Correlation between Cutting Clearance, Deformation Texture, and Magnetic Loss Prediction in Non-Oriented Electrical Steels

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure

3.2. Texture and Local Misorientation Profile

3.3. Nano Indentation Measurements

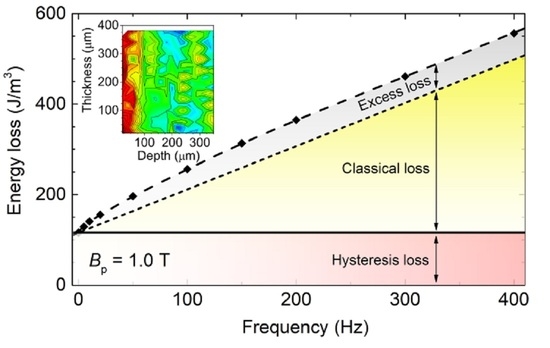

3.4. Analysis of Magnetic Loss

4. Conclusions

- The energy loss response of the non-oriented Fe-Si electrical steels can be favourably affected by lower cutting clearance and subsequent annealing.

- Fine-grained microstructure near the cutting edge is the most important structural parameter responsible for increasing magnetic loss with higher cutting clearance.

- The excess loss is found as the most sensitive loss component to cutting clearance and its magneto-structural correlation is quantified by uniform distribution of local pinning fields in non-annealed steels which evolves to non-uniform distribution after annealing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moses, A.J. Energy efficient electrical steels: Magnetic performance prediction and optimization. Scr. Mater. 2012, 67, 560–565. [Google Scholar] [CrossRef]

- Chatterjee, S.; Bhattacharjee, D.; Gope, N. Variation in structure and magnetic properties during decarb-annealing of electrical steel. Scr. Mater. 2003, 49, 355–360. [Google Scholar] [CrossRef]

- Jiao, H.; Xu, Y.; Xiong, W.; Zhang, Y.; Cao, G.; Li, C.; Niu, J.; Misra, R. High-permeability and thin-gauge non-oriented electrical steel through twin-roll strip casting. Mater. Des. 2017, 136, 23–33. [Google Scholar] [CrossRef]

- Plotkowski, A.; Carver, K.; List, F.; Pries, J.; Li, Z.; Rossy, A.M.; Leonard, D. Design and performance of an additively manufactured high-Si transformer core. Mater. Des. 2020, 194, 108894. [Google Scholar] [CrossRef]

- Bian, X.; Zeng, Y.; Nan, D.; Wu, M. The effect of copper precipitates on the recrystallization textures and magnetic properties of non-oriented electrical steels. J. Alloys Compd. 2014, 588, 108–113. [Google Scholar] [CrossRef]

- Sidor, Y.; Kovac, F.; Kvačkaj, T.; Sidor, J. Grain growth phenomena and heat transport in non-oriented electrical steels. Acta Mater. 2007, 55, 1711–1722. [Google Scholar] [CrossRef]

- Lee, H.; Park, J.-T. Effect of Cut-Edge Residual Stress on Magnetic Properties in Non-Oriented Electrical Steel. IEEE Trans. Magn. 2018, 55, 2000804. [Google Scholar] [CrossRef]

- Lewis, N.; Anderson, P.; Hall, J.; Gao, Y. Power Loss Models in Punched Non-Oriented Electrical Steel Rings. IEEE Trans. Magn. 2016, 52, 7300704. [Google Scholar] [CrossRef] [Green Version]

- Loisos, G.; Moses, A.J. Effect of mechanical and Nd:YAG laser cutting on magnetic flux distribution near the cut edge of non-oriented steels. J. Mater. Process. Technol. 2005, 161, 151–155. [Google Scholar] [CrossRef]

- Emura, M.; Landgraf, F.; Ross, W.; Barreta, J. The influence of cutting technique on the magnetic properties of electrical steels. J. Magn. Magn. Mater. 2003, 254, 358–360. [Google Scholar] [CrossRef]

- Paltanea, G.; Manescu, V.; Gavrila, H.; Peter, I.; Popovici, D. Magnetic property analysis in non-oriented silicon iron steels cut through water jet technology. In Proceedings of the 2016 International Symposium on Fundamentals of Electrical Engineering (ISFEE), Bucharest, Romania, 30 June–2 July 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Hofmann, M.; Naumoski, H.; Herr, U.; Herzog, H.-G. Magnetic Properties of Electrical Steel Sheets in Respect of Cutting: Micromagnetic Analysis and Macromagnetic Modeling. IEEE Trans. Magn. 2016, 52, 2000114. [Google Scholar] [CrossRef]

- Saleem, A.; Alatawneh, N.; Rahman, T.; Lowther, D.A.; Chromik, R.R. Effects of Laser Cutting on Microstructure and Magnetic Properties of Non-Orientation Electrical Steel Laminations. IEEE Trans. Magn. 2020, 56, 6100609. [Google Scholar] [CrossRef]

- Paltanea, G.; Paltanea, V.M.; Stefanoiu, R.; Nemoianu, I.V.; Gavrila, H. Correlation between Magnetic Properties and Chemical Composition of Non-Oriented Electrical Steels Cut through Different Technologies. Materials 2020, 13, 1455. [Google Scholar] [CrossRef] [Green Version]

- Paolinelli, S.C.; da Cunha, M.A. Development of a new generation of high permeability non-oriented silicon steels. J. Magn. Magn. Mater. 2006, 304, e596–e598. [Google Scholar] [CrossRef]

- Alves, E.M.M.; Silveira, C.C.; da Cunha, M.A. Influence of stress relief annealing temperature on the cutting edge microstructure and on the recovery of magnetic properties of grain oriented electrical steel. Mater. Charact. 2020, 166, 110408. [Google Scholar] [CrossRef]

- Alatawneh, N.; Saleem, A.; Rahman, T.; Lowther, D.A.; Chromik, R. Modelling and analysis of the effects of cutting of core laminations in electric machines. IET Electr. Power Appl. 2020, 14, 2355–2361. [Google Scholar] [CrossRef]

- Bayraktar, Ş.; Turgut, Y. Effects of different cutting methods for electrical steel sheets on performance of induction motors. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 1287–1294. [Google Scholar] [CrossRef]

- Dems, M.; Komeza, K.; Kubiak, W.; Szulakowski, J. Impact of Core Sheet Cutting Method on Parameters of Induction Motors. Energies 2020, 13, 1960. [Google Scholar] [CrossRef]

- Taupin, E.; Breitling, J.; Wu, W.-T.; Altan, T. Material fracture and burr formation in blanking results of FEM simulations and comparison with experiments. J. Mater. Process. Technol. 1996, 59, 68–78. [Google Scholar] [CrossRef]

- Weiss, H.A.; Trober, P.; Golle, R.; Steentjes, S.; Leuning, N.; Hameyer, K.; Volk, W. Loss reduction due to blanking parameter optimization for different non-grain oriented electrical steel grades. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Baudouin, P.; De Wulf, M.; Kestens, L.; Houbaert, Y. The effect of the guillotine clearance on the magnetic properties of electrical steels. J. Magn. Magn. Mater. 2003, 256, 32–40. [Google Scholar] [CrossRef]

- Subramonian, S.; Altan, T.; Ciocirlan, B.; Campbell, C. Optimum selection of variable punch-die clearance to improve tool life in blanking non-symmetric shapes. Int. J. Mach. Tools Manuf. 2013, 75, 63–71. [Google Scholar] [CrossRef]

- Cao, H.; Hao, L.; Yi, J.; Zhang, X.; Luo, Z.; Chen, S.; Li, R. The influence of punching process on residual stress and magnetic domain structure of non-oriented silicon steel. J. Magn. Magn. Mater. 2016, 406, 42–47. [Google Scholar] [CrossRef]

- Weiss, H.; Leuning, N.; Steentjes, S.; Hameyer, K.; Andorfer, T.; Jenner, S.; Volk, W. Influence of shear cutting parameters on the electromagnetic properties of non-oriented electrical steel sheets. J. Magn. Magn. Mater. 2017, 421, 250–259. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Cui, R.; Wang, X.; Wang, B. Influence of Grain Size and Blanking Clearance on Magnetic Properties Deterioration of Non-Oriented Electrical Steel. IEEE Trans. Magn. 2018, 54, 2000607. [Google Scholar] [CrossRef]

- Hambli, R. Prediction of burr height formation in blanking processes using neural network. Int. J. Mech. Sci. 2002, 44, 2089–2102. [Google Scholar] [CrossRef]

- He, J.; Wang, Z.; Li, S.; Dong, L.; Cao, X.; Zhang, W. Optimum clearance determination in blanking coarse-grained non-oriented electrical steel sheets: Experiment and simulation. Int. J. Mater. Form. 2018, 12, 575–586. [Google Scholar] [CrossRef]

- Walton, W.H. Feret’s Statistical Diameter as a Measure of Particle Size. Nat. Cell Biol. 1948, 162, 329–330. [Google Scholar] [CrossRef]

- Comité Européen de Normalisation (CEN). Cold Rolled Non-Oriented Electrical Steel Strip and Sheet Delivered in the Fully Processed States; STN EN 10106; CEN: Brussels, Belgium, 2006. [Google Scholar]

- Cotterill, P.; Mould, P.R. Recrystallization and Grain Growth in Metals, 1st ed.; Surrey University Press: London, UK, 1976; pp. 266–300. [Google Scholar]

- Gontarz, S.; Szulim, P.; Patyk, R.; Bohdal, L. Multiparameter Modeling and Analysis of Mechanical Cutting Process of Grain-Oriented Silicon Steel. IEEE Magn. Lett. 2021, 12, 2503405. [Google Scholar] [CrossRef]

- Bertotti, G. Hysteresis in Magnetism; Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Nunes, C.D.S.; Neto, A.S.; Miranda, V.A.Q.; de Matos, L.C.S.; Favarato, L.N.O.; Rocco, D.L. Influence of the cutting process, heat treatment, and maximum magnetic induction on the magnetic properties of highly oriented electrical steels. J. Magn. Magn. Mater. 2021, 537, 168211. [Google Scholar] [CrossRef]

- Silverman, D.; Soni, A. Neutrino oscillations: A review. AIP Conf. Proc. 1982, 81, 496–521. [Google Scholar] [CrossRef]

- Barbisio, E.; Fiorillo, F.; Ragusa, C.S. Predicting Loss in Magnetic Steels Under Arbitrary Induction Waveform and With Minor Hysteresis Loops. IEEE Trans. Magn. 2004, 40, 1810–1819. [Google Scholar] [CrossRef] [Green Version]

- Landgraf, F.; Ragusa, C.; Rodrigues, D.L.; Dias, M.; de la Barrière, O.; Mazaleyrat, F.; Fiorillo, F.; Appino, C.; Martino, L. Loss decomposition in plastically deformed and partially annealed steel sheets. J. Magn. Magn. Mater. 2020, 502, 166452. [Google Scholar] [CrossRef]

- Zhao, H.; Ragusa, C.S.; Appino, C.; De La Barriere, O.; Wang, Y.; Fiorillo, F. Energy Losses in Soft Magnetic Materials Under Symmetric and Asymmetric Induction Waveforms. IEEE Trans. Power Electron. 2019, 34, 2655–2665. [Google Scholar] [CrossRef]

- Zhao, H.; Ragusa, C.S.; De La Barriere, O.; Khan, M.; Appino, C.; Fiorillo, F. Magnetic Loss Versus Frequency in Non-Oriented Steel Sheets and Its Prediction: Minor Loops, PWM, and the Limits of the Analytical Approach. IEEE Trans. Magn. 2017, 53, 2003804. [Google Scholar] [CrossRef] [Green Version]

- Ferrara, E.; Fiorillo, F.; Beatrice, C.; Dobák, S.; Ragusa, C.S.; Magni, A.; Appino, C. Characterization and assessment of the wideband magnetic properties of nanocrystalline alloys and soft ferrites. J. Mater. Res. 2018, 33, 2120–2137. [Google Scholar] [CrossRef]

- Fiorillo, F.; Ferrara, E.; Coisson, M.; Beatrice, C.; Banu, N. Magnetic properties of soft ferrites and amorphous ribbons up to radiofrequencies. J. Magn. Magn. Mater. 2010, 322, 1497–1504. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Füzer, J.; Dobák, S.; Petryshynets, I.; Kollár, P.; Kováč, F.; Slota, J. Correlation between Cutting Clearance, Deformation Texture, and Magnetic Loss Prediction in Non-Oriented Electrical Steels. Materials 2021, 14, 6893. https://doi.org/10.3390/ma14226893

Füzer J, Dobák S, Petryshynets I, Kollár P, Kováč F, Slota J. Correlation between Cutting Clearance, Deformation Texture, and Magnetic Loss Prediction in Non-Oriented Electrical Steels. Materials. 2021; 14(22):6893. https://doi.org/10.3390/ma14226893

Chicago/Turabian StyleFüzer, Ján, Samuel Dobák, Ivan Petryshynets, Peter Kollár, František Kováč, and Ján Slota. 2021. "Correlation between Cutting Clearance, Deformation Texture, and Magnetic Loss Prediction in Non-Oriented Electrical Steels" Materials 14, no. 22: 6893. https://doi.org/10.3390/ma14226893

APA StyleFüzer, J., Dobák, S., Petryshynets, I., Kollár, P., Kováč, F., & Slota, J. (2021). Correlation between Cutting Clearance, Deformation Texture, and Magnetic Loss Prediction in Non-Oriented Electrical Steels. Materials, 14(22), 6893. https://doi.org/10.3390/ma14226893