Effect of Elevated Temperature on Compressive Strength and Physical Properties of Neem Seed Husk Ash Concrete

Abstract

:1. Introduction

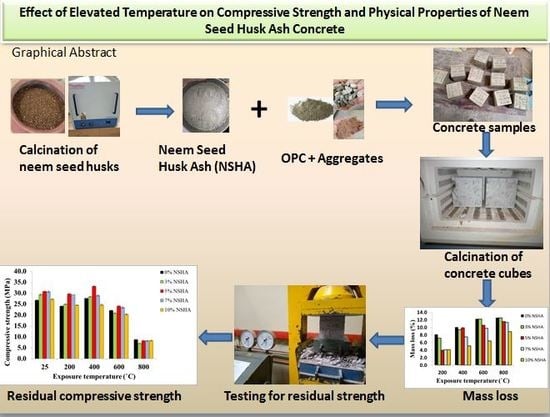

2. Materials and Methods

2.1. Materials

2.1.1. Binder

2.1.2. Aggregates

2.1.3. Water

2.2. Mix Proportioning

2.3. Specimen Preparation

2.4. Heating and Cooling Regimes

2.5. Testing Program

3. Results and Discussion

3.1. Characterization of NSHA

3.2. Physical Characteristics with Temperature Rise

3.3. Spalling and Mass Loss

3.4. Residual Compressive Strength

4. Conclusions

- For all concrete samples exposed up to 400 °C, there was no noticeable consequence on the surface. Significant fractures and localized spalling were noticed when the exposure temperature rose to 600 °C, and they were more pronounced at 800 °C. The color change was insignificant for all series of OPC and blended concrete considered.

- Specimens exposed to greater than 400 °C suffered spalling and mass loss. In previous findings by Bastami et al. [41], spalling was witnessed for specimens subjected to temperatures more than 300 °C. The spalling varied from slight aggregate spalling (characterized by surface pitting) to significant apportions of specimens being blown off with explosive force.

- The compressive strength of specimens fell notably for both normal concrete and NSHA blended concrete samples when exposed to the temperature exceeding 400 °C. The drop in compressive strength of about 60% and 69% was observed at 800 °C for the 7 and 28 days cured specimens, respectively.

- Grounded in the investigated strength and physical properties of NSHA concrete, it is evident that 5% NSHA concrete performed better than control concrete for all mixtures for temperatures up to 400 °C. This implies that the reaction of pozzolans with portlandite is favored between 100 °C and 400 °C, resulting in a considerable decrease of Ca(OH)2 content. Therefore, NSHA is worth being recommended as a pozzolanic material for structural applications in concrete structures, of which they will still perform at high temperatures up to 400 °C.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Parthasarathi, N.; Saraf, D.S.; Prakash, M.; Satyanarayanan, K.S. Analytical and Experimental study of the reinforced concrete specimen under elevated temperature. Mater. Today Proc. 2019, 14, 195–201. [Google Scholar] [CrossRef]

- Naqi, A.; Jang, J.G. Recent progress in green cement technology utilizing low-carbon emission fuels and raw materials: A review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef] [Green Version]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Khaliq, W.; Mujeeb, A. Effect of processed pozzolans on residual mechanical properties and macrostructure of high-strength concrete at elevated temperatures. Struct. Concr. 2019, 20, 307–317. [Google Scholar] [CrossRef] [Green Version]

- Ismail, M.; Ismail, M.E.; Muhammad, B. Influence of elevated temperatures on physical and compressive strength properties of concrete containing palm oil fuel ash. Constr. Build. Mater. 2011, 25, 2358–2364. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice husk ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Haloob, M.K. Effects of Exposure to Elevated Temperatures on Properties of Concrete Containing Rice Husk Ash. Ph.D. Thesis, Universiti Sains Malaysia, Penang, Malaysia, 2011. [Google Scholar]

- Mboya, H.A.; King’ondu, C.K.; Njau, K.N.; Mrema, A.L. Measurement of pozzolanic activity index of scoria, pumice, and rice husk ash as potential supplementary cementitious materials for Portland cement. Adv. Civ. Eng. 2017, 2017, 13. [Google Scholar] [CrossRef]

- Awal, A.A.; Shehu, I. Performance evaluation of concrete containing high volume palm oil fuel ash exposed to elevated temperature. Constr. Build. Mater. 2015, 76, 214–220. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Saeting, T.; Jaturapitakkul, C.; Kiattikomol, K.; Siripanichgorn, A. Use of waste ash from palm oil industry in concrete. Waste Manag. 2007, 27, 81–88. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Kanraj, D.; Dev, V.G.; Santhanam, M. Performance evaluation of sugarcane bagasse ash blended cement in concrete. Cem. Concr. Compos. 2015, 59, 77–88. [Google Scholar] [CrossRef]

- Gar, P.S.; Suresh, N.; Bindiganavile, V. Sugar cane bagasse ash as a pozzolanic admixture in concrete for resistance to sustained elevated temperatures. Constr. Build. Mater. 2017, 153, 929–936. [Google Scholar]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes—A review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Ali, M.H.; Mashud, M.; Rubel, M.R.; Ahmad, R.H. Biodiesel from Neem oil as an alternative fuel for Diesel engine. Procedia Eng. 2013, 56, 625–630. [Google Scholar] [CrossRef] [Green Version]

- Raheem, A.A.; Ibiwoye, E.O. A Study of Neem Seed Husk Ash as Partial Replacement for Cement in Concrete. Int. J. Sustain. Constr. Eng. Technol. 2018, 9, 55–65. [Google Scholar] [CrossRef] [Green Version]

- Ibiwoye, E.; Naalla, A. Effect of Neem Seed Husk Ash on the Workability of Concrete. TETFUND Spons. Kwara State Polytech. J. Res. Dev. Stud. 2017, 1, 11. [Google Scholar]

- Musa, N.M. Thermal analysis of cement paste partially replaced with Neem Seed Husk Ash. Int. J. Sci. Eng. Res. 2014, 5, 1101–1105. [Google Scholar]

- Musa, N.M.; Ejeh, S.P. Synergic effect of neem seed husk ash on strength properties of cement-sand mortar. Int. J. Eng. Res. Appl. 2012, 2, 27–30. [Google Scholar]

- Savva, A.; Manita, P.; Sideris, K. Influence of elevated temperatures on the mechanical properties of blended cement concretes prepared with limestone and siliceous aggregates. Cem. Concr. Compos. 2005, 27, 239–248. [Google Scholar] [CrossRef]

- Khoury, G. Compressive strength of concrete at high temperatures: A reassessment. Mag. Concr. Res. 1992, 44, 291–309. [Google Scholar] [CrossRef]

- Owaid, H.M.; Hamid, R.; Taha, M.R. Elevated Temperature Performance of Multiple-Blended Binder Concretes. High Perform. Concr. Technol. Appl. 2016, 9, 87. [Google Scholar]

- Wang, W.; Meng, Y.; Wang, D. Effect of Rice Husk Ash on High-Temperature Mechanical Properties and Microstructure of Concrete. Kemija U Industriji: Časopis Kemičara I Kemijskih Inženjera Hrvatske 2017, 66, 157–164. [Google Scholar] [CrossRef]

- Umasabor, R.; Okovido, J. Fire resistance evaluation of rice husk ash concrete. Heliyon 2018, 4, e01035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ishak, S.; Lee, H.S.; Singh, J.K.; Ariffin, M.A.M.; Lim, N.H.A.S.; Yang, H.M. Performance of Fly Ash Geopolymer Concrete Incorporating Bamboo Ash at Elevated Temperature. Materials 2019, 12, 3404. [Google Scholar] [CrossRef] [Green Version]

- Altwair, N.; Johari, M.A.M.; Hashim, S.F.S. Influence of calcination temperature on characteristics and pozzolanic activity of palm oil waste ash. Aust. J. Basic Appl. Sci. 2011, 5, 1010–1018. [Google Scholar]

- Butler, W.B.; Kanare, H.M. Testing Fly Ash for Fineness to ASTM C 430: Sieve Calibration. MRS Online Proc. Libr. Arch. 1988, 136, 107. [Google Scholar] [CrossRef]

- BSI. BS EN 933-1. Tests for Geometrical Properties of Aggregates, in Determination of Particle Size Distribution; Sieving Method; British Standards Institution: London, UK, 2012. [Google Scholar]

- ASTM. ASTM C127-01: Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- ASTM. A Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- BSI. Methods for Mixing and Sampling Fresh Concrete in the Laboratory, BS 1881: Part 125; British Standards Institution: London, UK, 1986. [Google Scholar]

- Chen, B.; Li, C.; Chen, L. Experimental study of mechanical properties of normal-strength concrete exposed to high temperatures at an early age. Fire Saf. J. 2009, 44, 997–1002. [Google Scholar] [CrossRef]

- BSI. Testing Hardened Concrete: Compressive Strength of Test Specimens; BSI: London, UK, 2009. [Google Scholar]

- ASTM. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Janotka, I.; Nürnbergerová, T. Effect of temperature on structural quality of the cement paste and high-strength concrete with silica fume. Nucl. Eng. Des. 2005, 235, 2019–2032. [Google Scholar] [CrossRef]

- Ramesh, K.; Raju, M.D.; Rekha, K. A Study on High Volume Fly Ash Concrete Exposed To Elevated Temperatures. Am. J. Eng. Res. 2016, 5, 227–238. [Google Scholar]

- Fares, H.; Noumowe, A.; Remond, S. Self-consolidating concrete subjected to high temperature: Mechanical and physicochemical properties. Cem. Concr. Res. 2009, 39, 1230–1238. [Google Scholar] [CrossRef]

- Aslani, F.; Bastami, M. Constitutive relationships for normal-and high-strength concrete at elevated temperatures. ACI Mater. J. 2011, 108, 355–364. [Google Scholar]

- Morsy, M.; Alsayed, S.; Aqel, M. Effect of elevated temperature on mechanical properties and microstructure of silica flour concrete. Int. J. Civ. Environ. Eng. 2010, 10, 1–6. [Google Scholar]

- Xu, Y.; Wong, Y.L.; Poon, C.S.; Anson, M. Impact of high temperature on PFA concrete. Cem. Concr. Res. 2001, 31, 1065–1073. [Google Scholar] [CrossRef]

- Ibrahim, R.K.; Ramyar, K.; Hamid, R.; Taha, M.R. The effect of high temperature on mortars containing silica fume. J. Appl. Sci. 2011, 11, 2666–2669. [Google Scholar] [CrossRef]

- Bastami, M.; Baghbadrani, M.; Aslani, F. Performance of nano-Silica modified high strength concrete at elevated temperatures. Constr. Build. Mater. 2014, 68, 402–408. [Google Scholar] [CrossRef]

| Properties | Coarse Aggregates | Fine Aggregates |

|---|---|---|

| Water absorption (%) | 1.65 | 1.89 |

| Specific gravity | 3.12 | 2.77 |

| Bulk density (kg/m3) | 1465 | 1590 |

| Moisture content (%) | 3.48 | 4.99 |

| Components (kg/m3) | Percent of OPC Replacement (wt%) | ||||

|---|---|---|---|---|---|

| 0 | 3 | 5 | 7 | 10 | |

| Cement | 410 | 397.7 | 389.5 | 381.3 | 369 |

| NSHA | 0 | 12.3 | 20.5 | 28.7 | 41 |

| Sand | 530 | 530 | 530 | 530 | 530 |

| Aggregates | 1260 | 1260 | 1260 | 1260 | 1260 |

| Water | 205 | 205 | 205 | 205 | 205 |

| Chemical Properties | Cement (%) | NSHA (%) |

|---|---|---|

| SiO2 | 17.4 | 45.2 |

| CaO | 57.4 | 2.6 |

| Al2O3 | 4.9 | 22.6 |

| Fe2O3 | 3.0 | 3.4 |

| MgO | 0.5 | 3.3 |

| SO3 | 2.7 | 0.8 |

| Loss on Ignition | 9.9 | 5.6 |

| Blaine-specific surface area (m2/kg) | 431 | 544 |

| Initial setting time (minutes) | 147 | – |

| Compressive strength 28 days (MPa) | 46 | – |

| Water absorption (%) | – | 1.5 |

| Mix | 200 °C | 400 °C | 600 °C | 800 °C |

|---|---|---|---|---|

| 0% NSHA |  |  |  |  |

| 3% NSHA |  |  |  |  |

| 5% NSHA |  |  |  |  |

| 7% NSHA |  |  |  |  |

| 10% NSHA |  |  |  |  |

| Exposure Temperature (°C) | Compressive Strength (MPa) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0% NSHA | 3% NSHA | 5% NSHA | 7% NSHA | 10% NSHA | ||||||

| 7 Days | 28 Days | 7 Days | 28 Days | 7 Days | 28 Days | 7 Days | 28 Days | 7 Days | 28 Days | |

| 25 | 19.7 | 26.8 | 20.9 | 29.4 | 24.3 | 30.8 | 20.0 | 30.7 | 20.0 | 27.3 |

| 200 | 19.1 | 24.1 | 24.4 | 25.0 | 26.8 | 29.3 | 24.5 | 29.3 | 23.1 | 24.5 |

| 400 | 23.2 | 27.7 | 24.0 | 28.4 | 30.1 | 33.2 | 25.8 | 29.0 | 24.0 | 24.7 |

| 600 | 9.7 | 22.1 | 15.7 | 20.9 | 20.4 | 24.1 | 17.0 | 23.5 | 15.0 | 20.3 |

| 800 | 7.3 | 8.7 | 8.1 | 7.0 | 7.9 | 8.2 | 6.7 | 8.1 | 9.0 | 8.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mwilongo, K.P.; Machunda, R.L.; Jande, Y.A.C. Effect of Elevated Temperature on Compressive Strength and Physical Properties of Neem Seed Husk Ash Concrete. Materials 2020, 13, 1198. https://doi.org/10.3390/ma13051198

Mwilongo KP, Machunda RL, Jande YAC. Effect of Elevated Temperature on Compressive Strength and Physical Properties of Neem Seed Husk Ash Concrete. Materials. 2020; 13(5):1198. https://doi.org/10.3390/ma13051198

Chicago/Turabian StyleMwilongo, Kizito Patrick, Revocatus Lazaro Machunda, and Yusufu Abeid Chande Jande. 2020. "Effect of Elevated Temperature on Compressive Strength and Physical Properties of Neem Seed Husk Ash Concrete" Materials 13, no. 5: 1198. https://doi.org/10.3390/ma13051198

APA StyleMwilongo, K. P., Machunda, R. L., & Jande, Y. A. C. (2020). Effect of Elevated Temperature on Compressive Strength and Physical Properties of Neem Seed Husk Ash Concrete. Materials, 13(5), 1198. https://doi.org/10.3390/ma13051198