Advanced Biofuels Based on Fischer–Tropsch Synthesis for Applications in Gasoline Engines

Abstract

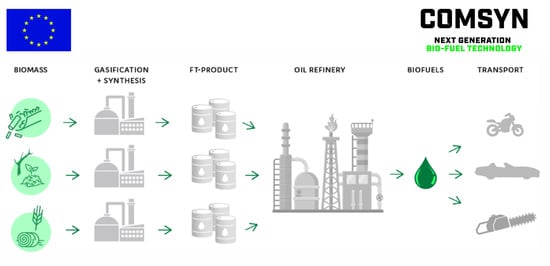

:1. Introduction

2. Materials and Methods

- 100 vol.% pure fossil gasoline (BA100).

- 3 vol.% FT-naphtha distillation fraction and 97 vol.% fossil gasoline (FT3).

- 5 vol.% FT-naphtha distillation fraction and 95 vol.% fossil gasoline (FT7).

- 10 vol.% FT-naphtha distillation fraction and 90 vol.% fossil gasoline (FT15).

- 25 vol.% FT-naphtha distillation fraction and 75 vol.% fossil gasoline (FT30).

- 50 vol.% FT-naphtha distillation fraction and 50 vol.% fossil gasoline (FT50).

- 70 vol.% FT-naphtha distillation fraction and 30 vol.% fossil gasoline (FT70).

- 100 vol.% pure FT-naphtha distillation fraction (FT100).

3. Results

3.1. Fuel Parameters

3.2. Volatility Characteristics

3.3. Composition Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32018L2001 (accessed on 16 May 2021).

- European Commission. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC; European Commission: Brussels, Belgium, 2009; Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:140:0016:0062:en:PDF (accessed on 28 April 2021).

- European Commission Sustainability Criteria. Available online: https://ec.europa.eu/energy/topics/renewable-energy/biofuels/sustainability-criteria_en (accessed on 28 April 2021).

- Frilund, C.; Simell, P.; Kurkela, E.; Eskelinen, P. Experimental bench-scale study of residual biomass syngas desulfurization using ZnO-based adsorbents. Energy Fuels 2020, 34, 3326–3335. [Google Scholar] [CrossRef]

- Pospíšil, M.; Šebor, G.; Šimáček, P.; Mužíková, Z. Nové trendy výroby biopaliv a jejich využití v dopravě. Chemické Listy 2012, 106, 953–960. [Google Scholar]

- Zeman, P.; Hönig, V.; Kotek, M.; Táborský, J.; Obergruber, M.; Mařík, J.; Hartová, V.; Pechout, M. Hydrotreated vegetable oil as a fuel from waste materials. Catalysts 2019, 9, 337. [Google Scholar] [CrossRef] [Green Version]

- Kolesinska, B.; Fraczyk, J.; Binczarski, M.; Modelska, M.; Berlowska, J.; Dziugan, P.; Antolak, H.; Kaminski, Z.J.; Witonska, I.A.; Kregiel, D. Butanol synthesis routes for biofuel production: Trends and perspectives. Materials 2019, 12, 350. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meurer, A.; Kern, J. Fischer–Tropsch synthesis as the key for decentralized sustainable kerosene production. Energies 2021, 14, 1836. [Google Scholar] [CrossRef]

- Dahmen, N.; Sauer, J. Evaluation of techno-economic studies on the bioliq® process for synthetic fuels production from biomass. Processes 2021, 9, 684. [Google Scholar] [CrossRef]

- Dębek, C. Modification of pyrolytic oil from waste tyres as a promising method for light fuel production. Materials 2019, 12, 880. [Google Scholar] [CrossRef] [Green Version]

- Papari, S.; Bamdad, H.; Berruti, F. Pyrolytic conversion of plastic waste to value-added products and fuels: A Review. Materials 2021, 14, 2586. [Google Scholar] [CrossRef] [PubMed]

- Świechowski, K.; Stępień, P.; Syguła, E.; Koziel, J.A.; Białowiec, A. Lab-scale study of temperature and duration effects on carbonized solid fuels properties produced from municipal solid waste components. Materials 2021, 14, 1191. [Google Scholar] [CrossRef]

- Wang, T.; Liu, H.; Duan, C.; Xu, R.; Zhang, Z.; She, D.; Zheng, J. The eco-friendly biochar and valuable bio-oil from Caragana korshinskii: Pyrolysis preparation, characterization, and adsorption applications. Materials 2020, 13, 3391. [Google Scholar] [CrossRef] [PubMed]

- Kosakowski, W.; Bryszewska, M.A.; Dziugan, P. Biochars from post-production biomass and waste from wood management: Analysis of carbonization products. Materials 2020, 13, 4971. [Google Scholar] [CrossRef]

- Yue, T.; Jiang, D.; Zhang, Z.; Zhang, Y.; Li, Y.; Zhang, T.; Zhang, Q. Recycling of shrub landscaping waste: Exploration of Bio-hydrogen production potential and optimization of photo-fermentation bio-hydrogen production process. Bioresour. Technol. 2021, 331, 125048. [Google Scholar] [CrossRef]

- Müller-Langer, F.; Majer, S.; O’Keeffe, S. Benchmarking biofuels—A comparison of technical, economic and environmental indicators. Energy Sustain. Soc. 2014, 4, 20. [Google Scholar] [CrossRef] [Green Version]

- Degnan, T.; Shinde, S.L. Waste-plastic processing provides global challenges and opportunities. MRS Bull. 2019, 44, 436–437. [Google Scholar] [CrossRef] [Green Version]

- van de Loosdrecht, J.; Botes, F.G.; Ciobica, I.M.; Ferreira, A.; Gibson, P.; Moodley, D.J.; Saib, A.M.; Visagie, J.L.; Weststrate, C.J.; Niemantsverdriet, J.W. Catalysts and Chemistry. In Comprehensive Inorganic Chemistry II, 2nd ed.; Reedijk, J., Poeppelmeier, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 525–557. ISBN 978-0-08-096529-1. [Google Scholar]

- Warheit, D.B. Hazard and risk assessment strategies for nanoparticle exposures: How far have we come in the past 10 years? F1000Research 2018, 7, 376. [Google Scholar] [CrossRef] [Green Version]

- Morgeneyer, M.; Aguerre-Chariol, O.; Bressot, C. STEM imaging to characterize nanoparticle emissions and help to design nanosafer paints. Chem. Eng. Res. Des. 2018, 136, 663–674. [Google Scholar] [CrossRef]

- Bressot, C.; Aubry, A.; Pagnoux, C.; Aguerre-Chariol, O.; Morgeneyer, M. Assessment of functional nanomaterials in medical applications: Can time mend public and occupational health risks related to the products’ fate? J. Toxicol. Environ. Health A 2018, 81, 957–973. [Google Scholar] [CrossRef]

- Bressot, C.; Shandilya, N.; Jayabalan, T.; Fayet, G.; Voetz, M.; Meunier, L.; Le Bihan, O.; Aguerre-Chariol, O.; Morgeneyer, M. Exposure assessment of nanomaterials at production sites by a Short Time Sampling (STS) approach strategy and first results of measurement campaigns. Process Saf. Environ. Prot. 2018, 116. [Google Scholar] [CrossRef]

- Morgeneyer, M.; Shandilya, N.; Chen, Y.M.; Le Bihan, O. Use of a modified Taber abrasion apparatus for investigating the complete stress state during abrasion and in-process wear particle aerosol generation. Chem. Eng. Res. Des. 2015, 93, 251. [Google Scholar] [CrossRef]

- Paulick, M.; Morgeneyer, M.; Kwade, A. A new method for the determination of particle contact stiffness. Granul. Matter 2015, 17, 83–93. [Google Scholar] [CrossRef]

- Röck, M.; Morgeneyer, M.; Schwedes, J.; Kadau, D.; Brendel, L.; Wolf, D.E. Steady state flow of cohesive and non-cohesive powders. Granul. Matter 2008, 10, 285–293. [Google Scholar] [CrossRef]

- Saleh, K.; Abou Jaoude, M.T.M.; Morgeneyer, M.; Lefrancois, E.; Le Bihan, O.; Bouillard, J. Dust generation from powders: A characterization test based on stirred fluidization. Powder Technol. 2014, 255, 141–148. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, J.; Ramos, Á.; Barba, J.; Cárdenas, D.; Delgado, J. Improving fuel economy and engine performance through gasoline fuel octane rating. Energies 2020, 13, 3499. [Google Scholar] [CrossRef]

- Li, J.; Zhu, J.; Wang, S.; Feng, Y.; Zhou, W.; Qian, Y.; Yu, L.; Lu, X. An Experimental and modeling study of autoignition characteristics of two real low-octane gasoline fuels in a heated rapid compression machine at elevated pressures. Fuel 2021, 295, 120645. [Google Scholar] [CrossRef]

- Stan, C.; Andreescu, C.; Dobre, A.; Iozsa, D. Experimental study on the distillation capacity of alcohol-gasoline blends. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012069. [Google Scholar] [CrossRef]

- Hönig, V.; Procházka, P.; Obergruber, M.; Kučerová, V.; Mejstřík, P.; Macků, J.; Bouček, J. Determination of Tractor engine oil change interval based on material properties. Materials 2020, 13, 5403. [Google Scholar] [CrossRef] [PubMed]

- Amine, M.; Awad, E.N.; Ibrahim, V.; Barakat, Y. Influence of ethyl acetate addition on phase stability and fuel characteristics of hydrous ethanol-gasoline blends. Egypt. J. Pet. 2018, 27, 1333–1336. [Google Scholar] [CrossRef]

- Shirazi, S.A.; Abdollahipoor, B.; Martinson, J.; Reardon, K.F.; Windom, B.C. Physiochemical property characterization of hydrous and anhydrous ethanol blended gasoline. Ind. Eng. Chem. Res. 2018, 57, 11239–11245. [Google Scholar] [CrossRef]

- Zhang, Q.; Kang, J.; Wang, Y. Development of novel catalysts for Fischer-Tropsch synthesis: Tuning the product selectivity. ChemCatChem 2010, 2, 1030–1058. [Google Scholar] [CrossRef]

- Gruber, H.; Groß, P.; Rauch, R.; Reichhold, A.; Zweiler, R.; Aichernig, C.; Müller, S.; Ataimisch, N.; Hofbauer, H. Fischer-Tropsch products from biomass-derived syngas and renewable hydrogen. Biomass Convers. Biorefinery 2019. [Google Scholar] [CrossRef] [Green Version]

- Komvokis, V.G.; Karakoulia, S.; Iliopoulou, E.F.; Papapetrou, M.C.; Vasalos, I.A.; Lappas, A.A.; Triantafyllidis, K.S. Upgrading of Fischer–Tropsch synthesis bio-waxes via catalytic cracking: Effect of acidity, porosity and metal modification of zeolitic and mesoporous aluminosilicate catalysts. Catal. Today 2012, 196, 42–55. [Google Scholar] [CrossRef]

- Flach, B.; Lieberz, S.; Bolla, S. EU-28 Biofuels Annual EU Biofuels Annual 2019. Available online: https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=Biofuels%20Annual_The%20Hague_EU-28_7-15-2019.pdf (accessed on 28 April 2021).

| Property | Standard |

|---|---|

| Diesel fuel | BS EN 590:2013 + A1:2017 |

| Density | ISO 12185:1996 |

| Distillation | ISO 3405:2011 |

| Octane number | ISO 5164:2014 |

| Refractive index | ISO 5661:1983 |

| Colour | ASTM D1500 |

| Vapour pressure | EN 13016-1 |

| Multidimensional gas chromatography | ISO 22854:2016 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hájek, J.; Hönig, V.; Obergruber, M.; Jenčík, J.; Vráblík, A.; Černý, R.; Pšenička, M.; Herink, T. Advanced Biofuels Based on Fischer–Tropsch Synthesis for Applications in Gasoline Engines. Materials 2021, 14, 3134. https://doi.org/10.3390/ma14113134

Hájek J, Hönig V, Obergruber M, Jenčík J, Vráblík A, Černý R, Pšenička M, Herink T. Advanced Biofuels Based on Fischer–Tropsch Synthesis for Applications in Gasoline Engines. Materials. 2021; 14(11):3134. https://doi.org/10.3390/ma14113134

Chicago/Turabian StyleHájek, Jiří, Vladimír Hönig, Michal Obergruber, Jan Jenčík, Aleš Vráblík, Radek Černý, Martin Pšenička, and Tomáš Herink. 2021. "Advanced Biofuels Based on Fischer–Tropsch Synthesis for Applications in Gasoline Engines" Materials 14, no. 11: 3134. https://doi.org/10.3390/ma14113134

APA StyleHájek, J., Hönig, V., Obergruber, M., Jenčík, J., Vráblík, A., Černý, R., Pšenička, M., & Herink, T. (2021). Advanced Biofuels Based on Fischer–Tropsch Synthesis for Applications in Gasoline Engines. Materials, 14(11), 3134. https://doi.org/10.3390/ma14113134