The Analysis of Erosive Wear Resistance of WC-Co Carbides Obtained by Spark Plasma Sintering Method

Abstract

:1. Introduction

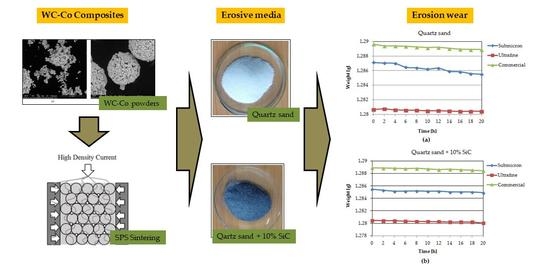

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- The erosive wear results confirm previous data obtained related to wear.

- The surface topography after the conducted tests indicates clear destructive effects of the applied media.

- Medium 1, i.e., quartz sand, is characterised by higher weight losses in the sintered samples, which indicates that it is more aggressive.

- The addition of 10% SiC in medium 2 resulted in the appearance of areas of pronounced plastic deformation, indicating collision sites between the hard phases (SiC and WC). This state of affairs indicates that the soft matrix (Co) takes over part of the destructive energy, counteracting the erosion phenomena.

- The soft Co matrix, as a result of contact with relatively soft particles of quartz sand, is destroyed and eroded hard WC particles are chipped off. This is due to the fact that sand particles degrade after impact, and the finest fragments penetrate the intermolecular spaces of the tested sinters.

- The analysis of the available literature indicates a significant lack of knowledge in the area of erosive wear phenomena for carbide composites. The study of erosive wear is a preliminary study aimed at understanding the phenomena accompanying the erosive wear of sintered carbides produced by the two methods. An important aspect of these studies is the connection between wear and manufacturing conditions.

- It is necessary to extend the study of erosive wear in the future, in order to develop a model of erosive wear of sintered materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, M.; Wang, J.; He, R.; Yang, H.; Ruan, J. Effect of cobalt content on the microstructure and mechanical properties of coarse grained WC-Co cemented carbides fabricated from chemically coated composite powder. J. Alloys Compd. 2018, 766, 556–563. [Google Scholar] [CrossRef]

- Huang, S.G.; Vanmeensel, K.; Li, L.; Van der Biest, O.; Vleugels, J. Influence of starting powder on the microstructure of WC–Co hardmetals obtained by spark plasma sintering. Mater. Sci. Eng. A 2008, 475, 87–91. [Google Scholar] [CrossRef]

- Qian, Y.; Zhao, Z. Microstructure and Properties of Ultrafine Cemented Carbides Prepared by Microwave Sintering of Nanocomposites. Crystals 2020, 10, 507. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, J.; Wang, B.; Wang, Y. Two-Step Spark Plasma Sintering Process of Ultrafine Grained WC-12Co-0.2VC Cemented Carbide. Materials 2019, 12, 2443. [Google Scholar] [CrossRef] [Green Version]

- Wohaibi, S.A.; Mohammed, A.S.; Laoui, T.; Hakeem, A.S.; Adesina, A.Y.; Patel, F. Tribological Characterization of Micron-/Nano-Sized WC-9%Co Cemented Carbides Prepared by Spark Plasma Sintering at Elevated Temperatures. Materials 2019, 12, 920. [Google Scholar] [CrossRef] [Green Version]

- Aleksandrov Fabijanić, T.; Jakovljević, S.; Franz, M.; Jeren, I. Influence of Grain Growth Inhibitors and Powder Size on the Properties of Ultrafine and Nanostructured Cemented Carbides Sintered in Hydrogen. Metals 2016, 6, 198. [Google Scholar] [CrossRef] [Green Version]

- Yin, C.; Peng, Y.; Ruan, J.; Zhao, L.; Zhang, R.; Du, Y. Influence of Cr3C2 and VC Content on WC Grain Size, WC Shape and Mechanical Properties of WC–6.0 wt. % Co Cemented Carbides. Materials 2021, 14, 1551. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Wang, Z.; Yin, Z.; Yuan, J.; Jia, J. Preparation and properties of the VC/Cr3C2/TaC doped ultrafine WC-Co tool material by spark plasma sintering. J. Alloys Compd. 2020, 816, 152598. [Google Scholar] [CrossRef]

- Rumman, R.; Chuan, L.C.; Quinton, J.S.; Ghomashchi, R. Mechanical properties and microstructural behaviour of microwave sintered WC–Co. Met. Mater. Int. 2020, 26, 844–853. [Google Scholar] [CrossRef]

- Mariani, M.; Goncharov, I.; Mariani, D.; De Gaudenzi, G.P.; Popovich, A.; Lecis, N.; Vedani, M. Mechanical and microstructural characterization of WC-Co consolidated by binder jetting additive manufacturing. Int. J. Refract. Met. Hard Mater. 2021, 100, 105639. [Google Scholar] [CrossRef]

- Siwak, P.; Garbiec, D. Microstructure and mechanical properties of WC–Co, WC–Co–Cr3C2 and WC–Co–TaC cermets fabricated by spark plasma sintering. Trans. Nonferr. Met. Soc. 2016, 26, 2641–2646. [Google Scholar] [CrossRef]

- Bagci, M.; Imrek, H. Application of Taguchi method on optimization of testing parameters for erosion of glass fiber reinforced epoxy composite materials. Mater. Design 2013, 46, 706–712. [Google Scholar] [CrossRef]

- Anderson, K.; Karimi, S.; Shirazi, S. Erosion testing and modeling of several non-metallic materials. Wear 2021, 477, 203811. [Google Scholar] [CrossRef]

- Faga, M.G.; Settineri, L. Innovative anti-wear coatings on cutting tools for wood machining. Surf. Coat. Technol. 2006, 201, 3002–3007. [Google Scholar] [CrossRef]

- Gutmanas, E.Y. Materials with fine microstructures by advanced powder metallurgy. Prog. Mater. Sci. 1990, 34, 261–366. [Google Scholar] [CrossRef]

- Tsutsui, T. Recent technology of powder metallurgy and applications. Hitachi Chem. Tech. Rep. 2012, 54, 12–20. [Google Scholar]

- Martins, V.; Rodrigues, W.C.; Ferrandini, P.L.; Villarinho, D.J.; Knörnschild, G.H.; Schaeffer, L. Comparative studies of WC-Co and WC-Co-Ni composites obtained by conventional powder metallurgy. Mater. Res. 2011, 14, 274–279. [Google Scholar] [CrossRef] [Green Version]

- McCandlish, L.E.; Kear, B.H.; Kim, B.K. Processing and properties of nanostructured WC-Co. ACS Sym. Ser. 1992, 1, 119–124. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, Y.W.; Jang, K.M.; Lee, J.W.; Park, M.-S.; Koo, H.Y.; Ha, G.-H.; Kang, Y.C. Phase control of WC–Co hardmetal using additive manufacturing technologies. Powder Metall. 2021, 1–9. [Google Scholar] [CrossRef]

- Balbino, N.A.N.; Correa, E.O.; de Carvalho Valeriano, L.; Amâncio, D.A. Microstructure and mechanical properties of 90WC-8Ni-2Mo2C cemented carbide developed by conventional powder metallurgy. Int. J. Refract. Met. Hard Mater. 2017, 68, 49–53. [Google Scholar] [CrossRef]

- Tokita, M. Progress of Spark Plasma Sintering (SPS) Method, Systems, Ceramics Applications and Industrialization. Ceramics 2021, 4, 14. [Google Scholar] [CrossRef]

- Bram, M.; Laptev, A.M.; Mishra, T.P.; Nur, K.; Kindelmann, M.; Ihrig, M.; Da Silva, J.G.P.; Steinert, R.; Buchkremer, H.P.; Litnovsky, A.; et al. Application of Electric Current-Assisted Sintering Techniques for the Processing of Advanced Materials. Adv. Eng. Mater. 2020, 22, 2000051. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; Olevsky, E.A. All-materials-inclusive flash spark plasma sintering. Sci. Rep. 2017, 7, 15071. [Google Scholar] [CrossRef] [PubMed]

- Weston, N.S.; Thomas, B.; Jackson, M. Processing metal powders via field assisted sintering technology (FAST): A critical review. Mater. Sci. Technol. Ser. 2019, 35, 1306–1328. [Google Scholar] [CrossRef]

- Chaim, R.; Chevallier, G.; Weibel, A.; Estournès, C. Grain growth during spark plasma and flash sintering of ceramic nanoparticles: A review. J. Mater. Sci. 2018, 53, 3087–3105. [Google Scholar] [CrossRef] [Green Version]

- Nayebi, B.; Asl, M.S.; Akhlaghi, M.; Ahmadi, Z.; Tayebifard, S.A.; Salahi, E.; Mohammadi, M. Spark plasma sintering of TiB2-based ceramics with Ti3AlC2. Ceram. Int. 2021, 47, 11929–11934. [Google Scholar] [CrossRef]

- Wachowicz, J.; Truszkowski, T.; Rosiński, M.; Ossowski, M.; Skrabalak, G.; Cyrankowski, M. Tribological Properties of WCCo/cBNComposites Produced by Pulse Plasma Sintering. Arch. Metall. Mater. 2018, 63, 1763. [Google Scholar]

- Zarębski, K.; Putyra, P.; Mierzwiński, D. Porosity and Microstructure Iron-Based Graded Materials Sintered by Spark Plasma Sintering and the Conventional Method. Metals 2019, 9, 264. [Google Scholar] [CrossRef] [Green Version]

- Tokita, M. Mechanism of Spark Plasma Sintering (SPS). In Proceedings of the PM2000 Powder MetallurgyWorld Congress, Kyoto, Japan, 12–16 November 2001; Part-I. pp. 252–255. [Google Scholar]

- Omori, M. Sintering consolidation, reaction and crystal growth by the spark plasma system (SPS). Mater. Sci. Eng. 2000, 287, 183–188. [Google Scholar] [CrossRef]

- Chaim, R. Densification mechanisms in spark plasma sintering of nanocrystalline ceramics. Mater. Sci. Eng. 2007, 443, 25–32. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, Z.F.; Lu, J.F.; Shen, X.B.; Wang, F.C.; Wang, Y.D. The sintering mechanism in spark plasma sintering–Proof of the occurrence of spark discharge. Scr. Mater. 2014, 81, 56–59. [Google Scholar] [CrossRef]

- Groza, J.R.; Zavaliangos, A. Sintering activation by external electrical field. Mater. Sci. Eng. 2000, 287, 171–177. [Google Scholar]

- Wachowicz, J.; Dembiczak, T.; Stradomski, G.; Bałaga, Z.; Dyner, M.; Wilkowski, J. Properties of WCCo Composites Produced by the SPS Method Intended for Cutting Tools for Machining of Wood-Based Materials. Materials 2021, 14, 2618. [Google Scholar] [CrossRef]

- Blicharski, M. Inżynieria Powierzchni; Wydawnictwo Naukowo Techniczne: Warszawa, Poland, 2012. [Google Scholar]

- Stradomski, G.; Wróbel, A.; Szarek, A.; Dyja, H. The analysis of tribological and erosive properties of sintered material on the base of X2CRNI18-9 steel made with various techniques. In Proceedings of the 25th Anniversary International Conference on Metallurgy and Materials, Brno, Czech Republic, 25–27 May 2016; pp. 641–646. [Google Scholar]

- Antonov, M.; Pirso, J.; Vallikivi, A.; Goljandin, D.; Hussainova, I. The effectof fine erodent retained on the surface during erosion of metals, ceramics, plastic, rubber and hardmetal. Wear 2016, 354–355, 53–68. [Google Scholar] [CrossRef]

- Antonov, M.; Hussainova, I. Cermets surface transformation under erosive and abrasive wear. Tribol. Int. 2010, 43, 1566–1575. [Google Scholar] [CrossRef]

- Kumara, R.; Antonov, M.; Besteb, U.; Goljandin, D. Assessment of 3D printed steels and composites intended for wear applications in abrasive, dry or slurry erosive conditions. Int. J. Refract. Met. Hard Mater. 2020, 86, 105126. [Google Scholar] [CrossRef]

- Javaheri, V.; Oskari Haiko, O.; Sadeghpour, S.; Valtonen, K.; Komi, J.; Porter, D. On the role of grain size on slurry erosion behavior of a novel medium-carbon, low-alloy pipeline steel after induction hardening. Wear 2021, 476, 203678. [Google Scholar] [CrossRef]

| Sample | Materials Composition | Processing Conditions | Relative Densities (100%) | Hardness HV30 | Mean Fracture Toughness KIC (MPam1/2) |

|---|---|---|---|---|---|

| Submicron | WC-6Co | SPS 1170 °C | 99.26 | 1736 ± 38 | 11.3 |

| Ultrafine | WC-4.5Co | SPS 1170 °C | 99.99 | 1622 ± 40 | 12.5 |

| Commercial | WC-4.5Co | Unknown | 100.0 | 1705 ± 40 | 26.6 |

| Sample | Geometrical Structure Parameters [μm] | ||||||

|---|---|---|---|---|---|---|---|

| Sa | Sz | Sv | Sp | Sku | Ssk | Sq | |

| Submicron | 1.02 | 11.61 | 3.62 | 7.99 | 2.29 | −0.06 | 1.17 |

| Ultrafine | 0.81 | 7.03 | 3.03 | 7.99 | 2.29 | −0.06 | 1.17 |

| Commercial | 0.69 | 7.41 | 4.02 | 3.39 | 3.31 | −0.87 | 0.88 |

| Sample | Geometrical Structure Parameters [μm] | ||||||

|---|---|---|---|---|---|---|---|

| Sa | Sz | Sv | Sp | Sku | Ssk | Sq | |

| Submicron | 3.36 | 27.93 | 23.91 | 3.02 | 1.18 | −0.04 | 1.85 |

| Ultrafine | 1.62 | 11.75 | 5.62 | 6.13 | 4.86 | −0.11 | 5.72 |

| Commercial | 2.02 | 14.07 | 7.73 | 6.34 | 1.22 | −0.76 | 2.17 |

| Sample | Geometrical Structure Parameters [μm] | ||||||

|---|---|---|---|---|---|---|---|

| Sa | Sz | Sv | Sp | Sku | Ssk | Sq | |

| Submicron | 1.81 | 15.02 | 6.13 | 8.89 | 1.97 | −0.15 | 2.13 |

| Ultrafine | 2.05 | 12.03 | 5.68 | 6.35 | 1.99 | −0.35 | 2.38 |

| Commercial | 1.66 | 11.86 | 7.01 | 4.85 | 2.46 | −0.38 | 0.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wachowicz, J.; Dembiczak, T.; Stradomski, G.; Bałaga, Z.; Jasińska, J.; Rydz, D.; Wilkowski, J.; Dyner, M. The Analysis of Erosive Wear Resistance of WC-Co Carbides Obtained by Spark Plasma Sintering Method. Materials 2021, 14, 7326. https://doi.org/10.3390/ma14237326

Wachowicz J, Dembiczak T, Stradomski G, Bałaga Z, Jasińska J, Rydz D, Wilkowski J, Dyner M. The Analysis of Erosive Wear Resistance of WC-Co Carbides Obtained by Spark Plasma Sintering Method. Materials. 2021; 14(23):7326. https://doi.org/10.3390/ma14237326

Chicago/Turabian StyleWachowicz, Joanna, Tomasz Dembiczak, Grzegorz Stradomski, Zbigniew Bałaga, Joanna Jasińska, Dariusz Rydz, Jacek Wilkowski, and Marcin Dyner. 2021. "The Analysis of Erosive Wear Resistance of WC-Co Carbides Obtained by Spark Plasma Sintering Method" Materials 14, no. 23: 7326. https://doi.org/10.3390/ma14237326

APA StyleWachowicz, J., Dembiczak, T., Stradomski, G., Bałaga, Z., Jasińska, J., Rydz, D., Wilkowski, J., & Dyner, M. (2021). The Analysis of Erosive Wear Resistance of WC-Co Carbides Obtained by Spark Plasma Sintering Method. Materials, 14(23), 7326. https://doi.org/10.3390/ma14237326