Surface Reflectance: An Optical Method for Multiscale Curvature Characterization of Wear on Ceramic–Metal Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Selection of Surfaces

2.1.2. Mechanical Testing by Micro-Indentation

2.2. Reflectance Measurements

2.2.1. Principles

2.2.2. Topographic slope acquisition by reflectance transformation imaging (RTI)

2.3. Quantification of the SGCLR Relevance

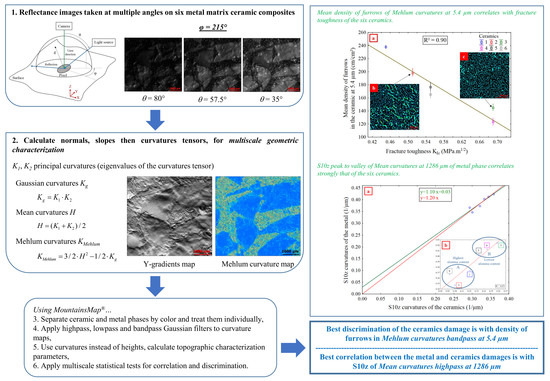

- Step 1. Reflectance images, described in Section 2.2.2.

- Step 2. Gradients and curvatures computation, described in Section 2.2.1.

- Step 3. Surface segmentation: images were segmented, with an algorithm in MATLAB®, according to the colors of the ceramic and metal phases. The algorithm draws shapes by following edges of color regions. The generated binary mask (Figure 9a) was imported into MountainsMap® and was applied to the shapes on each map (Figure 9b,c) in order to separate the ceramic grains from the metal phase.

- Step 4. Filtering was done in MountainsMap® for multiscale decompositions, with curvatures replacing heights. Gaussian filters were applied for low pass, high pass, and band pass, to all the ceramic and metal sections of the curvature maps, with 59 cutoff wavelengths ε varying from 2.2 to 4413 µm. High pass filtering keeps higher spatial frequencies, shorter spatial wavelengths, corresponding to roughness (low cutoffs). Low pass filtering keeps low spatial frequencies, longer wavelengths (high cutoffs), corresponding to waviness and form. Band pass is calculated by applying a high pass filter on the surface at a given cutoff ε and finally a low pass filter on the filtered surface at the cutoff ε-1.

- Step 5. From these topographic representations of curvatures, within color segmentations, decomposed by multiscale filtering, 3D topographic characterization parameters were calculated in MountainsMap®. A total of 75 topographic characterization parameters were studied (ISO 25178, EUR 15178N, and software modules) treating curvatures as if they are heights.

- Step 6. Statistical analyses by bootstrapping [40] and analysis of variance (ANOVA) [41] were done to determine the relevance (F) of different characterization parameters for discriminating the ceramics. A relevance index (RI) is calculated from the relevance F, the 95th percentile and the 5th percentile in order to normalize values:

3. Results and Discussion

4. Conclusions

- The density of furrows for Mehlum curvatures and S10z for mean curvatures, curvatures calculated from reflectance acquisitions, quantify the wear of the ceramics and of the metal at different scales: small, i.e., high spatial frequencies for density of furrows for Mehlum curvatures, and large, i.e., low spatial frequencies for S10z for mean curvatures.

- The density of furrows for Mehlum curvatures, at a scale of 5.4 µm, is the most relevant parameter for evaluating the wear difference between the ceramics.

- The density of furrows for Mehlum curvatures, at 5.4 µm, is proportional to the number of scratches, which are indications of an elementary wear mechanism namely abrasive wear.

- Material damage is related to mechanical properties. A strong correlation exists between the density of furrows for Mehlum curvatures, at 5.4 µm, and the fracture toughness (R² = 0.90). A material with a high KIc presents less scratches.

- A strong correlation (R² = 0.87) is found between the S10z for curvatures, with a high pass filter at 1286 µm, of the metal and the ceramics, with the metal more damaged than the ceramics.

- There are no heterogeneities in the results showing any influence of the material color on the SGCLR. The SGCLR method is not sensitive to surface colors.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | ||||||

| ANOVA | ANalysis Of VAriance | |||||

| MMC | Metal matrix composite | |||||

| RTI | Reflectance transformation imaging | |||||

| SGCLR | Surface gradient characterization by light reflectance | |||||

| Roughness parameters | ||||||

| S10z | Ten point height | |||||

| Sa | Arithmetic mean height | |||||

| Svi | Valley fluid retention index | |||||

| Mechanical parameters | ||||||

| α | Ceramic phase | |||||

| β | Metal phase | |||||

| d | Depth of scratch | |||||

| Hv | Hardness | |||||

| KIc | Fracture toughness | |||||

| Lc | Crack length | |||||

| w | Width of scratch | |||||

| RTI and curvature parameters | ||||||

| ϕ | Azimuth | |||||

| θ | Elevation | |||||

| H | Mean curvature | |||||

| K1 | Minimum principal curvature | |||||

| K2 | Maximum principal curvature | |||||

| Kg | Gaussian curvature | |||||

| KMehlum | Mehlum curvature | |||||

| Multiscale and statistical parameters | ||||||

| ε | Cutoff length | |||||

| F | Relevance | |||||

Appendix A

| SEM Images | Mehlum Curvature Maps | Furrows Maps | |

| Surface 1 KIc = 0.457 MPa√m 50–80% of alumina Black and cubic grains |  |  |  |

| Surface 2 KIc = 0.503 MPa√m 50–80% of alumina Black and cubic grains |  |  |  |

| Surface 3 KIc = 0.682 MPa√m 10–30% of alumina White and cubic grains |  |  |  |

| Surface 4 KIc = 0.683 MPa√m 10–30% of alumina White and spherical grains |  |  |  |

| Surface 5 KIc = 0.553 MPa√m 30–50% of alumina White and spherical grains |  |  |  |

| Surface 6 KIc = 0.557 MPa√m 30–50% of alumina White and cubic grains |  |  |  |

Appendix B

| Surfaces | 1 and 2 | 5 and 6 | 3 and 4 |

| Alumina content | High (50–80%) | Medium (30–50%) | Low (10–30%) |

| Mean KIc (MPa√m) | 0.48 | 0.55 | 0.68 |

| SEM zoom |  |  |  |

References

- Le Goïc, G.; Bigerelle, M.; Samper, S.; Favrelière, H.; Pillet, M. Multiscale roughness analysis of engineering surfaces: A comparison of methods for the investigation of functional correlations. Mech. Syst. Signal Process. 2016, 66–67, 437–457. [Google Scholar] [CrossRef]

- Brown, C.A.; Hansen, H.N.; Jiang, X.J.; Blateyron, F.; Berglund, J.; Senin, N.; Bartkowiak, T.; Dixon, B.; Le Goïc, G.; Quinsat, Y.; et al. Multiscale analyses and characterizations of surface topographies. CIRP Ann. 2018, 67, 839–862. [Google Scholar] [CrossRef]

- Bataille, C.; Bigerelle, M. Influence des conditions d’anodisation sur les mécanismes tribologiques de Stick-Slip. In 23ème Congrès Français de Mécanique, Lille (FR); Association Française de Mécanique: Courbevoie, France, 2017. [Google Scholar]

- Van Gorp, A.; Bigerelle, M.; Najjar, D. Relationship between brightness and roughness of polypropylene abraded surfaces. Polym. Eng. Sci. 2016, 56, 103–117. [Google Scholar] [CrossRef]

- Shu, D.J.; Gong, X.G. Curvature effect on surface diffusion: The nanotube. J. Chem. Phys. 2001, 114, 10922–10926. [Google Scholar] [CrossRef] [Green Version]

- Shen, X.; Avital, E.; Paul, G.; Rezaienia, M.A.; Wen, P.; Korakianitis, T. Experimental study of surface curvature effects on aerodynamic performance of a low Reynolds number airfoil for use in small wind turbines. J. Renew. Sustain. Energy 2016, 8, 053303. [Google Scholar] [CrossRef]

- Golden, J.M. The Effect of Surface Curvature on the Friction Coefficient. Wear 1978, 48, 73–86. [Google Scholar] [CrossRef]

- Fang, X.; Li, Y.; Feng, X. Curvature effect on the surface topography evolution during oxidation at small scale. J. Appl. Phys. 2017, 121, 125301. [Google Scholar] [CrossRef]

- Bartkowiak, T.; Lehner, J.T.; Hyde, J.; Wang, Z.; Pedersen, D.B.; Hansen, H.N.; Brown, C.A. Multi-scale areal curvature analysis of fused deposition surfaces. In Proceedings of the ASPE Spring Topical Meeting on Achieving Precision Tolerances in Additive Manufacturing, Raleigh, NC, USA, 26–29 April 2015. [Google Scholar]

- Vulliez, M.; Gleason, M.; Souto-Lebel, A.; Quinsat, Y.; Lartigue, C.; Kordel, S.; Lemoine, A.; Brown, C. Multi-scale Curvature Analysis and Correlations with the Fatigue Limit on Steel Surfaces after Milling. In Proceedings of the 2nd CIRP Conference on Surface Integrity (CSI), Birmingham, UK, 28–30 May 2014; Volume 13, pp. 308–313. [Google Scholar]

- Bartkowiak, T.; Berglund, J.; Brown, C.A. Establishing functional correlations between multiscale areal curvatures and coefficients of friction for machined surfaces. Surf. Topogr. Metrol. Prop. 2018, 6, 034002. [Google Scholar] [CrossRef]

- Bartkowiak, T.; Brown, C. Multi-scale curvature tensor analysis of machined surfaces. Arch. Mech. Technol. Mater. 2016, 36, 44–50. [Google Scholar] [CrossRef] [Green Version]

- Maleki, I.; Wolski, M.; Woloszynski, T.; Podsiadlo, P.; Stachowiak, G. A Comparison of Multiscale Surface Curvature Characterization Methods for Tribological Surfaces. Tribol. Online 2019, 14, 8–17. [Google Scholar] [CrossRef] [Green Version]

- Bigerelle, M.; Nianga, J.M.; Najjar, D.; Iost, A.; Hubert, C.; Kubiak, K.J. Roughness signature of tribological contact calculated by a new method of peaks curvature radius estimation on fractal surfaces. Tribol. Int. 2013, 65, 235–247. [Google Scholar] [CrossRef] [Green Version]

- Malzbender, T.; Gelb, D.; Wolters, H. Polynomial texture maps. In Proceedings of the ACM SIGGRAPH Conference on Computer Graphics and Interactive Techniques, Los Angeles, CA, USA, 12–17 August 2001; pp. 519–528. [Google Scholar]

- Shipulski, E.M.; Brown, C.A. A scale-based model of reflectivity. Fractals 1994, 2, 413–416. [Google Scholar] [CrossRef]

- Everton, S.; Hirsch, M.; Stravroulakis, P.; Leach, R.; Clare, A. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Davaajav, N.; Sukigara, S. Surface Characterization of Cashmere Fabrics Using Optical and Transient Thermal Properties. J. Fash. Technol. Text. Eng. 2018, 6. [Google Scholar] [CrossRef]

- Lindqvist, M.; Evertsson, M.; Chenje, T.; Radziszewski, P. Influence of particle size on wear rate in compressive crushing. Miner. Eng. 2006, 19, 1328–1335. [Google Scholar] [CrossRef]

- Jensen, L.R.D.; Friis, H.; Fundal, E.; Møller, P.; Brockhoff, P.B.; Jespersen, M. Influence of quartz particles on wear in vertical roller mills. Part I: Quartz concentration. Miner. Eng. 2010, 23, 390–398. [Google Scholar] [CrossRef]

- Jensen, L.R.D.; Fundal, E.; Møller, P.; Jespersen, M. Wear mechanism of abrasion resistant wear parts in raw material vertical roller mills. Wear 2011, 271, 2707–2719. [Google Scholar] [CrossRef]

- Lindqvist, M.; Evertsson, C.M. Liner wear in jaw crushers. Miner. Eng. 2003, 16, 1–12. [Google Scholar] [CrossRef]

- Cleary, P.W.; Sinnott, M.D. Simulation of particle flows and breakage in crushers using DEM: Part 1-Compression crushers. Miner. Eng. 2015, 74, 178–197. [Google Scholar] [CrossRef]

- Lindqvist, M.; Evertsson, C.M. Development of wear model for cone crushers. Wear 2006, 261, 435–442. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Jiang, X.; Ye, P. Analysis and study of the crushing mechanism of the MPS vertical roller mill. In Proceedings of the 2nd International Conference on Mechanic Automation and Control, Hohhot, China, 15–17 July 2011; pp. 1029–1032. [Google Scholar]

- Evans, A.G.; Charles, E.A. Fracture Toughness Determinations by Indentation. J. Am. Ceram. Soc. 1976, 59, 371–372. [Google Scholar] [CrossRef]

- Castro, Y.; Pitard, G.; Le Goïc, G.; Brost, V.; Mansouri, A.; Pamart, A.; Vallet, J.-M.; De Luca, L. A new method for calibration of the spatial distribution of light positions in free-form RTI acquisitions. In Optics for Arts, Architecture, and Archaeology VII; International Society for Optics and Photonics: Bellingham, WA, USA, 2019. [Google Scholar]

- Degrigny, C.; Piqué, F.; Papiashvili, N.; Guery, J.; Mansouri, A.; Le Goïc, G.; Detalle, V.; Martos-Levif, D.; Mounier, A.; Wefers, S.; et al. Technical study of Germolles’ wall paintings: The input of imaging techniques. Virtual Archaeol. Rev. 2016, 7, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Pitard, G.; Le Goïc, G.; Mansouri, A.; Favrelière, H.; Desage, S.-F.; Samper, S.; Pillet, M. Discrete Modal Decomposition: A new approach for the reflectance modeling and rendering of real surfaces. Mach. Vis. Appl. 2017, 28, 607–621. [Google Scholar] [CrossRef]

- Pitard, G.; Le Goïc, G.; Mansouri, A.; Favrelière, H.; Pillet, M.; George, S.; Hardeberg, J. Robust Anomaly Detection Using Reflectance Transformation Imaging for Surface Quality Inspection. Image Anal. 2017, 10269, 550–561. [Google Scholar]

- Nurit, M.; Castro, Y.; Zendagui, A.; Le Goïc, G.; Favreliere, H.; Mansouri, A. High dynamic range reflectance transformation imaging: An adaptive multi-light approach for visual surface quality assessment. In Fourteenth International Conference on Quality Control. by Artificial Vision; International Society for Optics and Photonics: Bellingham, WA, USA, 2019. [Google Scholar]

- Le Goïc, G. Qualité Géométrique & Aspect des Surfaces: Approches Locales et Globales. Ph.D. Thesis, Université de Grenoble, Grenoble, French, 2012. [Google Scholar]

- Malzbender, T.; Gelb, D.G. Apparatus for and Method of Enhancing Shape Perception with Parametric Texture Maps; US Patent Office: Alexandria, VA, USA, 2000.

- Gautron, P.; Krivanek, J.; Pattanaik, S.; Bouatouch, K. A Novel Hemispherical Basis for Accurate and Efficient Rendering. Render. Tech. 2004, 321–330. [Google Scholar] [CrossRef]

- Pitard, G.; Le Goïc, G.; Favrelière, H.; Samper, S.; Desage, S.-F.; Pillet, M. Discrete Modal Decomposition for surface appearance modelling and rendering. In Optical Measurement Systems for Industrial Inspection IX; International Society for Optics and Photonics: Bellingham, WA, USA, 2015. [Google Scholar]

- Woodham, R.J. Photometric Method For Determining Surface Orientation From Multiple Images. Opt. Eng. 1980, 19, 139–144. [Google Scholar] [CrossRef]

- MacDonald, L.W. Visualising an Egyptian Artefact in 3D: Comparing RTI with Laser Scanning. In Proceedings of the International Conference on Electronic Visualisation and the Arts (EVA), London, UK, 6–8 July 2011. [Google Scholar]

- Mehlum, E.; Tarrou, C. Invariant smoothness measures for surfaces. Adv. Comput. Math. 1998, 8, 49–63. [Google Scholar] [CrossRef]

- Efron, B.; Tibshirani, R. An Introduction to the Bootstrap. In Chapman Hall/CRC Monographs on Statistics and Applied Probability; CRC: Boca Raton, FL, USA, 1994. [Google Scholar]

- Deltombe, R.; Kubiak, K.J.; Bigerelle, M. How to select the most relevant 3D roughness parameters of a surface: Relevance of 3D roughness parameters. Scanning 2014, 36, 150–160. [Google Scholar] [CrossRef] [Green Version]

- Akono, A.-T.; Ulm, F.-J. Scratch test model for the determination of fracture toughness. Eng. Fract. Mech. 2011, 78, 334–342. [Google Scholar] [CrossRef]

- Gahr, K.-H.Z. Wear by hard particles. Tribol. Int. 1998, 31, 587–596. [Google Scholar] [CrossRef]

- Joshi, P.; Séquin, C. Energy Minimizers for Curvature-Based Surface Functionals. Comput. Aided Des. Appl. 2007, 4, 607–617. [Google Scholar] [CrossRef]

- Griffith, A.A. The Phenomena of Rupture and Flow. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 1921, 221, 163–198. [Google Scholar]

- Francfort, G.A.; Marigo, J.-J. Revisiting brittle fracture as an energy minimization problem. J. Mech. Phys. Solids 1998, 46, 1319–1342. [Google Scholar] [CrossRef]

- Torrance, A.A. Modelling abrasive wear. Wear 2005, 258, 281–293. [Google Scholar] [CrossRef]

| Criteria | Surface Characteristics | Can SGCLR… |

|---|---|---|

| C1 | Different levels loading for the same wear mechanism | Quantify graduated morphological differences ? |

| C2 | Multiscale topographical structure (fractal) | Detect different topographical scales ? |

| C3 | Different wear mechanisms, abrasion versus spalling | Detect and quantify elementary physical mechanisms that are sources of gradients ? |

| C4 | Composite with two materials with different topographies (metal matrix and ceramic) | Segment surfaces for determining morphological indicators discriminating zones ? |

| C5 | Different surface colors | Be invariant with respect to colors ? |

| Surfaces | 2a (µm) | c (µm) | Hv (MPa) | KIc (MPa√m) |

|---|---|---|---|---|

| 1 | 78.9 | 88.6 | 1489 | 0.4565 |

| 2 | 77.8 | 83.2 | 1532 | 0.5029 |

| 3 | 82.0 | 67.5 | 1378 | 0.6817 |

| 4 | 84.9 | 68.2 | 1288 | 0.6829 |

| 5 | 84.1 | 76.9 | 1310 | 0.5526 |

| 6 | 82.7 | 76.5 | 1356 | 0.5566 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lemesle, J.; Robache, F.; Le Goic, G.; Mansouri, A.; Brown, C.A.; Bigerelle, M. Surface Reflectance: An Optical Method for Multiscale Curvature Characterization of Wear on Ceramic–Metal Composites. Materials 2020, 13, 1024. https://doi.org/10.3390/ma13051024

Lemesle J, Robache F, Le Goic G, Mansouri A, Brown CA, Bigerelle M. Surface Reflectance: An Optical Method for Multiscale Curvature Characterization of Wear on Ceramic–Metal Composites. Materials. 2020; 13(5):1024. https://doi.org/10.3390/ma13051024

Chicago/Turabian StyleLemesle, Julie, Frederic Robache, Gaetan Le Goic, Alamin Mansouri, Christopher A. Brown, and Maxence Bigerelle. 2020. "Surface Reflectance: An Optical Method for Multiscale Curvature Characterization of Wear on Ceramic–Metal Composites" Materials 13, no. 5: 1024. https://doi.org/10.3390/ma13051024

APA StyleLemesle, J., Robache, F., Le Goic, G., Mansouri, A., Brown, C. A., & Bigerelle, M. (2020). Surface Reflectance: An Optical Method for Multiscale Curvature Characterization of Wear on Ceramic–Metal Composites. Materials, 13(5), 1024. https://doi.org/10.3390/ma13051024