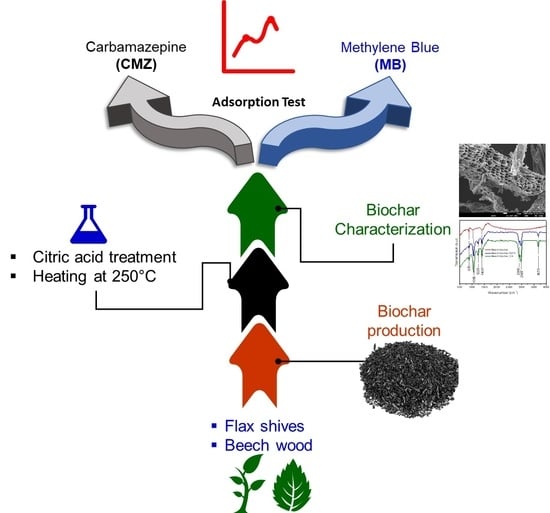

Potential of Flax Shives and Beech Wood-Derived Biochar in Methylene Blue and Carbamazepine Removal from Aqueous Solutions

Abstract

:1. Statement of Novelty

2. Introduction and State of the Art

3. Materials and Methods

3.1. Biomass Feedstock and Biochar Production

3.2. Post Treatment of the Biochars

3.2.1. Citric Acid Treatment (CA)

3.2.2. Low-Temperature Surface Oxidation (Oxide)

3.3. Adsorbate

3.4. Characterization of Biochars

3.5. Experimental Protocol of Batch Adsorption

3.6. Adsorption Isotherm Modelling

3.6.1. Langmuir Fit

3.6.2. Freundlich Isotherm

4. Results and Discussion

4.1. Surface Morphology Results: Scanning Electron Microscopy (SEM)

4.2. Surface Morphology Results: BET Surface Area Results

4.3. Thermogravimetric Analysis

4.4. ICP Analysis

4.5. Adsorption Isotherms

4.6. Functional Groups

4.7. pH and Point of Zero Charge (pHpzc) of the Tested Biochars

4.8. Effect of Adsorbent Dose and Initial Dye Concentration

4.9. Desorption Study

5. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Crini, G.; Lichtfouse, E. Advantages and disadvantages of techniques used for wastewater treatment. Environ. Chem. Lett. 2019, 17, 145–155. [Google Scholar] [CrossRef]

- Katheresan, V.; Kansedo, J.; Lau, S.Y. Efficiency of Various Recent Wastewater Dye Removal Methods: A Review. Biochem. Pharmacol. 2018, 6, 4676–4697. [Google Scholar] [CrossRef]

- Kim, M.H.; Jeong, I.T.; Park, S.B.; Kim, J.W. Analysis of environmental impact of activated carbon production from wood waste. Environ. Eng. Res. 2019, 24, 117–126. [Google Scholar] [CrossRef] [Green Version]

- Strouse, R. Industry insights. Online Wilton Connect. 2001, 25, 86. [Google Scholar]

- Joseph, B.; Kaetzl, K.; Hensgen, F.; Schäfer, B.; Wachendorf, M. Sustainability assessment of activated carbon from residual biomass used for micropollutant removal at a full-scale wastewater treatment plant. Environ. Res. Lett. 2020, 15, 064023. [Google Scholar] [CrossRef]

- Lonappan, L.; Liu, Y.; Rouissi, T.; Brar, S.K.; Surampalli, R.Y. Development of biochar-based green functional materials using organic acids for environmental applications. J. Clean. Prod. 2020, 244, 118841. [Google Scholar] [CrossRef]

- Zubair, M.; Mu’azu, N.D.; Jarrah, N.; Blaisi, N.I.; Aziz, H.A.; Al-Harthi, M. Adsorption Behavior and Mechanism of Methylene Blue, Crystal Violet, Eriochrome Black T, and Methyl Orange Dyes onto Biochar-Derived Date Palm Fronds Waste Produced at Different Pyrolysis Conditions. Water Air Soil Pollut. 2020, 231, 240. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, Y.; Liu, S.; Tan, X.; Zeng, G.; Zeng, W.; Ding, Y.; Cao, W.; Zheng, B. Enhanced adsorption of methylene blue by citric acid modification of biochar derived from water hyacinth (Eichornia crassipes). Environ. Sci. Pollut. Res. 2016, 23, 23606–23618. [Google Scholar] [CrossRef]

- Sud, D.; Mahajan, G.; Kaur, M.P. Agricultural waste material as potential adsorbent for sequestering heavy metal ions from aqueous solutions—A review. Bioresour. Technol. 2008, 99, 6017–6027. [Google Scholar] [CrossRef]

- Bello, O.S.; Owojuyigbe, E.S.; Babatunde, M.A.; Folaranmi, F.E. Sustainable conversion of agro-wastes into useful adsorbents. Appl. Water Sci. 2017, 7, 3561–3571. [Google Scholar] [CrossRef] [Green Version]

- Fryda, L.; Visser, R. Biochar for Soil Improvement: Evaluation of Biochar from Gasification and Slow Pyrolysis. Agriculture 2015, 5, 1076–1115. [Google Scholar] [CrossRef] [Green Version]

- Fryda, L.; Visser, R.; Schmidt, J. Biochar replaces peat in horticulture: Environmental impact assessment of combined biochar & bioenergy production. Detritus 2019, 5, 132–149. [Google Scholar]

- Leng, L.; Xiong, Q.; Yang, L.; Li, H.; Zhou, Y.; Zhang, W.; Jiang, S.; Li, H.; Huang, H. An overview on engineering the surface area and porosity of biochar. Sci. Total Environ. 2021, 763, 144204. [Google Scholar] [CrossRef]

- Li, R.; Wang, J.J.; Gaston, L.A.; Zhou, B.; Li, M.; Xiao, R.; Wang, Q.; Zhang, Z.; Huang, H.; Liang, W.; et al. An overview of carbothermal synthesis of metal–biochar composites for the removal of oxyanion contaminants from aqueous solution. Carbon 2018, 129, 674–687. [Google Scholar] [CrossRef]

- Suliman, W.; Harsh, J.B.; Abu-Lail, N.I.; Fortuna, A.-M.; Dallmeyer, I.; Garcia-Perez, M. Modification of biochar surface by air oxidation: Role of pyrolysis temperature. Biomass Bioenergy 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Kozyatnyk, I.; Oesterle, P.; Wurzer, C.; Mašek, O.; Jansson, S. Removal of contaminants of emerging concern from multicomponent systems using carbon dioxide activated biochar from lignocellulosic feedstocks. Bioresour. Technol. 2021, 340, 125561. [Google Scholar] [CrossRef]

- Bardestani, R.; Kaliaguine, S. Steam activation and mild air oxidation of vacuum pyrolysis biochar. Biomass Bioenergy 2018, 108, 101–112. [Google Scholar] [CrossRef]

- Boumediene, M.; Benaïssa, H.; George, B.; Molina, S.; Merlin, A. Effects of pH and ionic strength on methylene blue removal from synthetic aqueous solutions by sorption onto orange peel and desorption study. J. Mater. Environ. Sci. 2018, 9, 1700–1711. [Google Scholar]

- Li, X.; Shen, Q.; Zhang, D.; Mei, X.; Ran, W.; Xu, Y.; Yu, G. Functional Groups Determine Biochar Properties (pH and EC) as Studied by Two-Dimensional 13C NMR Correlation Spectroscopy. PLoS ONE 2013, 8, e65949. [Google Scholar] [CrossRef] [Green Version]

- Sun, L.; Chen, D.; Wan, S.; Yu, Z. Performance, kinetics, and equilibrium of methylene blue adsorption on biochar derived from eucalyptus saw dust modified with citric, tartaric, and acetic acids. Bioresour. Technol. 2015, 198, 300–308. [Google Scholar] [CrossRef]

- Rashid, U.S.; Bezbaruah, A.N. Citric acid modified granular activated carbon for enhanced defluoridation. Chemosphere 2020, 252, 126639. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Cui, C.; Wang, P. Pomelo peel modified with citrate as a sustainable adsorbent for removal of methylene blue from aqueous solution. Molecules 2018, 23, 1342. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; Yan, Z.; Liang, L.; Ran, M.; Wu, T.; Wang, B.; Zou, X.; Zhao, M.; Fang, G.; Shen, K. Comparative evaluation of organic acid pretreatment of eucalyptus for kraft dissolving pulp production. Materials 2020, 13, 361. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ambaye, T.G.; Vaccari, M.; van Hullebusch, E.D.; Amrane, A.; Rtimi, S. Mechanisms and adsorption capacities of biochar for the removal of organic and inorganic pollutants from industrial wastewater. Int. J. Environ. Sci. Technol. 2021, 18, 3273–3294. [Google Scholar] [CrossRef]

- Zeng, H.; Qi, W.; Zhai, L.; Wang, F.; Zhang, J.; Li, D. Preparation and characterization of sludge-based magnetic biochar by pyrolysis for methylene blue removal. Nanomaterials 2021, 11, 2473. [Google Scholar] [CrossRef]

- Décima, M.A.; Marzeddu, S.; Barchiesi, M.; Di Marcantonio, C.; Chiavola, A.; Boni, M.R. A review on the removal of carbamazepine from aqueous solution by using activated carbon and biochar. Sustainability 2021, 13, 11760. [Google Scholar] [CrossRef]

- Salazar-Rabago, J.J.; Leyva-Ramos, R.; Rivera-Utrilla, J.; Ocampo-Perez, R.; Cerino-Cordova, F.J. Biosorption mechanism of Methylene Blue from aqueous solution onto White Pine (Pinus durangensis) sawdust: Effect of operating conditions. Sustain. Environ. Res. 2017, 27, 32–40. [Google Scholar] [CrossRef]

- Salazar-Rabago, J.J.; Leyva-Ramos, R. Novel biosorbent with high adsorption capacity prepared by chemical modification of white pine (Pinus durangensis) sawdust. Adsorption of Pb(II) from aqueous solutions. J. Environ. Manag. 2016, 169, 303–312. [Google Scholar] [CrossRef]

- Wang, B.; Lian, G.; Lee, X.; Gao, B.; Li, L.; Liu, T.; Zhang, X.; Zheng, Y. Phosphogypsum as a novel modifier for distillers grains biochar removal of phosphate from water. Chemosphere 2020, 238, 124684. [Google Scholar] [CrossRef]

- Freundlich, H. Über die Adsorption in Lösungen. Z. Für Phys. Chem. 1907, 57, 385–470. [Google Scholar] [CrossRef]

- Leyva-Ramos, R.; Berber-Mendoza, M.S.; Salazar-Rabago, J.; Guerrero-Coronado, R.M.; Mendoza-Barron, J. Adsorption of lead(II) from aqueous solution onto several types of activated carbon fibers. Adsorption 2011, 17, 515–526. [Google Scholar] [CrossRef]

- Bibi, I.; Icenhower, J.; Niazi, N.K.; Naz, T.; Shahid, M.; Bashir, S. Clay minerals: Structure, chemistry and significance in contaminated environments and geological CO2 sequestration. In Environmental Materials and Waste: Resource Recovery and Pollution Prevention; Materials and Waste: Resource Recovery and Pollution, Prevention; Prasad, M.N.V., Shih, K.B.T.-E., Eds.; Academic Press: London, UK, 2016; pp. 543–567. ISBN 9780128038376. [Google Scholar]

- Foo, K.Y.; Hameed, B.H. Preparation, characterization and evaluation of adsorptive properties of orange peel based activated carbon via microwave induced K2CO3 activation. Bioresour. Technol. 2012, 104, 679–686. [Google Scholar] [CrossRef]

- El Nemr, A.; Abdelwahab, O.; El-Sikaily, A.; Khaled, A. Removal of direct blue-86 from aqueous solution by new activated carbon developed from orange peel. J. Hazard. Mater. 2009, 161, 102–110. [Google Scholar] [CrossRef]

- Tseng, R.-L.; Wu, F.-C. Inferring the favorable adsorption level and the concurrent multi-stage process with the Freundlich constant. J. Hazard. Mater. 2008, 155, 277–287. [Google Scholar] [CrossRef]

- Shin, J.; Lee, Y.-G.; Lee, S.-H.; Kim, S.; Ochir, D.; Park, Y.; Kim, J.; Chon, K. Single and competitive adsorptions of micropollutants using pristine and alkali-modified biochars from spent coffee grounds. J. Hazard. Mater. 2020, 400, 123102. [Google Scholar] [CrossRef]

- Zhu, Y.; Yi, B.; Yuan, Q.; Wu, Y.; Wang, M.; Yan, S. Removal of methylene blue from aqueous solution by cattle manure-derived low temperature biochar. RSC Adv. 2018, 8, 19917–19929. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Chen, F.; Ji, B.; Zhu, L.; Song, H. Insights into the mechanism of methylene blue removed by novel and classic biochars. Water Sci. Technol. 2019, 79, 1561–1570. [Google Scholar] [CrossRef]

- Shan, D.; Deng, S.; Zhao, T.; Wang, B.; Wang, Y.; Huang, J.; Yu, G.; Winglee, J.; Wiesner, M.R. Preparation of ultrafine magnetic biochar and activated carbon for pharmaceutical adsorption and subsequent degradation by ball milling. J. Hazard. Mater. 2016, 305, 156–163. [Google Scholar] [CrossRef] [Green Version]

- Chen, D.; Xie, S.; Chen, C.; Quan, H.; Hua, L.; Luo, X.; Guoa, L. Activated biochar derived from pomelo peel as a high-capacity sorbent for removal of carbamazepine from aqueous solution. RSC Adv. 2017, 7, 54969–54979. [Google Scholar] [CrossRef] [Green Version]

- Li, F.T.; Yang, H.; Zhao, Y.; Xu, R. Novel modified pectin for heavy metal adsorption. Chin. Chem. Lett. 2007, 18, 325–328. [Google Scholar] [CrossRef]

- Singh, R.; Naik, D.V.; Dutta, R.K.; Kanaujia, P.K. Biochars for the removal of naphthenic acids from water: A prospective approach towards remediation of petroleum refinery wastewater. J. Clean. Prod. 2020, 266, 121986. [Google Scholar] [CrossRef]

- Liang, S.; Guo, X.; Feng, N.; Tian, Q. Isotherms, kinetics and thermodynamic studies of adsorption of Cu2+ from aqueous solutions by Mg2+/K+ type orange peel adsorbents. J. Hazard. Mater. 2010, 174, 756–762. [Google Scholar] [CrossRef] [PubMed]

- Bai, X.; Zhang, Y.; Shi, J.; Xu, L.; Wang, Y.; Jin, P. A new application pattern for sludge-derived biochar adsorbent: Ideal persulfate activator for the high-efficiency mineralization of pollutants. J. Hazard. Mater. 2021, 419, 126343. [Google Scholar] [CrossRef]

- Zhang, P.; O’Connor, D.; Wang, Y.; Jiang, L.; Xia, T.; Wang, L.; Tsang, D.C.W.; Ok, Y.S.; Hou, D. A green biochar/iron oxide composite for methylene blue removal. J. Hazard. Mater. 2020, 384, 121286. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Wu, L.; Li, P.; Yang, L.; He, L.; Chen, S.; Yang, Y.; Gao, F.; Qi, X.; Zhang, Z. A novel, efficient and sustainable magnetic sludge biochar modified by graphene oxide for environmental concentration imidacloprid removal. J. Hazard. Mater. 2021, 407, 124777. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Xue, Y.; Zhang, D. Preparation of magnetic biochar with different magnetization sequences for efficient removal of oxytetracycline from aqueous solution. Colloids Surf. A Physicochem. Eng. Asp. 2021, 626, 126987. [Google Scholar] [CrossRef]

- Hou, Y.; Liang, Y.; Hu, H.; Tao, Y.; Zhou, J.; Cai, J. Facile preparation of multi-porous biochar from lotus biomass for methyl orange removal: Kinetics, isotherms, and regeneration studies. Bioresour. Technol. 2021, 329, 124877. [Google Scholar] [CrossRef]

- Chen, Y.D.; Lin, Y.C.; Ho, S.H.; Zhou, Y.; Ren, N.Q. Highly efficient adsorption of dyes by biochar derived from pigments-extracted macroalgae pyrolyzed at different temperature. Bioresour. Technol. 2018, 259, 104–110. [Google Scholar] [CrossRef]

- Dawood, S.; Sen, T.K.; Phan, C. Synthesis and characterization of slow pyrolysis pine cone bio-char in the removal of organic and inorganic pollutants from aqueous solution by adsorption: Kinetic, equilibrium, mechanism and thermodynamic. Bioresour. Technol. 2017, 246, 76–81. [Google Scholar] [CrossRef] [Green Version]

- Lyu, H.; Gao, B.; He, F.; Zimmerman, A.R.; Ding, C.; Huang, H.; Tang, J. Effects of ball milling on the physicochemical and sorptive properties of biochar: Experimental observations and governing mechanisms. Environ. Pollut. 2018, 233, 54–63. [Google Scholar] [CrossRef]

- Aghababaei, A.; Azargohar, R.; Dalai, A.K.; Soltan, J.; Niu, C.H. Effective adsorption of carbamazepine from water by adsorbents developed from flax shives and oat hulls: Key factors and characterization. Ind. Crops Prod. 2021, 170, 113721. [Google Scholar] [CrossRef]

- Phuong, D.T.M.; Loc, N.X.; Miyanishi, T. Efficiency of dye adsorption by biochars produced from residues of two rice varieties, Japanese Koshihikari and Vietnamese IR50404. Desalin. Water Treat. 2019, 165, 333–351. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Cao, Y. Waste printed circuit boards as novel potential engineered catalyst for catalytic degradation of orange II. J. Clean. Prod. 2019, 221, 234–241. [Google Scholar] [CrossRef]

| Biomass | Ash 550 °C | Vol % | Fixed Carbon% | C % | H % | N % | Cl mg/kg | Ca mg/kg | P mg/kg | K mg/kg | Cu mg/kg | Fe mg/kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flax shives | 1.7 | 77.6 | 18.7 | 48.5 | 5.8 | 0.6 | 380 | 4149 | 985 | 3098 | 2.8 | 352 |

| Beech | 0.9 | 80.6 | 17.5 | 50.3 | 6.0 | 0.2 | 35 | 1925 | 270 | 1150 | 1.4 | 348 |

| Biochar | Treatment | Tested Polutants |

|---|---|---|

| Beech | Only demineralised water washed (washing) | Methylene blue, Carbamazepine |

| Beech-heat_oxid | Washing and heating | Methylene blue, Carbamazepine |

| Beech_CA | Washing and acid treating | Methylene blue, Carbamazepine |

| Flax shives | Only demineralised water washed (washing) | Methylene blue, Carbamazepine |

| Flax_heat_oxid | Washing and heating | Methylene blue, |

| Flax_CA | Washing and acid treating | Methylene blue |

| Adsorbent Material | qExp (mg/g) | SBET (m2/g) | Qm/SBET (mg/m2) | Reference | |

|---|---|---|---|---|---|

| Beech-natural | 81.06 | 368 | 0.215 | Methylene Blue | Present study |

| Beech-heat_oxid | 113.22 | 388 | 0.286 | Methylene Blue | Present study |

| Beech_CA | 117.33 | 146 | 0.835 | Methylene Blue | Present study |

| Flax shives-natural | 24.74 | 190 | 0.113 | Methylene Blue | Present study |

| Flax-heat_oxid | 45.73 | 272 | 0.163 | Methylene Blue | Present study |

| Flax CA | 77.64 | 148 | 0.555 | Methylene Blue | Present study |

| Cattle manure-derived biochar | 40 | 3.6 | 11.1 | Methylene Blue | [37] |

| Water hyacinth biochar | 80 | 93 | 0.45 | Methylene Blue | [8] |

| Water hyacinth biochar CA | 395 | 57 | 6.9 | Methylene Blue | [8] |

| Date Palm Waste biochar B 700 4 | 206 | 432 | 0.478 | Methylene Blue | [7] |

| Date Palm Waste biochar B 800 2 | 164 | 268 | 0.478 | Methylene Blue | [7] |

| Magnolia grandiflora Linn. leaves biochar (MBC). | 67 | 98 | 0.683 | Methylene Blue | [38] |

| Badam shell biochar (BBC). | 25 | 269 | 0.09 | Methylene Blue | [38] |

| Pomelo (Citrus grandis) peel biochar (PBC) | 32 | 0.026 | - | Methylene Blue | [38] |

| Beech-natural | 10.33 | 368 | 0.038 | Carbamazepine | Present study |

| Beech-heat_oxid | 17.79 | 388 | 0.05 | Carbamazepine | Present study |

| Beech_CA | 16.64 | 146 | 0.142 | Carbamazepine | Present study |

| Flax shives-natural | 3.13 | 190 | 0.019 | Carbamazepine | Present study |

| Flax-heat_oxid | 6.39 | 272 | 0.024 | Carbamazepine | Present study |

| Flax CA | - | 148 | - | Carbamazepine | Present study |

| Coconut shell biochar | 89.6 | 365 | 0.245 | Carbamazepine | [39] |

| Pomelo peel biochar B400 | 14.75 | 94 | 0.157 | Carbamazepine | [40] |

| Pomelo peel biochar AB600 | 80.64 | 198.0 | 0.407 | Carbamazepine | [40] |

| Pomelo peel biochar AB700 | 286.5 | 904 | 0.317 | Carbamazepine | [40] |

| Pinenut and walnut shell biochars | 30–45 | 0.245 | Carbamazepine | [39] |

| Concentration (mg/g Biochar) | Ca | Cr | Cu | Fe | K | Mn | Ni | Rb | Zn | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| Beech | 20.57 | 0.42 | nn | 5.93 | 14.65 | 2.63 | 3.27 | nn | nn | 47.47 |

| Beech_-heat_oxid | 18.61 | 0.55 | nn | 4.69 | 4.48 | 2.02 | 14.69 | nn | nn | 45.04 |

| Beech_CA | 16.31 | <0.30 | nn | 2.82 | 2.68 | 1.96 | 4.89 | nn | nn | 28.66 |

| Flax shives | 13.08 | nn | nn | 1.05 | 10.11 | <0.25 | nn | nn | nn | 24.24 |

| Flax shives_-heat_oxid | 12.69 | nn | nn | 1.99 | 10.35 | <0.25 | nn | nn | <0.50 | 25.03 |

| Flax shive_CA | 7.07 | <0.31 | nn | <0.31 | 1.91 | <0.26 | nn | nn | nn | 8.98 |

| Materials/Isotherms | qExperimental (mg/g) | Langmuir | Freundlich | ||||

|---|---|---|---|---|---|---|---|

| qm (mg/g) | KL | R2 | Kf | n | R2 | ||

| MB | |||||||

| Beech Biochar, Natural | 81.06 | 78.38 | 2.28 | 0.68 | 42.49 | 0.19 | 0.68 |

| Beech Biochar, Heat Oxid | 113.22 | 105.6 | 0.61 | 0.88 | 48.45 | 0.21 | 0.91 |

| Beech Biochar, CA | 117.33 | 118.23 | 0.7 | 0.95 | 48.61 | 0.27 | 0.94 |

| CMZ | |||||||

| Beech Biochar, Natural | 10.33 | 13.92 | 1.05 | 0.98 | 6.84 | 0.4 | 0.91 |

| Beech Biochar, Heat Oxid | 17.79 | 20.05 | 1.53 | 0.92 | 10.36 | 0.4 | 0.91 |

| Beech Biochar, CA | 16.64 | 19.05 | 2.9 | 0.96 | 12.99 | 0.32 | 0.86 |

| MB | |||||||

| Flax Biochar, Natural | 24.74 | 19.24 | 0.42 | 0.79 | 6.79 | 0.28 | 0.8 |

| Flax Biochar, Heat Oxid | 45.73 | 23.83 | −0.28 | 0.36 | 16.64 | 0.29 | 0.78 |

| Flax Biochar, CA | 77.64 | 79.85 | 1.01 | 0.81 | 40.51 | 0.21 | 0.7 |

| CMZ | |||||||

| Flax Biochar, Natural | 3.13 | 0.00 | −0.20 | −2.08 | 1.07 | 0.43 | 0.83 |

| Flax Biochar, Heat Oxid | 6.39 | 6.49 | 0.35 | 0.94 | 1.68 | 0.46 | 0.95 |

| Sample/Solution | pH | Begin | End | pHpzc |

|---|---|---|---|---|

| Beech biochar | 11.0 | - | - | 8.2 |

| Beech biochar_heat_oxid | 9.9 | - | - | 8.9 |

| Beech biochar, CA | 9.9 | - | - | 7.3 |

| Solution MB 20–50 mg/L, with beech | 6.5 | 8.3–8.7 | ||

| Solution MB 50–100 mg/L, with beech | 6.0 | 8.1–8.5 | ||

| Solution CMZ 1–20 mg/L, with beech | 8.4 | 8.5–9.0 | ||

| Flax biochar | 10.4 | - | - | 8.0 |

| Flax biochar_heat_oxid | 10.5 | - | - | 8.1 |

| Flax biochar, CA | 7.8 | - | - | 7.1 |

| Solution MB 20–50 mg/L, with flax | 6.5 | 7.7–7.9 | ||

| Solution MB 50–100 mg/L, with flax | 6.0 | 7.5 | ||

| Solution CMZ 1–20 mg/L, with flax | 7.7 | 7.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeghioud, H.; Fryda, L.; Mahieu, A.; Visser, R.; Kane, A. Potential of Flax Shives and Beech Wood-Derived Biochar in Methylene Blue and Carbamazepine Removal from Aqueous Solutions. Materials 2022, 15, 2824. https://doi.org/10.3390/ma15082824

Zeghioud H, Fryda L, Mahieu A, Visser R, Kane A. Potential of Flax Shives and Beech Wood-Derived Biochar in Methylene Blue and Carbamazepine Removal from Aqueous Solutions. Materials. 2022; 15(8):2824. https://doi.org/10.3390/ma15082824

Chicago/Turabian StyleZeghioud, Hicham, Lydia Fryda, Angélique Mahieu, Rian Visser, and Abdoulaye Kane. 2022. "Potential of Flax Shives and Beech Wood-Derived Biochar in Methylene Blue and Carbamazepine Removal from Aqueous Solutions" Materials 15, no. 8: 2824. https://doi.org/10.3390/ma15082824

APA StyleZeghioud, H., Fryda, L., Mahieu, A., Visser, R., & Kane, A. (2022). Potential of Flax Shives and Beech Wood-Derived Biochar in Methylene Blue and Carbamazepine Removal from Aqueous Solutions. Materials, 15(8), 2824. https://doi.org/10.3390/ma15082824