Influences of Air-Voids on the Performance of 3D Printing Cementitious Materials

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Fluidity

3.2. Evolution of Yield Stress

3.3. Strength

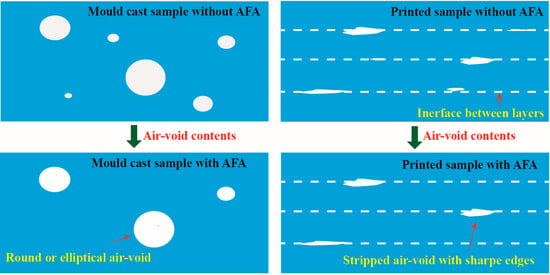

3.4. Air-Void Content

3.5. Air-Void Size Distribution

3.6. Electron Microscope Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef] [Green Version]

- Labonnote, N.; Ronnquist, A.; Manum, B.; Ruther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual. Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef] [Green Version]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, H.L.; Li, Z.J.; Ma, G.W. Mechanical behaviors of 3D printed lightweight concrete structure with hollow section. Arch. Civ. Mech. Eng. 2020, 20, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Khoshnevis, B. Automated construction by contour crafting—related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N. Digital concrete: Opportunities and challenges. Rilem Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- Dakhli, Z.; Lafhaj, Z. Experimental and numerical prototyping of a complex cement column formwork for construction. Archit. Eng. Des. Manag. 2017, 13, 147–165. [Google Scholar] [CrossRef]

- Camacho, D.D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of additive manufacturing in the construction industry—A forward-looking review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Zhang, J.C.; Wang, J.L.; Dong, S.F.; Yu, X.; Han, B.G. A review of the current progress and application of 3D printed concrete. Compos. Part A Appl. Sci. Manuf. 2019, 125, 1–8. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Correlation between destructive compression tests and non-destructive ultrasonic measurements on early age 3D printed concrete. Constr. Build. Mater. 2018, 181, 447–454. [Google Scholar] [CrossRef]

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Chen, M.X.; Li, L.B.; Wang, J.A.; Huang, Y.B.; Wang, S.D.; Zhao, P.Q.; Lu, L.C.; Cheng, X. Rheological parameters and building time of 3D printing sulphoaluminate cement paste modified by retarder and diatomite. Constr. Build. Mater. 2020, 234, 1–13. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Design 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of surface moisture on inter-layer strength of 3D printed concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Z.H.; Ma, G.W.; Zhang, M. Interlayer bonding improvement of 3D printed concrete with polymer modified mortar: Experiments and molecular dynamics studies. Cem. Concr. Compos. 2020, 110, 1–13. [Google Scholar] [CrossRef]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudilliere, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef] [Green Version]

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Interlayer adhesion and strength of structures in Contour Crafting—Effects of aggregate size, extrusion rate, and layer thickness. Autom. Constr. 2017, 81, 112–121. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef] [Green Version]

- Fonseca, P.; Scherer, G. An image analysis procedure to quantify the air void system of mortar and concrete. Mater. Struct. 2015, 48, 3087–3098. [Google Scholar] [CrossRef] [Green Version]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. Mechanical characterization of 3D printable concrete. Constr. Build. Mater. 2019, 227, 1–12. [Google Scholar] [CrossRef]

- Ma, G.W.; Salman, N.M.; Wang, L.; Wang, F. A novel additive mortar leveraging internal curing for enhancing interlayer bonding of cementitious composite for 3D printing. Constr. Build. Mater. 2020, 244. [Google Scholar] [CrossRef]

- Nerella, V.N.; Hempel, S.; Mechtcherine, V. Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Constr. Build. Mater. 2019, 205, 586–601. [Google Scholar] [CrossRef]

- Sahmaran, M.; Ozbay, E.; Yucel, H.E.; Lachemi, M.; Li, V.C. Frost resistance and microstructure of Engineered Cementitious Composites: Influence of fly ash and micro poly-vinyl-alcohol fiber. Cem. Concr. Compos. 2012, 34, 156–165. [Google Scholar] [CrossRef]

- Gao, P.W.; Wu, S.X.; Lin, P.H.; Wu, Z.R.; Tang, M.S. The characteristics of air void and frost resistance of RCC with fly ash and expansive agent. Constr. Build. Mater. 2006, 20, 586–590. [Google Scholar] [CrossRef]

- Lazniewska-Piekarczyk, B. Investigations on the relationship between porosity and strength of admixtures modified high performance self-compacting concrete. J. Civ. Eng. Manag. 2016, 22, 520–528. [Google Scholar] [CrossRef] [Green Version]

- Wu, T.; Li, C.; Wang, Y.; Li, Y.; Tang, S.; Borg, R. Improved non-contact variable-frequency AC impedance instrument for cement hydration and pore structure based on SVM calibration method. Measurement 2021, 179, 109402. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.M.; Zhou, S.H.; Tang, S.W.; Lu, X. Investigation of microstructure of C-S-H and micro-mechanics of cement pastes under NH4NO3 dissolution by 29Si MAS NMR and microhardness. Measurement 2021, accepted. [Google Scholar]

- Tang, S.; Wang, Y.; Geng, Z.; Xu, X.; Yu, W.; Chen, J. Structure, fractality, mechanics and durability of calcium silicate hydrates. Fractal Fract. 2021, 5, 47. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Lin, Y.; Yang, H.; Tang, S.W. Comparison between the effects of phosphorous slag and fly ash on the C-S-H structure, long-term hydration heat and volume deformation of cement-based materials. Constr. Build. Mater. 2020, 250, 118807. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.; Guo, F.; Wang, Y.; Tang, S. Pore structural and fractal analysis of the influence of fly ash and silica fume on the mechanical property and abrasion resistance of concrete. Fractals 2021, 29, 2140003-1–2140003-18. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.; Tang, S. Comparison of fly ash, PVA fiber, MgO and shrinkage-reducing admixture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals 2021, 29, 2140002-1–2140002-18. [Google Scholar] [CrossRef]

- Wang, L.; Luo, R.; Zhang, W.; Jin, M.; Tang, S. Effects of fineness and content of phosphorus slag on cement hydration, permeability, pore structure and fractal dimension of concrete. Fractals 2021, 29, 2140004-1–2140004-18. [Google Scholar] [CrossRef]

- Yang, H.; Li, W.; Che, Y. 3D printing cementitious materials containing nano-CaCO3: Workability, strength, and microstructure. Front. Mater. 2020, 7, 1–15. [Google Scholar] [CrossRef]

- Lazniewska-Piekarczyk, B. The influence of anti-foaming agent on the properties of selfcompacting concrete. Cem. Wapno Beton 2010, 15, 164–168. [Google Scholar]

- Kim, J.-H.; Robertson, R.E. Prevention of air void formation in polymer-modified cement mortar by pre-wetting. Cem. Concr. Res. 1997, 27, 171–176. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Han, T.-S. Reconstruction of random two-phase polycrystalline solids using low-order probability functions and evaluation of mechanical behavior. Comput. Mater. Sci. 2010, 49, 705–719. [Google Scholar] [CrossRef]

- Roussel, N.; Ovarlez, G.; Garrault, S.; Brumaud, C. The origins of thixotropy of fresh cement pastes. Cem. Concr. Res. 2012, 42, 148–157. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhou, D.J.; Li, B.Y.; Huang, H.; Shi, C.J. Effect of mineral admixtures on the structural build-up of cement paste. Constr. Build. Mater. 2018, 160, 117–126. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Lootens, D.; Jousset, P.; Martinie, L.; Roussel, N.; Flatt, R.J. Yield stress during setting of cement pastes from penetration tests. Cem. Concr. Res. 2009, 39, 401–408. [Google Scholar] [CrossRef]

- Ostrowski, K.; Stefaniuk, D.; Sadowski, L.; Krzywinski, K.; Gicala, M.; Rozanska, M. Potential use of granite waste sourced from rock processing for the application as coarse aggregate in high-performance self-compacting concrete. Constr. Build. Mater. 2020, 238. [Google Scholar] [CrossRef]

- Ostrowski, K.; Sadowski, L.; Stefaniuk, D.; Walach, D.; Gawenda, T.; Oleksik, K.; Usydus, I. The effect of the morphology of coarse aggregate on the properties of self-compacting high-performance fibre-reinforced concrete. Materials 2018, 11, 1372. [Google Scholar] [CrossRef] [Green Version]

- Jayathilakage, R.; Rajeev, P.; Sanjayan, J.G. Yield stress criteria to assess the buildability of 3D concrete printing. Constr. Build. Mater. 2020, 240, 1–14. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef] [Green Version]

- Khalil, N.; Aouad, G.; El Cheikh, K.; Remond, S. Use of calcium sulfoaluminate cements for setting control of 3D-printing mortars. Constr. Build. Mater. 2017, 157, 382–391. [Google Scholar] [CrossRef]

- Weng, Y.W.; Li, M.Y.; Tan, M.J.; Qian, S.Z. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Constr. Build. Mater. 2018, 163, 600–610. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. 3D printable concrete: Mixture design and test methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Chen, M.X.; Yang, L.; Zheng, Y.; Huang, Y.B.; Li, L.B.; Zhao, P.Q.; Wang, S.D.; Lu, L.C.; Cheng, X. Yield stress and thixotropy control of 3D-printed calcium sulfoaluminate cement composites with metakaolin related to structural build-up. Constr. Build. Mater. 2020, 252, 1–9. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Jia, D. Effects of rheological performance, antifoaming admixture, and mixing procedure on air bubbles and strength of UHPC. J. Mater. Civil. Eng. 2019, 31, 1–11. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.M.; Wu, Y.H.; Zhou, Y.X.; Tang, S.W. Hydration, shrinkage, pore structure and fractal dimension of silica fume modified low heat Portland cement-based materials. Constr. Build. Mater. 2021, 272, 121952. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Lazniewska-Piekarczyk, B. The influence of admixtures type on the air-voids parameters of non-air-entrained and air-entrained high performance SCC. Constr. Build. Mater. 2013, 41, 109–124. [Google Scholar] [CrossRef]

- Lazniewska-Piekarczyk, B.; Szwabowski, J. Anti-foaming admixture (Afa) and tts influences on the properties of a fresh self-compacting concrete mix. J. Civ. Eng. Manag. 2012, 18, 151–157. [Google Scholar] [CrossRef]

- Feng, P.; Meng, X.; Chen, J.-F.; Ye, L. Mechanical properties of structures 3D printed with cementitious powders. Constr. Build. Mater. 2015, 93, 486–497. [Google Scholar] [CrossRef] [Green Version]

- Wyrzykowski, M.; Kiesewetter, R.; Muench, B.; Baumann, R.; Lura, P. Pore structure of mortars with cellulose ether additions—Study of the air-void structure. Cem. Concr. Compos. 2015, 62, 117–124. [Google Scholar] [CrossRef]

- Choi, P.; Yeon, J.H.; Yun, K.K. Air-void structure, strength, and permeability of wet-mix shotcrete before and after shotcreting operation: The influences of silica fume and air-entraining agent. Cem. Concr. Compos. 2016, 70, 69–77. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | CO2 | Na2O | K2O | TiO2 | P2O5 | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 18.46 | 4.29 | 3.50 | 64.24 | 1.74 | 3.05 | 2.72 | 0.24 | 0.60 | 0.35 | 0.25 | 0.28 |

| Mixture | PC (%) | LS (%) | NC (%) | AFA (%) | HRWRA (%) | HPMC (%) | Water to Binder Ratio | Binder to Sand Ratio |

|---|---|---|---|---|---|---|---|---|

| AFA0 | 90 | 10 | 1 | 0 | 0.06 | 0.1 | 0.40 | 0.50 |

| AFA005 | 90 | 10 | 1 | 0.05 | 0.06 | 0.1 | 0.40 | 0.50 |

| AFA01 | 90 | 10 | 1 | 0.1 | 0.06 | 0.1 | 0.40 | 0.50 |

| AFA05 | 90 | 10 | 1 | 0.5 | 0.06 | 0.1 | 0.40 | 0.50 |

| AFA1 | 90 | 10 | 1 | 1.0 | 0.06 | 0.1 | 0.40 | 0.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che, Y.; Tang, S.; Yang, H.; Li, W.; Shi, M. Influences of Air-Voids on the Performance of 3D Printing Cementitious Materials. Materials 2021, 14, 4438. https://doi.org/10.3390/ma14164438

Che Y, Tang S, Yang H, Li W, Shi M. Influences of Air-Voids on the Performance of 3D Printing Cementitious Materials. Materials. 2021; 14(16):4438. https://doi.org/10.3390/ma14164438

Chicago/Turabian StyleChe, Yujun, Shengwen Tang, Huashan Yang, Weiwei Li, and Mengyuan Shi. 2021. "Influences of Air-Voids on the Performance of 3D Printing Cementitious Materials" Materials 14, no. 16: 4438. https://doi.org/10.3390/ma14164438

APA StyleChe, Y., Tang, S., Yang, H., Li, W., & Shi, M. (2021). Influences of Air-Voids on the Performance of 3D Printing Cementitious Materials. Materials, 14(16), 4438. https://doi.org/10.3390/ma14164438