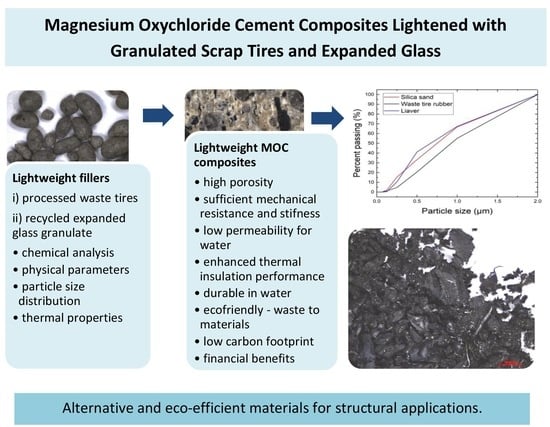

Magnesium Oxychloride Cement Composites Lightened with Granulated Scrap Tires and Expanded Glass

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- (i)

- application of processed ELT and glass granulate resulted in an increased porosity and great drop in bulk density;

- (ii)

- the develop lightweight materials had sufficient mechanical strength and stiffness which were suitable also for structural applications;

- (iii)

- the use of non-absorbing rubber particles and glass granulate repelled the water ingress, the composites, therefore, exhibited low permeability for water;

- (iv)

- the both lightweight aggregates used improved the thermal insulation performance of the manufactured composites compared to reference material with silica sand as the only filler;

- (v)

- because of the low water penetration, the novel materials were durable with respect to moisture damage.

Author Contributions

Funding

Conflicts of Interest

References

- Eriksson, O.; Bisaillon, M.; Haraldsson, M.; Sundberg, J. Integrated waste management as a mean to promote renewable energy. Renew. Energy 2017, 61, 38–42. [Google Scholar]

- Byström, J. Eco efficiency, a path towards integrated resource management. Waste Manag. 2012, 32, 797–798. [Google Scholar]

- ETRMA—European Tyre & Rubber Manufactures’ Association. European Tyre and Rubber Industry Statistics. 2019. Available online: https://www.etrma.org/wp-content/uploads/2019/10/20191114-Statistics-booklet-2019-Final-for-web.pdf (accessed on 15 September 2020).

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef] [PubMed]

- Toretta, V.; Rada, E.C.; Ragazzi, M.; Trulli, E.; Istrate, I.A.; Cioca, L.I. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Noorzad, R.; Raveshi, M. Mechanical behavior of waste tire crumbs-sand mixtures determined by triaxial tests. Geotech. Geol. Eng. 2017, 35, 1793–1802. [Google Scholar]

- Pantea, D.; Darmstadt, H.; Kaliaguine, S.; Roy, C. Heat-treatment of carbon blacks obtained by pyrolysis of used tires. Effect on the surface chemistry, porosity and electrical conductivity. J. Anal. Pyrol. 2003, 67, 55–76. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Reuse of deconstructed tires as anti-reflective cracking mat systems in asphalt pavements. Constr. Build. Mater. 2014, 53, 182–189. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N. Laboratory investigation of moisture damage in rubberised asphalt mixtures containing reclaimed asphalt pavement. Int. J. Pavement Eng. 2009, 10, 319–328. [Google Scholar]

- Yu, X.; Wang, Y.; Luo, Y. Effects of types and content of warm-mix additives on CRMA. J. Mater. Civ. Eng. 2013, 25, 939–945. [Google Scholar]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar]

- Akisetty, C.; Xiao, F.; Gandhi, T.; Amirkhanian, S. Estimating correlations between rheological and engineering properties of rubberized asphalt concrete mixtures containing warm mix asphalt additive. Constr. Build. Mater. 2011, 25, 950–956. [Google Scholar] [CrossRef]

- Lo Presti, D.; Airey, G. Tyre rubber-modified bitumens development: The effect of varying processing conditions. Road Mater. Pavement 2013, 14, 888–900. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 2014, 73, 562–574. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber—An overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, X.; Jiao, Y.; Sha, T. Experimental investigation of the mechanical and durability properties of crumb rubber concrete. Materials 2019, 9, 172. [Google Scholar] [CrossRef]

- Boudaoud, Z.; Beddar, M. Effects of recycled tires rubber aggregates on the characteristics of cement concrete. Open J. Civ. Eng. 2012, 2, 193–197. [Google Scholar] [CrossRef] [Green Version]

- Záleská, M.; Pavlík, Z.; Čítek, D.; Jankovský, O.; Pavlíková, M. Ecco-friendly concrete with scrap-tyre-rubber-based aggregate – Properties and thermal stability. Constr. Build. Mater. 2019, 225, 709–722. [Google Scholar] [CrossRef]

- Lavagna, L.; Nisticò, R.; Sarasso, M.; Pavese, M. An analytical mini-review on the compression strength of rubberized concrete as a function of the amount of recycled tires crumb rubber. Materials 2020, 13, 1234. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohammed, B.S.; Hossain, K.M.A.; Swee, J.T.E.; Wong, G.; Abdullahi, M. Properties of crumb rubber hollow concrete block. J. Clean. Prod. 2012, 23, 57–67. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel. Constr. Build. Mater. 2008, 23, 1084–1092. [Google Scholar] [CrossRef]

- de Souza Kazmiercziak, C.; Schneider, S.D.; Aguilera, O.; Albert, C.C.; Mancio, M. Rendering mortars with crumb rubber: Mechanical strength, thermal and fire properties and durability behavior. Constr. Build. Mater. 2020, 253, 119002. [Google Scholar] [CrossRef]

- Oikonomou, N.; Mavridou, S. Improvement of chloride ion penetration resistance in cement mortars modified with rubber from worn automobile tires. Cem. Concr. Compos. 2009, 31, 403–407. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Langlet, T.; Mezreb, K.; Roucoult, J.M.; Quéneudec, M. Physico-mechanical properties and water absorption of cement composite containing shredded rubber wastes. Cem. Concr. Compos. 2007, 29, 732–740. [Google Scholar] [CrossRef]

- Xu, H.; Lian, J.; Gao, M.; Fu, D.; Yan, Y. Self-Healing Concrete Using Rubber Particles to Immobilize Bacterial Spores. Materials 2019, 12, 2313. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Segre, N.; Joekes, I.; Galves, A.D.; Rodrigues, J.A. Rubber-mortar composite: Effect of composition on properties. J. Mater. Sci. 2004, 39, 3319–3327. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlíková, M.; Jankovský, O.; Lojka, M.; Pivák, A.; Pavlík, Z. Experimental Analysis of MOC Composite with a Waste-Expanded Polypropylene-Based Aggregate. Materials 2018, 11, 931. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Yu, H.; Zheng, L.; Wen, J.; Wu, C.; Tan, Y. Compressive strength of fly ash magnesium oxychloride cement containing granite wastes. Constr. Build. Mater. 2013, 38, 1–7. [Google Scholar] [CrossRef]

- Jankovský, O.; Lojka, M.; Lauermannová, A.-M.; Antončík, F.; Pavlíková, M.; Záleská, M.; Pavlík, Z.; Pivák, A.; Sedmidubský, D. Towards novel building materials: High-strength nanocomposites based on graphene, graphite oxide and magnesium oxychloride. Appl. Mater. Today 2020, 20, 100766. [Google Scholar] [CrossRef]

- Qing, H.; Ying, L.; Jing, W.; Weixin, Z.; Chenggong, C.; Jinmei, D.; Danchun, A.; Xueying, X.; Yuan, Z. Effect of ethyl silicate on the water resistance of magnesium oxychloride cement. Ceram. Silikáty 2020, 64, 75–83. [Google Scholar] [CrossRef] [Green Version]

- Deng, D. The mechanism for soluble phosphates to improve the water resistance of magnesium oxychloride cement. Cem. Concr. Res. 2008, 33, 1311–1317. [Google Scholar] [CrossRef]

- Bockstal, L.; Berchem, T.; Schmetz, Q.; Richel, A. Devulcanisation and reclaiming of tires and rubber by physical and chemical processes: A review. J. Clean. Prod. 2019, 236, 117574. [Google Scholar]

- Záleská, M.; Pavlíková, M.; Pokorný, J.; Jankovský, O.; Pavlík, Z.; Černý, R. Structural, mechanical and hygrothermal properties of lightweight concrete based on the application of waste plastics. Constr. Build. Mater. 2018, 180, 1–11. [Google Scholar]

- Testing for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution, EN 933-1; European Committee for Standardization: Brussels, Belgium, 2012.

- Binders for Magnesite Screeds—Caustic Magnesia and Magnesium Chloride—Part 2: Test Methods, EN 14016-2; European Committee for Standardization: Brussels, Belgium, 2004.

- Pivák, A.; Pavlíková, M.; Záleská, M.; Lojka, M.; Jankovský, O.; Pavlík, Z. Magnesium oxychloride cement composites with silica filler and coal fly ash admixture. Materials 2020, 13, 2537. [Google Scholar]

- Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar, EN 1015-10; European Committee for Standardization: Brussels, Belgium, 1999.

- Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar, EN 1015-11; European Committee for Standardization: Brussels, Belgium, 1999.

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete, 2nd ed.; CRC Press LLC: Boca Raton, FL, USA, 2003. [Google Scholar]

- He, P.; Poon, C.S.; Tsang, D.C.W. Effect of pulverized fuel ash and CO2 curing on the water resistance of magnesium oxychloride cement (MOC). Cem. Concr. Res. 2017, 97, 115–122. [Google Scholar]

- Tang, S.; Hu, Y.; Ren, W.; Yu, P.; Huang, Q.; Qi, X.; Li, Y.; Chen, E. Modeling on the hydration and leaching of eco-friendly magnesium oxychloride cement paste at the micro-scale. Constr. Build. Mater. 2019, 204, 684–690. [Google Scholar]

- Zhou, J.; Liu, P.; Wu, C.; Du, Z.; Zong, J.; Miao, M.; Pang, R.; Yu, H. Properties of foam concrete prepared from magnesium oxychloride cement. Ceram. Silikáty 2020, 64, 200–214. [Google Scholar]

- Natural Stone Test Methods—Determination of Water Absorption at Atmospheric Pressure, EN 13755; European Committee for Standardization: Brussels, Belgium, 2008.

- Pavlík, Z.; Černý, R. Determination of moisture diffusivity as a function of both moisture and temperature. Int. J. Thermophys. 2012, 33, 1704–1714. [Google Scholar]

- Feng, C.; Guimarães, A.S.; Ramos, N.; Sun, L.; Gawin, D.; Konca, P.; Hall, C.; Zhao, J.; Hirsch, H.; Grunewald, J.; et al. Hygric properties of porous building materials (VI): A round robin campaign. Build. Environ. 2020, 185, 107242. [Google Scholar]

- Methods of Test for Mortar for Masonry—Part 18: Determination of Water-Absorption Coefficient Due to Capillary Action of Hardened Mortar, EN 1015-18; European Committee for Standardization: Brussels, Belgium, 2002.

- Feng, C.; Janssen, H. Hygric properties of porous building materials (III): Impact factors and data processing methods of the capillary absorption test. Build. Environ. 2018, 134, 21–34. [Google Scholar]

- Kumaran, M.K. Moisture diffusivity of building materials from water absorption measurements. J. Therm. Envel. Build. Sci. 1999, 22, 349–355. [Google Scholar]

- Gustafsson, S.E. Transient plane source techniques for thermal conductivity and thermal diffusivity measurements of solid materials. Rev. Sci. Instrum. 1991, 62, 797. [Google Scholar] [CrossRef]

- Sizov, A.D.; Cederkrantz, D.; Salmi, L.; Rosén, A.; Jacobson, L.S.; Gustafsson, S.E.; Gustavsson, M. Thermal conductivity versus depth profiling of inhomogeneous materials using the hot disc technique. Rev. Sci. Instrum. 2016, 87, 074901. [Google Scholar] [CrossRef] [Green Version]

- Xu, B.; Ma, H.; Hu, C.; Li, Z. Influence of cenospheres on properties of magnesium oxychloride cement-based composites. Mater. Struct. 2016, 49, 1319–1326. [Google Scholar]

- Chandra, S.; Berntsson, L. Lightweight Aggregate Concrete, Science, Technology, and Applications; Noyes Publications/Wiliam Andrew Publishing: Norwich, CT, USA, 2002. [Google Scholar]

- Pivák, A.; Pavlíková, M.; Záleská, M.; Lojka, M.; Lauermannová, A.-M.; Jankovský, O.; Pavlík, Z. Low-carbon composite based on MOC, silica sand and ground porcelain insulator waste. Processes 2020, 8, 829. [Google Scholar] [CrossRef]

- Concrete—Specification, Performance, Production and Conformit, EN 206+A1; European Committee for Standardization: Brussels, Belgium, 2016.

- Thienel, K.-C.; Haller, T.; Beuntner, N. Lightweight concrete—From basics to innovations. Materials 2020, 13, 1120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, Y.; Zhang, Y.; Soe, K.; Hutchinson, W.D.; Timmers, H.; Poblete, M.R. Effect of fly ash on mechanical properties of magnesium cement under water attack. Struct. Concr. 2020, 21, 1181–1199. [Google Scholar] [CrossRef]

- Hall, D.A.; Stevens, R.; El-Jazairi, B. The effect of retarders on the microstructure and mechanical properties of magnesia–phosphate cement mortar. Cem. Concr. Res. 2001, 31, 455–465. [Google Scholar]

- Misra, A.K.; Mathur, R. Magnesium oxychloride cement concrete. Bull. Mat. Sci. 2007, 30, 239–246. [Google Scholar] [CrossRef] [Green Version]

- Eurocode 2: Design of Concrete Structures. Part 1-1, General Rules and Rules for Buildings, EN 1992-1-1; European Committee for Standardization: Brussels, Belgium, 2019.

- Guo, Y.; Zhang, Y.; Soe, K.; Pulham, M. Recent development in magnesium oxychloride cement. Struct. Concr. 2018, 19, 1290–1300. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlíková, M.; Jankovský, O.; Lojka, M.; Antončík, F.; Pivák, A.; Pavlík, Z. Influence of waste plastic aggregate and water-repellent additive on the properties of lightweight magnesium oxychloride cement composite. Appl. Sci. 2019, 9, 5463. [Google Scholar] [CrossRef] [Green Version]

- Yu, K.; Guo, Y.; Zhang, Y.X.; Soe, K. Magnesium oxychloride cement-based strain-hardening cementitious composite: Mechanical property and water resistance. Constr. Build. Mater. 2020, 261, 119970. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, Y.; Grover, L. Effect of phosphoric acid on the properties of magnesium oxychloride cement as biomaterial. Cem. Concr. Res. 2014, 56, 69–74. [Google Scholar] [CrossRef]

- Li, Y.; Yu, H. Rapid assessment method for water resistance of magnesium oxychloride cement based on measurement of high temperature erosion thickness. J. Chin. Ceram. Soc. 2014, 42, 1047–1054. [Google Scholar]

| Composite | Silica Sand | Rubber Granulate | Liaver |

|---|---|---|---|

| MOC-S | 3 × 1080 | - | - |

| MOC-WT | - | 3 × 350 | - |

| MOC-WT+L10 | - | 3 × 315 | 72.4 |

| MOC-WT+L20 | - | 3 × 279.9 | 144.9 |

| MOC-WT+L30 | - | 3 × 244.9 | 217.3 |

| Filler | Specific Density ρsf (kg∙m−3) |

|---|---|

| Silica Sand | 2652 |

| Granulated rubber | |

| 0–1 mm | 1195 |

| 1–2 mm | 1172 |

| Liaver | |

| 0.1–0.3 mm | 1240 |

| 0.25–0.5 mm | 843 |

| 0.5–1.0 mm | 717 |

| 1.0–2.0 mm | 579 |

| Aggregate | State | Powder Density ρp (kg∙m−3) | Thermal Conductivity λf (W∙m−1∙K−1) | Volumetric Heat Capacity Cwf × 106 (J m−3∙K−1) |

|---|---|---|---|---|

| Silica Sand | loose | 1363 | 0.399 | 0.256 |

| compacted | 1910 | 0.539 | 0.324 | |

| Granulated rubber | loose | 441 | 0.085 | 0.270 |

| compacted | 517 | 0.096 | 0.290 | |

| Liaver | loose | 305 | 0.080 | 0.237 |

| compacted | 346 | 0.094 | 0.249 |

| Materials | Spread Diameter (mm) | ρs (kg∙m−3) | ρb (kg∙m−3) | Ψ (%) |

|---|---|---|---|---|

| MOC-S | 160/165 ± 5 | 2320 ± 28 | 2165 ± 30 | 6.7 ± 0.1 |

| MOC-WT | 125/125 ± 5 | 1671 ± 20 | 1440 ± 20 | 13.8 ± 0.3 |

| MOC-WT+L10 | 130/130± 5 | 1662 ± 20 | 1413 ± 20 | 15.0 ± 0.3 |

| MOC-WT+L20 | 130/135 ± 5 | 1654 ± 20 | 1365 ± 19 | 17.5 ± 0.4 |

| MOC-WT+L30 | 135/135 ± 5 | 1609 ± 19 | 1316 ± 18 | 18.2 ± 0.4 |

| Materials | ff (MPa) | fc (MPa) | Ed (GPa) |

|---|---|---|---|

| MOC-S | 18.9 ± 0.3 | 80.1 ± 1.1 | 44.5 |

| MOC-WT | 4.5 ± 0.1 | 12.7 ± 0.2 | 8.6 |

| MOC-WT+L10 | 3.8 ± 0.1 | 11.4 ± 0.2 | 9.4 |

| MOC-WT+L20 | 4.1 ± 0.1 | 11.7 ± 0.2 | 9.6 |

| MOC-WT+L30 | 5.3 ± 0.1 | 11.9 ± 0.2 | 10.0 |

| Materials | Wa (%) | Aw ×10−4 (kg∙m−2s−1/2) | wcap (kg∙m−3) | Dapp ×10−9 (m2∙s−1) |

|---|---|---|---|---|

| MOC-S | 1.33 ± 0.02 | 6.0 ± 0.1 | 50.3 ± 0.9 | 0.14 ± 0.03 |

| MOC-WT | 2.01 ± 0.02 | 13.3 ± 0.3 | 63.5 ± 1.1 | 0.44 ± 0.10 |

| MOC-WT+L10 | 2.45 ± 0.03 | 13.7 ± 0.3 | 74.7 ± 1.3 | 0.33 ± 0.08 |

| MOC-WT+L20 | 2.51 ± 0.03 | 14.0 ± 0.3 | 75.5 ± 1.4 | 0.34 ± 0.08 |

| MOC-WT+L30 | 2.86 ± 0.03 | 19.6 ± 0.5 | 79.7 ± 1.4 | 0.61 ± 0.14 |

| Materials | λ (W∙m−1∙K−1) | a ×10−6 (m2∙s−1) | Cv ×106 (J∙m−3∙K−1) |

|---|---|---|---|

| MOC-S | 3.247 | 1.455 | 2.233 |

| MOC-WT | 0.787 | 0.384 | 2.055 |

| MOC-WT+L10 | 0.771 | 0.391 | 1.977 |

| MOC-WT+L20 | 0.751 | 0.432 | 1.743 |

| MOC-WT+L30 | 0.731 | 0.426 | 1.716 |

| Materials | αw (GPa) |

|---|---|

| MOC-S | 1.1 |

| MOC-WT | 1.2 |

| MOC-WT+L10 | 1.3 |

| MOC-WT+L20 | 1.2 |

| MOC-WT+L30 | 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlíková, M.; Pivák, A.; Záleská, M.; Jankovský, O.; Reiterman, P.; Pavlík, Z. Magnesium Oxychloride Cement Composites Lightened with Granulated Scrap Tires and Expanded Glass. Materials 2020, 13, 4828. https://doi.org/10.3390/ma13214828

Pavlíková M, Pivák A, Záleská M, Jankovský O, Reiterman P, Pavlík Z. Magnesium Oxychloride Cement Composites Lightened with Granulated Scrap Tires and Expanded Glass. Materials. 2020; 13(21):4828. https://doi.org/10.3390/ma13214828

Chicago/Turabian StylePavlíková, Milena, Adam Pivák, Martina Záleská, Ondřej Jankovský, Pavel Reiterman, and Zbyšek Pavlík. 2020. "Magnesium Oxychloride Cement Composites Lightened with Granulated Scrap Tires and Expanded Glass" Materials 13, no. 21: 4828. https://doi.org/10.3390/ma13214828

APA StylePavlíková, M., Pivák, A., Záleská, M., Jankovský, O., Reiterman, P., & Pavlík, Z. (2020). Magnesium Oxychloride Cement Composites Lightened with Granulated Scrap Tires and Expanded Glass. Materials, 13(21), 4828. https://doi.org/10.3390/ma13214828