Turning Waste into Treasure: The Full Technological Process and Product Performance Characterization of Flushable Wet Wipes Prepared from Corn Stalk

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Methods

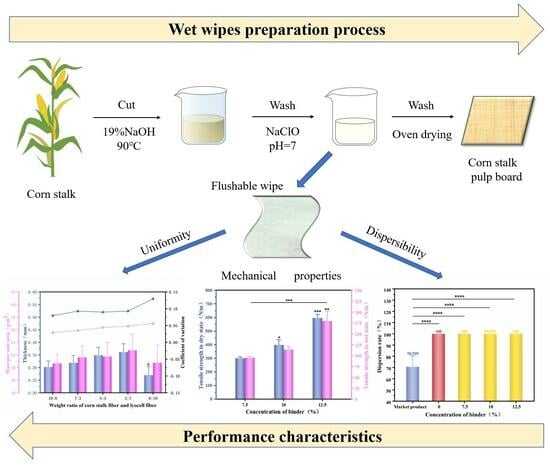

2.2.1. Preparation of Corn Stalk Pulp

2.2.2. Preparation of Corn Stalk Pulp Boards

2.2.3. Preparation of Flushable Wipes

2.3. Characterization

2.3.1. Characterization of Corn Stalk Pulp

Yield of Corn Stalk Pulp

Whiteness

2.3.2. Characterization of Corn Stalk Pulp Board

Morphology

Fourier Transform Infrared Spectroscopy (FTIR)

X-ray Diffractometer (XRD)

Mechanical Properties

Component Analysis

2.3.3. Characterization of Flushable Wipes

Thickness and Mass per Unit Area

Optical Image Analysis of the Web

Mechanical Properties

Dispersibility

Absorption

2.3.4. Data Analysis

3. Results and Discussion

3.1. Alkali Treatment and Bleaching of Corn Stalk Pulp

3.2. Performance of the Corn Stalk Pulp Board

3.2.1. Morphology of the Corn Stalk Pulp Board

3.2.2. Structure and Crystallinity

3.2.3. Mechanical Properties

3.2.4. Components of Corn Stalk

3.3. Performance of the Flushable Wet Wipes

3.3.1. Uniformity of the Flushable Wet Wipes

3.3.2. Mechanical Properties

3.3.3. Dispersibility

3.3.4. Absorption Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shruti, V.C.; Pérez-Guevara, F.; Kutralam-Muniasamy, G. Wet wipes contribution to microfiber contamination under COVID-19 era: An important but overlooked problem. Environ. Chall. 2021, 5, 100267. [Google Scholar] [CrossRef]

- Munoz, L.P.; Baez, A.G.; McKinney, D.; Garelick, H. Characterisation of “flushable” and “non-flushable” commercial wet wipes using microRaman, FTIR spectroscopy and fluorescence microscopy: To flush or not to flush. Environ. Sci. Pollut. Res. 2018, 25, 20268–20279. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Jeong, S.; Chae, K.J. Discharge of microplastics fibres from wet wipes in aquatic and solid environments under different release conditions. Sci. Total Environ. 2021, 784, 147144. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.L.P.; Prata, J.C.; Duarte, A.C.; Soares, A.M.V.M.; Rocha-Santos, T. Microplastics in landfill leachates: The need for reconnaissance studies and remediation technologies. Case Stud. Chem. Environ. Eng. 2021, 3, 100072. [Google Scholar] [CrossRef]

- Lima, A.R.A.; Ferreira, G.V.B.; Barrows, A.P.W.; Christiansen, K.S.; Treinish, G.; Toshack, M.C. Global patterns for the spatial distribution of floating microfibers: Arctic Ocean as a potential accumulation zone. J. Hazard. Mater. 2021, 403, 123796. [Google Scholar] [CrossRef] [PubMed]

- Kutralam-Muniasamy, G.; Pérez-Guevara, F.; Elizalde-Martinez, I.; Shruti, V.C. An overview of recent advances in micro/nano beads and microfibers research: Critical assessment and promoting the less known. Sci. Total Environ. 2020, 740, 139991. [Google Scholar] [CrossRef]

- Li, W.A.; Liu, N.; Nie, D.; Li, S.Y. Study on performance and material of flushable wet wipes. Text. Rep. 2020, 39, 16–20. [Google Scholar]

- Gao, J.Y.; Wu, H.B. Manufacture Technology of Flushable Material Used for Wet Wipes. China Pulp Pap. 2012, 31, 15–18. [Google Scholar]

- Zhang, Y.J.; Xu, Y.K.; Zhao, Y.; Huang, C.; Jin, X.Y. Effects of short-cut fiber type and water-jet pressure sum on wet strength and dispersibility of wood pulp-based wetlaid/spunlace wipes. Eur. J. Wood Wood Prod. 2018, 77, 33–43. [Google Scholar] [CrossRef]

- Deng, C.; Liu, W.J.; Zhang, Y.J.; Huang, C.; Zhao, Y.; Jin, X.Y. Environmentally friendly and breathable wet-laid hydroentangled nonwovens for personal hygiene care with excellent water absorbency and flushability. R. Soc. Open Sci. 2018, 5, 171486. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Deng, C.; Wang, Y.X.; Huang, C.; Zhao, Y.; Jin, X.Y. A new dispersible moist wipe from wetlaid/spunlace nonwoven: Development and characterization. J. Ind. Text. 2019, 48, 1136–1150. [Google Scholar] [CrossRef]

- Atasagun, H.G.; Bhat, G.S. Advancement in flushable wipes: Modern technologies and characterization. J. Ind. Text. 2020, 49, 722–747. [Google Scholar] [CrossRef]

- Durukan, S.; Karadagli, F. Physical characteristics, fiber compositions, and tensile properties of nonwoven wipes and toilet papers in relevance to what is flushable. Sci. Total Environ. 2019, 697, 134135. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Jin, Z.Y.; Meng, K.; Zhang, T.H.; Zhao, H.J. The development of flushable wipes. Tech. Text. 2021, 39, 1–8. [Google Scholar]

- Harter, T.; Steiner, H.; Bracic, M.; Kargl, R.; Hirn, U. Deteriorating dispersibility of flushable wet wipes during storage: Role of fibre swelling and ionic shielding. J. Ind. Text. 2022, 52. [Google Scholar] [CrossRef]

- Xu, Y.W.; Ji, Y.L.; Ma, J.H. Temperature-sensitive mussel-inspired citrate-based tissue adhesives with low-swelling. J. Adhes. 2023, 99, 1244–1261. [Google Scholar] [CrossRef]

- Kim, J.K.; Park, J.Y.; Lee, D.W.; Ro, D.; Lee, M.C.; Han, H.S. Temperature-sensitive anti-adhesive poloxamer hydrogel decreases fascial adhesion in total knee arthroplasty: A prospective randomized controlled study. J. Biomater. Appl. 2019, 34, 386–395. [Google Scholar] [CrossRef]

- Mei, Y.; Che, Q.; Yang, Q.; Draper, C.; Yang, H.P.; Zhang, S.H.; Chen, H.P. Torrefaction of different parts from a corn stalk and its effect on the characterization of products. Ind. Crop. Prod. 2016, 92, 26–33. [Google Scholar] [CrossRef]

- Xu, F.; Zhong, X.C.; Sun, R.C.; Lu, Q. Anatomy, ultrastructure and lignin distribution in cell wall of Caragana Korshinskii. Ind. Crop. Prod. 2006, 24, 186–193. [Google Scholar] [CrossRef]

- GB/T 24218.2-2009; Textiles—Test Methods for Nonwovens—Part 2: Determination of Thickness. Standards Press of China: Beijing, China, 2009.

- GB/T 24218.1-2009; Textiles—Test Methods for Nonwovens—Part 1: Determination of Mass per Unit Area. China Standards Press: Beijing, China, 2009.

- GB/T 40181-2021; Test Method and Evaluation of Flushability of Disposable Hygienic Nonwoven Materials. Standards Press of China: Beijing, China, 2021.

- GB/T 24218.6-2010; Test Methods for Textiles Non-Woven Fabrics Part 6: Determination of Absorption. Standards Press of China: Beijing, China, 2010.

- Wang, D.M. Experimental discussion on the bleaching effect of sodium hypochlorite bleaching solution pH value and temperature on viscose filament. Artif. Fiber 2007, 37, 13–15. [Google Scholar]

- Wu, A.B. Bleaching Cotton Linter Pulp with Sodium Hypochlorite. Pap. Chem. 2010, 22, 34–35. [Google Scholar]

- Huang, S.; Zhou, L.; Li, M.C.; Wu, Q.L.; Zhou, D.G. Cellulose Nanocrystals (CNCs) from Corn Stalk: Activation Energy Analysis. Materials 2017, 10, 80. [Google Scholar] [CrossRef] [PubMed]

- Durukan, S.; Karadagli, F. Experimental data for physical characteristics, fiber compositions, and tensile properties of nonwoven wipes and toilet papers. Data Brief 2020, 28, 104818. [Google Scholar] [CrossRef] [PubMed]

- Taylor, L.D.; Cerankowski, L.D. Preparation of films exhibiting a balanced temperature dependence to permeation by aqueous solutions—A study of lower consolute behavior. J. Polym. Sci. Polym. Chem. Ed. 1975, 13, 2551–2570. [Google Scholar] [CrossRef]

- Ruel-Gariépy, E.; Leroux, J.C. In situ-forming hydrogels--review of temperature-sensitive systems. Eur. J. Pharm. Biopharm. 2004, 58, 409–426. [Google Scholar] [CrossRef] [PubMed]

- Schild, H.G. Poly(N-isopropylacrylamide): Experiment, theory and application. Prog. Polym. Sci. 1992, 17, 163–249. [Google Scholar] [CrossRef]

- Park, K. Controlled Drug Delivery: Challenges and strategies. J. Am. Chem. Soc. 1998, 120, 4554–4555. [Google Scholar] [CrossRef]

- Fawaz, F.; Koffi, A.; Guyot, M.; Millet, P. Comparative in vitro-in vivo study of two quinine rectal gel formulations. Int. J. Pharm. 2004, 280, 151–162. [Google Scholar] [CrossRef] [PubMed]

- Michels, L.R.; Fachel, F.N.S.; Schuh, R.S.; Azambuja, J.H.; de Souza, P.O.; Gelsleichter, N.E.; Lenz, G.S.; Visioli, F.; Braganhol, E.; Teixeira, H.F. Nasal administration of a temozolomide-loaded thermoresponsive nanoemulsion reduces tumor growth in a preclinical glioblastoma model. J. Control. Release 2023, 355, 343–357. [Google Scholar] [CrossRef]

- Wang, C.J.; Zhuo, Y.; Lu, F.F.; Chen, B. Research progress on the gumming mechanism of temperature-sensitive gel materials. China Pharm. 2013, 24, 3545–3547. [Google Scholar]

- Wanka, G.; Hoffmann, H.; Ulbricht, W. Phase diagrams and aggregation behavior of Poly(oxyethylene)-Poly(oxypropylene)-Poly(oxyethylene) triblock copolymers in aqueous solutions. Macromolecules 1994, 27, 10. [Google Scholar] [CrossRef]

- Jin, H.; Zha, C.; Gu, L. Direct dissolution of cellulose in NaOH/thiourea/urea aqueous solution. Carbohydr. Res. 2007, 342, 851–858. [Google Scholar] [CrossRef] [PubMed]

- Xu, M. Application of corn stalk waste in the field of pulp and paper. East China Pulp. Pap. Ind. 2020, 50, 26–29. [Google Scholar]

| Number | Cellulose Ⅰ | Number | Cellulose Ⅱ |

|---|---|---|---|

| 2 | 110 (15.5) | 1 | 110 (12.1) |

| 3 | 110 (16.3) | 4 | 110 (20.3) |

| 6 | 200 (22.3) | 5 | 200 (21.9) |

| 7 | 004 (34.5) |

| Alpha-Cellulose (%) | Moisture Content (%) | Ash Content (%) | |

|---|---|---|---|

| Corn stalk pulp board | 89.95 | 4.63 | 0.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Wang, Y.; He, Z.; Cai, Y.; Meng, K.; Zhang, K.-Q.; Zhao, H. Turning Waste into Treasure: The Full Technological Process and Product Performance Characterization of Flushable Wet Wipes Prepared from Corn Stalk. Materials 2023, 16, 7189. https://doi.org/10.3390/ma16227189

Liu L, Wang Y, He Z, Cai Y, Meng K, Zhang K-Q, Zhao H. Turning Waste into Treasure: The Full Technological Process and Product Performance Characterization of Flushable Wet Wipes Prepared from Corn Stalk. Materials. 2023; 16(22):7189. https://doi.org/10.3390/ma16227189

Chicago/Turabian StyleLiu, Lulu, Yeying Wang, Ziying He, Yang Cai, Kai Meng, Ke-Qin Zhang, and Huijing Zhao. 2023. "Turning Waste into Treasure: The Full Technological Process and Product Performance Characterization of Flushable Wet Wipes Prepared from Corn Stalk" Materials 16, no. 22: 7189. https://doi.org/10.3390/ma16227189

APA StyleLiu, L., Wang, Y., He, Z., Cai, Y., Meng, K., Zhang, K. -Q., & Zhao, H. (2023). Turning Waste into Treasure: The Full Technological Process and Product Performance Characterization of Flushable Wet Wipes Prepared from Corn Stalk. Materials, 16(22), 7189. https://doi.org/10.3390/ma16227189