Fabrication and Characterization of Steel-Base Metal Matrix Composites Reinforced by Yttria Nanoparticles through Friction Stir Processing

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

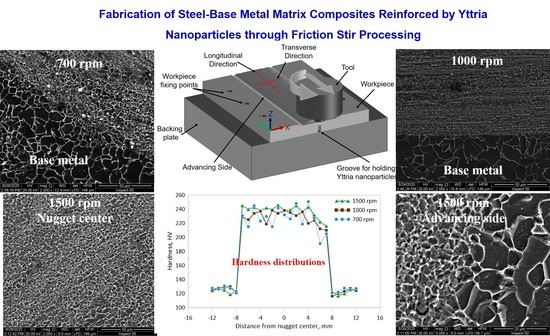

3.1. General Features of the Stir Zone

3.2. Microscopic Investigation of the Stir Zones after the First Pass

3.3. Microscopic Investigation of the Stir Zones after Second Passes

3.4. Hardness Measurements

3.5. Mechanical Properties

3.6. Impact Toughness

4. Conclusions

- Metal matrix composite composed of steel matrix and reinforced with yttria nano-sized particles was successfully fabricated through friction stir processing, at rotational speeds of more than 700 rpm. At a rotation speed of 500 rpm, the tool acted as a driller and destroyed the processed zone.

- After the first pass, the distributions of the yttria nano-sized particles were concentrated on the advancing side and the nugget centers. Some defect-like cracks appeared on the retreating side, especially at a lower rotation speed.

- The yttria nano-sized particles were distributed as narrow elliptical bands, and their band pitches were equal to the rotation speed (rpm) over traveling speed (mm/min).

- The application of the second pass, in the opposite direction of the first pass, improved the dispersion of the yttria nano-sized particles in the nugget zone, especially at higher rotation speeds. The added particles were distributed homogeneously throughout the nugget zone without any noticeable defects at the rotational speed of 1500 rpm.

- The grain size of the steel matrix was reduced to less than 2 μm after the application of double FSP passes by the effect of FSP severe plastic deformation and the pinning effect of the added particles. There was very narrow heat affect zone.

- After two passes, the hardness values of the FSPed zones were approximately twice that of the steel base metal in all the used rotational speeds. The distributions of the hardness values within the nugget zone were uniform, especially at higher rotation speeds.

- The fabricated composites’ tensile strength was significantly improved compared to the base metal, especially at a rotation speed of more than 700 rpm, while the results showed a reduction in elongation.

- The Charpy impact toughness values of the fabricated composites were almost half that of the base metal.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- El-Bitar, T.; Gamil, M.; Mousa, I.; Helmy, F. Development of carbon-Low alloy steel grades for low temperature applications. Mater. Sci. Eng. A 2011, 528, 6039–6044. [Google Scholar] [CrossRef]

- Xie, Z.J.; Shang, C.J.; Wang, X.L.; Wang, X.M.; Han, G. Recent progress in third-generation low alloy steels developed under M3 microstructure control. Int. J. Miner. Metall. Mater. 2020, 27, 515–525. [Google Scholar] [CrossRef]

- Kusmanov, S.A.; Smirnov, A.A.; Silkin, S.A.; Belkin, P.N. Increasing wear and corrosion resistance of low-alloy steel by anode plasma electrolytic nitriding. Surf. Coat. Technol. 2016, 307, 1350–1356. [Google Scholar] [CrossRef]

- Commisso, M.S.; Le Bourlot, C.; Bonnet, F.; Zanelatto, O.; Maire, E. Thermo-mechanical characterization of steel-based metal matrix composite reinforced with TiB2 particles using synchrotron X-ray diffraction. Materialia 2019, 6, 100311. [Google Scholar] [CrossRef] [Green Version]

- Sung, B.; Rawlings, M.J.S.; Dunand, D.C. Effect of aging on coarsening- and creep resistance of a Ti-modified Fe–Ni–Al–Cr–Mo ferritic steel with L21/B2 composite precipitates. Mater. Sci. Eng. A 2020, 776, 138987. [Google Scholar] [CrossRef]

- Yu, W.H.; Sing, S.L.; Chua, C.K.; Kuo, C.N.; Tian, X.L. Particle-reinforced metal matrix nanocomposites fabricated by selective laser melting: A state of the art review. Prog. Mater. Sci. 2019, 104, 330–379. [Google Scholar] [CrossRef]

- Sharma, A.S.; Yadav, S.; Biswas, K.; Basu, B. High-entropy alloys and metallic nanocomposites: Processing challenges, microstructure development and property enhancement. Mater. Sci. Eng. R 2018, 131, 1–42. [Google Scholar] [CrossRef]

- Olejnik, E.; Szymański, Ł.; Tokarski, T.; Opitek, B.; Kurtyka, P. Local composite reinforcements of TiC/FeMn type obtained in situ in steel castings. Arch. Civ. Mech. Eng. 2019, 19, 997–1005. [Google Scholar] [CrossRef]

- Yadav, P.; Ranjan, A.; Kumar, H.; Mishra, A.; Yoon, J. A Contemporary Review of Aluminium MMC Developed through Stir-Casting Route. Materials 2021, 14, 6386. [Google Scholar] [CrossRef] [PubMed]

- Babu, J.; Srinivasan, A.; Kang, C.G. Nano and macromechanical properties of aluminium (A356) based hybrid composites reinforced with multiwall carbon nanotubes/alumina fiber. J. Compos. Mater. 2016, 51, 1631–1642. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites. Ceram. Int. 2018, 44, 20599–20612. [Google Scholar] [CrossRef]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting—Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- Dinaharan, I.; Murugan, N.; Thangarasu, A. Development of empirical relationships for prediction of mechanical and wear properties of AA6082 aluminum matrix composites produced using friction stir processing. Eng. Sci. Technol. Int. J. 2016, 19, 1132–1144. [Google Scholar] [CrossRef] [Green Version]

- Sekban, D.M.; Aktarer, S.M.; Xue, P.; Ma, Z.Y.; Purcek, G. Impact toughness of friction stir processed low carbon steel used in shipbuilding. Mater. Sci. Eng. A 2016, 672, 40–48. [Google Scholar] [CrossRef]

- Moustafa, E.B. Dynamic Characteristics Study for Surface Composite of AMMNCs Matrix Fabricated by Friction Stir Process. Materials 2018, 11, 1240. [Google Scholar] [CrossRef] [Green Version]

- Węglowski, M.S. Friction stir processing—State of the art. Arch. Civ. Mech. Eng. 2018, 18, 114–129. [Google Scholar] [CrossRef]

- Aktarer, S.M.; Sekban, D.M.; Saray, O.; Kucukomeroglu, T.; Ma, Z.Y.; Purcek, G. Effect of two-pass friction stir processing on the microstructure and mechanical properties of as-cast binary Al–12Si alloy. Mater. Sci. Eng. A 2015, 636, 311–319. [Google Scholar] [CrossRef]

- Azimi-Roeen, G.; Kashani-Bozorg, S.F.; Nosko, M.; Orovcik, L.; Lotfian, S. Effect of multi-pass friction stir processing on textural evolution and grain boundary structure of Al–Fe3O4 system. J. Mater. Res. Technol. 2020, 9, 1070–1086. [Google Scholar] [CrossRef]

- Lakshminarayanan, A.K.; Ramachandran, C.S.; Balasubramanian, V. Feasibility of surface-coated friction stir welding tools to join AISI 304 grade austenitic stainless steel. Def. Technol. 2014, 10, 360–370. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, M.; Kumar, K.; Mishra, R.S. Friction stir lap welded advanced high strength steels: Microstructure and mechanical properties. Mater. Sci. Eng. A 2011, 528, 8111–8119. [Google Scholar] [CrossRef]

- Cheng, C.; Kadoi, K.; Tokita, S.; Fujii, H.; Ushioda, K.; Inoue, H. Effects of carbon and chromium on microstructure evolution and mechanical properties of friction stir weldment in medium-carbon steel. Mater. Sci. Eng. A 2019, 762, 138060. [Google Scholar] [CrossRef]

- Ghasemi-kahrizsangi, A.; Kashani-Bozorg, S.F.; Moshref-Javadi, M. Effect of friction stir processing on the tribological performance of Steel/Al2O3 nanocomposites. Surf. Coat. Technol. 2015, 276, 507–515. [Google Scholar] [CrossRef]

- Mahmoud, E.R.I.; Ikeuchi, K.; Takahashi, M. Fabrication of SiC particle reinforced composite on aluminium surface by friction stir processing. Sci. Technol. Weld. Join. 2008, 13, 607–618. [Google Scholar] [CrossRef]

- Kumar, H.; Khan, M.Z.; Vashista, M. Microstructure, mechanical and electrical characterization of zirconia reinforced copper based surface composite by friction stir processing. Mater. Res. Express 2018, 5, 86505. [Google Scholar] [CrossRef]

- Kumar, H.; Vashista, M.; Yusufzai, M.Z.K. Microstructure and Wear Behavior of Zircon Reinforced Copper Based Surface Composite Synthesized by Friction Stir Processing Route. Trans. Indian Inst. Met. 2018, 71, 2025–2033. [Google Scholar] [CrossRef]

- Prakash, J.; Khan, S.; Chauhan, S.; Biradar, A.M. Metal oxide-nanoparticles and liquid crystal composites: A review of recent progress. J. Mol. Liq. 2020, 297, 112052. [Google Scholar] [CrossRef]

- Lei, P.; Dai, B.; Zhu, J.; Chen, X.; Liu, G.; Zhu, Y.; Han, J. Controllable phase formation and physical properties of yttrium oxide films governed by substrate heating and bias voltage. Ceram. Int. 2015, 41, 8921–8930. [Google Scholar] [CrossRef]

- Kanyane, L.R.; Gandazha, K.; Fayomi, O.S.I.; Popoola, A.P.I. Microstructural evolution and mechanical properties of Zn-Ni composite coating with Y2O3 as a dopant. Procedia Manuf. 2019, 35, 814–819. [Google Scholar] [CrossRef]

- Bouaeshi, W.B.; Li, D.Y. Effects of Y2O3 addition on microstructure, mechanical properties, electrochemical behavior, and resistance to corrosive wear of aluminum. Tribol. Int. 2007, 40, 188–199. [Google Scholar] [CrossRef]

- Kim, G.; Hong, S.; Lee, M.; Kim, S.; Ioka, I.; Kim, B.; Kim, I. Effect of Oxide Dispersion on Dendritic Grain Growth Characteristics of Cast Aluminum Alloy. Mater. Trans. 2010, 51, 1951–1957. [Google Scholar] [CrossRef] [Green Version]

- Kumar, J.R.; Jayaraman, M.; Kumar, T.S.; Priyadharshini, G.S.; Kumar, J.S. Characterization of Y2O3 particles reinforced AA6082 aluminum matrix composites produced using friction stir processing. Mater. Res. Express 2019, 6, 86509. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater. Des. 2008, 29, 362–373. [Google Scholar] [CrossRef]

- Avila, J.A.; Giorjao, R.A.; Rodriguez, J.; Fonseca, E.B.; Ramirez, A.J. Modeling of thermal cycles and microstructural analysis of pipeline steels processed by friction stir processing. Int. J. Adv. Manuf. Technol. 2018, 98, 2611–2618. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.S.; Murugan, N.; Ramachandran, K.K. Effect of tool tilt angle on weld joint properties of friction stir welded AISI 316L stainless steel sheets. Measurement 2020, 150, 107083. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, A.; Kashani-Bozorg, S.F. Microstructure and mechanical properties of steel/TiC nano-composite surface layer produced by friction stir processing. Surf. Coat. Technol. 2012, 209, 15–22. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Review: Friction stir welding tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Selvakumar, S.; Dinaharan, I.; Palanivel, R.; Babu, B.G. Development of stainless steel particulate reinforced AA6082 aluminum matrix composites with enhanced ductility using friction stir processing. Mater. Sci. Eng. A 2017, 685, 317–326. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Chen, T.J.; Qin, Y.H. Effects of solution treatment on tensile properties and strengthening mechanisms of SiCp/6061Al composites fabricated by powder thixoforming. Mater. Des. 2016, 99, 182–192. [Google Scholar] [CrossRef]

- Wang, J.; Shen, Y.; Xue, W.Y.; Jia, N. The significant impact of introducing nanosize precipitates and decreased effective grain size on retention of high toughness of simulated heat affected zone (HAZ). Mater. Sci. Eng. A 2020, 803, 140484. [Google Scholar] [CrossRef]

- Boostani, A.F.; Tahamtan, S.; Jiang, Z.Y.; Wei, D.; Yazdani, S.; Khosroshahi, R.A.; Mousavian, R.T.; Xu, J.; Zhang, X.; Gong, D. Enhanced tensile properties of aluminium matrix composites reinforced with graphene encapsulated SiC nanoparticles. Compos. A Appl. Sci. Manuf. 2015, 68, 155–163. [Google Scholar] [CrossRef] [Green Version]

- Khodabakhshi, F.; Gerlich, A.P.; Švecc, P. Fabrication of a high strength ultra-fine grained Al-Mg-SiC nanocomposite by multi-step friction-stir processing. Mater. Sci. Eng. A 2017, 698, 313–325. [Google Scholar] [CrossRef]

- Du, Z.; Tan, M.J.; Guo, J.F.; Bi, G.; Wei, J. Fabrication of a new Al-Al2O3-CNTs composite using friction stir processing (FSP). Mater. Sci. Eng. A 2016, 667, 125–131. [Google Scholar] [CrossRef]

- Zhanga, Z.; Yanga, R.; Guob, Y.; Chena, G.; Leia, Y.; Ye, Y.; Yue, Y. Microstructural evolution and mechanical properties of ZrB2/6061Al nanocomposites processed by multi-pass friction stir processing. Mater. Sci. Eng. A 2017, 689, 411–418. [Google Scholar] [CrossRef]

- Wu, H.; Huang, S.; Zhu, C.; Zhu, H.; Xie, Z. Influence of Cr content on the microstructure and mechanical properties of CrxFeNiCu high entropy alloys. Prog. Nat. Sci. Mater. Int. 2020, 30, 239–245. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Sanusi, K.O. Microstructural characteristics, mechanical and wear behaviour of aluminium matrix hybrid composites reinforced with alumina, rice husk ash and graphite. Eng. Sci. Technol. Int. J. 2015, 18, 416–422. [Google Scholar] [CrossRef] [Green Version]

- AlMangour, B.; Kim, Y.K.; Grzesiak, D.; Lee, K. Novel TiB2-reinforced 316L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos. B Eng. 2019, 156, 51–63. [Google Scholar] [CrossRef]

- Fatile, B.O.; Adewuyi, B.O.; Owoyemi, H.T. Synthesis and characterization of ZA-27 alloy matrix composites reinforced with zinc oxide nanoparticles. Eng. Sci. Technol. Int. J. 2017, 20, 1147–1154. [Google Scholar] [CrossRef]

- Kareem, A.; Abu Qudeiri, J.; Abdudeen, A.; Thanveer Ahammed, T.; Ziout, A. A Review on AA 6061 Metal Matrix Composites Produced by Stir Casting. Materials 2021, 14, 175. [Google Scholar] [CrossRef]

- Ali, K.S.A.; Mohanavel, V.; Vendan, S.A.; Ravichandran, M.; Yadav, A.; Gucwa, M.; Winczek, J. Mechanical and Microstructural Characterization of Friction Stir Welded SiC and B4C Reinforced Aluminium Alloy AA6061 Metal Matrix Composites. Materials 2021, 14, 3110. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Fajemisin, A.V. Evaluation of the damping behaviour of Al-Mg-Si alloy based composites reinforced with steel, steel and graphite, and silicon carbide particulates. Eng. Sci. Technol. Int. J. 2018, 21, 798–805. [Google Scholar] [CrossRef]

- Ozden, S.; Ekici, R.; Nair, F. Investigation of impact behaviour of aluminium based SiC particle reinforced metal–matrix composites. Compos. Appl. Sci. Manuf. 2007, 38, 484–494. [Google Scholar] [CrossRef]

| Chemical Compositions (Wt. %) | Hardness, HV0.2N | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Fe | |

| 0.08 | 0.26 | 0.33 | 0.02 | 0.01 | Bal. | 124 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmoud, E.R.I.; Almohamadi, H.; Aljabri, A.; Khan, S.Z.; Saquib, A.N.; Farhan, M.; Elkotb, M.A.-G. Fabrication and Characterization of Steel-Base Metal Matrix Composites Reinforced by Yttria Nanoparticles through Friction Stir Processing. Materials 2021, 14, 7611. https://doi.org/10.3390/ma14247611

Mahmoud ERI, Almohamadi H, Aljabri A, Khan SZ, Saquib AN, Farhan M, Elkotb MA-G. Fabrication and Characterization of Steel-Base Metal Matrix Composites Reinforced by Yttria Nanoparticles through Friction Stir Processing. Materials. 2021; 14(24):7611. https://doi.org/10.3390/ma14247611

Chicago/Turabian StyleMahmoud, Essam R. I., Hamad Almohamadi, Abdulrahman Aljabri, Sohaib Z. Khan, Ahmad N. Saquib, Mohammed Farhan, and Mohammed Abdel-Ghani Elkotb. 2021. "Fabrication and Characterization of Steel-Base Metal Matrix Composites Reinforced by Yttria Nanoparticles through Friction Stir Processing" Materials 14, no. 24: 7611. https://doi.org/10.3390/ma14247611

APA StyleMahmoud, E. R. I., Almohamadi, H., Aljabri, A., Khan, S. Z., Saquib, A. N., Farhan, M., & Elkotb, M. A. -G. (2021). Fabrication and Characterization of Steel-Base Metal Matrix Composites Reinforced by Yttria Nanoparticles through Friction Stir Processing. Materials, 14(24), 7611. https://doi.org/10.3390/ma14247611