Simulation of the Light Transmittance in Macroporous Silica

Abstract

:1. Introduction

2. Generation of Porous Silica Models

- -

- A certain amount of seeding points are created first, corresponding to the cells of the final structure. A Random Sequential Absorption Algorithm [33] is imposed to make the equal-sized spheres (centred at the created seeding points) distributed in the given space without overlapping for the random structures.

- -

- The space is partitioned into polyhedral regions with the seeding points by Voronoi diagram [34].

- -

- The resulting structure is optimized by Surface Evolver [35] for energy stability.

- -

- Polygonal struts are created with the final skeleton.

- (1)

- Porosity, p, indicates the proportion of the gas phase. In this paper, the porosities of models are limited in the range , corresponding to the products prepared by sol-gel method in experiments.

- (2)

- Coefficient of variation, , figures the dispersion of cell size distribution of random structures, where and are the standard deviation of cell diameter and the average equivalent cell diameter respectively. In this paper, the Gaussian unimodal distribution with different standard deviations is used for different cell size distributions.

- (3)

- Diameter ratio, , represents the ratio of the cross section diameter between the middle and the end of a strut, where and are the minimum and maximum diameter. Table 1 shows the illustration of the struts with different diameter ratios.

- (4)

- Normalized curvature, , governs the shape of the cross section of a strut, where stands for the curvature radius of the circumcircle of the cross section and is the curvature radius of the sides of the cross section. Table 2 exhibits the illustration of the cross sections with different normalized curvatures.

3. Numerical Simulation

3.1. Mesh Sensitivity

3.2. Boundary Value Problem

4. Results and Discussion

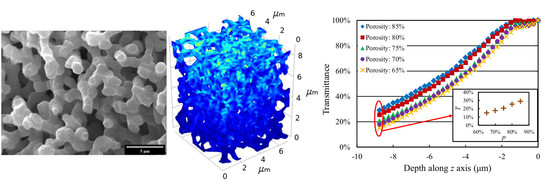

4.1. Analysis of Light Propagation

4.2. Influences of the Morphological Parameters

4.2.1. Porosity p

4.2.2. Coefficient of Variation

4.2.3. Diameter Ratio t

4.2.4. Normalized Curvature k

4.3. Influence of the Wavelength

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Baillis, D.; Coquard, R. Radiative and Conductive Thermal Properties of Foams. In Cellular and Porous Materials: Thermal Properties Simulation and Prediction; Wiley-VCH Verlag GmbH & Co. KGaA: Hoboken, NJ, USA, 2008; pp. 343–384. [Google Scholar]

- Kaemmerlen, A.; Vo, C.; Asllanaj, F.; Jeandel, G.; Baillis, D. Radiative properties of extruded polystyrene foams: Predictive model and experimental results. J. Quant. Spectrosc. Radiat. Transf. 2010, 111, 865–877. [Google Scholar] [CrossRef]

- Iluk, A. Global stability of an aluminum foam stand-alone energy absorber. Arch. Civ. Mech. Eng. 2013, 13, 137–143. [Google Scholar] [CrossRef]

- Jung, A.; Beex, L.; Diebels, S.; Bordas, S. Open-cell aluminium foams with graded coatings as passively controllable energy absorbers. Mater. Des. 2015, 87, 36–41. [Google Scholar] [CrossRef] [Green Version]

- Fischer, S.F. Energy absorption efficiency of open-cell pure aluminum foams. Mater. Lett. 2016, 184, 208–210. [Google Scholar] [CrossRef]

- Yin, S.; Rayess, N. Characterization of Polymer-metal Foam Hybrids for Use in Vibration Dampening and Isolation. Procedia Mater. Sci. 2014, 4, 311–316. [Google Scholar] [CrossRef] [Green Version]

- Coquard, R.; Baillis, D.; Randrianalisoa, J. Homogeneous phase and multi-phase approaches for modeling radiative transfer in foams. Int. J. Therm. Sci. 2011, 50, 1648–1663. [Google Scholar] [CrossRef]

- Coquard, R.; Rousseau, B.; Echegut, P.; Baillis, D.; Gomart, H.; Iacona, E. Investigations of the radiative properties of Al-NiP foams using tomographic images and stereoscopic micrographs. Int. J. Heat Mass Transf. 2012, 55, 1606–1619. [Google Scholar] [CrossRef]

- Cunsolo, S.; Coquard, R.; Baillis, D.; Bianco, N. Radiative properties modeling of open cell solid foam: Review and new analytical law. Int. J. Therm. Sci. 2016, 104, 122–134. [Google Scholar] [CrossRef]

- Cunsolo, S.; Coquard, R.; Baillis, D.; Chiu, W.K.; Bianco, N. Radiative properties of irregular open cell solid foams. Int. J. Therm. Sci. 2017, 117, 77–89. [Google Scholar] [CrossRef] [Green Version]

- Baillis, D.; Coquard, R.; Cunsolo, S. Effective conductivity of Voronoi’s closed- and open-cell foams: analytical laws and numerical results. J. Mater. Sci. 2017, 52, 11146–11167. [Google Scholar] [CrossRef]

- Cunsolo, S.; Baillis, D.; Bianco, N. Improved Monte Carlo methods for computational modelling of thermal radiation applied to porous cellular materials. Int. J. Therm. Sci. 2019, 137, 161–179. [Google Scholar] [CrossRef]

- Gaitanaros, S.; Kyriakides, S. On the effect of relative density on the crushing and energy absorption of open-cell foams under impact. Int. J. Impact Eng. 2015, 82, 3–13. [Google Scholar] [CrossRef] [Green Version]

- Ye, W.; Barbier, C.; Zhu, W.; Combescure, A.; Baillis, D. Macroscopic multiaxial yield and failure surfaces for light closed-cell foams. Int. J. Solids Struct. 2015, 69–70, 60–70. [Google Scholar] [CrossRef]

- Storm, J.; Abendroth, M.; Kuna, M. Numerical and analytical solutions for anisotropic yield surfaces of the open-cell Kelvin foam. Int. J. Mech. Sci. 2016, 105, 70–82. [Google Scholar] [CrossRef]

- Zhu, W.; Blal, N.; Cunsolo, S.; Baillis, D. Micromechanical modeling of effective elastic properties of open-cell foam. Int. J. Solids Struct. 2017, 115, 61–72. [Google Scholar] [CrossRef]

- Zhu, W.; Blal, N.; Cunsolo, S.; Baillis, D. Effective elastic properties of periodic irregular open-cell foams. Int. J. Solids Struct. 2018, 143, 155–166. [Google Scholar] [CrossRef]

- Zhu, W.; Blal, N.; Cunsolo, S.; Baillis, D.; Michaud, P.M. Effective Elastic Behavior of Irregular Closed-Cell Foams. Materials 2018, 11, 2100. [Google Scholar] [CrossRef] [Green Version]

- Ciambelli, P.; Palma, V.; Palo, E. Comparison of ceramic honeycomb monolith and foam as Ni catalyst carrier for methane autothermal reforming. Catal. Today 2010, 155, 92–100. [Google Scholar] [CrossRef]

- Gauthier, S.; Lebas, E.; Baillis, D. SFGP 2007-natural gas/hydrogen mixture combustion in a porous radiant burner. Int. J. Chem. React. Eng. 2007, 5, A114. [Google Scholar] [CrossRef]

- Mey-Cloutier, S.; Caliot, C.; Kribus, A.; Gray, Y.; Flamant, G. Experimental study of ceramic foams used as high temperature volumetric solar absorber. Sol. Energy 2016, 136, 226–235. [Google Scholar] [CrossRef]

- Jing, L.; Wang, Z.; Zhao, L. The dynamic response of sandwich panels with cellular metal cores to localized impulsive loading. Compos. Part B Eng. 2016, 94, 52–63. [Google Scholar] [CrossRef]

- Guo, X.; Ding, L.; Kanamori, K.; Nakanishi, K.; Yang, H. Functionalization of hierarchically porous silica monoliths with polyethyleneimine (PEI) for CO2 adsorption. Microporous Mesoporous Mater. 2017, 245, 51–57. [Google Scholar] [CrossRef]

- Liu, J.H.; Wang, A.Q.; Chi, Y.S.; Lin, H.P.; Mou, C.Y. Synergistic Effect in an Au-Ag Alloy Nanocatalyst: CO Oxidation. J. Phys. Chem. B 2005, 109, 40–43. [Google Scholar] [CrossRef] [PubMed]

- Akhavan, O.; Azimirad, R.; Moshfegh, A. Low temperature self-agglomeration of metallic Ag nanoparticles on silica sol-gel thin films. J. Phys. D Appl. Phys. 2008, 41, 195305. [Google Scholar] [CrossRef]

- Sánchez, B.; Sánchez-Muñoz, M.; Muñoz-Vicente, M.; Cobas, G.; Portela, R.; Suárez, S.; González, A.E.; Rodríguez, N.; Amils, R. Photocatalytic elimination of indoor air biological and chemical pollution in realistic conditions. Chemosphere 2012, 87, 625–630. [Google Scholar] [CrossRef]

- Lorencik, S.; Yu, Q.; Brouwers, H. Photocatalytic coating for indoor air purification: Synergetic effect of photocatalyst dosage and silica modification. Chem. Eng. J. 2016, 306, 942–952. [Google Scholar] [CrossRef]

- Mamaghani, A.H.; Haghighat, F.; Lee, C.S. Photocatalytic oxidation technology for indoor environment air purification: The state-of-the-art. Appl. Catal. B Environ. 2017, 203, 247–269. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, Y.; Yang, H.; Nakanishi, K.; Kanamori, K.; Guo, X. Facile preparation of silver nanoparticles homogeneously immobilized in hierarchically monolithic silica using ethylene glycol as reductant. Dalton Trans. 2014, 43, 12648–12656. [Google Scholar] [CrossRef]

- Galarneau, A.; Sachse, A.; Said, B.; Pelisson, C.H.; Boscaro, P.; Brun, N.; Courtheoux, L.; Olivi-Tran, N.; Coasne, B.; Fajula, F. Hierarchical porous silica monoliths: A novel class of microreactors for process intensification in catalysis and adsorption. Comptes Rendus Chimie 2016, 19, 231–247. [Google Scholar] [CrossRef]

- Guo, X.; Wang, R.; Yu, H.; Zhu, Y.; Nakanishi, K.; Kanamori, K.; Yang, H. Spontaneous preparation of hierarchically porous silica monoliths with uniform spherical mesopores confined in a well-defined macroporous framework. Dalton Trans. 2015, 44, 13592–13601. [Google Scholar] [CrossRef]

- Webb, P.A. An Introduction to the Physical Characterization of Materials by Mercury Intrusion Porosimetry with Emphasis on Reduction and Presentation of Experimental Data; Micromeritics Instrument Corp: Norcross, GA, USA, 2001. [Google Scholar]

- Kraynik, A.M.; Reinelt, D.A.; van Swol, F. Structure of random monodisperse foam. Phys. Rev. E 2003, 67, 031403. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rycroft, C.H. VORO++: A three-dimensional Voronoi cell library in C++. Chaos 2009, 19, 041111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brakke, K.A. The Surface Evolver. Exp. Math. 1992, 1, 141–165. [Google Scholar] [CrossRef]

- MATLAB. MATLAB Primer; The MathWorks Inc.: Natick, MA, USA, 2016. [Google Scholar]

- COMSOL, A.B. COMSOL Multiphysics - Reference Manual, version 5.2a ed.; COMSOL AB: Stockholm, Sweden, 2016. [Google Scholar]

- ANSYS. ICEM CFD User’s Manual; ANSYS, Inc.: Canonsburg, PA, USA, 2013. [Google Scholar]

- Düster, A.; Sehlhorst, H.G.; Rank, E. Numerical homogenization of heterogeneous and cellular materials utilizing the finite cell method. Comput. Mech. 2012, 50, 413–431. [Google Scholar] [CrossRef]

| t | 1 | ||

|---|---|---|---|

| Struts |  |  |  |

| k | 0 | 1 | ||

|---|---|---|---|---|

| Struts |  |  |  |  |

| Variable | Range |

|---|---|

| Porosity p | (, , , , ) |

| Coefficient of variation | (0.0, 0.1, 0.2, 0.3, 0.4) |

| Diameter ratio t | (0.33, 0.40, 0.50, 0.67, 1.00) |

| Normalized curvature k | (-0.3, 0.0, 0.3, 0.6, 1.0) |

| Wavelength | (400 nm, 500 nm, 600 nm, 700 nm, 770 nm) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, W.; Guo, X.; Wu, L.; Yang, H. Simulation of the Light Transmittance in Macroporous Silica. Materials 2020, 13, 1635. https://doi.org/10.3390/ma13071635

Zhu W, Guo X, Wu L, Yang H. Simulation of the Light Transmittance in Macroporous Silica. Materials. 2020; 13(7):1635. https://doi.org/10.3390/ma13071635

Chicago/Turabian StyleZhu, Wenqi, Xingzhong Guo, Lan Wu, and Hui Yang. 2020. "Simulation of the Light Transmittance in Macroporous Silica" Materials 13, no. 7: 1635. https://doi.org/10.3390/ma13071635

APA StyleZhu, W., Guo, X., Wu, L., & Yang, H. (2020). Simulation of the Light Transmittance in Macroporous Silica. Materials, 13(7), 1635. https://doi.org/10.3390/ma13071635