Microcomputed X-Ray Tomographic Imaging and Image Processing for Microstructural Characterization of Explosives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Computed Tomography

3. Results

3.1. Plastic-Bonded Explosives

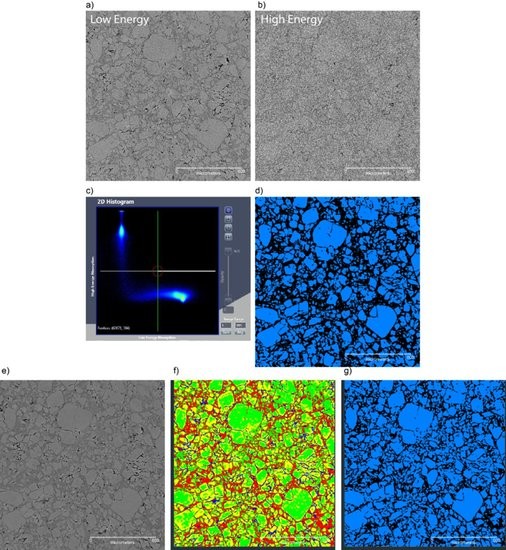

3.1.1. Segmentation of PBX 9501 and PBX 9502

3.1.2. Comparison of Three Highly-Loaded HMX Formulations

3.2. HE Materials without a Binder

4. Discussion

4.1. New State-of-the-Art for Full PBX Segmentation

4.2. Measurements of Voids and Implications for Modeling

4.3. Future Work with Non-Phase-Segmentable HE

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Khasainov, B.A.; Ermolaev, B.S.; Presles, H.N.; Vidal, P. On the effect of grain size on shock sensitivity of heterogeneous high explosives. Shock Waves 1997, 7, 89–105. [Google Scholar] [CrossRef]

- Bellitto, V.J.; Melnik, M.I.; Sherlock, M.H.; Chang, J.C.; O’Connor, J.H.; Mackey, J.A. Microstructure effects on the detonation velocity of a heterogeneous high-explosive. J. Energy Mater. 2018, 36, 485–492. [Google Scholar] [CrossRef]

- Parfenov, A.; Voskoboinikov, I.J.C. Low-velocity detonation of powdered explosives. Combust. Explos. Shock Waves 1969, 5, 240–244. [Google Scholar] [CrossRef]

- Hill, L.G.; Aslam, T.D. Detonation shock dynamics calibration for PBX 9502 with temperature, density, and material lot variations. In Proceedings of the Fourteenth International Detonation Symposium, Office of Naval Research, Coeur d’Alene, ID, USA, 1 January 2010; pp. 779–788. [Google Scholar]

- Dobratz, B.M. The Insensitive High Explosive Triaminotrinitrobenzene (TATB): Development and Characterization—1888 to 1994; LA-13014-H; Los Alamos National Lab: Los Alamos, NM, USA, 1995. [Google Scholar]

- Barua, A.; Zhou, M. A Lagrangian framework for analyzing microstructural level response of polymer-bonded explosives. Modell. Simul. Mater. Sci. Eng. 2011, 19, 055001. [Google Scholar] [CrossRef]

- Barua, A.; Kim, S.; Horie, Y.; Zhou, M. Prediction of probabilistic ignition behavior of polymer-bonded explosives from microstructural stochasticity. J. Appl. Phys. 2013, 113, 184907. [Google Scholar] [CrossRef] [Green Version]

- Perry, W.L.; Clements, B.; Ma, X.; Mang, J.T. Relating microstructure, temperature, and chemistry to explosive ignition and shock sensitivity. Combust. Flame 2018, 190, 171–176. [Google Scholar] [CrossRef]

- Rai, N.K.; Udaykumar, H.S. Mesoscale simulation of reactive pressed energetic materials under shock loading. J. Appl. Phys. 2015, 118, 245905. [Google Scholar] [CrossRef]

- Salyer, T.R. The effects of PBX 9502 ratchet growth on detonation failure as determined via the LANL failure cone test. AIP Conf. Proc. 2012, 1426, 243–246. [Google Scholar]

- An, C.W.; Guo, X.D.; Song, X.L.; Wang, Y.; Li, F.S. Preparation and safety of well-dispersed rdx particles coated with cured HTPB. J. Energy Mater. 2009, 27, 118–132. [Google Scholar] [CrossRef]

- Kasprzyk, D.J.; Bell, D.A.; Flesner, R.L.; Larson, S.A. Characterization of a Slurry Process Used to Make a Plastic-Bonded Explosive. Propellants Explos. Pyrotech. 1999, 24, 333–338. [Google Scholar] [CrossRef]

- Paraskos, A.J. Energetic Polymers: Synthesis and Applications. In Energetic Materials: From Cradle to Grave; Shukla, M.K., Boddu, V.M., Steevens, J.A., Damavarapu, R., Leszczynski, J., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 91–134. [Google Scholar]

- Dattelbaum, D. Equations of State of Binders and Related Polymers. In Static Compression of Energetic Materials; Peiris, S.M., Piermarini, G.J., Eds.; Springer: Berlin, Germany, 2008. [Google Scholar]

- Li, J.-S.; Chen, J.-J.; Hwang, C.-C.; Lu, K.-T.; Yeh, T.-F. Study on Thermal Characteristics of TNT Based Melt-Cast Explosives. Propellants Explos. Pyrotech. 2019, 44, 1270–1281. [Google Scholar] [CrossRef]

- Cooper, P.W.; Kurowski, S.R. Introduction to the Technology of Explosives; John Wiley and Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Peterson, P.D.; Fletcher, M.A.; Roemer, E.L. Influence of Pressing Intensity on the Microstructure of PBX 9501. J. Energy Mater. 2003, 21, 247–260. [Google Scholar] [CrossRef]

- Skidmore, C.B.; Phillips, D.S.; Asay, B.W.; Idar, D.J.; Howe, P.M.; Bolme, D.S. Microstructural effects in PBX 9501 damaged by shear impact. AIP Conf. Proc. 2000, 505, 659–662. [Google Scholar]

- Knepper, R.; Tappan, A.S.; Wixom, R.R.; Rodriguez, M.A. Controlling the microstructure of vapor-deposited pentaerythritol tetranitrate films. J. Mater. Res. 2011, 26, 1605–1613. [Google Scholar] [CrossRef]

- Banerjee, B.; Adams, D.O. On predicting the effective elastic properties of polymer bonded explosives using the recursive cell method. Int. J. Solids Struct. 2004, 41, 481–509. [Google Scholar] [CrossRef]

- Benson, D.J.; Conley, P. Eulerian finite-element simulations of experimentally acquired HMX microstructures. Modell. Simul. Mater. Sci. Eng. 1999, 7, 333–354. [Google Scholar] [CrossRef]

- Siviour, C.R.; Laity, P.R.; Proud, W.G.; Field, J.E.; Porter, D.; Church, P.D.; Gould, P.; Huntingdon-Thresher, W. High strain rate properties of a polymer-bonded sugar: Their dependence on applied and internal constraints. Proc. R. Soc. A Math. Phys. Eng. Sci. 2008, 464, 1229–1255. [Google Scholar] [CrossRef]

- Manner, V.W.; Yeager, J.D.; Patterson, B.M.; Walters, D.J.; Stull, J.A.; Cordes, N.L.; Luscher, D.J.; Henderson, K.C.; Schmalzer, A.M.; Tappan, B.C. In situ imaging during compression of plastic bonded explosives for damage modeling. Materials 2017, 10, 638. [Google Scholar] [CrossRef] [Green Version]

- Kort-Kamp, W.J.M.; Cordes, N.L.; Ionita, A.; Glover, B.B.; Duque, A.L.H.; Perry, W.L.; Patterson, B.M.; Dalvit, D.A.R.; Moore, D.S. Microscale electromagnetic heating in heterogeneous energetic materials based on x-ray computed tomography. Phys. Rev. Appl. 2016, 5, 044008. [Google Scholar] [CrossRef] [Green Version]

- Willey, T.M.; Lauderbach, L.; Gagliardi, F.; van Buuren, T.; Glascoe, E.A.; Tringe, J.W.; Lee, J.R.I.; Springer, H.K.; Ilavsky, J. Mesoscale evolution of voids and microstructural changes in HMX-based explosives during heating through the β-δ phase transition. J. Appl. Phys. 2015, 118, 055901. [Google Scholar] [CrossRef]

- Chen, N.; Koker, M.K.A.; Uzun, S.; Silberstein, M.N. In-situ X-ray study of the deformation mechanisms of non-woven polypropylene. Int. J. Solids Struct. 2016, 97, 200–208. [Google Scholar] [CrossRef]

- Wang, Y.; Que, J.M.; Wang, C.; Li, C.H. Three-dimensional observations of meso-structural changes in bimsoil using X-ray computed tomography (CT) under triaxial compression. Constr. Building Mater. 2018, 190, 773–786. [Google Scholar] [CrossRef]

- Patterson, B.M.; Cordes, N.L.; Henderson, K.; Mertens, J.C.E.; Clarke, A.J.; Hornberger, B.; Merkle, A.; Etchin, S.; Tkachuk, A.; Leibowitz, M.; et al. In situ laboratory-based transmission x-ray microscopy and tomography of material deformation at the nanoscale. Exp. Mech. 2016, 56, 1585–1597. [Google Scholar] [CrossRef]

- Yuan, Z.-N.; Chen, H.; Li, J.-M.; Dai, B.; Zhang, W.-B. In-situ X-ray tomography observation of structure evolution in 1,3,5-triamino-2,4,6-trinitrobenzene based polymer bonded explosive (TATB-PBX) under thermo-mechanical loading. Materials 2018, 11, 732. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dai, B.; Zhang, W.-B.; Lan, L.-G.; Tian, Y. Experimental Study and DEM Simulation of Micro–Macro Behavior of TATB Granules During Compaction Using X-ray Tomography. Propellants Explos. Pyrotech. 2015, 40, 688–698. [Google Scholar] [CrossRef]

- Yeager, J.D.; Manner, V.W.; Stull, J.A.; Walters, D.J.; Schmalzer, A.M.; Luscher, D.J.; Patterson, B.M. Importance of microstructural features in mechanical response of cast-cured HMX formulations. AIP Conf. Proc. 2018, 1979, 070033. [Google Scholar]

- Liu, R.; Chen, P.W. Modeling ignition prediction of HMX-based polymer bonded explosives under low velocity impact. Mech. Mater. 2018, 124, 106–117. [Google Scholar] [CrossRef]

- Hu, R.; Prakash, C.; Tomar, V.; Harr, M.; Gunduz, I.E.; Oskay, C. Experimentally-validated mesoscale modeling of the coupled mechanical–thermal response of AP–HTPB energetic material under dynamic loading. Int. J. Fract. 2017, 203, 277–298. [Google Scholar] [CrossRef]

- Walters, D.J.; Luscher, D.J.; Yeager, J.D.; Patterson, B.M. Cohesive finite element modeling of the delamination of HTPB binder and HMX crystals under tensile loading. Int. J. Mech. Sci. 2018, 140, 151–162. [Google Scholar] [CrossRef]

- Patterson, B.M.; Cordes, N.L.; Henderson, K.; Xiao, X.; Chawla, N. Data challenges of in situ X-ray tomography for materials discovery and characterization. In Materials Discovery and Design; Springer: Cham, Switzerland, 2018; pp. 129–165. [Google Scholar]

- Rae, P.J.; Goldrein, H.T.; Palmer, S.J.P.; Field, J.E.; Lewis, A.L. Quasi-Static Studies of the Deformation and Failure of b-HMX Based Polymer Bonded Explosives. Proc. Math. Phys. Eng. Sci. 2002, 458, 743–762. [Google Scholar] [CrossRef]

- Skidmore, C.B.; Phillips, D.S.; Son, S.F.; Asay, B.W. Characterization of HMX particles in PBX 9501. AIP Conf. Proc. 1998, 429, 579–582. [Google Scholar]

- Yeager, J.D.; Ramos, K.J.; Singh, S.; Rutherford, M.E.; Majewski, J.; Hooks, D.E. Nanoindentation of explosive polymer composites to simulate deformation and failure. Mater. Sci. Technol. 2012, 28, 1147–1155. [Google Scholar] [CrossRef]

- Peterson, P.D.; Idar, D.J. Microstructural Differences between Virgin and Recycled Lots of PBX 9502. Propellants Explos. Pyrotech. 2005, 30, 88–94. [Google Scholar] [CrossRef]

- Willey, T.M.; Lauderbach, L.; Gagliardi, F.; Cunningham, B.; Lorenz, K.T.; Lee, J.I.; van Buuren, T.; Call, R.; Landt, L.; Overturf, G. Comprehensive Characterization of Voids and Microstructure in TATB-based Explosives from 10 nm to 1 cm: Effects of Temperature Cycling and Compressive Creep. In Proceedings of the Fourteenth International Detonation Symposium, Coeur d’Alene, ID, USA, 11–16 April 2010. [Google Scholar]

- Kinney, J.; Willey, T.; Overturf, G. On the nature of variations in density and composition within TATB-based plastic bonded explosives. In Proceedings of the Thirteenth International Detonation Symposium, Norfolk, VA, USA, 23–28 July 2006. [Google Scholar]

- Bennett, K.C.; Zecevic, M.; Luscher, D.J.; Lebensohn, R.A. A thermo-elastoplastic self-consistent homogenization method for inter-granular plasticity with application to thermal ratcheting of TATB. Adv. Model. Simul. Eng. Sci. 2020, 7, 3. [Google Scholar] [CrossRef]

- Luscher, D.; Yeager, J.; Clausen, B.; Vogel, S.; Duque, A.H.; Brown, D. Using neutron diffraction to investigate texture evolution during consolidation of deuterated triaminotrinitrobenzene (d-TATB) Explosive Powder. Crystals 2017, 7, 138. [Google Scholar] [CrossRef] [Green Version]

- Yeager, J.D.; Watkins, E.B.; Duque, A.L.H.; Majewski, J. The thermal and microstructural effect of plasticizing HMX-Nitrocellulose composites. J. Energy Mater. 2018, 36, 13–28. [Google Scholar] [CrossRef]

- Gustavsen, R.L.; Sheffield, S.A.; Alcon, R.R. Extended Run Distance Measurements Of Shock Initiation In Pbx 9502. AIP Conf. Proc. 2007, 955, 915–918. [Google Scholar]

- Hoffman, D.M.; Willey, T.M.; Mitchell, A.R.; Depiero, S.C. Comparison of New and Legacy TATBs. J. Energy Mater. 2008, 26, 139–162. [Google Scholar] [CrossRef] [Green Version]

- Bourne, N.K.; Milne, A.M. Shock to detonation transition in a plastic bonded explosive. J. Appl. Phys. 2004, 95, 2379–2385. [Google Scholar] [CrossRef]

- Massoni, J.; Saurel, R.; Baudin, G.; Demol, G. A mechanistic model for shock initiation of solid explosives. Phys. Fluids 1999, 11, 710–736. [Google Scholar] [CrossRef]

- Hamate, Y.; Horie, Y. Ignition and detonation of solid explosives: A micromechanical burn model. Shock Waves 2006, 16, 125–147. [Google Scholar] [CrossRef]

- Burbelko, A.A.; Fraś, E.; Kapturkiewicz, W. About Kolmogorov’s statistical theory of phase transformation. Mater. Sci. Eng. A 2005, 413, 429–434. [Google Scholar] [CrossRef]

- Hayes, D.B.; Sandia National Labs. Shock Induced Hot-Spot Formation and Subsequent Decomposition in Granular, Porous HNS Explosive. In Shock Waves, Explosions, and Detonations; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1983; pp. 445–467. [Google Scholar]

- Nichols, A.L., III; Tarver, C.M. A statistical hot spot reactive flow model for shock initiation and detonation of solid high explosives. In Proceedings of the Twelfth International Symposium on Detonation, San Diego, CA, USA, 11–16 August 2002; Office of Naval Research: Arlington, VA, USA, 2002. [Google Scholar]

- Shaw, M.S.; Menikoff, R. A reactive burn model for shock initiation in a PBX: Scaling and separability based on the hot spot concept. In Proceedings of the 14th International Detonation Symposium, Los Alamos, NM, USA, 11 April 2010. [Google Scholar]

- Hill, L. The Statistical Hot Spot Model: Dimensionality and the Effects of Time-Distributed Nucleation. In Proceedings of the 21st APS Topical Conference on Shock Waves in Condensed Matter, Portland, OR, USA, 16–21 June 2019. [Google Scholar]

| Sample | Mass Composition (wt%) | Processing Method |

|---|---|---|

| HMX-HTPB | 80% HMX 1 20% HTPB 2 | Cast cured as a block, then cut to shape |

| PBX 9501 | 95% HMX 5% Plasticized Estane 5703 | Slurry formulated to form molding prills, then pressed |

| PBX 9502 | 95% TATB 3 5% Kel-F | Slurry formulated to form molding prills, then pressed |

| PBX 9404 | 94% HMX 6% Plasticized Nitrocellulose | Slurry formulated to form molding prills, then pressed |

| LX-14 | 95.5% HMX 4.5% Estane 5703 | Slurry formulated to form molding prills, then pressed |

| PBXN-5 | 95% HMX 5% Viton A | Slurry formulated to form molding prills, then pressed |

| PBXW-14 | 50% HMX 45% TATB5% Viton A | Slurry formulated to form molding prills, then pressed |

| Composition B | 60% RDX 4 40% TNT 5 | Melt cast, then pressed |

| Octol | 75% HMX 25% TNT | Melt cast, then pressed |

| TATB | 100% TATB | Pressed |

| Sample | Images | Time (s) | Pixel Size (µm) | Dual Energy? |

|---|---|---|---|---|

| HMX-HTPB | 4501 | 30 | 0.82 | |

| PBX 9501 | 4501 | 20 | 0.76 | X |

| PBX 9502 | 4501 | 25 | 0.76 | X |

| PBX 9404 | 4501 | 20 | 0.76 | X |

| LX-14 | 4501 | 20 | 0.76 | X |

| PBXN-5 | 4501 | 25 | 0.76 | X |

| PBXW-14 | 3201 | 13 | 0.84 | |

| Composition B | 4501 | 25 | 0.76 | X |

| Octol | 2401 | 15 | 0.89 | |

| TATB | 4501 | 25 | 0.76 | X |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeager, J.D.; Kuettner, L.A.; Duque, A.L.; Hill, L.G.; Patterson, B.M. Microcomputed X-Ray Tomographic Imaging and Image Processing for Microstructural Characterization of Explosives. Materials 2020, 13, 4517. https://doi.org/10.3390/ma13204517

Yeager JD, Kuettner LA, Duque AL, Hill LG, Patterson BM. Microcomputed X-Ray Tomographic Imaging and Image Processing for Microstructural Characterization of Explosives. Materials. 2020; 13(20):4517. https://doi.org/10.3390/ma13204517

Chicago/Turabian StyleYeager, John D., Lindsey A. Kuettner, Amanda L. Duque, Larry G. Hill, and Brian M. Patterson. 2020. "Microcomputed X-Ray Tomographic Imaging and Image Processing for Microstructural Characterization of Explosives" Materials 13, no. 20: 4517. https://doi.org/10.3390/ma13204517

APA StyleYeager, J. D., Kuettner, L. A., Duque, A. L., Hill, L. G., & Patterson, B. M. (2020). Microcomputed X-Ray Tomographic Imaging and Image Processing for Microstructural Characterization of Explosives. Materials, 13(20), 4517. https://doi.org/10.3390/ma13204517