrossRef] [Green Version]

- You, I.; Yoo, D.-Y.; Kim, S.; Kim, M.-J.; Zi, G. Electrical and Self-Sensing Properties of Ultra-High-Performance Fiber-Reinforced Concrete with Carbon Nanotubes. Sensors 2017, 17, 2481. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, W.; Li, W.; Tao, Z.; Wang, K. Piezoresistive properties of cement-based sensors: Review and perspective. Constr. Build. Mater. 2019, 203, 146–163. [Google Scholar] [CrossRef]

- Rao, R.K.; Sasmal, S. Smart nano-engineered cementitious composite sensors for vibration-based health monitoring of large structures. Sens. Actuators A Phys. 2020, 311, 112088. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Wang, K.; Guo, Y.; Sheng, D.; Shah, S.P. Piezoresistivity enhancement of functional carbon black filled cement-based sensor using polypropylene fibre. Powder Technol. 2020, 373, 184–194. [Google Scholar] [CrossRef]

- Lee, S.J.; You, I.; Zi, G.; Yoo, D.Y. Experimental Investigation of the Piezoresistive Properties of Cement Composites with Hybrid Carbon Fibers and Nanotubes. Sensors 2017, 17, 2516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Strain and damage sensing properties on multifunctional cement composites with CNF admixture. Cem. Concr. Compos. 2014, 46, 90–98. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Chen, Z.; Han, Z.; Zhang, Y.; Pacheco-Torgal, F. Nano-carbon black and carbon fiber as conductive materials for the diagnosing of the damage of concrete beam. Constr. Build. Mater. 2013, 43, 233–241. [Google Scholar] [CrossRef] [Green Version]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Tkalya, E.E.; Ghislandi, M.; de With, G.; Koning, C.E. The use of surfactants for dispersing carbon nanotubes and graphene to make conductive nanocomposites. Curr. Opin. Colloid Interface Sci. 2012, 17, 225–232. [Google Scholar] [CrossRef]

- Alrekabi, S.; Cundy, A.B.; Lampropoulos, A.; Whitby, R.L.D.; Savina, I. Mechanical performance of novel cement-based composites prepared with nano-fibres, and hybrid nano- and micro-fibres. Compos. Struct. 2017, 178, 145–156. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Naqi, A.; Abbas, N.; Zahra, N.; Hussain, A.; Shabbir, S.Q. Effect of multi-walled carbon nanotubes (MWCNTs) on the strength development of cementitious materials. J. Mater. Res. Technol. 2019, 8, 1203–1211. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Shi, T.; Li, Z.; Guo, J.; Gong, H.; Gu, C. Research progress on CNTs/CNFs-modified cement-based composites—A review. Constr. Build. Mater. 2019, 202, 290–307. [Google Scholar] [CrossRef]

- Pang, S.D.; Gao, H.; Xu, C.; Quek, S.T.; Du, H. Strain and damage self-sensing cement composites with conductive graphene nanoplatelet. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems; SPIE: Bellingham, WA, USA, 2014. [Google Scholar]

- Sun, S.; Han, B.; Jiang, S.; Yu, X.; Wang, Y.; Li, H.; Ou, J. Nano graphite platelets-enabled piezoresistive cementitious composites for structural health monitoring. Constr. Build. Mater. 2017, 136, 314–328. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Han, B.; Ouyang, J.; Yu, X.; Sun, S.; Ou, J. Multifunctionality of cement based composite with electrostatic self-assembled CNT/NCB composite filler. Arch. Civ. Mech. Eng. 2017, 17, 354–364. [Google Scholar] [CrossRef]

- Aguilar, J.O.; Bautista-Quijano, J.R.; Avilés, F. Influence of carbon nanotube clustering on the electrical conductivity of polymer composite films. Express Polym. Lett. 2010, 4, 292–299. [Google Scholar] [CrossRef]

- Li, J.; Ma, P.C.; Chow, W.S.; To, C.K.; Tang, B.Z.; Kim, J.-K. Correlations between Percolation Threshold, Dispersion State, and Aspect Ratio of Carbon Nanotubes. Adv. Funct. Mater. 2007, 17, 3207–3215. [Google Scholar] [CrossRef]

- Martin, C.A.; Sandler, J.K.W.; Shaffer, M.S.P.; Schwarz, M.K.; Bauhofer, W.; Schulte, K.; Windle, A.H. Formation of percolating networks in multi-wall carbon-nanotube–epoxy composites. Compos. Sci. Technol. 2004, 64, 2309–2316. [Google Scholar] [CrossRef]

- Hernández, J.J.; García-Gutiérrez, M.C.; Nogales, A.; Rueda, D.R.; Kwiatkowska, M.; Szymczyk, A.; Roslaniec, Z.; Concheso, A.; Guinea, I.; Ezquerra, T.A. Influence of preparation procedure on the conductivity and transparency of SWCNT-polymer nanocomposites. Compos. Sci. Technol. 2009, 69, 1867–1872. [Google Scholar] [CrossRef]

- Abedi, M.; Fangueiro, R.; Correia, A.G. An Effective Method for Hybrid CNT/GNP Dispersion and Its Effects on the Mechanical, Microstructural, Thermal, and Electrical Properties of Multifunctional Cementitious Composites. J. Nanomater. 2020, 2020, 6749150. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Characterizing dispersion and long term stability of concentrated carbon nanotube aqueous suspensions for fabricating ductile cementitious composites. Powder Technol. 2017, 307, 1–9. [Google Scholar] [CrossRef]

- Yu, H.; Hermann, S.; Schulz, S.E.; Gessner, T.; Dong, Z.; Li, W.J. Optimizing sonication parameters for dispersion of single-walled carbon nanotubes. Chem. Phys. 2012, 408, 11–16. [Google Scholar] [CrossRef]

- Baig, Z.; Mamat, O.; Mustapha, M.; Mumtaz, A.; Munir, K.S.; Sarfraz, M. Investigation of tip sonication effects on structural quality of graphene nanoplatelets (GNPs) for superior solvent dispersion. Ultrason. Sonochemistry 2018, 45, 133–149. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Rhee, I.; Wang, Y.; Xi, Y. Compressive Strength, Chloride Permeability, and Freeze-Thaw Resistance of MWNT Concretes under Different Chemical Treatments. Sci. World J. 2014, 2014, 572102. [Google Scholar] [CrossRef]

- Du, M.; Jing, H.; Gao, Y.; Su, H.; Fang, H. Carbon nanomaterials enhanced cement-based composites: Advances and challenges. Nanotechnol. Rev. 2020, 9, 115. [Google Scholar]

- Farooq, F.A.A.; Khushnood, R.A.; Muhammad, W.L.B.; Rehman, S.K.U.; Javed, M.F. Experimental Investigation of Hybrid Carbon Nanotubes and Graphite Nanoplatelets on Rheology, Shrinkage, Mechanical, and Microstructure of SCCM. Materials 2020, 13, 230. [Google Scholar] [CrossRef] [Green Version]

- Ferro, G.; Tulliani, J.M.; Lopez, A.; Jagdale, P. New cementitious composite building material with enhanced toughness. Theor. Appl. Fract. Mech. 2015, 76, 67–74. [Google Scholar] [CrossRef]

- Campillo, I.; Dolado, J.; Porro, A. High-performance nanostructured materials for construction. Spec. Publ. -Royal Soc. Chem. 2004, 292, 215–226. [Google Scholar]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Musso, S.; Tulliani, J.-M.; Ferro, G.; Tagliaferro, A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites. Compos. Sci. Technol. 2009, 69, 1985–1990. [Google Scholar] [CrossRef]

- Melo, V.S.; Calixto, J.M.; Ladeira, L.O.; Silva, A.P. Macro- and Micro-Characterization of Mortars Produced with Carbon Nanotubes. ACI Mater. J. 2011, 108, 327. [Google Scholar]

- Kumar, S.; Kolay, P.; Malla, S.; Mishra, S. Effect of Multiwalled Carbon Nanotubes on Mechanical Strength of Cement Paste. J. Mater. Civ. Eng. 2012, 24, 84–91. [Google Scholar] [CrossRef]

- Babak, F.; Abolfazl, H.; Alimorad, R.; Parviz, G. Preparation and Mechanical Properties of Graphene Oxide: Cement Nanocomposites. Sci. World J. 2014, 2014, 10. [Google Scholar] [CrossRef]

- Kim, G.M.; Yang, B.J.; Cho, K.J.; Kim, E.M.; Lee, H.K. Influences of CNT dispersion and pore characteristics on the electrical performance of cementitious composites. Compos. Struct. 2017, 164, 32–42. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; You, I.; Lee, S.-J. Electrical Properties of Cement-Based Composites with Carbon Nanotubes, Graphene, and Graphite Nanofibers. Sensors 2017, 17, 1064. [Google Scholar] [CrossRef]

- Liu, C.; Liu, G.; Ge, Z.; Guan, Y.; Cui, Z.; Zhou, J. Mechanical and Self-Sensing Properties of Multiwalled Carbon Nanotube-Reinforced ECCs. Adv. Mater. Sci. Eng. 2019, 2019, 9. [Google Scholar] [CrossRef] [Green Version]

- Rhee, I.; Lee, J.S.; Kim, Y.A.; Kim, J.H.; Kim, J.H. Electrically conductive cement mortar: Incorporating rice husk-derived high-surface-area graphene. Constr. Build. Mater. 2016, 125, 632–642. [Google Scholar] [CrossRef]

- Monteiro, A.O.; Cachim, P.B.; Costa, P.M. Self-sensing piezoresistive cement composite loaded with carbon black particles. Cem. Concr. Compos. 2017, 81, 59–65. [Google Scholar] [CrossRef]

- Donnini, J.; Bellezze, T.; Corinaldesi, V. Mechanical, electrical and self-sensing properties of cementitious mortars containing short carbon fibers. J. Build. Eng. 2018, 20, 8–14. [Google Scholar] [CrossRef]

- Camacho-Ballesta, C.; Zornoza, E.; Garcés, P. Performance of cement-based sensors with CNT for strain sensing. Adv. Cem. Res. 2016, 28, 274–284. [Google Scholar] [CrossRef] [Green Version]

| GNP | ||||||||||

| Surface Area (m2 g−1) | Density (g/cm3) | Carbon Content (%) | Tensile Modulus (GPa) | PH Value (30 °C) | Tensile Strength (GPa) | Layers | Dimension | Form | Part Number | |

| 120–150 | 0.6 | >99.5 | 1000 | 7–7.65 | 5 | <20 | Thickness | Diameter | Gray Powder | TGN201 |

| 4–20 nm | 5–10 µm | |||||||||

| MWCNT | ||||||||||

| Surface Area (m2 g–1) | Density (g/cm3) | Color | Outside Diameter (nm) | Length (µm) | Ash (wt.%) | Carbon Content (%) | Part Number | |||

| 350 | 0.27 | Black | <8 | 30–10 | <1.5 | >98 | GCM327 | |||

| Mesh Size (mm) | 0.08 | 0.16 | 0.5 | 1 | 1.6 | 2 |

|---|---|---|---|---|---|---|

| Cumulative retained (%) | 99 ± 1 | 87 ± 5 | 67 ± 5 | 33 ± 5 | 7 ± 5 | 0 |

| SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | MgO (%) | CaO (%) | Na2O (%) | TiO2 (%) | K2O (%) | MnO (%) | P2O5 (%) | SO3 (%) | LOI a (%) | Finenes (m2/kg) | Specific Gravity (kg/dm3) | Initial Setting Time (min) b | Soundness (mm) b | Blaine’s Surface (cm2/g) b |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19.9 | 4.7 | 3.38 | 1.3 | 63.93 | 0.17 | 0.245 | 0.446 | 0.079 | 0.063 | 2.54 | 2.97 | 360 | 3.15 | 194 | 1.1 | 4220 |

| Dispersion Method | Nanoparticles Type and Weight Fraction (% *) | Results and Improvement (%) | Standard | References |

|---|---|---|---|---|

| Ultrasonication | CNT (1%) | (6%) Compressive | N.A | [40] |

| Nitric and sulfuric acid by carboxylation plus Sonication | CNT (0.5%) | (19%) Compressive_(25%) Flexural | N.A | [41] |

| Modified acrylic polymer and acetone plus sonication and superplasticizers | CNT (0.5%) | (11%) Compressive_(33%) Flexural | UNI-EN 196-1 | [42] |

| Modified polycarboxylate admixtures and naphthalene-sulfonate plasticizer | CNT (0.3%) | (12%) Compressive_(34%) Splitting Tensile_(14%) Modulus | NBR 7215, 8522,7222 | [43] |

| Ultrasonication | CNT (0.5%) | (15%) Compressive_(36%) Splitting Tensile | ASTM C39 C496 | [44] |

| Polycarboxylate superplasticizer | GO (1.5%) | (48%) Tensile | N.A | [45] |

| Pluronic F-127 and Tributyl phosphate by optimized temperature and ultrasonication | GNP + CNT (0.5% half by half) | (36%) Compressive_(41%) Flexural | BS EN 196-1:1995 | Present Study |

| Sample ID | Age | Ultrasonic Wave Time Passing (μs) for 150 kH | |

|---|---|---|---|

| Longitudinal | Transverse | ||

| Plain Mortar | 7D | 36.46 | 10.69 |

| 28D | 36.40 | 9.60 | |

| GC 0.1% | 7D | 35.90 | 10.17 |

| 28D | 34.70 | 9.38 | |

| GC 0.3% | 7D | 35.20 | 9.61 |

| 28D | 34.10 | 8.93 | |

| GC 0.5% | 7D | 33.24 | 9.21 |

| 28D | 33.18 | 8.72 | |

| GC 0.7% | 7D | 33.70 | 9.43 |

| 28D | 32.90 | 8.64 | |

| GC 1% | 7D | 34.10 | 9.93 |

| 28D | 33.97 | 9.49 | |

| Matrix | Nanoparticles Type | Weight Fraction (wt.%) | Electrical Resistivity (Ω·m) | References |

|---|---|---|---|---|

| Mortar | GNP | 5 | 21.02 | [1] |

| Paste | CNF | 2 | 11 | [16] |

| Mortar | GNP | 5 | 78.2 | [1] |

| Mortar | GNP | 5 | 27.96 | [1] |

| Mortar | CNT | 0.7 | 24 | [48] |

| Mortar | Graphene | 1 | 4000 | [49] |

| Mortar | Carbon Black | 10 | 4.53 | [50] |

| Paste | GNP | 4.8 | 20 | [3] |

| Mortar | Short Carbon fiber | 2 | 2.4 | [51] |

| Mortar | GNP + CNT | 1 (half by half) | 15.3 | Present Study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abedi, M.; Fangueiro, R.; Gomes Correia, A. Ultra-Sensitive Affordable Cementitious Composite with High Mechanical and Microstructural Performances by Hybrid CNT/GNP. Materials 2020, 13, 3484. https://doi.org/10.3390/ma13163484

Abedi M, Fangueiro R, Gomes Correia A. Ultra-Sensitive Affordable Cementitious Composite with High Mechanical and Microstructural Performances by Hybrid CNT/GNP. Materials. 2020; 13(16):3484. https://doi.org/10.3390/ma13163484

Chicago/Turabian StyleAbedi, Mohammadmahdi, Raul Fangueiro, and António Gomes Correia. 2020. "Ultra-Sensitive Affordable Cementitious Composite with High Mechanical and Microstructural Performances by Hybrid CNT/GNP" Materials 13, no. 16: 3484. https://doi.org/10.3390/ma13163484

APA StyleAbedi, M., Fangueiro, R., & Gomes Correia, A. (2020). Ultra-Sensitive Affordable Cementitious Composite with High Mechanical and Microstructural Performances by Hybrid CNT/GNP. Materials, 13(16), 3484. https://doi.org/10.3390/ma13163484