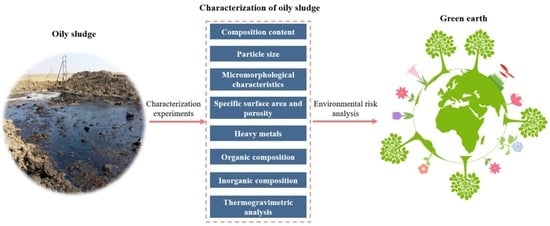

Environmental Risk Analysis Based on Characterization of Ground Oily Sludge

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Experimental Methods

2.2. Data Analysis Method

3. Results and Discussion

3.1. Density, Oil Content, Water Content and Solid Content of Oily Sludge

3.2. Particle Size Distribution of Oily Sludge

3.3. Micromorphological Characteristics, Specific Surface Area and Porosity of Oily Sludge

3.4. Contents of Heavy Metals in Oily Sludge

3.5. Analysis of Organic Compounds in Oily Sludge

3.6. Analysis of Inorganic Compounds in Oily Sludge

3.7. Thermogravimetric Analysis of Oily Sludge

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Retention Time (min) | Products | Molecular Formulas | Relative Peak Areas (%) | Categories | CAS |

|---|---|---|---|---|---|

| 1.179 | Sulfur dioxide | O2S | 0.23 | Other | 007446-09-5 |

| 1.248 | Carbon disulfide | CS2 | 0.09 | Other | 000075-15-0 |

| 1.277 | Thiourea | CH4N2S | 0.09 | Other | 000062-56-6 |

| 1.416 | 3-Chlorohexane | C6H13Cl | 0.15 | Other | 002346-81-8 |

| 1.514 | 2-cyclopropyl-Pentane | C8H16 | 0.06 | Alkanes | 005458-16-2 |

| 1.583 | 1-Heptene | C7H14 | 0.06 | Olefin | 000592-76-7 |

| 10.39 | 1-Tridecene | C13H26 | 0.17 | Olefin | 002437-56-1 |

| 10.448 | 1-Tetradecene | C14H28 | 0.16 | Olefin | 001120-36-1 |

| 10.581 | Tridecane | C13H28 | 0.27 | Alkanes | 000629-50-5 |

| 12.764 | 2-Tetradecene, (E)- | C14H28 | 0.32 | Olefin | 035953-53-8 |

| 12.908 | Tetradecane | C14H30 | 0.29 | Alkanes | 000629-59-4 |

| 13.33 | 2,6-dimethyl-Naphthalene | C12H12 | 0.11 | Aromatics | 000581-42-0 |

| 13.844 | 2-hexyl-1-Decanol | C16H34O | 0.08 | Other | 2425-77-6 |

| 13.919 | Decane, 2-methyl- | C11H24 | 0.18 | Alkanes | 006975-98-0 |

| 14.052 | 2-Buten-1-one, 1-(2,6,6-trimethyl-3-cyclohexen-1-yl)- | C13H20O | 0.09 | Ester | 041436-42-4 |

| 14.358 | 1-Pentadecene | C15H30 | 0.28 | Olefin | 013360-61-7 |

| 14.456 | Pentadecane | C15H32 | 0.3 | Alkanes | 000629-62-9 |

| 15.092 | Naphthalene, 1,6,7-trimethyl- | C13H14 | 0.05 | Aromatics | 002245-38-7 |

| 15.178 | Magnesium, bis(acetylacetonate) | C10H14MgO4.2(H2O) | 0.1 | Other | 068488-07-3 |

| 15.536 | 2-Tetradecene, (E)- | C14H28 | 0.33 | Olefin | 035953-53-8 |

| 15.606 | Hexadecane | C16H34 | 0.3 | Alkanes | 000544-76-3 |

| 16.091 | Pentadecane, 2,6,10-trimethyl- | C18H38 | 0.22 | Alkanes | 003892-00-0 |

| 16.172 | 3-Methyl-4-(methoxycarbonyl)hexa-2,4-dienoic acid | C9H12O4 | 0.12 | Ester | 1000104-10-8 |

| 16.224 | 4-n-Hexylthiane | C11H22S | 0.13 | Other | 070928-52-8 |

| 16.345 | 4-n-Hexylthiane | C11H22S | 0.22 | Other | 070928-52-8 |

| 16.403 | 4-n-Hexylthiane | C11H22S | 0.11 | Other | 070928-52-8 |

| 16.495 | 1-Heptadecene | C17H34 | 0.11 | Olefin | 006765-39-5 |

| 16.558 | Heptadecane | C17H36 | 0.43 | Alkanes | 000629-78-7 |

| 16.605 | Pentadecane, 2,6,10,14-tetramethyl | C19H40 | 0.39 | Alkanes | 001921-70-6 |

| 16.639 | .beta.-iso-Methyl ionone | C14H22O | 0.18 | Ketone | 1000285-40-2 |

| 16.882 | 4-n-Hexylthiane | C11H22S | 0.15 | Other | 070928-52-8 |

| 17.09 | Silane, dichlorocyclohexylmethyl- | C7H14Cl2Si | 0.28 | Other | 005578-42-7 |

| 17.286 | Cyclopentane, 1-butyl-2-pentyl- | C14H28 | 0.29 | Alkanes | 061142-52-7 |

| 17.332 | 1-Octadecene | C18H36 | 0.43 | Olefin | 000112-88-9 |

| 17.384 | Octadecane | C18H38 | 0.61 | Alkanes | 000593-45-3 |

| 17.459 | Hexadecane, 2,6,10,14-tetramethyl- | C20H42 | 0.5 | Alkanes | 000638-36-8 |

| 17.65 | 3-Eicosene, (E)- | C20H40 | 0.43 | Olefin | 074685-33-9 |

| 17.76 | Cyclohexanebutanoic acid, 2,2-dimethyl-6-methylene-, methyl ester | C14H24O2 | 0.32 | Ester | 095452-15-6 |

| 17.852 | 1H-Indene, 5-butyl-6-hexyloctahydro | C19H36 | 0.45 | Alkanes | 055044-36-5 |

| 17.904 | 2-Butanone, 4-(2,2,6-trimethylcyclohexyl)- | C13H24O | 0.19 | Ketone | 006138-85-8 |

| 18.002 | Cyclohexene, 4-(4-ethylcyclohexyl)-1-pentyl- | C19H34 | 0.002 | Alkanes | 301643-32-3 |

| 18.083 | 1-Nonadecene | C19H38 | 0.81 | Olefin | 018435-45-5 |

| 18.129 | Heptadecane | C17H36 | 0.56 | Alkanes | 000629-78-7 |

| 18.176 | 8-Hexadecyne | C16H30 | 0.3 | Other | 019781-86-3 |

| 18.228 | 1H-Indene, 2-butyl-5-hexyloctahydro- | C19H36 | 0.23 | Alkanes | 055044-33-2 |

| 18.297 | 1-Octadecene | C18H36 | 0.41 | Olefin | 000112-88-9 |

| 18.337 | 11,13-Dimethyl-12-tetradecen-1-olacetate | C18H34O2 | 0.36 | Ester | 1000130-81-0 |

| 18.47 | Phenanthrene, 4-methyl- | C15H12 | 0.39 | Aromatics | 000832-64-4 |

| 18.511 | Phenanthrene, 1-methyl- | C15H12 | 0.34 | Aromatics | 000832-69-9 |

| 18.563 | 2-Dodecen-1-yl(-)succinic anhydrid | C16H26O3 | 0.35 | Other | 019780-11-1 |

| 18.643 | Cyclohexane, 1-(1,5-dimethylhexyl)-4-(4-methylpentyl)- | C20H40 | 0.27 | Other | 056009-20-2 |

| 18.707 | 2-Eicosanol, (.+/−.)- | C20H42O | 0.42 | Other | 4340-76-5 |

| 18.776 | 1-Nonadecene | C19H38 | 0.76 | Olefin | 018435-45-5 |

| 18.817 | Eicosane | C20H42 | 0.67 | Alkanes | 000112-95-8 |

| 18.949 | Cyclotetradecane, 1,7,11-trimethyl | C20H40 | 0.55 | Alkanes | 001786-12-5 |

| 19.082 | 11,13-Dimethyl-12-tetradecen-1-olacetate | C18H34O2 | 0.38 | Ester | 1000130-81-0 |

| 19.209 | 11,13-Dimethyl-12-tetradecen-1-olacetate | C18H34O2 | 0.39 | Ester | 1000130-81-0 |

| 19.25 | Phenanthrene, 3,6-dimethyl- | C16H14 | 0.35 | Aromatics | 001576-67-6 |

| 19.325 | Oxirane, hexadecyl- | C18H36O | 0.81 | Other | 007390-81-0 |

| 19.429 | 1-Nonadecene | C19H38 | 0.8 | Olefin | 018435-45-5 |

| 19.463 | Heneicosane | C21H44 | 0.81 | Alkanes | 000629-94-7 |

| 19.596 | Z-8-Methyl-9-tetradecen-1-ol acetate | C17H32O2 | 0.5 | Ester | 1000130-82-4 |

| 19.671 | Oxirane, tridecyl- | C15H30O | 0.47 | Other | 018633-25-5 |

| 19.706 | Cyclotetradecane, 1,7,11-trimethyl-4-(1-methylethyl)- | C20H40 | 0.51 | Alkanes | 001786-12-5 |

| 19.781 | Cyclohexene, 1-pentyl-4-(4-propylcyclohexyl)- | C20H36 | 0.4 | Olefin | 108067-20-5 |

| 19.833 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 0.46 | Alkanes | 055044-36-5 |

| 19.954 | E-8-Methyl-9-tetradecen-1-ol acetate | C17H32O2 | 0.63 | Ester | 1000130-81-4 |

| 20.041 | 1-Nonadecene | C19H38 | 0.71 | Olefin | 018435-45-5 |

| 20.07 | Docosane | C22H46 | 0.87 | Alkanes | 000629-97-0 |

| 20.289 | Hexadecane, 2-methyl- | C17H36 | 0.6 | Alkanes | 001560-92-5 |

| 20.382 | Pregnane | C21H36 | 0.68 | Alkanes | 000481-26-5 |

| 20.526 | 9-Cedranone | C15H24O | 0.55 | Ketone | 1000156-23-2 |

| 20.624 | 9-Tricosene, (Z)- | C23H46 | 0.79 | Olefin | 027519-02-4 |

| 20.653 | Tricosane | C23H48 | 0.86 | Alkanes | 000638-67-5 |

| 20.803 | Cyclohexene, 4-(4-ethylcyclohexyl)-1-pentyl- | C19H34 | 0.37 | Alkanes | 301643-32-3 |

| 20.85 | 10,13-Octadecadienoic acid, methylester | C19H34O2 | 0.46 | Other | 056554-62-2 |

| 21.034 | 9,12-Octadecadienoic acid (Z,Z)-,methyl ester | C19H34O2 | 0.77 | Other | 000112-63-0 |

| 21.184 | 1-Hexacosene | C26H52 | 0.82 | Olefin | 018835-33-1 |

| 21.208 | Tetracosane | C24H50 | 0.81 | Alkanes | 000646-31-1 |

| 21.329 | Tricosane | C23H48 | 0.77 | Alkanes | 000638-67-5 |

| 21.444 | 1-Docosanol, acetate | C24H48O2 | 0.54 | Ester | 000822-26-4 |

| 21.537 | 1-Bromo-11-iodoundecane | C11H22BrI | 0.54 | Other | 139123-69-6 |

| 21.635 | Cyclohexene, 4-(4-ethylcyclohexyl)-1-pentyl- | C19H34 | 0.53 | Alkanes | 301643-32-3 |

| 21.739 | Docosane | C22H46 | 2.01 | Alkanes | 000629-97-0 |

| 22.033 | Octadecane, 2,6,10,14-tetramethyl- | C22H46 | 0.66 | Alkanes | 054964-82-8 |

| 22.253 | Hexacosane | C26H54 | 1.59 | Alkanes | 000630-01-3 |

| 22.449 | 1,1′:3′,1″-Tercyclopentane, 2′-dodecyl- | C27H50 | 1.1 | Alkanes | 055282-68-3 |

| 22.547 | 1-Bromo-11-iodoundecane | C11H22BrI | 1.32 | Other | 139123-69-6 |

| 22.686 | 11,12-Dibromo-tetradecan-1-ol acetate | C16H30Br2O2 | 1 | Ester | 1000130-78-5 |

| 22.75 | Hexacosane | C26H54 | 1.47 | Other | 000630-01-3 |

| 22.83 | 11,12-Dibromo-tetradecan-1-ol acetate | C16H30Br2O2 | 0.67 | Other | 1000130-78-5 |

| 22.865 | 11,12-Dibromo-tetradecan-1-ol acetate | C16H30Br2O2 | 0.46 | Ester | 1000130-78-5 |

| 22.888 | Octadecanoic acid, 2-oxo-, methyl ester | C19H36O3 | 0.55 | Ester | 002380-18-9 |

| 22.952 | 2-Dodecen-1-yl(-)succinic anhydrid | C16H26O3 | 0.88 | Other | 019780-11-1 |

| 23.085 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 0.5 | Alkanes | 055044-36-5 |

| 23.223 | Hexacosane | C26H54 | 2.24 | Alkanes | 000630-01-3 |

| 23.316 | 1,1′:3′,1″-Tercyclopentane, 2′-dodecyl- | C27H50 | 0.72 | Alkanes | 055282-68-3 |

| 23.373 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 1.11 | Alkanes | 055044-36-5 |

| 23.483 | Cholestane | C27H48 | 0.82 | Alkanes | 000481-21-0 |

| 23.523 | Cholestane | C27H48 | 1.12 | Alkanes | 000481-21-0 |

| 23.564 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 0.82 | Alkanes | 055044-36-5 |

| 23.604 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 1 | Alkanes | 055044-36-5 |

| 23.703 | Cholestane | C27H48 | 2.21 | Alkanes | 000481-21-0 |

| 23.755 | 3,7-Dimethyl-6-nonen-1-ol acetate | C13H24O2 | 1.2 | Ester | 1000131-34-9 |

| 23.858 | (-)-Neoclovene-(I), dihydro- | C15H26 | 1.34 | Olefin | 1000152-82-1 |

| 23.893 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 0.66 | Alkanes | 055044-36-5 |

| 24.055 | Cholestane | C27H48 | 1.09 | Alkanes | 000481-21-0 |

| 24.101 | Cholestan-3-one | C27H46O | 1.33 | Alkanes | 015600-08-5 |

| 24.153 | Silane, dimethyldi(2-propylphenoxy)- | C20H28O2Si | 1.17 | Other | 1000347-41-8 |

| 24.292 | Cholestane | C27H48 | 1.04 | Alkanes | 000481-21-0 |

| 24.355 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 0.97 | Alkanes | 055044-36-5 |

| 24.436 | Stigmastane | C29H52 | 2.14 | Alkanes | 000601-58-1 |

| 24.552 | Stigmastane | C29H52 | 2.09 | Alkanes | 000601-58-1 |

| 24.846 | Stigmastane | C29H52 | 1.99 | Alkanes | 000601-58-1 |

| 25.042 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 2.02 | Alkanes | 055044-36-5 |

| 25.216 | 1H-Indene, 5-butyl-6-hexyloctahydro- | C19H36 | 0.8 | Alkanes | 055044-36-5 |

| 25.343 | 2,6-Diphenylpyridine | C17H13N | 0.54 | Other | 003558-69-8 |

| 25.429 | Benzophenone, 2-methylamino-5-chloro- | C14H12ClNO | 1.52 | Other | 074966-83-9 |

| 25.562 | 1-Penten-3-one, 1-(2,6,6-trimethyl-1-cyclohexen-1-yl)- | C14H22O | 3.22 | Ketone | 000127-43-5 |

| 25.782 | Sophocarpine, N-oxide | C15H22N2O2 | 0.76 | Other | 26904-64-3 |

| 26.018 | Lanosterol | C30H50O | 0.45 | Other | 000079-63-0 |

| 26.758 | Bromacil | C9H13BrN2O2 | 0.39 | Other | 000314-40-9 |

| 27.058 | Anthracene, 9-butyl- | C18H18 | 0.75 | Aromatics | 001498-69-7 |

| 27.329 | Tricosane | C23H48 | 0.25 | Alkanes | 000638-67-5 |

| 28.04 | 1-Penten-3-one, 1-(2,6,6-trimethyl-1-cyclohexen-1-yl)- | C14H22O | 0.36 | Ketone | 000127-43-5 |

| 28.323 | 1-Penten-3-one, 1-(2,6,6-trimethyl-1-cyclohexen-1-yl)- | C14H22O | 0.25 | Ketone | 000127-43-5 |

| 29.27 | 1,2-Bis(trimethylsilyl)benzene | C12H22Si2 | 0.2 | Other | 017151-09-6 |

| 29.703 | Benzo[h]quinoline, 2,4-dimethyl- | C15H13N | 0.18 | Other | 000605-67-4 |

| 30.766 | 2-(Acetoxymethyl)-3-(methoxycarbonyl)biphenylene | C17H14O4 | 0.16 | Ester | 093103-70-9 |

References

- Wang, Z.; Gong, Z.; Wang, Z.; Li, X.; Chu, Z. Application and development of pyrolysis technology in petroleum oily sludge treatment. Environ. Eng. Res. 2021, 26, 190460. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, K.; Wu, X.; Ling, Q.; Hu, J.; Li, X.; Liu, H. Effect of Oily Sludge Treatment with Molten Blast Furnace Slag on the Mineral Phase Reconstruction of Water-Quenched Slag Properties. Materials 2021, 14, 7285. [Google Scholar] [CrossRef] [PubMed]

- Hui, K.; Tang, J.; Lu, H.; Xi, B.; Qu, C.; Li, J. Status and prospect of oil recovery from oily sludge: A review. Arab. J. Chem. 2020, 13, 6523–6543. [Google Scholar] [CrossRef]

- Liu, H.; Li, S.; Guo, G.; Gong, L.; Zhang, L.; Qie, Y.; Hu, H.; Yao, H. Ash formation and the inherent heavy metal partitioning behavior in a 100 t/d hazardous waste incineration plant. Sci. Total Environ. 2021, 814, 151938. [Google Scholar] [CrossRef]

- Jiang, G.; Li, J.; Yu, J.; Jiang, H.; Li, H.; Xu, B.; Zhao, L.; Wang, H. Research on the influencing factors and mechanism of single-phase microemulsion cleaning of shale gas oil-based cuttings. Environ. Technol. 2021, 43, 2530–2539. [Google Scholar] [CrossRef]

- Wu, X.; Yue, B.; Su, Y.; Wang, Q.; Huang, Q.; Wang, Q.; Cai, H. Pollution characteristics of polycyclic aromatic hydrocarbons in common used mineral oils and their transformation during oil regeneration. J. Environ. Sci. 2017, 56, 247–253. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, J.; Yan, Y.; Yang, L.; Xing, G.; Li, H.; Wu, P.; Wang, M.; Zheng, H. Application of coagulation/flocculation in oily wastewater treatment: A review. Sci. Total Environ. 2021, 765, 142795. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.-X.; Peng, K.-M.; Zhao, X.; Xiong, Y.; Huang, X.-F. A review of the interfacial stability mechanism of aging oily sludge: Heavy components, inorganic particles, and their synergism. J. Hazard. Mater. 2021, 415, 125624. [Google Scholar] [CrossRef]

- Wang, J.; Liu, T.-L.; Huang, Q.-X.; Ma, Z.-Y.; Chi, Y.; Yan, J.-H. Production and characterization of high quality activated carbon from oily sludge. Fuel Process. Technol. 2017, 162, 13–19. [Google Scholar] [CrossRef]

- Jin, X.; Teng, D.; Fang, J.; Liu, Y.; Jiang, Z.; Song, Y.; Zhang, T.; Siyal, A.A.; Dai, J.; Fu, J. Petroleum oil and products recovery from oily sludge: Characterization and analysis of pyrolysis products. Environ. Res. 2021, 202, 111675. [Google Scholar] [CrossRef]

- Jasmine, J.; Mukherji, S. Characterization of oily sludge from a refinery and biodegradability assessment using various hydrocarbon degrading strains and reconstituted consortia. J. Environ. Manag. 2015, 149, 118–125. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Lin, F.; Xiang, L.; Zheng, F.; Che, L.; Tian, W.; Guo, X.; Yan, B.; Song, Y.; Chen, G. Hazardous elements flow during pyrolysis of oily sludge. J. Hazard. Mater. 2021, 409, 124986. [Google Scholar] [CrossRef] [PubMed]

- Wan, G.; Bei, L.; Yu, J.; Xu, L.; Sun, L. Products distribution and hazardous elements migration during pyrolysis of oily sludge from the oil refining process. Chemosphere 2022, 288, 132524. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Lin, F.; Li, K.; Zheng, F.; Yan, B.; Che, L.; Tian, W.; Chen, G.; Yoshikawa, K. A critical review on energy recovery and non-hazardous disposal of oily sludge from petroleum industry by pyrolysis. J. Hazard. Mater. 2021, 406, 124706. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.; Feng, H.; He, P.; Li, J.; Hewage, K.; Sadiq, R. Comparative life-cycle assessment of traditional and emerging oily sludge treatment approaches. J. Clean. Prod. 2020, 251, 119594. [Google Scholar] [CrossRef]

- Gao, N.; Duan, Y.; Li, Z.; Quan, C.; Yoshikawa, K. Hydrothermal treatment combined with in-situ mechanical compression for floated oily sludge dewatering. J. Hazard. Mater. 2021, 402, 124173. [Google Scholar] [CrossRef]

- Gao, N.; Li, J.; Quan, C.; Wang, X.; Yang, Y. Oily sludge catalytic pyrolysis combined with fine particle removal using a Ni-ceramic membrane. Fuel 2020, 277, 118134. [Google Scholar] [CrossRef]

- Rahbari-Sisakht, M.; Pouranfard, A.; Darvishi, P.; Ismail, A.F. Biosurfactant production for enhancing the treatment of produced water and bioremediation of oily sludge under the conditions of Gachsaran oil field. J. Chem. Technol. Biotechnol. 2017, 92, 1053–1064. [Google Scholar] [CrossRef]

- Deng, S.; Wang, X.; Tan, H.; Mikulčić, H.; Yang, F.; Li, Z.; Duić, N. Thermogravimetric study on the co-combustion characteristics of oily sludge with plant biomass. Thermochim. Acta 2016, 633, 69–76. [Google Scholar] [CrossRef]

- Johnson, O.A.; Affam, A.C. Petroleum sludge treatment and disposal: A review. Environ. Eng. Res. 2019, 24, 191–201. [Google Scholar] [CrossRef] [Green Version]

- Fellah Jahromi, A.; Elektorowicz, M. Electrokinetically assisted oil-water phase separation in oily sludge with implementing novel controller system. J. Hazard. Mater. 2018, 358, 434–440. [Google Scholar] [CrossRef]

- Wang, J.; Han, X.; Huang, Q.; Ma, Z.; Chi, Y.; Yan, J. Characterization and migration of oil and solids in oily sludge during centrifugation. Environ. Technol. 2018, 39, 1350–1358. [Google Scholar] [CrossRef] [PubMed]

- Gao, N.; Li, J.; Quan, C.; Tan, H. Product property and environmental risk assessment of heavy metals during pyrolysis of oily sludge with fly ash additive. Fuel 2020, 266, 117090. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X.; Sun, L.; Xie, X.; Yang, S.; Mei, N. Study on the fast pyrolysis of oil sludge by PY-GC/MS. Pet. Sci. Technol. 2019, 37, 2108–2113. [Google Scholar] [CrossRef]

- Lin, B.; Huang, Q.; Chi, Y. Co-pyrolysis of oily sludge and rice husk for improving pyrolysis oil quality. Fuel Process. Technol. 2018, 177, 275–282. [Google Scholar] [CrossRef]

- Vamvuka, D.; Salpigidou, N.; Kastanaki, E.; Sfakiotakis, S. Possibility of using paper sludge in co-firing applications. Fuel 2009, 88, 637–643. [Google Scholar] [CrossRef]

- GB/T 10359-2008; Determination of Oil Content in Oil Cake Part 1: Hexane (or Petroleum Ether) Extraction Method. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China: Beijing, China, 2008; p. 12.

- GB/T 260-2016; Distillation Method for Determination of Water Content in Petroleum Products. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China: Beijing, China, 2016; p. 20.

- Kubínová, R.; Neumann, M.; Kavka, P. Aggregate and particle size distribution of the soil sediment eroded on steep artificial slopes. Appl. Sci. 2021, 11, 4427. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, A.; Li, K.; Wang, Q.; Han, Y.; Yao, B.; Gao, X.; Feng, L. Research on the pretreatment and mechanical performance of undisturbed phosphogypsum. Case Stud. Constr. Mater. 2020, 13, e00400. [Google Scholar] [CrossRef]

- Generali, L.; Malovo, A.; Bolelli, G.; Borghi, A.; La Rosa, G.R.M.; Puddu, P.; Lusvarghi, L.; Rota, A.; Consolo, U.; Pedullà, E. Mechanical properties and metallurgical features of new green NiTi reciprocating instruments. Materials 2020, 13, 3736. [Google Scholar] [CrossRef]

- Miao, Y.; Luo, H.; Pudukudy, M.; Zhi, Y.; Zhao, W.; Shan, S.; Jia, Q.; Ni, Y. CO2 capture performance and characterization of cellulose aerogels synthesized from old corrugated containers. Carbohydr. Polym. 2020, 227, 115380. [Google Scholar] [CrossRef]

- Xin, L.; Jihong, Q.; Hui, S.; Zhiwei, G.; Wenqing, C.; Zhi, L. Leaching of heavy metals and their impacting factors from a spent catalyst in the refinery industry. Environ. Chem. 2021, 4, 1147–1156. [Google Scholar]

- Deng, L.; Yao, B.; Lu, W.; Zhang, M.; Li, H.; Chen, H.; Zhao, M.; Du, Y.; Zhang, M.; Ma, Y. Effect of SiO2/Al2O3 ratio on the crystallization and heavy metal immobilization of glass ceramics derived from stainless steel slag. J. Non-Crystal. Solids 2022, 593, 121770. [Google Scholar] [CrossRef]

- Shebis, Y.; Vanegas, A.; Tish, N.; Fallik, E.; Rodov, V.; Poverenov, E. Facile method for preparation of oligo-carboxymethyl cellulose and other oligosaccharides: Physicochemical properties and bioactivity. Food Hydrocoll. 2022, 127, 107530. [Google Scholar] [CrossRef]

- Erarpat, S.; Cağlak, A.; Bodur, S.; Chormey, S.D.; Engin, Ö.G.; Bakırdere, S. Simultaneous determination of fluoxetine, estrone, pesticides, and endocrine disruptors in wastewater by gas chromatography–mass spectrometry (GC–MS) following switchable solvent–liquid phase microextraction (SS–LPME). Anal. Lett. 2019, 52, 869–878. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, Y.; Wang, C.-C.; Hou, M.; Li, A. Recent progress in instrumental techniques for architectural heritage materials. Herit. Sci. 2019, 7, 36. [Google Scholar] [CrossRef]

- Wu, J.; Pan, J.; Wang, H.; Wang, L.; Liu, W.; Zhang, L. Cyclone Oil Desorption Technology for the Disposal of Oil-Based Mud Cuttings. Soc. Pet. Eng. J. 2021, 26, 3561–3574. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.; Geng, X.; Zhang, H. Ecological Remediation of Petroleumcontaminated Soil Based on Microbial Degradation. Appl. Ecol. Environ. Res. 2020, 18, 2727–2746. [Google Scholar] [CrossRef]

- Kuppusamy, S.; Maddela, N.R.; Megharaj, M.; Venkateswarlu, K. Ecological impacts of total petroleum hydrocarbons. In Total Petroleum Hydrocarbons; Springer: Berlin/Heidelberg, Germany, 2020; pp. 95–138. [Google Scholar]

- Johnston, J.E.; Lim, E.; Roh, H. Impact of upstream oil extraction and environmental public health: A review of the evidence. Sci. Total Environ. 2019, 657, 187–199. [Google Scholar] [CrossRef]

- Pereira, L.B.; Sad, C.M.; Castro, E.V.; Filgueiras, P.R.; Lacerda, V., Jr. Environmental impacts related to drilling fluid waste and treatment methods: A critical review. Fuel 2022, 310, 122301. [Google Scholar] [CrossRef]

- Abouelnasr, D.; Al Zubaidy, E.A. Treatment and recovery of oil-based sludge using solvent extraction. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, OnePetro, Abu Dhabi, United Arab Emirates, 3–6 November 2008. [Google Scholar]

- Wu, J.; Zeng, L.; Ma, W.; Zhang, S.; Yi, X.; Nie, Q. Influence of cyclone oil desorption technology on the change of Oil-Based mud cuttings properties. Fuel 2022, 324, 124524. [Google Scholar] [CrossRef]

- Fard, A.K.; Bukenhoudt, A.; Jacobs, M.; McKay, G.; Atieh, M.A. Novel hybrid ceramic/carbon membrane for oil removal. J. Membr. Sci. 2018, 559, 42–53. [Google Scholar] [CrossRef]

- AlHumaidan, F.S.; Rana, M.S.; Tanoli, N.J.; Lababidi, H.M.; Al-Najdi, N.A. Changes in asphaltene surface topography with thermal treatment. Arab. J. Chem. 2020, 13, 5377–5389. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, X.; Liu, D.; Li, Z.; Guo, S.; Zhu, W.; Shi, N.; Wen, F.; Dong, J. Insight into essential channel effect of pore structures and hydrogen bonds on the solvent extraction of oily sludge. J. Hazard. Mater. 2020, 389, 121826. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Cheng, X.; Zhang, C.; Gao, X.; Zhuang, J.; Guo, X. Evolution of pore structure of oil well cement slurry in suspension–solid transition stage. Constr. Buil. Mater. 2019, 214, 382–398. [Google Scholar] [CrossRef]

- Lu, T.; Yuan, H.; Wang, Y.; Huang, H.; Chen, Y. Characteristic of heavy metals in biochar derived from sewage sludge. J. Mater. Cycles Waste Manag. 2016, 18, 725–733. [Google Scholar] [CrossRef]

- GB 5085.3-2007; Hazardous Waste Identification Standards Leaching Toxicity Identification. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China: Beijing, China, 2007; 180p.

- Zhao, Z.; Gong, X.; Ding, Q.; Jin, M.; Wang, Z.; Lu, S.; Zhang, L. Environmental implications from the priority pollutants screening in impoundment reservoir along the eastern route of China’s South-to-North Water Diversion Project. Sci. Total Environ. 2021, 794, 148700. [Google Scholar] [CrossRef]

- Zeng, S.; Ma, J.; Yang, Y.; Zhang, S.; Liu, G.-J.; Chen, F. Spatial assessment of farmland soil pollution and its potential human health risks in China. Sci. Total Environ. 2019, 687, 642–653. [Google Scholar] [CrossRef]

- Taha, R.A.; Mohamedzein, Y.E.-A.; Al-Rawas, A.A.; Al-Suleimani, Y. Solidification of tank bottom sludge. Geotechn. Geol. Eng. 2010, 28, 15–25. [Google Scholar] [CrossRef]

- Xiao, W.; Yao, X.; Zhang, F. Recycling of oily sludge as a roadbed material utilizing phosphogypsum-based cementitious materials. Adv. Civ. Eng. 2019, 2019, 6280715. [Google Scholar] [CrossRef]

- Kaštanek, F.E.; Topka, P.; Soukup, K.; Šolcová, O. Thermal treatment. In The Handbook of Environmental Remediation: Classic and Modern Techniques; Royal Society of Chemistry: London, UK, 2020; p. 53. [Google Scholar]

| Indexes | Density (g/cm3) | Oil Content (%) | Water Content (%) | Solid Content (%) |

|---|---|---|---|---|

| Values | 1.75 | 10.3 | 29.9 | 59.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Wu, J.; Nie, Q.; Duan, X.; Yi, X. Environmental Risk Analysis Based on Characterization of Ground Oily Sludge. Materials 2022, 15, 9054. https://doi.org/10.3390/ma15249054

Zhang S, Wu J, Nie Q, Duan X, Yi X. Environmental Risk Analysis Based on Characterization of Ground Oily Sludge. Materials. 2022; 15(24):9054. https://doi.org/10.3390/ma15249054

Chicago/Turabian StyleZhang, Shifan, Jiwei Wu, Qi Nie, Xiaoxu Duan, and Xianzhong Yi. 2022. "Environmental Risk Analysis Based on Characterization of Ground Oily Sludge" Materials 15, no. 24: 9054. https://doi.org/10.3390/ma15249054

APA StyleZhang, S., Wu, J., Nie, Q., Duan, X., & Yi, X. (2022). Environmental Risk Analysis Based on Characterization of Ground Oily Sludge. Materials, 15(24), 9054. https://doi.org/10.3390/ma15249054