Preparation, Characterization, and In Vitro Evaluation of Resveratrol-Loaded Cellulose Aerogel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

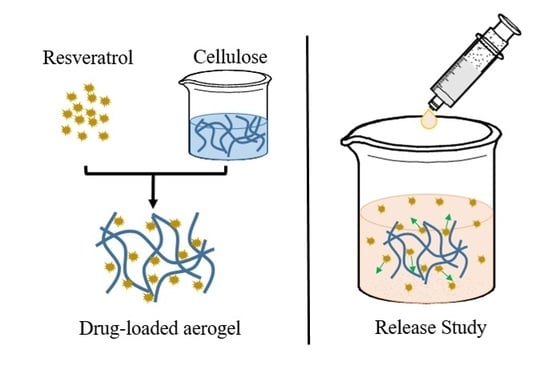

2.2. Preparations of TC Aerogels Loaded with Res

2.3. Freeze-Drying of RLTAs and Res

2.4. Characterizations

2.5. In Vitro Drug Release of RLTAs

2.6. In Vitro Cytotoxicity of RLTAs

3. Results and Discussion

3.1. Synthesis and Morphology of RLTAs

3.2. The Microstructure of TC Aerogel, Res, and RLTAs

3.3. The Pore Size Distribution of TC Aerogel, Res, and RLTA

3.4. The FTIR Spectra of the TC Aerogel, Res and RLTAs

3.5. The 13C NMR Spectra of the TC Aerogel, Res, and RLTAs

3.6. The XRD Spectra of the TC Aerogel, Res, and RLTAs

3.7. In Vitro Drug Release of RLTAs

3.8. Mechanism of Release

3.9. In Vitro Cytotoxicity of RLTAs

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Du, A.; Zhou, B.; Zhang, Z.; Shen, J. A Special Material or a New State of Matter: A Review and Reconsideration of the Aerogel. Materials 2013, 6, 941–968. [Google Scholar] [CrossRef] [Green Version]

- Fricke, J. Aerogels — Highly tenuous solids with fascinating properties. J. Non-Cryst. Solids 1988, 100, 169–173. [Google Scholar] [CrossRef]

- Fricke, J.; Emmerling, A. Aerogels—Recent Progress in Production Techniques and Novel Applications. J. Sol-Gel Sci. Technol. 1998, 13, 299–303. [Google Scholar] [CrossRef]

- Pierre, A.C.; Pajonk, G.M. Chemistry of Aerogels and Their Applications. Chem. Rev. 2002, 102, 4243–4266. [Google Scholar] [CrossRef] [PubMed]

- Kistler, S.S. Coherent Expanded-Aerogels. J. Phys. Chem. 1932, 36, 52–64. [Google Scholar] [CrossRef]

- Kistler, S.S. Coherent Expanded Aerogels and Jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Hüsing, N.; Schubert, U. Aerogels airy materials: Chemistry, structure, and properties. Angew. Chem. Int. Ed. 1998, 37, 23–45. [Google Scholar] [CrossRef]

- Du, A.; Wang, H.; Zhou, B.; Zhang, C.; Wu, X.; Ge, Y.; Niu, T.; Ji, X.; Zhang, T.; Zhang, Z.; et al. Multifunctional Silica Nanotube Aerogels Inspired by Polar Bear Hair for Light Management and Thermal Insulation. Chem. Mater. 2018, 30, 6849–6857. [Google Scholar] [CrossRef]

- Wang, Y.; Kao, Z.; Zhang, T.; Zhang, Y.; Qin, L.; Zhang, Z.; Zhou, B.; Wu, G.; Shen, J.; Du, A. Diffusion of Resveratrol in Silica Alcogels. Molecules 2019, 24, 3931. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Wang, H.; Zhou, B.; Ji, X.; Wang, H.; Du, A. One-dimension diffusion preparation of concentration-gradient Fe2O3/SiO2 aerogel. Molecules 2018, 23, 1502. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Guo, H.; Lei, C.; Liu, L.; Xu, L.; Feng, Y.; Ke, J.; Fang, W.; Song, H.; Xu, C.; et al. Nanotherapy in Joints: Increasing Endogenous Hyaluronan Production by Delivering Hyaluronan Synthase 2. Adv. Mater. 2019, 31, e1904535. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, Y.; Liu, Q.; Yang, L.; Zhu, R.; Yu, C.; Wang, S. Rational Design of Multifunctional Dendritic Mesoporous Silica Nanoparticles to Load Curcumin and Enhance Efficacy for Breast Cancer Therapy. ACS Appl. Mater. Interfaces 2016, 8, 26511–26523. [Google Scholar] [CrossRef] [PubMed]

- Rinaudo, M. Main properties and current applications of some polysaccharides as biomaterials. Polym. Int. 2008, 57, 397–430. [Google Scholar] [CrossRef]

- Cai, J.; Kimura, S.; Wada, M.; Kuga, S. Nanoporous Cellulose as Metal Nanoparticles Support. Biomacromolecules 2009, 10, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.-C.; Yu, H.; Fan, X.; Gu, J.; Ye, S.; Yao, J.; Ni, Q.-Q. High Aspect Ratio Carboxylated Cellulose Nanofibers Cross-linked to Robust Aerogels for Superabsorption–Flocculants: Paving Way from Nanoscale to Macroscale. ACS Appl. Mater. Interfaces 2018, 10, 20755–20766. [Google Scholar] [CrossRef] [PubMed]

- Jiang, F.; Hsieh, Y.-L. Amphiphilic superabsorbent cellulose nanofibril aerogels. J. Mater. Chem. A 2014, 2, 6337–6342. [Google Scholar] [CrossRef] [Green Version]

- Mogoșanu, G.D.; Grumezescu, A.M. Natural and synthetic polymers for wounds and burns dressing. Int. J. Pharm. 2014, 463, 127–136. [Google Scholar] [CrossRef]

- Zaborowska, M.; Bodin, A.; Bäckdahl, H.; Popp, J.; Goldstein, A.; Gatenholm, P. Microporous bacterial cellulose as a potential scaffold for bone regeneration. Acta Biomater. 2010, 6, 2540–2547. [Google Scholar] [CrossRef] [PubMed]

- Martínez, H.; Brackmann, C.; Enejder, A.; Gatenholm, P. Mechanical stimulation of fibroblasts in micro-channeled bacterial cellulose scaffolds enhances production of oriented collagen fibers. J. Biomed. Mater. Res. Part A 2012, 100, 948–957. [Google Scholar] [CrossRef]

- Shi, Z.; Gao, H.; Feng, J.; Ding, B.; Cao, X.; Kuga, S.; Wang, Y.; Zhang, L.; Cai, J. In Situ Synthesis of Robust Conductive Cellulose/Polypyrrole Composite Aerogels and Their Potential Application in Nerve Regeneration. Angew. Chem. Int. Ed. 2014, 53, 5380–5384. [Google Scholar] [CrossRef]

- Ulker, Z.; Erkey, C. An emerging platform for drug delivery: Aerogel based systems. J. Control. Release 2014, 177, 51–63. [Google Scholar] [CrossRef]

- Huang, L.; Chen, X.; Nguyen, T.X.; Tang, H.; Zhang, L.; Yang, G. Nano-cellulose 3D-networks as controlled-release drug carriers. J. Mater. Chem. B 2013, 1, 2976. [Google Scholar] [CrossRef]

- Valo, H.K.; Kovalainen, M.; Laaksonen, P.; Häkkinen, M.; Auriola, S.; Peltonen, L.; Linder, M.; Järvinen, K.; Hirvonen, J.T.; Laaksonen, T. Immobilization of protein-coated drug nanoparticles in nanofibrillar cellulose matrices—Enhanced stability and release. J. Control. Release 2011, 156, 390–397. [Google Scholar] [CrossRef] [PubMed]

- Baur, J.; Sinclair, D.A. Therapeutic potential of resveratrol: The in vivo evidence. Nat. Rev. Drug Discovery 2006, 5, 493–506. [Google Scholar] [CrossRef]

- Frozza, R.L.; Bernardi, A.; Paese, K.; Hoppe, J.B.; Da Silva, T.; Battastini, A.M.O.; Pohlmann, A.R.; Guterres, S.S.; Salbego, C. Characterization of trans-resveratrol-loaded lipid-core nanocapsules and tissue distribution studies in rats. J. Biomed. Nanotechnol. 2010, 6, 694–703. [Google Scholar] [CrossRef] [PubMed]

- Wegiel, L.A.; Mauer, L.J.; Edgar, K.J.; Taylor, L.S. Crystallization of Amorphous Solid Dispersions of Resveratrol during Preparation and Storage—Impact of Different Polymers. J. Pharm. Sci. 2013, 102, 171–184. [Google Scholar] [CrossRef] [PubMed]

- Valo, H.K.; Arola, S.; Laaksonen, P.; Torkkeli, M.; Peltonen, L.; Linder, M.B.; Serimaa, R.; Kuga, S.; Hirvonen, J.T.; Laaksonen, T. Drug release from nanoparticles embedded in four different nanofibrillar cellulose aerogels. Eur. J. Pharm. Sci. 2013, 50, 69–77. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Domszy, R.C.; Hu, N.; Yang, A.J.; Yang, J.; David, A.E. Synthesis of silica–alginate nanoparticles and their potential application as pH-responsive drug carriers. J. Sol.-Gel Sci. Technol. 2019, 91, 11–20. [Google Scholar] [CrossRef]

- Cai, J.; Kimura, S.; Wada, M.; Kuga, S.; Zhang, L. Cellulose Aerogels from Aqueous Alkali Hydroxide–Urea Solution. ChemSusChem 2008, 1, 149–154. [Google Scholar] [CrossRef]

- Isogai, A.; Saito, T.; Fukuzumi, H. TEMPO-oxidized cellulose nanofibers. Nanoscale 2011, 3, 71–85. [Google Scholar] [CrossRef]

- Mulyadi, A.; Zhang, Z.; Deng, Y. Fluorine-Free Oil Absorbents Made from Cellulose Nanofibril Aerogels. ACS Appl. Mater. Interfaces 2016, 8, 2732–2740. [Google Scholar] [CrossRef] [PubMed]

- Saito, T.; Kimura, S.; Nishiyama, Y.; Isogai, A. Cellulose Nanofibers Prepared by TEMPO-Mediated Oxidation of Native Cellulose. Biomacromolecules 2007, 8, 2485–2491. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Feng, J.; Feng, J.; Jiang, Y.; Ding, F. Carbon aerogels by pyrolysis of TEMPO-oxidized cellulose. Appl. Surf. Sci. 2018, 440, 873–879. [Google Scholar] [CrossRef]

- Kruk, M.; Jaroniec, M. Gas Adsorption Characterization of Ordered Organic−Inorganic Nanocomposite Materials. Chem. Mater. 2001, 13, 3169–3183. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Abell, A.; Willis, K.; Lange, D. Mercury Intrusion Porosimetry and Image Analysis of Cement-Based Materials. J. Colloid Interface Sci. 1999, 211, 39–44. [Google Scholar] [CrossRef]

- Meng, Y.; Young, T.M.; Liu, P.; Contescu, C.; Huang, B.; Wang, S. Ultralight carbon aerogel from nanocellulose as a highly selective oil absorption material. Cellulose 2014, 22, 435–447. [Google Scholar] [CrossRef]

- Haniffa, M.A.C.M.; Ching, Y.C.; Chuah, C.H.; Ching, K.Y.; Nazri, N.; Abdullah, L.C.; Nai-Shang, L.; Kuan, Y.C. Effect of TEMPO-oxidization and rapid cooling on thermo-structural properties of nanocellulose. Carbohydr. Polym. 2017, 173, 91–99. [Google Scholar] [CrossRef]

- Wang, M.; Shao, C.; Zhou, S.; Yang, J.; Xu, F. Preparation of carbon aerogels from TEMPO-oxidized cellulose nanofibers for organic solvents absorption. RSC Adv. 2017, 7, 38220–38230. [Google Scholar] [CrossRef] [Green Version]

- Bourassa, P.; Kanakis, C.D.; Tarantilis, P.; Pollissiou, M.G.; Tajmir-Riahi, H.A. Resveratrol, Genistein, and Curcumin Bind Bovine Serum Albumin†. J. Phys. Chem. B 2010, 114, 3348–3354. [Google Scholar] [CrossRef]

- Li, B.; Wegiel, L.A.; Taylor, L.S.; Edgar, K.J. Stability and solution concentration enhancement of resveratrol by solid dispersion in cellulose derivative matrices. Cellulose 2013, 20, 1249–1260. [Google Scholar] [CrossRef]

- Commodari, F.; Khiat, A.; Ibrahimi, S.; Brizius, A.R.; Kalkstein, N. Comparison of the phytoestrogentrans-resveratrol (3,4′,5-trihydroxystilbene) structures from x-ray diffraction and solution NMR. Magn. Reson. Chem. 2005, 43, 567–572. [Google Scholar] [CrossRef] [PubMed]

- Bates, S.; Zografi, G.; Engers, D.; Morris, K.; Crowley, K.; Newman, A.W. Analysis of Amorphous and Nanocrystalline Solids from Their X-Ray Diffraction Patterns. Pharm. Res. 2006, 23, 2333–2349. [Google Scholar] [CrossRef] [PubMed]

- Ansari, K.A.; Vavia, P.R.; Trotta, F.; Cavalli, R. Cyclodextrin-Based Nanosponges for Delivery of Resveratrol: In Vitro Characterisation, Stability, Cytotoxicity and Permeation Study. AAPS PharmSciTech 2011, 12, 279–286. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zupančič, Š.; Lavrič, Z.; Kristl, J. Stability and solubility of trans-resveratrol are strongly influenced by pH and temperature. Eur. J. Pharm. Biopharm. 2015, 93, 196–204. [Google Scholar] [CrossRef]

- Dokoumetzidis, A.; Papadopoulou, V.; Macheras, P. Analysis of Dissolution Data Using Modified Versions of Noyes–Whitney Equation and the Weibull Function. Pharm. Res. 2006, 23, 256–261. [Google Scholar]

- Dubernet, C.; Benoît, J.P.; Peppas, N.A.; Puisieux, F. Ibuprofen-loaded ethylcellulose microspheres: Release studies and analysis of the matrix structure through the Higuchi model. J. Microencapsul. 1990, 7, 555–565. [Google Scholar] [CrossRef]

- Khanafer, K.; Vafai, K. The role of porous media in biomedical engineering as related to magnetic resonance imaging and drug delivery. Heat Mass Transf. 2006, 42, 939–953. [Google Scholar] [CrossRef]

- Ritger, P.L.; Peppas, N.A. A simple equation for description of solute release I. Fickian and non-fickian release from non-swellable devices in the form of slabs, spheres, cylinders or discs. J. Control. Release 1987, 5, 23–36. [Google Scholar] [CrossRef]

- Mosmann, T. Rapid colorimetric assay for cellular growth and survival: Application to proliferation and cytotoxicity assays. J. Immunol. Methods 1983, 65, 55–63. [Google Scholar] [CrossRef]

| R | ||||

|---|---|---|---|---|

| Sample | PH Value | Zero-Order | First-Order | Higuchi |

| Res | 7.4 | 0.836 | 0.989 | 0.905 |

| 1.5 | 0.892 | 0.971 | 0.969 | |

| R:T = 1:2 | 7.4 | 0.779 | 0.805 | 0.857 |

| 1.5 | 0.888 | 0.963 | 0.978 | |

| R:T = 2:3 | 7.4 | 0.789 | 0.798 | 0.841 |

| 1.5 | 0.886 | 0.985 | 0.962 | |

| R:T = 3:2 | 7.4 | 0.845 | 0.923 | 0.954 |

| 1.5 | 0.841 | 0.997 | 0.907 | |

| R:T = 2:1 | 7.4 | 0.792 | 0.891 | 0.836 |

| 1.5 | 0.86 | 0.939 | 0.976 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, L.; Zhao, X.; He, Y.; Wang, H.; Wei, H.; Zhu, Q.; Zhang, T.; Qin, Y.; Du, A. Preparation, Characterization, and In Vitro Evaluation of Resveratrol-Loaded Cellulose Aerogel. Materials 2020, 13, 1624. https://doi.org/10.3390/ma13071624

Qin L, Zhao X, He Y, Wang H, Wei H, Zhu Q, Zhang T, Qin Y, Du A. Preparation, Characterization, and In Vitro Evaluation of Resveratrol-Loaded Cellulose Aerogel. Materials. 2020; 13(7):1624. https://doi.org/10.3390/ma13071624

Chicago/Turabian StyleQin, Lili, Xinyu Zhao, Yiwei He, Hongqiang Wang, Hanjing Wei, Qiong Zhu, Ting Zhang, Yao Qin, and Ai Du. 2020. "Preparation, Characterization, and In Vitro Evaluation of Resveratrol-Loaded Cellulose Aerogel" Materials 13, no. 7: 1624. https://doi.org/10.3390/ma13071624

APA StyleQin, L., Zhao, X., He, Y., Wang, H., Wei, H., Zhu, Q., Zhang, T., Qin, Y., & Du, A. (2020). Preparation, Characterization, and In Vitro Evaluation of Resveratrol-Loaded Cellulose Aerogel. Materials, 13(7), 1624. https://doi.org/10.3390/ma13071624