Linear Friction Welding of an AZ91 Magnesium Alloy and the Effect of Ca Additions on the Weld Characteristics

Abstract

:1. Introduction

2. Materials and Methods

3. Results

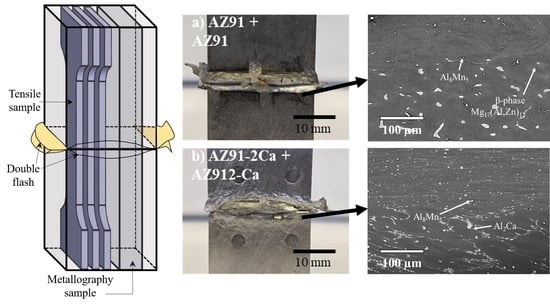

3.1. Thermal History and Macroscopic Examinations

3.2. Microstructural Characteristics of the Base Materials and Weld Zone Phase Identification

3.3. Microstructural Investigation

3.4. Grain Structure and Texture

3.5. Mechanical Properties of the Welded Couples

4. Discussion

4.1. Thermal Influences on the Flash and Weld Macroscopic Characteristics

4.2. Microstructure and Texture

4.3. Mechanical Properties

5. Conclusions

- For the parametric conditions examined for LFW, the AZ91/AZ91 and AZ91–2Ca/AZ91–2Ca welds exhibited intimate bonding without the presence of discontinuities such as pores, voids, and/or cracks at the joint interface.

- Both alloys showed microstructural changes with increasing temperature during LFW. At the welding temperatures, the β–Mg17(Al, Zn)12 phase dissolved, enriching the α–Mg matrix in Al. The Al8Mn5 phase remained in both Mg alloys and the Al2Ca remained in AZ91–2Ca, albeit evenly dispersed through the central weld zone due to deformation.

- The LFW process generated a recrystallized microstructure in the central weld zone of the AZ91/AZ91 and AZ91–2Ca/AZ91–2Ca welds. Compared to large grain size of AZ91 and AZ91–2Ca base materials (~1000 µm), the fine equiaxed grains in the central weld zone were about 2–6 µm in size. This grain refinement contributed to increase in the hardness of the central weld zone to 87 ± 3.0 HV0.5 and 88 ± 2.7 HV0.5 in the AZ91/AZ91 and AZ91–2Ca/AZ91–2Ca welds, respectively. Relative to the AZ91 and AZ91–2Ca base material, the central weld zone was about 32% harder.

- Tensile testing of the AZ91/AZ91 and AZ91–2Ca/AZ91–2Ca welds was undertaken using digital image correlation to measure the strain distribution in the gauge length section of the tensile samples. The tensile strength properties of the welds were similar or slightly higher than the base materials and final failure occurred exclusively in the AZ91 and AZ91–2Ca base materials. Examination of the strain distribution across the AZ91/AZ91 and AZ91–2Ca/AZ91–2Ca joints just before final fracture indicated that the local strains in the central weld zone were about 50% lower than those in the base material regions.

- A basal recrystallization texture developed in the weld region of the AZ91/AZ91 and AZ91–2Ca/AZ91–2Ca joints, such that the basal planes were oriented perpendicular to the LFW forging direction and the tensile stress axis. This strong basal texture also strengthened the weld region locally (as evidenced by the lower local strains in the central weld zone) relative to the base material during tensile testing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AA | Aluminum alloy |

| Al | Aluminum |

| Ar | Argon |

| ASTM | American Society for Testing and Materials |

| AZ | Magnesium, Aluminum, Zinc, and Manganese alloys |

| BSE | Backscattered Electron |

| Ca | Calcium |

| D | Depth |

| EBSD | Electron Backscattered Diffraction |

| EL | Elongation |

| FSP | Friction Stir Processing |

| FSW | Friction Stir Welding |

| HCP | Hexagonal Close-Packed |

| He | Helium |

| HV | Hardness Vickers |

| ICP-AES | Inductively Coupled Plasma-Atomic Emission Spectrometry |

| L | Length |

| LFW | Linear Friction Welding |

| Mg | Magnesium |

| NADCAP | National Aerospace and Defense Contractors Accreditation Program |

| NIST | National Institute of Standards and Technology |

| PDS | Process Development System |

| PSN | Particle Stimulated Nucleation |

| SEM | Scanning Electron Microscope |

| TIN | Twin Induced Nucleation |

| UTS | Ultimate Tensile Strength |

| W | Width |

| XRD | X-Ray Diffraction |

| YS | Yield Strength |

| Zn | Zinc |

| ρ | Density |

References

- Schäfer, A.W.; Evans, A.D.; Reynolds, T.G.; Dray, L. Costs of mitigating CO2 emissions from passenger aircraft. Nat. Clim. Chang. 2016, 6, 412–417. [Google Scholar] [CrossRef] [Green Version]

- Snyder, C.A.; Berton, J.; Brown, G.V.; Dolce, J. Propulsion Investigation for Zero and Near-Zero Emissions Aircraft. 2009. Available online: https://ntrs.nasa.gov/search.jsp?R=20090023315&qs=N%3D4294966788%2B4294937329%26No%3D10 (accessed on 24 July 2020).

- Mouritz, A.P. Materials Selection for Aerospace. In Introduction to Aerospace Materials; Elsevier: Amsterdam, The Netherlands, 2012; Volume 1, pp. 569–600. [Google Scholar]

- Gulbransen, E.A. The Oxidation and Evaporation of Magnesium at Temperatures from 400° to 500 °C. Trans. Electrochem. Soc. 1945, 87, 589–599. [Google Scholar] [CrossRef]

- Coffin, K.P. Some physical aspects of the combustion of magnesium ribbons. Symp. Int. Combust. 1955, 5, 267–276. [Google Scholar] [CrossRef]

- Aydin, D.S.; Bayindir, Z.; Pekguleryuz, M.O. The effect of strontium (Sr) on the ignition temperature of magnesium (Mg): A look at the pre-ignition stage of Mg–6 wt% Sr. J. Mater. Sci. 2013, 48, 8117–8132. [Google Scholar] [CrossRef]

- Tan, Q.; Mo, N.; Jiang, B.; Pan, F.; Atrens, A.; Zhang, M.-X. Combined influence of Be and Ca on improving the high-temperature oxidation resistance of the magnesium alloy Mg-9Al-1Zn. Corros. Sci. 2017, 122, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Prasad, A.; Shi, Z.; Atrens, A. Flammability of Mg-X Binary Alloys. Adv. Eng. Mater. 2012, 14, 772–784. [Google Scholar] [CrossRef]

- Aydin, D.; Bayindir, Z.; Hoseini, M.; Pekguleryuz, M. The high temperature oxidation and ignition behavior of Mg–Nd alloys part I: The oxidation of dilute alloys. J. Alloy. Compd. 2013, 569, 35–44. [Google Scholar] [CrossRef]

- Zhou, N.; Zhang, Z.; Dong, J.; Jin, L.; Ding, W. Selective oxidation behavior of an ignition-proof Mg-Y-Ca-Ce alloy. J. Rare Earths 2013, 31, 1003–1008. [Google Scholar] [CrossRef]

- Mebarki, N.; Kumar, N.V.R.; Blandin, J.J.; Suéry, M.; Pelloux, F.; Khélifati, G. Correlation between ignition and oxidation behaviours of AZ91 magnesium alloy. Mater. Sci. Technol. 2005, 21, 1145–1151. [Google Scholar] [CrossRef]

- Suzuki, K.; Saito, N.; Huang, X.; Yuasa, M.; Chino, Y. Effects of Measurement Conditions on Ignition Temperature of Magnesium Alloys. Mater. Trans. 2017, 58, 1616–1623. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Peh, W.Y.; Nagarajan, V.; Ho, M.K.; Danno, A.; Chua, B.W.; Tan, M.J. Development of non-flammable high strength AZ91 + Ca alloys via liquid forging and extrusion. Mater. Des. 2016, 99, 37–43. [Google Scholar] [CrossRef]

- Nami, B.; Shabestari, S.; Razavi, H.; Mirdamadi, S.; Miresmaeili, S. Effect of Ca, RE elements and semi-solid processing on the microstructure and creep properties of AZ91 alloy. Mater. Sci. Eng. A 2011, 528, 1261–1267. [Google Scholar] [CrossRef]

- Kondori, B.; Mahmudi, R. Effect of Ca additions on the microstructure and creep properties of a cast Mg–Al–Mn magnesium alloy. Mater. Sci. Eng. A 2017, 700, 438–447. [Google Scholar] [CrossRef]

- Itoh, D.; Terada, Y.; Sato, T. Effect of Calcium Additions on Creep Properties of a Die-Cast AM50 Magnesium Alloy. Mater. Trans. 2008, 49, 1957–1962. [Google Scholar] [CrossRef]

- Qudong, W.; Wenzhou, C.; Xiaoqin, Z.; Yizhen, L.; Wenjiang, D.; Yanping, Z.; Xiaoping, X.; Mabuchi, M. Effects of Ca addition on the microstructure and mechanical properties of AZ91magnesium alloy. J. Mater. Sci. 2001, 36, 3035–3040. [Google Scholar] [CrossRef]

- Saha, P.K. Aerospace Manufacturing Processes; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Avedesian, M.M.; Baker, H. ASM Specialty Handbook: Magnesium and Magnesium Alloys; ASM International: Materials Park, OH, USA, 1999. [Google Scholar]

- Liu, L. Introduction to the Welding and Joining of Magnesium. In Welding and Joining of Magnesium Alloys; Elsevier: Amsterdam, The Netherlands, 2010; pp. 3–8. [Google Scholar]

- Marya, M.; Edwards, G.R. The Laser Welding of Magnesium Alloy AZ91, Weld. World 2000, 44, 31–37. [Google Scholar]

- Cao, X.; Jahazi, M.; Immarigeon, J.; Wallace, W. A review of laser welding techniques for magnesium alloys. J. Mater. Process. Technol. 2006, 171, 188–204. [Google Scholar] [CrossRef]

- Nene, S.; Zellner, S.; Mondal, B.; Komarasamy, M.; Mishra, R.; Brennan, R.; Cho, K. Friction stir processing of newly-designed Mg-5Al-3.5Ca-1Mn (AXM541) alloy: Microstructure evolution and mechanical properties. Mater. Sci. Eng. A 2018, 729, 294–299. [Google Scholar] [CrossRef]

- Xu, N.; Feng, R.; Song, Q.; Bao, Y. Microstructure and mechanical properties’ modification of low-temperature friction stir welded non-combustive Mg-9A1-1Zn-1Ca alloy joint. J. Mater. Res. Technol. 2019, 8, 4448–4456. [Google Scholar] [CrossRef]

- Kumar, P.; Thakur, L.; Bhadouria, N.; Dixit, S. Microstructure and mechanical behaviour of friction stir processed AZ91-D magnesium alloy—Optimization of process parameters by using the Taguchi method. Met. Mater. 2020, 57, 207–217. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Vairis, A.; Preuss, M.; Ma, T. Linear and rotary friction welding review. Int. Mater. Rev. 2016, 61, 71–100. [Google Scholar] [CrossRef]

- Bhamji, I.; Preuss, M.; Threadgill, P.L.; Addison, A.C. Solid state joining of metals by linear friction welding: A literature review. Mater. Sci. Technol. 2011, 27, 2–12. [Google Scholar] [CrossRef]

- Bhamji, I.; Preuss, M.; Moat, R.J.; Threadgill, P.L.; Addison, A.C. Linear friction welding of aluminium to magnesium. Sci. Technol. Weld. Join. 2012, 17, 368–374. [Google Scholar] [CrossRef]

- Zander, D.; Schnatterer, C.; Kuhnt, C. Influence of heat treatments and Ca additions on the passivation behaviour of high-pressure die cast AM50. Mater. Corros. 2015, 66, 1519–1528. [Google Scholar] [CrossRef]

- Nam, N.; Bian, M.; Forsyth, M.; Seter, M.; Tan, M.; Shin, K. Effect of calcium oxide on the corrosion behaviour of AZ91 magnesium alloy. Corros. Sci. 2012, 64, 263–271. [Google Scholar] [CrossRef]

- Kim, K.H.; Nam, N.D.; Kim, J.G.; Shin, K.S.; Jung, H.C. Effect of calcium addition on the corrosion behavior of Mg–5Al alloy. Intermetallics 2011, 19, 1831–1838. [Google Scholar] [CrossRef]

- Mingo, B.; Mohedano, M.; Blawert, C.; del Olmo, R.; Hort, N.; Arrabal, R. Role of Ca on the corrosion resistance of Mg–9Al and Mg–9Al–0.5Mn alloys. J. Alloy. Compd. 2019, 811, 151992. [Google Scholar] [CrossRef]

- Choi, B.-H.; You, B.-S.; Park, W.-W.; Huang, Y.-B.; Park, I.-M. Effect of Ca addition on the oxidation resistance of AZ91 magnesium alloys at elevated temperatures. Met. Mater. Int. 2003, 9, 395–398. [Google Scholar] [CrossRef]

- Cheng, S.-L.; Yang, G.-C.; Fan, J.-F.; Li, Y.-J.; Zhou, Y.-H. Effect of Ca and Y additions on oxidation behavior of AZ91 alloy at elevated temperatures. Trans. Nonferrous Met. Soc. China 2009, 19, 299–304. [Google Scholar] [CrossRef]

- Elsayed, A.; Ravindran, C. Effect of Melt Cleanliness on the Mechanical Properties and Microstructure on AZ91E Mg Alloy Castings. J. Mater. Eng. Perform. 2013, 23, 628–636. [Google Scholar] [CrossRef]

- Wanjara, P.; Jahazi, M. Linear friction welding of Ti-6Al-4V: Processing, microstructure, and mechanical-property inter-relationships. Met. Mater. Trans. A 2005, 36, 2149–2164. [Google Scholar] [CrossRef]

- ASTM International. ASTM E8/E8M-16a, Standard Test Methods for Tension Testing of Metallic Materials. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/E8E8M-16A.htm (accessed on 13 April 2021).

- Sarafan, S.; Wanjara, P.; Lévesque, J.-B.; Gholipour, J.; Champliaud, H.; Mathieu, L. Through-Thickness Residual Stresses, Microstructure, and Mechanical Properties of Electron Beam-Welded CA6NM Martensitic Stainless Steel after Postweld Heat Treatment. Adv. Mater. Sci. Eng. 2020, 2020, 7194214. [Google Scholar] [CrossRef] [Green Version]

- Wanjara, P.; Dalgaard, E.; Gholipour, J.; Cao, X.; Cuddy, J.; Jonas, J.J. Effect of Pre- and Post-weld Heat Treatments on Linear Friction Welded Ti-5553. Met. Mater. Trans. A 2014, 45, 5138–5157. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of metal alloys in the semisolid state. Met. Mater. Trans. A 1991, 22, 957–981. [Google Scholar] [CrossRef]

- Zeng, G.; Xian, J.W.; Gourlay, C.M. Growth of Al8Mn5 Intermetallic in AZ91. Proc. Int. Conf. Martensitic Transform. Chic. 2017, 18, 85–92. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Z.Y.; Nakata, K.; Feng, J.C.; Huang, Y.X.; Liao, J.S. Microstructure and Fatigue Behavior of Friction Stir-welded Noncombustive Mg-9Al-Zn-Ca Magnesium Alloy. J. Mater. Eng. Perform. 2016, 25, 2403–2411. [Google Scholar] [CrossRef]

- Chen, J.; Fujii, H.; Sun, Y.; Morisada, Y.; Kondoh, K. Optimization of mechanical properties of fine-grained non-combustive magnesium alloy joint by asymmetrical double-sided friction stir welding. J. Mater. Process. Technol. 2017, 242, 117–125. [Google Scholar] [CrossRef] [Green Version]

- Zhou, M.; Morisada, Y.; Fujii, H.; Ishikawa, T. Mechanical properties optimization of AZX612-Mg alloy joint by double-sided friction stir welding. J. Mater. Process. Technol. 2018, 254, 91–99. [Google Scholar] [CrossRef]

- Romero, J.; Attallah, M.; Preuss, M.; Karadge, M.; Bray, S. Effect of the forging pressure on the microstructure and residual stress development in Ti–6Al–4V linear friction welds. Acta Mater. 2009, 57, 5582–5592. [Google Scholar] [CrossRef]

- Chamanfar, A.; Jahazi, M.; Gholipour, J.; Wanjara, P.; Yue, S. Maximizing the integrity of linear friction welded Waspaloy. Mater. Sci. Eng. A 2012, 555, 117–130. [Google Scholar] [CrossRef]

- Wanjara, P.; Naik, B.S.; Yang, Q.; Cao, X.; Gholipour, J.; Chen, D.L. Linear Friction Welding of Dissimilar Materials 316L Stainless Steel to Zircaloy-4. Met. Mater. Trans. A 2018, 49, 1641–1652. [Google Scholar] [CrossRef]

- Dalgaard, E.; Wanjara, P.; Trigo, G.; Jahazi, M.; Comeau, G.; Jonas, J.J. Linear friction welding of Al–Cu Part 2—Interfacial characteristics. Can. Met. Q. 2011, 50, 360–370. [Google Scholar] [CrossRef]

- Wanjara, P.; Dalgaard, E.; Trigo, G.; Mandache, C.; Comeau, G.; Jonas, J.J. Linear friction welding of Al–Cu: Part 1—Process evaluation. Can. Met. Q. 2011, 50, 350–359. [Google Scholar] [CrossRef]

- Wanjara, P.; Gholipour, J.; Watanabe, K.; Nezaki, K.; Tian, Y.; Brochu, M. Linear Friction Welding of IN718 to Ti6Al4V. Mater. Sci. Forum 2016, 879, 2072–2077. [Google Scholar] [CrossRef]

- Dalgaard, E.; Wanjara, P.; Gholipour, J.; Jonas, J. Evolution of microstructure, microtexture and mechanical properties of linear friction welded IMI 834. Can. Met. Q. 2012, 51, 269–276. [Google Scholar] [CrossRef]

- Dalgaard, E.; Wanjara, P.; Gholipour, J.; Cao, X.; Jonas, J. Linear friction welding of a near-β titanium alloy. Acta Mater. 2012, 60, 770–780. [Google Scholar] [CrossRef]

- Rajan, S.; Wanjara, P.; Gholipour, J.; Kabir, A.S. Joining of Dissimilar Alloys Ti-6Al-4V and Ti-6Al-2Sn-4Zr-2Mo-0.1Si Using Linear Friction Welding. Materials 2020, 13, 3664. [Google Scholar] [CrossRef] [PubMed]

- Rajan, S.; Wanjara, P.; Gholipour, J.; Kabir, A.S. Microstructure, Tensile Properties, and Fatigue Behavior of Linear Friction-Welded Ti-6Al-2Sn-4Zr-2Mo-0.1Si. Materials 2020, 14, 30. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H. Basal plane texture and flow pattern in friction stir weld of a magnesium alloy. Met. Mater. Trans. A 2003, 34, 987–994. [Google Scholar] [CrossRef]

- Su, J.; Sanjari, M.; Kabir, A.S.H.; Jung, I.-H.; Yue, S. Dynamic recrystallization mechanisms during high speed rolling of Mg–3Al–1Zn alloy sheets. Scr. Mater. 2016, 113, 198–201. [Google Scholar] [CrossRef]

- Mackenzie, L.; Pekguleryuz, M. The influences of alloying additions and processing parameters on the rolling microstructures and textures of magnesium alloys. Mater. Sci. Eng. A 2008, 480, 189–197. [Google Scholar] [CrossRef]

- Wu, Y.; Zhu, R. Effect of Rolling Temperature on the Microstructure and Mechanical Properties of AZ31 Alloy Sheet Processed through Variable-Plane Rolling. J. Mater. Eng. Perform. 2019, 28, 6182–6191. [Google Scholar] [CrossRef]

- Ma, Q.; Li, B.; Marin, E.; Horstemeyer, S. Twinning-induced dynamic recrystallization in a magnesium alloy extruded at 450 °C. Scr. Mater. 2011, 65, 823–826. [Google Scholar] [CrossRef]

- Pekguleryuz, M.; Celikin, M.; Hoseini, M.; Becerra, A.; Mackenzie, L. Study on edge cracking and texture evolution during 150 °C rolling of magnesium alloys: The effects of axial ratio and grain size. J. Alloys Compd. 2012, 510, 15–25. [Google Scholar] [CrossRef]

| Element | Al | Ca | Si | Cu | Fe | Mn | Ni | Zn | Mg |

|---|---|---|---|---|---|---|---|---|---|

| AZ91–2Ca | 9.71 | 2.23 | – | <0.001 | 0.009 | 0.34 | <0.001 | 1.13 | Balance |

| AZ91 [35] | 9.64 | – | 0.03 | 0.01 | 0.004 | 0.31 | <0.001 | 0.78 | Balance |

| Alloy | Phase-Crystal Structure | Phase wt.% |

|---|---|---|

| AZ91 | α Mg–HCP–A3 | 87.44 |

| β–Mg17(Al, Zn)12 | 11.92 | |

| Al8Mn5–D810 | 0.38 | |

| AZ91–2Ca | α Mg–HCP–A3 | 87.65 |

| β–Mg17(Al, Zn)12 | 6.68 | |

| Al8Mn5–D810 | 0.28 | |

| Al2Ca–C15 | 4.57 | |

| Mg6(Al,Zn)5–φ | 0.37 |

| Weld | Average Hardness (HV0.5) | |

|---|---|---|

| Base Material | Central Weld Zone | |

| AZ91/AZ91 | 65.6 ± 4.0 | 87 ± 3.0 |

| AZ91–2Ca/AZ01–2Ca | 66.3 ± 3.1 | 88 ± 2.7 |

| Materials | UTS (MPa) | YS (MPa) | Final Strain or EL (%) |

|---|---|---|---|

| LFW AZ91 | 138 | 95 | 2 |

| LFW AZ91–2Ca | 99 | 86 | 1 |

| AZ91 [35] | 153 | 93 | 2 |

| AZ91–2Ca | 110 | 75 | 1 |

| AZ91 Welded Structure (Quenched from 351 °C) | AZ91 As-Cast Structure | ||

|---|---|---|---|

| Phases | Amount of Phase, wt% | Phases | Amount of Phase, wt% |

| α Mg–HCP–A3 | 95.85 | α Mg–HCP–A3 | 87.44 |

| β–Mg17(Al, Zn)12 | 3.26 | β–Mg17(Al, Zn)12 | 11.92 |

| Al4Mn | 0.89 | Al8Mn5–D810 | 0.38 |

| AZ91–2Ca Welded Structure (Quenched from 407 °C) | AZ91–2Ca As-Cast Structure | ||

|---|---|---|---|

| Phases | Amount of Phase, wt% | Phases | Amount of Phase, wt% |

| α Mg–HCP–A3 | 94.24 | α Mg–HCP–A3 | 87.65 |

| β–Mg17(Al, Zn)12 | 0 | β–Mg17(Al, Zn)12 | 6.68 |

| Mn2CaAl10 | 1.1461 | Al8Mn5–D810 | 0.28 |

| Al2Ca–C15 | 4.61 | Al2Ca–C15 | 4.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the National Research Council of Canada. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villegas-Armenta, L.A.; Wanjara, P.; Gholipour, J.; Nakatsugawa, I.; Chino, Y.; Pekguleryuz, M. Linear Friction Welding of an AZ91 Magnesium Alloy and the Effect of Ca Additions on the Weld Characteristics. Materials 2021, 14, 3130. https://doi.org/10.3390/ma14113130

Villegas-Armenta LA, Wanjara P, Gholipour J, Nakatsugawa I, Chino Y, Pekguleryuz M. Linear Friction Welding of an AZ91 Magnesium Alloy and the Effect of Ca Additions on the Weld Characteristics. Materials. 2021; 14(11):3130. https://doi.org/10.3390/ma14113130

Chicago/Turabian StyleVillegas-Armenta, Luis Angel, Priti Wanjara, Javad Gholipour, Isao Nakatsugawa, Yasumasa Chino, and Mihriban Pekguleryuz. 2021. "Linear Friction Welding of an AZ91 Magnesium Alloy and the Effect of Ca Additions on the Weld Characteristics" Materials 14, no. 11: 3130. https://doi.org/10.3390/ma14113130

APA StyleVillegas-Armenta, L. A., Wanjara, P., Gholipour, J., Nakatsugawa, I., Chino, Y., & Pekguleryuz, M. (2021). Linear Friction Welding of an AZ91 Magnesium Alloy and the Effect of Ca Additions on the Weld Characteristics. Materials, 14(11), 3130. https://doi.org/10.3390/ma14113130