Puncture Resistance and UV aging of Nanoparticle-Loaded Waterborne Polyurethane-Coated Polyester Textiles

Abstract

:1. Introduction

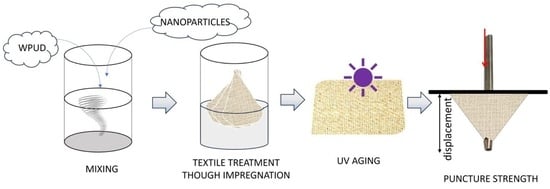

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Characterization Techniques

3. Results

3.1. Visual Aspects of Sample Surface

3.2. Puncture Performance

3.3. Infrared Spectroscopic Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ravi, R.S.S.; Risfanali, S.R.; Raja, R.R. Wear Resistance and Water Absorption Study of Sic Reinforced Polyester Composite. Mater. Today Proc. 2018, 5, 14567–14572. [Google Scholar]

- Looney, F.S.; Handy, C.T. The Effects of Construction on the Wear Wrinkling of Dacron®/Wool Suitings. Text. Res. J. 1968, 38, 989–998. [Google Scholar] [CrossRef]

- Ahmad, S.; Ullah, T.; Ziauddin. Fibers for Technical Textiles. In Topics in Mining, Metallurgy and Materials Engineering; Ahmad, S., Rasheed, A., Nawab, Y., Eds.; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2020; pp. 21–47. [Google Scholar]

- Singha, K. A Review on Coating & Lamination in Textiles: Processes and Applications. Am. J. Polym. Sci. 2012, 2, 39–49. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Wang, Y.; Song, J.; Zhao, Y.; Zhang, L. Quasi-static puncture resistance behaviors of architectural coated fabric. Compos. Struct. 2021, 273, 114307. [Google Scholar] [CrossRef]

- Kanesalingam, S.; Nayak, R.; Wang, L.; Padhye, R.; Arnold, L. Stab and puncture resistance of silica-coated Kevlar–wool and Kevlar–wool–nylon fabrics in quasistatic conditions. Text. Res. J. 2019, 89, 2219–2235. [Google Scholar] [CrossRef]

- Firouzi, D.; Foucher, D.A.; Bougherara, H. Nylon-coated ultra high molecular weight polyethylene fabric for enhanced penetration resistance. J. Appl. Polym. Sci. 2014, 131, 40350. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Mottaghitalab, V.; Babaei, H.; Rezaei, M. The influence of carbon nanotubes on quasi-static puncture resistance and yarn pull-out behavior of shear-thickening fluids (STFs) impregnated woven fabrics. Compos. Part A Appl. Sci. Manuf. 2016, 88, 263–271. [Google Scholar] [CrossRef]

- Somarathna, H.M.C.C.; Raman, S.N.; Mohotti, D.; Mutalib, A.A.; Badri, K.H. The use of polyurethane for structural and infrastructural engineering applications: A state-of-the-art review. Constr. Build. Mater. 2018, 190, 995–1014. [Google Scholar] [CrossRef]

- Pongsathit, S.; Chen, S.Y.; Rwei, S.P.; Pattamaprom, C. Eco-friendly high-performance coating for polyester fabric. J. Appl. Polym. Sci. 2019, 136, 48002. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, D. Structure-property relationships of waterborne polyurethane (WPU) in aqueous formulations. J. Vinyl Addit. Technol. 2023, 29, 589–606. [Google Scholar] [CrossRef]

- Yang, H.-H.; Gupta, S.K.; Dhital, N.B. Emission factor, relative ozone formation potential and relative carcinogenic risk assessment of VOCs emitted from manufacturing industries. Sustain. Environ. Res. 2020, 20, 28–43. [Google Scholar] [CrossRef]

- Honarkar, H. Waterborne polyurethanes: A review. J. Dispers. Sci. Technol. 2018, 39, 507–516. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Raju, K.V.S.N. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, D. Waterborne polyurethane in textiles treatment. In Waterborne Polyurethanes (WBPUs): Production, Chemistry and Applications; Mohammadi, A., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2023; pp. 251–272. [Google Scholar]

- Bragaglia, M.; Cherubini, V.; Nanni, F. PEEK -TiO2 composites with enhanced UV resistance. Compos. Sci. Technol. 2020, 199, 108365. [Google Scholar] [CrossRef]

- Gorrasi, G.; Sorrentino, A. Photo-oxidative stabilization of carbon nanotubes on polylactic acid. Polym. Degrad. Stab. 2013, 98, 963–971. [Google Scholar] [CrossRef]

- Cheraghian, G.; Wistuba, M.P. Effect of Fumed Silica Nanoparticles on Ultraviolet Aging Resistance of Bitumen. Nanomater. 2021, 11, 454. [Google Scholar] [CrossRef]

- Rashvand, M.; Ranjbar, Z.; Rastegar, S. Nano zinc oxide as a UV-stabilizer for aromatic polyurethane coatings. Prog. Org. Coatings 2011, 71, 362–368. [Google Scholar] [CrossRef]

- Allen, N.S.; Edge, M.; Hussain, S. Perspectives on yellowing in the degradation of polymer materials: Inter-relationship of structure, mechanisms and modes of stabilisation. Polym. Degrad. Stab. 2022, 201, 109977. [Google Scholar] [CrossRef]

- Broasca, G.; Borcia, G.; Dumitrascu, N.; Vrinceanu, N. Characterization of ZnO coated polyester fabrics for UV protection. Appl. Surf. Sci. 2013, 282, 974–980. [Google Scholar] [CrossRef]

- Becheri, A.; Dürr, M.; Lo Nostro, P.; Baglioni, P. Synthesis and characterization of zinc oxide nanoparticles: Application to textiles as UV-absorbers. J. Nanoparticle Res. 2008, 10, 679–689. [Google Scholar] [CrossRef]

- Grigoriadou, I.; Paraskevopoulos, K.M.; Chrissafis, K.; Pavlidou, E.; Stamkopoulos, T.G.; Bikiaris, D. Effect of different nanoparticles on HDPE UV stability. Polym. Degrad. Stab. 2011, 96, 151–163. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, D. The effect of silica/polyurethane waterborne dispersion on the perforating features of impregnated polypropylene-based fabric. Text. Res. J. 2020, 90, 1201–1211. [Google Scholar] [CrossRef]

- Patti, A.; Costa, F.; Perrotti, M.; Barbarino, D.; Acierno, D. Polyurethane Impregnation for Improving the Mechanical and the Water Resistance of Polypropylene-Based Textiles. Materials 2021, 14, 1951. [Google Scholar] [CrossRef] [PubMed]

- Patti, A.; Acierno, D. The Puncture and Water Resistance of Polyurethane- Impregnated Fabrics after UV Weathering. Polymers 2019, 12, 15. [Google Scholar] [CrossRef]

- Aljoumaa, K.; Abboudi, M. Physical ageing of polyethylene terephthalate under natural sunlight: Correlation study between crystallinity and mechanical properties. Appl. Phys. A 2015, 122, 6. [Google Scholar] [CrossRef]

- Li, L.; Frey, M.; Browning, K.J. Biodegradability Study on Cotton and Polyester Fabrics. J. Eng. Fiber. Fabr. 2010, 5, 42–53. [Google Scholar] [CrossRef]

- Lando, G.A.; Marconatto, L.; Kessler, F.; Lopes, W.; Schrank, A.; Vainstein, M.H.; Weibel, D.E. UV-Surface Treatment of Fungal Resistant Polyether Polyurethane Film-Induced Growth of Entomopathogenic Fungi. Int. J. Mol. Sci. 2017, 18, 1536. [Google Scholar] [CrossRef]

- Sung, L.P.; Jasmin, J.; Cu, X.; Nguyen, T.; Martins, J.W. Use of laser scanning confocal microscopy for characterizing changes in film thickness and local surface morphology of UV-exposed polymer coatings. J. Coatings Technol. Res. 2004, 1, 267–276. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Liu, W.; Wang, R.; Yang, F.; Hao, L.; Zheng, T.; Jiao, W.; Jiang, L. Remarkable improvement in interfacial shear strength of carbon fiber/epoxy composite by large-scare sizing with epoxy sizing agent containing amine-treated MWCNTs. Polym. Compos. 2018, 39, 2734–2742. [Google Scholar] [CrossRef]

- Xie, F.; Zhang, T.; Bryant, P.; Kurusingal, V.; Colwell, J.M.; Laycock, B. Degradation and stabilization of polyurethane elastomers. Prog. Polym. Sci. 2019, 90, 211–268. [Google Scholar] [CrossRef]

- Nagaraju, G.; Udayabhanu; Shivaraj; Prashanth, S.A.; Shastri, M.; Yathish, K.V.; Anupama, C.; Rangappa, D. Electrochemical heavy metal detection, photocatalytic, photoluminescence, biodiesel production and antibacterial activities of Ag–ZnO nanomaterial. Mater. Res. Bull. 2017, 94, 54–63. [Google Scholar] [CrossRef]

- Cohen, S.; Chejanovsky, I.; Suckeveriene, R.Y. Grafting of Poly(Ethylene Imine) to Silica Nanoparticles for Odor Removal from Recycled Materials. Nanomaterials 2022, 12, 2237. [Google Scholar] [CrossRef] [PubMed]

- Dolatzadeh, F.; Moradian, S.; Jalili, M.M. Influence of various surface treated silica nanoparticles on the electrochemical properties of SiO2/polyurethane nanocoatings. Corros. Sci. 2011, 53, 4248–4257. [Google Scholar] [CrossRef]

| WPU | ZnO | SiO2 (200) | SiO2 (R812) | CNT | |

|---|---|---|---|---|---|

| FAB-PU | 13 g | / | / | / | / |

| FAB-PU + 1% ZnO | 13 g | 1% in wt. (* = 0.04 g) | / | / | / |

| FAB-PU + 4% ZnO | 13 g | 4% in wt. (* = 0.18 g) | / | / | / |

| FAB-PU + 1% SiO2 (200) | 13 g | / | 1% in wt. (* = 0.04 g) | / | / |

| FAB-PU + 4% SiO2 (200) | 13 g | / | 4% in wt. (* = 0.18 g) | / | / |

| FAB-PU + 1% SiO2 (R812) | 13 g | / | / | 1% in wt. (* = 0.04 g) | / |

| FAB-PU + 4% SiO2 (R812) | 13 g | / | / | 4% in wt. (* = 0.18 g) | / |

| FAB-PU + 1% CNT | 13 g | / | / | / | 1% in wt. (* = 0.04 g) |

| FAB-PU + 4% CNT | 13 g | / | / | / | 4% in wt. (* = 0.18 g) |

| Load | Displacement | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Before UV | MN | MD | MIN | MAX | STD | MN | MD | MIN | MAX | STD |

| FAB | 162 | 157 | 152 | 182 | 9 | 28 | 26 | 21 | 51 | 7 |

| FAB-PU | 202 | 201 | 170 | 244 | 28 | 26 | 26 | 15 | 35 | 20 |

| FAB-PU + 1% ZnO | 187 | 188 | 158 | 214 | 16 | 20 | 18 | 15 | 26 | 4 |

| FAB-PU + 4% ZnO | 201 | 197 | 161 | 241 | 22 | 21 | 21 | 14 | 35 | 5 |

| FAB-PU + 1% SiO2 (200) | 196 | 195 | 153 | 239 | 22 | 22 | 21 | 12 | 33 | 6 |

| FAB-PU + 4% SiO2 (200) | 203 | 205 | 153 | 237 | 22 | 21 | 19 | 13 | 33 | 6 |

| FAB-PU + 1% SiO2 (R812) | 188 | 190 | 127 | 246 | 30 | 19 | 17 | 11 | 44 | 8 |

| FAB-PU + 4% SiO2 (R812) | 202 | 211 | 162 | 250 | 31 | 19 | 18 | 12 | 27 | 5 |

| FAB-PU + 1% CNT | 205 | 207 | 161 | 244 | 27 | 18 | 18 | 12 | 27 | 3 |

| FAB-PU + 4% CNT | 203 | 204 | 144 | 240 | 34 | 19 | 19 | 15 | 33 | 4 |

| After UV | ||||||||||

| FAB | 153 | 149 | 134 | 194 | 18 | 25 | 23 | 16 | 44 | 7 |

| FAB-PU | 162 | 156 | 134 | 201 | 23 | 20 | 18 | 15 | 33 | 5 |

| FAB-PU + 1% ZnO | 194 | 197 | 144 | 261 | 32 | 20 | 19 | 14 | 31 | 5 |

| FAB-PU + 4% ZnO | 187 | 181 | 139 | 258 | 31 | 19 | 18 | 13 | 29 | 4 |

| FAB-PU + 1% SiO2 (200) | 182 | 184 | 137 | 246 | 28 | 18 | 17 | 10 | 29 | 5 |

| FAB-PU + 4% SiO2 (200) | 179 | 180 | 127 | 237 | 35 | 19 | 17 | 10 | 38 | 7 |

| FAB-PU + 1% SiO2 (R812) | 189 | 190 | 130 | 239 | 31 | 18 | 17 | 13 | 31 | 5 |

| FAB-PU + 4% SiO2 (R812) | 205 | 205 | 163 | 245 | 26 | 17 | 16 | 11 | 27 | 4 |

| FAB-PU + 1% CNT | 192 | 200 | 159 | 212 | 19 | 16 | 17 | 11 | 23 | 3 |

| FAB-PU + 4% CNT | 204 | 205 | 162 | 235 | 21 | 16 | 15 | 12 | 23 | 4 |

| L2930 | L1730 | L1530 | L1245 | |

|---|---|---|---|---|

| FAB-PU | 0.73 | 0.72 | 0.80 | 0.84 |

| FAB-PU + 4% ZnO | 0.75 | 0.85 | 0.67 | 0.81 |

| FAB-PU + 4% SiO2 (200) | 1.25 | 0.85 | 0.66 | 0.80 |

| FAB-PU + 4% SiO2 (R812) | 0.77 | 0.83 | 0.89 | 0.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acierno, D.; Graziosi, L.; Patti, A. Puncture Resistance and UV aging of Nanoparticle-Loaded Waterborne Polyurethane-Coated Polyester Textiles. Materials 2023, 16, 6844. https://doi.org/10.3390/ma16216844

Acierno D, Graziosi L, Patti A. Puncture Resistance and UV aging of Nanoparticle-Loaded Waterborne Polyurethane-Coated Polyester Textiles. Materials. 2023; 16(21):6844. https://doi.org/10.3390/ma16216844

Chicago/Turabian StyleAcierno, Domenico, Lucia Graziosi, and Antonella Patti. 2023. "Puncture Resistance and UV aging of Nanoparticle-Loaded Waterborne Polyurethane-Coated Polyester Textiles" Materials 16, no. 21: 6844. https://doi.org/10.3390/ma16216844

APA StyleAcierno, D., Graziosi, L., & Patti, A. (2023). Puncture Resistance and UV aging of Nanoparticle-Loaded Waterborne Polyurethane-Coated Polyester Textiles. Materials, 16(21), 6844. https://doi.org/10.3390/ma16216844