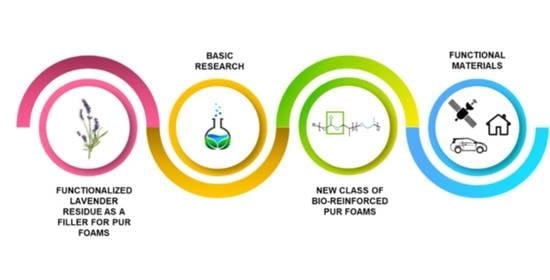

Polyurethane Hybrid Composites Reinforced with Lavender Residue Functionalized with Kaolinite and Hydroxyapatite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- Polyether polyol with a brand name of Stapanpol PS-2352 was purchased from Stepan Company (Northfield, IL, USA),

- Polymeric diphenylmethane diisocyanate with a brand name of Purocyn B was purchased from Purinova Company (Bydgoszcz, Poland).

- Potassium octoate with a brand name of Kosmos 75 and potassium acetate with a brand name of Kosmos 33 were purchased from Evonik Industry (Essen, Germany),

- Silicone-based surfactant with a brand name of Tegostab B8513 was purchased from Evonik Industry (Essen, Germany),

- Pentane, cyclopentane, sodium hydroxide (pellets, anhydrous), kaolinite (aluminum silicate, powder), hydroxyapatite (nanopowder, <200 nm) were purchased from Sigma-Aldrich Corporation (Saint Louis, MO, USA)

- Lavender residue was obtained from a local company (Lodz, Poland).

2.2. Methods and Instruments

2.3. Filler Functionalization and Production Process of PUR Composites

3. Results and Discussion

3.1. Filler Characterization

3.2. PUR Composites Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kurańska, M.; Beneš, H.; Sałasińska, K.; Prociak, A.; Malewska, E.; Polaczek, K. Development and Characterization of “Green Open-Cell Polyurethane Foams” with Reduced Flammability. Materials 2020, 13, 5459. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, R.; Barczewski, M.; Prociak, A.; Polaczek, K. Thermal Insulation and Sound Absorption Properties of Open-Cell Polyurethane Foams Modified with Bio-Polyol Based on Used Cooking Oil. Materials 2020, 13, 5673. [Google Scholar] [CrossRef]

- Kurańska, M.; Malewska, E.; Polaczek, K.; Prociak, A.; Kubacka, J. A Pathway toward a New Era of Open-Cell Polyurethane Foams—Influence of Bio-Polyols Derived from Used Cooking Oil on Foams Properties. Materials 2020, 13, 5161. [Google Scholar] [CrossRef] [PubMed]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane foams: Past, present, and future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [Green Version]

- Arévalo-Alquichire, S.; Valero, M. Castor Oil Polyurethanes as Biomaterials. In Elastomers; Çankaya, N., Ed.; InTech: Rijeka, Croatia, 2017. [Google Scholar]

- Engels, H.W.; Pirkl, H.G.; Albers, R.; Albach, R.W.; Krause, J.; Hoffmann, A.; Casselmann, H.; Dormish, J. Polyurethanes: Versatile materials and sustainable problem solvers for today’s challenges. Angew. Chemie Int. Ed. 2013, 52, 9422–9441. [Google Scholar] [CrossRef]

- Joshi, M.; Adak, B.; Butola, B.S. Polyurethane nanocomposite based gas barrier films, membranes and coatings: A review on synthesis, characterization and potential applications. Prog. Mater. Sci. 2018, 97, 230–282. [Google Scholar] [CrossRef]

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes; Rapra Technology: Shropshire, UK, 2005; ISBN 9781847350350. [Google Scholar]

- Wang, S.X.; Zhao, H.B.; Rao, W.H.; Huang, S.C.; Wang, T.; Liao, W.; Wang, Y.Z. Inherently flame-retardant rigid polyurethane foams with excellent thermal insulation and mechanical properties. Polymer 2018, 153, 616–625. [Google Scholar] [CrossRef]

- Zhang, G.; Lin, X.; Zhang, Q.; Jiang, K.; Chen, W.; Han, D. Anti-flammability, mechanical and thermal properties of bio-based rigid polyurethane foams with the addition of flame retardants. RSC Adv. 2020, 10, 32156–32161. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Application in Polymer Composite (part II). Materials 2020, 13, 2901. [Google Scholar] [CrossRef] [PubMed]

- Herrán, R.; Amalvy, J.I.; Chiacchiarelli, L.M. Highly functional lactic acid ring-opened soybean polyols applied to rigid polyurethane foams. J. Appl. Polym. Sci. 2019, 136, 1–13. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Barbu, M.C.; Sepperer, T.; Tudor, E.M.; Petutschnigg, A. Walnut and hazelnut shells: Untapped industrial resources and their suitability in lignocellulosic composites. Appl. Sci. 2020, 10, 6340. [Google Scholar] [CrossRef]

- Liszkowska, J.; Moraczewski, K.; Borowicz, M.; Paciorek-Sadowska, J.; Czupryński, B.; Isbrandt, M. The effect of accelerated aging conditions on the properties of rigid polyurethane-polyisocyanurate foams modified by cinnamon extract. Appl. Sci. 2019, 9, 2663. [Google Scholar] [CrossRef] [Green Version]

- Liszkowska, J.; Borowicz, M.; Paciorek-Sadowska, J.; Isbrandt, M.; Czupryński, B.; Moraczewski, K. Assessment of photodegradation and biodegradation of RPU/PIR foams modified by natural compounds of plant origin. Polymers 2020, 12, 33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, X.; Sethi, J.; Geng, S.; Berglund, L.; Frisk, N.; Aitomäki, Y.; Sain, M.M.; Oksman, K. Dispersion and reinforcing effect of carrot nanofibers on biopolyurethane foams. Mater. Des. 2016, 110, 526–531. [Google Scholar] [CrossRef]

- Paberza, A.; Cabulis, U.; Arshanitsa, A. Wheat straw lignin as filler for rigid polyurethane foams on the basis of tall oil amide. Polimery/Polymers 2014, 59, 477–481. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Ratiarisoa, R.V.; Magniont, C.; Ginestet, S.; Oms, C.; Escadeillas, G. Assessment of distilled lavender stalks as bioaggregate for building materials: Hygrothermal properties, mechanical performance and chemical interactions with mineral pozzolanic binder. Constr. Build. Mater. 2016, 124, 801–815. [Google Scholar] [CrossRef]

- Lesage-Meessen, L.; Bou, M.; Ginies, C.; Chevret, D.; Navarro, D.; Drula, E.; Bonnin, E.; Del Río, J.C.; Odinot, E.; Bisotto, A.; et al. Lavender- and lavandin-distilled straws: An untapped feedstock with great potential for the production of high-added value compounds and fungal enzymes. Biotechnol. Biofuels 2018, 11, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Lesage-Meessen, L.; Bou, M.; Sigoillot, J.C.; Faulds, C.B.; Lomascolo, A. Essential oils and distilled straws of lavender and lavandin: A review of current use and potential application in white biotechnology. Appl. Microbiol. Biotechnol. 2015, 99, 3375–3385. [Google Scholar] [CrossRef]

- Park, C.H.; Park, Y.E.; Yeo, H.J.; Chun, S.W.; Baskar, T.B.; Lim, S.S.; Park, S.U. Chemical compositions of the volatile oils and antibacterial screening of solvent extract from downy lavender. Foods 2019, 8, 132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Smigielski, K.; Prusinowska, R.; Stobiecka, A.; Kunicka-Styczyñska, A.; Gruska, R. Biological Properties and Chemical Composition of Essential Oils from Flowers and Aerial Parts of Lavender (Lavandula angustifolia). J. Essent. Oil-Bearing Plants 2018, 21, 1303–1314. [Google Scholar] [CrossRef]

- Rota, C.; Carramiñana, J.J.; Burillo, J.; Herrera, A. In vitro antimicrobial activity of essential oils from aromatic plants against selected foodborne pathogens. J. Food Prot. 2004, 67, 1252–1256. [Google Scholar] [CrossRef] [PubMed]

- Martucci, J.F.; Gende, L.B.; Neira, L.M.; Ruseckaite, R.A. Oregano and lavender essential oils as antioxidant and antimicrobial additives of biogenic gelatin films. Ind. Crops Prod. 2015, 71, 205–213. [Google Scholar] [CrossRef]

- Kaur, R.; Kumar, M. Addition of anti-flaming agents in castor oil based rigid polyurethane foams: Studies on mechanical and flammable behaviour. Mater. Res. Express 2020, 7, 015333. [Google Scholar] [CrossRef]

- Jiao, L.; Xiao, H.; Wang, Q.; Sun, J. Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym. Degrad. Stab. 2013, 98, 2687–2696. [Google Scholar] [CrossRef]

- Wrześniewska-Tosik, K.; Zajchowski, S.; Bryśkiewicz, A.; Ryszkowska, J. Feathers as a flame-retardant in elastic polyurethane foam. Fibres Text. East. Eur. 2014, 103, 119–128. [Google Scholar]

- Thirumal, M.; Khastgir, D.; Nando, G.B.; Naik, Y.P.; Singha, N.K. Halogen-free flame retardant PUF: Effect of melamine compounds on mechanical, thermal and flame retardant properties. Polym. Degrad. Stab. 2010, 95, 1138–1145. [Google Scholar] [CrossRef]

- Ye, L.; Meng, X.-Y.; Liu, X.-M.; Tang, J.-H.; Li, Z.-M. Flame-Retardant and Mechanical Properties of High-Density Rigid Polyurethane Foams Filled with Decabrominated Dipheny Ethane and Expandable Graphite. J. Appl. Polym. Sci. 2009, 111, 2373–2380. [Google Scholar] [CrossRef]

- Xu, W.; Wang, G.; Zheng, X. Research on highly flame-retardant rigid PU foams by combination of nanostructured additives and phosphorus flame retardants. Polym. Degrad. Stab. 2015, 111, 142–150. [Google Scholar] [CrossRef]

- Lindholm, J.; Brink, A.; Wilen, C.-E.; Hupa, M. Cone Calorimeter Study of Inorganic Salts as Flame Retardants in Polyurethane Adhesive with Limestone Filler. J. Appl. Polym. Sci. 2012, 123, 1793–1800. [Google Scholar] [CrossRef]

- Shi, L.; Li, Z.-M.; Xie, B.-H.; Wang, J.-H.; Tian, C.-R.; Yang, M.-B. Flame retardancy of different-sized expandable graphite particles for high-density rigid polyurethane foams. Polym. Int. 2006, 55, 862–871. [Google Scholar] [CrossRef]

- Fanglong, Z.; Qun, X.; Qianqian, F.; Rangtong, L.; Kejing, L. Influence of nano-silica on flame resistance behavior of intumescent flame retardant cellulosic textiles: Remarkable synergistic effect? Surf. Coatings Technol. 2016, 294, 90–94. [Google Scholar] [CrossRef]

- Zhao, P.; Guo, C.; Li, L. Exploring the effect of melamine pyrophosphate and aluminum hypophosphite on flame retardant wood flour/polypropylene composites. Constr. Build. Mater. 2018, 170, 193–199. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.Z. A review on flame retardant technology in China. Part I: Development of flame retardants. Polym. Adv. Technol. 2010, 21, 1–26. [Google Scholar] [CrossRef]

- Ai, L.; Chen, S.; Zeng, J.; Yang, L.; Liu, P. Synergistic Flame Retardant Effect of an Intumescent Flame Retardant Containing Boron and Magnesium Hydroxide. ACS Omega 2019, 4, 3314–3321. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Zhang, T.; Zou, B.; Hu, W.; Wang, B.; Zhan, J.; Ma, C.; Hu, Y. Synthesis of a novel liquid phosphorus-containing flame retardant for flexible polyurethane foam: Combustion behaviors and thermal properties. Polym. Degrad. Stab. 2020, 171, 109029. [Google Scholar] [CrossRef]

- Shehata, A.B.; Hassan, M.A.; Darwish, N.A. Kaolin modified with new resin-iron chelate as flame retardant system for polypropylene. J. Appl. Polym. Sci. 2004, 92, 3119–3125. [Google Scholar] [CrossRef]

- Murray, H.H. Traditional and new applications for kaolin, smectite, and palygorskite: A general overview. Appl. Clay Sci. 2000, 17, 207–221. [Google Scholar] [CrossRef]

- Batistella, M.; Otazaghine, B.; Sonnier, R.; Petter, C.; Lopez-Cuesta, J.M. Fire retardancy of polypropylene/kaolinite composites. Polym. Degrad. Stab. 2016, 129, 260–267. [Google Scholar] [CrossRef]

- Ansari, D.M.; Price, G.J. Correlation of mechanical properties of clay filled polyamide mouldings with chromatographically measured surface energies. Polymer 2004, 45, 3663–3670. [Google Scholar] [CrossRef] [Green Version]

- Vahabi, H.; Batistella, M.A.; Otazaghine, B.; Longuet, C.; Ferry, L.; Sonnier, R.; Lopez-Cuesta, J.M. Influence of a treated kaolinite on the thermal degradation and flame retardancy of poly(methyl methacrylate). Appl. Clay Sci. 2012, 70, 58–66. [Google Scholar] [CrossRef]

- Ullah, S.; Ahmad, F.; Shariff, A.M.; Bustam, M.A. Synergistic effects of kaolin clay on intumescent fire retardant coating composition for fire protection of structural steel substrate. Polym. Degrad. Stab. 2014, 110, 91–103. [Google Scholar] [CrossRef]

- Nabipour, H.; Wang, X.; Song, L.; Hu, Y. A fully bio-based coating made from alginate, chitosan and hydroxyapatite for protecting flexible polyurethane foam from fire. Carbohydr. Polym. 2020, 246, 116641. [Google Scholar] [CrossRef]

- Guo, W.; Liu, J.; Zhang, P.; Song, L.; Wang, X.; Hu, Y. Multi-functional hydroxyapatite/polyvinyl alcohol composite aerogels with self-cleaning, superior fire resistance and low thermal conductivity. Compos. Sci. Technol. 2018, 158, 128–136. [Google Scholar] [CrossRef]

- Guo, W.; Wang, X.; Zhang, P.; Liu, J.; Song, L.; Hu, Y. Nano-fibrillated cellulose-hydroxyapatite based composite foams with excellent fire resistance. Carbohydr. Polym. 2018, 195, 71–78. [Google Scholar] [CrossRef]

- Khalili, P.; Liu, X.; Zhao, Z.; Blinzler, B. Fully biodegradable composites: Thermal, flammability, moisture absorption and mechanical properties of Natural fibre-reinforced composites with nano-hydroxyapatite. Materials 2019, 12, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Heim, H.P.; Feldmann, M. Effects of surface modification on dispersion, mechanical, thermal and dynamic mechanical properties of injection molded PLA-hydroxyapatite composites. Compos. Part A Appl. Sci. Manuf. 2017, 103, 96–105. [Google Scholar]

- Behera, K.; Sivanjineyulu, V.; Chang, Y.H.; Chiu, F.C. Thermal properties, phase morphology and stability of biodegradable PLA/PBSL/HAp composites. Polym. Degrad. Stab. 2018, 154, 248–260. [Google Scholar]

- Członka, S.; Strakowska, A.; Pospiech, P.; Strzelec, K. Effects of chemically treated eucalyptus fibers on mechanical, thermal and insulating properties of polyurethane composite foams. Materials 2020, 13, 1781. [Google Scholar] [CrossRef] [Green Version]

- Cao, X.; James Lee, L.; Widya, T.; Macosko, C. Polyurethane/clay nanocomposites foams: Processing, structure and properties. Polymer 2005, 46, 775–783. [Google Scholar] [CrossRef]

- Lee, L.J.; Zeng, C.; Cao, X.; Han, X.; Shen, J.; Xu, G. Polymer nanocomposite foams. Compos. Sci. Technol. 2005, 65, 2344–2363. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

- Barczewski, M.; Kurańska, M.; Sałasińska, K.; Michałowski, S.; Prociak, A.; Uram, K.; Lewandowski, K. Rigid polyurethane foams modified with thermoset polyester-glass fiber composite waste. Polym. Test. 2020, 81, 106190. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid polyurethane foams reinforced with industrial potato protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M.; Czupryński, B.; Apiecionek, Ł. The use of waste from the production of rapeseed oil for obtaining of new polyurethane composites. Polymers 2019, 11, 1431. [Google Scholar] [CrossRef] [Green Version]

- Cichosz, S.; Masek, A. Thermal Behavior of Green Cellulose-Filled Thermoplastic Elastomer Polymer Blends. Molecules 2020, 25, 1279. [Google Scholar] [CrossRef] [Green Version]

- Cichosz; Masek Cellulose Fibers Hydrophobization via a Hybrid Chemical Modification. Polymers 2019, 11, 1174. [CrossRef] [Green Version]

- Cichosz, S.; Masek, A.; Rylski, A. Cellulose Modification for Improved Compatibility with the Polymer Matrix: Mechanical Characterization of the Composite Material. Materials 2020, 13, 5519. [Google Scholar] [CrossRef]

- Tian, H.; Wu, J.; Xiang, A. Polyether polyol-based rigid polyurethane foams reinforced with soy protein fillers. J. Vinyl Addit. Technol. 2018, 24, E105–E111. [Google Scholar] [CrossRef]

- Mizera, K.; Ryszkowska, J.; Kurańska, M.; Prociak, A. The effect of rapeseed oil-based polyols on the thermal and mechanical properties of ureaurethane elastomers. Polym. Bull. 2020, 77, 823–846. [Google Scholar] [CrossRef] [Green Version]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer 2020, 190, 1–7. [Google Scholar] [CrossRef]

- Luo, X.; Xiao, Y.; Wu, Q.; Zeng, J. Development of high-performance biodegradable rigid polyurethane foams using all bioresource-based polyols: Lignin and soy oil-derived polyols. Int. J. Biol. Macromol. 2018, 115, 786–791. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Xu, C. Preparation of bio-based rigid polyurethane foam using hydrolytically depolymerized Kraft lignin via direct replacement or oxypropylation. Eur. Polym. J. 2015, 68, 1–9. [Google Scholar] [CrossRef]

- Gómez-Fernández, S.; Ugarte, L.; Calvo-Correas, T.; Peña-Rodríguez, C.; Corcuera, M.A.; Eceiza, A. Properties of flexible polyurethane foams containing isocyanate functionalized kraft lignin. Ind. Crops Prod. 2017, 100, 51–64. [Google Scholar] [CrossRef]

- Mosiewicki, M.A.; Dell’Arciprete, G.A.; Aranguren, M.I.; Marcovich, N.E. Polyurethane foams obtained from castor oil-based polyol and filled with wood flour. J. Compos. Mater. 2009, 43, 3057–3072. [Google Scholar] [CrossRef]

- Finlay, K.A.; Gawryla, M.D.; Schiraldi, D.A. Effects of fiber reinforcement on clay aerogel composites. Materials 2015, 8, 5440–5451. [Google Scholar] [CrossRef] [Green Version]

- Federation of European Rigid Polyurethane Foam Associations. Thermal Insulation Materials Made of Rigid Polyurethane Foam (PUR/PIR) Properties-Manufacture; European Rigid Polyurethane Foam Associations: Brussels, Belgium, 2006; Available online: http://highperformanceinsulation.eu/wpcontent/uploads/2016/08/Thermal_insulation_materials_made_of_rigid_polyurethane_foam.pdf (accessed on 14 January 2020).

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Gloc, M.; Kulesza, M.; Kowalski, M.; Krauze, S.; Lewandowska, M. Flammability, mechanical properties and structure of rigid polyurethane foams with different types of carbon reinforcing materials. Compos. Struct. 2016, 140, 67–76. [Google Scholar] [CrossRef]

- Gu, R.; Konar, S.; Sain, M. Preparation and characterization of sustainable polyurethane foams from soybean oils. J. Am. Oil Chem. Soc. 2012, 89, 2103–2111. [Google Scholar] [CrossRef]

- Holešová, S.; Hundáková, M.; Pazdziora, E. Antibacterial Kaolinite Based Nanocomposites. Procedia Mater. Sci. 2016, 12, 124–129. [Google Scholar] [CrossRef] [Green Version]

- Seyedmajidi, S.; Rajabnia, R.; Seyedmajidi, M. Evaluation of antibacterial properties of hydroxyapatite/bioactive glass and fluorapatite/bioactive glass nanocomposite foams as a cellular scaffold of bone tissue. J. Lab. Physicians 2018, 10, 265–270. [Google Scholar] [CrossRef] [PubMed]

- Vega, O.; Araya, J.J.; Chavarría, M.; Castellón, E. Antibacterial biocomposite materials based on essential oils embedded in sol–gel hybrid silica matrices. J. Sol-Gel Sci. Technol. 2016, 79, 584–595. [Google Scholar] [CrossRef]

- Aranberri, I.; Montes, S.; Wesołowska, E.; Rekondo, A.; Wrześniewska-Tosik, K.; Grande, H.-J. Improved Thermal Insulating Properties of Renewable Polyol Based Polyurethane Foams Reinforced with Chicken Feathers. Polymers 2019, 11, 2002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; El Bouari, A. Mechanical and thermal conductivity properties of hemp fiber reinforced polyurethane composites. Case Stud. Constr. Mater. 2018, 8, 203–212. [Google Scholar] [CrossRef]

- de Avila Delucis, R.; Magalhães, W.L.E.; Petzhold, C.L.; Amico, S.C. Forest-based resources as fillers in biobased polyurethane foams. J. Appl. Polym. Sci. 2018, 135, 1–7. [Google Scholar] [CrossRef]

- Joanna, P.S.; Bogusław, C.; Joanna, L. Application of waste products from agricultural-food industry for production of rigid polyurethane-polyisocyanurate foams. J. Porous Mater. 2011, 18, 631–638. [Google Scholar] [CrossRef] [Green Version]

- Saada, A.; Siffert, B.; Papirer, E. Comparison of the hydrophilicity/hydrophobicity of illites and kaolinites. J. Colloid Interface Sci. 1995, 174, 185–190. [Google Scholar] [CrossRef]

- Bouiahya, K.; Oulguidoum, A.; Laghzizil, A.; Shalabi, M.; Nunzi, J.M. Hydrophobic chemical surface functionalization of hydroxyapatite nanoparticles for naphthalene removal. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 595, 124706. [Google Scholar] [CrossRef]

- Wolski, K.; Cichosz, S.; Masek, A. Surface hydrophobisation of lignocellulosic waste for the preparation of biothermoelastoplastic composites. Eur. Polym. J. 2019, 118, 481–491. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, H.; Wang, X.; Li, S.; Zhou, Y.; Zhang, F.; Wang, Y.; Qu, W.; Wang, D.; Pang, X. Effects of flame-retardant ramie fiber on enhancing performance of the rigid polyurethane foams. Polym. Adv. Technol. 2019, 30, 3091–3098. [Google Scholar] [CrossRef]

| Component | PUR_REF | PUR_L | PUR_L_K | PUR_L_HA |

|---|---|---|---|---|

| Parts by Weight (wt.%) | ||||

| STEPANPOL PS-2352 | 100 | 100 | 100 | 100 |

| PUROCYN B | 160 | 160 | 160 | 160 |

| Kosmos 75 | 6 | 6 | 6 | 6 |

| Kosmos 33 | 0.8 | 0.8 | 0.8 | 0.8 |

| Tegostab B8513 | 2.5 | 2.5 | 2.5 | 2.5 |

| Water | 0.5 | 0.5 | 0.5 | 0.5 |

| Pentane/cyclopentane | 11 | 11 | 11 | 11 |

| Lavender non-functionalized | 0 | 2 | 0 | 0 |

| Lavender functionalized with Kaolinite (K) | 0 | 0 | 2 | 0 |

| Lavender functionalized with Hydroxyapatite (HA) | 0 | 0 | 0 | 2 |

| PUR_REF | PUR_L | PUR_L_K | PUR_L_HA | |

|---|---|---|---|---|

| Dynamic viscosity at 10 rpm (mPa·s) | 860 ± 7 | 1215 ± 9 | 1015 ± 8 | 1050 ± 6 |

| Cream time (s) | 40 ± 4 | 56 ± 2 | 49 ± 2 | 48 ± 3 |

| Expansion time (s) | 268 ± 3 | 335 ± 8 | 315 ± 6 | 310 ± 4 |

| Tack-free time (s) | 345 ± 5 | 330 ± 9 | 310 ± 7 | 315 ± 8 |

| Cell size (µm) | 485 ± 6 | 470 ± 5 | 450 ± 6 | 455 ± 7 |

| Closed-cell content (%) | 87.2 ± 0.7 | 85.4 ± 0.5 | 87.9 ± 0.6 | 88.2 ± 0.4 |

| Apparent density (kg m−3) | 36.8 ± 0.8 | 37.4 ± 0.7 | 38.9 ± 0.5 | 38.6 ± 0.5 |

| Sample | Tmax (°C) | Residue (at 600 °C) (wt.%) | ||

|---|---|---|---|---|

| 1st Stage | 2nd Stage | 3rd Stage | ||

| PUR_REF | 220 | 322 | 580 | 28.0 |

| PUR_L | 222 | 325 | 585 | 30.0 |

| PUR_L_K | 220 | 334 | 590 | 33.1 |

| PUR_L_HA | 235 | 335 | 592 | 35.2 |

| Sample | Bacteria | Fungi | |||

|---|---|---|---|---|---|

| E. coli | S. aureus | B. subtilis | C. albicans | A. niger | |

| PUR_REF | − | − | − | − | − |

| PUR_L | + | + | + | − | - |

| PUR_L_K | + | + | + | - | - |

| PUR_L_HA | + | + | + | - | - |

| Sample | IT (s) | pHRR (kW m−2) | TSR (m2 m−2) | THR (MJ m−2) | COY (kg kg−1) | CO2Y (kg kg−1) | COY/CO2Y (−) | LOI (%) |

|---|---|---|---|---|---|---|---|---|

| PUR_REF | 4 | 263 | 1500 | 21.5 | 0.210 | 0.240 | 0.875 | 20.2 |

| PUR_L | 4 | 203 | 1400 | 21.1 | 0.190 | 0.225 | 0.844 | 20.5 |

| PUR_L_K | 6 | 144 | 1060 | 20.5 | 0.140 | 0.190 | 0.736 | 22.2 |

| PUR_L_HA | 6 | 130 | 1055 | 19.8 | 0.142 | 0.180 | 0.788 | 22.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Członka, S.; Kairytė, A.; Miedzińska, K.; Strąkowska, A. Polyurethane Hybrid Composites Reinforced with Lavender Residue Functionalized with Kaolinite and Hydroxyapatite. Materials 2021, 14, 415. https://doi.org/10.3390/ma14020415

Członka S, Kairytė A, Miedzińska K, Strąkowska A. Polyurethane Hybrid Composites Reinforced with Lavender Residue Functionalized with Kaolinite and Hydroxyapatite. Materials. 2021; 14(2):415. https://doi.org/10.3390/ma14020415

Chicago/Turabian StyleCzłonka, Sylwia, Agnė Kairytė, Karolina Miedzińska, and Anna Strąkowska. 2021. "Polyurethane Hybrid Composites Reinforced with Lavender Residue Functionalized with Kaolinite and Hydroxyapatite" Materials 14, no. 2: 415. https://doi.org/10.3390/ma14020415

APA StyleCzłonka, S., Kairytė, A., Miedzińska, K., & Strąkowska, A. (2021). Polyurethane Hybrid Composites Reinforced with Lavender Residue Functionalized with Kaolinite and Hydroxyapatite. Materials, 14(2), 415. https://doi.org/10.3390/ma14020415