Finite Element Analysis of Split Sleeve Cold Expansion Process on Multiple Hole Aluminum Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Test Piece Parameters

2.2. Strain Definition

2.3. Finite Element Model

2.4. Test Equipment and Methods

3. Results and Discussion

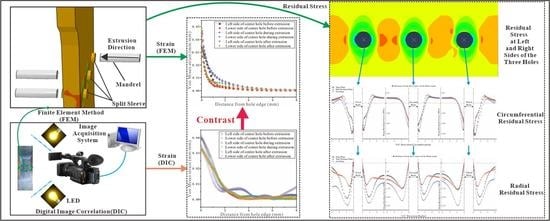

3.1. Finite Element Simulation

3.2. Strain Results of Test Piece Measured by DIC

4. Conclusions

- (1)

- A mandrel extrusion split sleeve may occur along the axial drag during the SSCE for single-hole specimens, and the exit radial plane generates tensile residual stress. However, in the case of multi-hole SSCE, the superposition of stress optimizes this phenomenon.

- (2)

- Compared with the single-hole SSCE, the radial residual compressive stress at the hole edge increases significantly during the three-hole SSCE due to the stress superposition effect, and this gain effect is more significant in the order of center hole, then left hole, and right hole. When SSCE is performed for multiple holes in actual working conditions, the SSCE sequence of middle hole, left hole, and right hole can be selected preferentially. However, in order to avoid the interference of the left and right holes with the next SSCE, it is necessary to use inserting pins for the adjacent left and right holes, and when the SSCE of these three holes is completed, the pins are removed and the sequence is repeated to perform SSCE for other holes in sequence.

- (3)

- The hole edge strain results of FEM and DIC are in good agreement. The single-hole strain results show that the hole edge strain amplitude is concentrated at the left side of the split sleeve opening and at the diagonal position, and the strain tends to transfer to the specimen edge. The multi-hole strain results further verify that the hole edge strains are transmitted in the direction of hole alignment and produce a superposition effect.

- (4)

- When the hole spacing is greater than or equal to four times the hole diameter, the strain distribution under SSCE in the adjacent hole interference is reduced and the corresponding strengthening effect is smaller. Combined with the FEM results, the interference effect between the adjacent holes with spacing four times the hole diameter can be ignored, and in the actual process the inter-hole spacing between multiple holes can be regarded as single-hole SSCE if it is greater than four times the hole diameter.

- (5)

- Based on residual compressive stress results of both circumferential and radial components, it appears that the configuration with the smaller distance between the SSCE holes is the most beneficial. However, if the plate is subjected to a tensile plane deformation, for example, by applying a force normal to the line formed by the centers of three holes, tensile stress is created in the material between the holes. Such tensile stress increases as the hole spacing decreases. Thus, these opposite effects must be considered when optimizing the configuration of the holes in the airframe.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, R.; Li, D.; Hu, D.; Meng, F.; Liu, H.; Ma, Q. A combined critical distance and highly-stressed-volume model to evaluate the statistical size effect of the stress concentrator on low cycle fatigue of TA19 plate. Int. J. Fatigue 2017, 95, 8–17. [Google Scholar] [CrossRef]

- Liu, H.; Hu, D.; Wang, R.; Wang, X.; Jin, S.; Gu, Y. Experimental and numerical investigations on the influence of cold expansion on low cycle fatigue life of bolt holes in aeroengine superalloy disk at elevated temperature. Int. J. Fatigue 2020, 132, 105390. [Google Scholar] [CrossRef]

- Shahriary, P.; Chakherlou, T.N. Investigating the effect of cold expansion on frictional force evolution during fretting fatigue tests of AL2024-T3 plates. Int. J. Mech. Sci. 2018, 135, 146–157. [Google Scholar] [CrossRef]

- Zhu, S.P.; Ye, W.L.; Correia, J.A.; Jesus, A.M.; Wang, Q. Stress gradient effect in metal fatigue: Review and solutions. Theor. Appl. Fract. Mech. 2022, 121, 103513. [Google Scholar] [CrossRef]

- Hou, S.; Zhu, Y.; Cai, Z.; Wang, Y.; Ni, Y.; Du, X. Effect of hole cold expansion on fatigue performance of corroded 7B04-T6 aluminium alloy. Int. J. Fatigue 2019, 126, 210–220. [Google Scholar] [CrossRef]

- Chakherlou, T.N.; Alvandi-Tabrizi, Y.; Kiani, A. On the fatigue behavior of cold expanded fastener holes subjected to bolt tightening. Int. J. Fatigue 2011, 33, 800–810. [Google Scholar] [CrossRef]

- Liu, J.; Shao, X.J.; Liu, Y.; Yue, Z. Effect of cold expansion on fatigue performance of open holes. Mater. Sci. Eng. A 2008, 477, 271–276. [Google Scholar] [CrossRef]

- Kim, C.; Kim, D.J.; Seok, C.-S.; Yang, W.-H. Finite element analysis of the residual stress by cold expansion method under the influence of adjacent holes. J. Mater. Process. Technol. 2004, 153, 986–991. [Google Scholar] [CrossRef]

- Fu, Y.; Ge, E.; Su, H.; Xu, J.; Li, R. Cold expansion technology of connection holes in aircraft structures: A review and prospect. Chin. J. Aeronaut. 2015, 28, 961–973. [Google Scholar] [CrossRef] [Green Version]

- Amrouche, A.; Su, M.; Aid, A.; Mesmacque, G. Numerical study of the optimum degree of cold expansion: Application for the pre-cracked specimen with the expanded hole at the crack tip. J. Mater. Process. Technol. 2008, 197, 250–254. [Google Scholar] [CrossRef]

- Curto-Cárdenas, D.; Calaf-Chica, J.; Díez, P.M.B.; Calzada, M.P.; Garcia-Tarrago, M.-J. Cold Expansion Process with Multiple Balls—Numerical Simulation and Comparison with Single Ball and Tapered Mandrels. Materials 2020, 13, 5536. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.Z.; Wang, X.S.; Gao, H.; Yue, Z. Effect of split sleeve cold expansion on cracking behaviors of titanium alloy TC4 holes. Eng. Fract. Mech. 2012, 88, 79–89. [Google Scholar] [CrossRef]

- Yuan, X.; Yue, Z.F.; Wen, S.; Li, L.; Feng, T. Numerical and experimental investigation of the cold expansion process with split sleeve in titanium alloy TC4. Int. J. Fatigue 2015, 77, 78–85. [Google Scholar] [CrossRef]

- Özdemir, A.T. Experimental assessment of the redistribution of 3-D residual stresses during early fatigue at split-sleeve cold expanded reamed A/C fastener holes. Sci. Iran. 2018, 25, 1153–1168. [Google Scholar] [CrossRef] [Green Version]

- Achard, V.; Daidié, A. Numerical modelling of the cold expansion process in mechanical stacked assemblies. In Advances on Mechanics, Design Engineering and Manufacturing, Proceedings of the International Joint Conference on Mechanics, Design Engineering & Advanced Manufacturing (JCM 2016), Catania, Italy, 14–16 September 2016; Springer: Cham, Switzerland, 2017; pp. 501–508. [Google Scholar]

- Amjad, K.; Wang, W.C.; Patterson, E. A comparison of split sleeve cold expansion in thick and thin plates. J. Strain Anal. Eng. Des. 2016, 51, 375–386. [Google Scholar] [CrossRef]

- Liu, Y.; Geng, D.; Shao, Z.; Zhou, Z.; Jiang, X.; Zhang, D. A study on strengthening and machining integrated ultrasonic peening drilling of Ti-6Al-4V. Mater. Des. 2021, 212, 110238. [Google Scholar] [CrossRef]

- Faghih, S.; Shaha, S.K.; Behravesh, S.B.; Jahed, H. Split sleeve cold expansion of AZ31B sheet: Microstructure, texture and residual stress. Mater. Des. 2020, 186, 108213. [Google Scholar] [CrossRef]

- Li, Q.; Xue, Q.; Hu, Q.; Song, T.; Wang, Y.; Li, S. Cold Expansion Strengthening of 7050 Aluminum Alloy Hole: Structure, Residual Stress, and Fatigue Life. Int. J. Aerosp. Eng. 2022, 2022, 4057898. [Google Scholar] [CrossRef]

- Chakherlou, T.N.; Shahriary, P.; Akbari, A. Experimental and numerical investigation on the fretting fatigue behavior of cold expanded Al-alloy 2024-T3 plates. Eng. Fail. Anal. 2021, 123, 105324. [Google Scholar] [CrossRef]

- Calaf-Chica, J.; Marín, M.M.; Rubio, E.M.; Teti, R.; Segreto, T. Parametric analysis of the mandrel geometrical data in a cold expansion process of small holes drilled in thick plates. Materials 2019, 12, 4105. [Google Scholar] [CrossRef] [Green Version]

- Dey, M.K.; Kim, D.; Tan, H. Finite element parametric study of the split sleeve cold expansion on residual stresses and pulling force. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 2447–2461. [Google Scholar] [CrossRef]

- Lu, G.; Li, H.; Pei, X.; Cassar, G.; Ji, Z.; Gao, R.; Wang, Q.; Yao, C. Modeling and Analysis of Variable Parameters for Compound Hole Expansion of Fit Bushing. J. Mater. Eng. Perform. 2021, 30, 8210–8223. [Google Scholar] [CrossRef]

- Zhang, T.; Du, X.; He, Y.; Ma, B.; Zhang, T. Finite Element Simulation of Residual Stress around Split Sleeve Cold Expanded Hole for AA7075. J. Phys. Conf. Ser. 2020, 1624, 022041. [Google Scholar] [CrossRef]

- Seifi, R. Total fatigue lives, crack growth paths and cycles in cold expanded adjacent holes. Int. J. Fatigue 2018, 113, 69–77. [Google Scholar] [CrossRef]

- Seifi, R.; Zolfaghari, M.H.; Shirazi, A. Experimental and numerical study of residual stresses caused by cold expansion of adjacent holes. Meccanica 2014, 49, 687–706. [Google Scholar] [CrossRef]

- Anil Kumar, S.; Mahendra Babu, N.C. Sequential Cold Expansion and Resulting Beneficial Residual Stress Prediction around Adjacent Fastener Holes. Mater. Phys. Mech 2018, 37. [Google Scholar] [CrossRef]

- Hassanifard, S.; Mohammadpour, M.; Rashid, H.A. A novel method for improving fatigue life of friction stir spot welded joints using localized plasticity. Mater. Des. 2014, 53, 962–971. [Google Scholar] [CrossRef]

- Wang, Z.; Ning, X.; Meng, Q.; Sun, S.; Fu, W. A new insight into manufacturing fine-grained heavy retaining rings. Mater. Des. 2016, 103, 152–159. [Google Scholar] [CrossRef]

- Pan, B. Digital image correlation for surface deformation measurement: Historical developments, recent advances and future goals. Meas. Sci. Technol. 2018, 29, 082001. [Google Scholar] [CrossRef]

- Cirello, A.; Pasta, S. Displacement Measurement Through Digital Image Correlation and Digital Speckle Pattern Interferometry Techniques in Cold-Expanded Holes. Strain 2010, 46, 581–588. [Google Scholar] [CrossRef]

- Pucillo, G.P.; Carrabs, A.; Cuomo, S.; Elliott, A.; Meo, M. Cold expansion of rail-end-bolt holes: Finite element predictions and experimental validation by DIC and strain gauges. Int. J. Fatigue 2021, 149, 106275. [Google Scholar] [CrossRef]

- Backman, D.; Liao, M.; Crichlow, L.; Yanishevsky, M.; A Patterson, E. The use of digital image correlation in a parametric study on the effect of edge distance and thickness on residual strains after hole cold expansion. J. Strain Anal. Eng. Des. 2008, 43, 781–789. [Google Scholar] [CrossRef]

- Backman, D.; Cowal, C.; Patterson, E.A. Analysis of the effects of cold expansion of holes using thermoelasticity and image correlation. Fatigue Fract. Eng. Mater. Struct. 2010, 33, 859–870. [Google Scholar] [CrossRef]

- Abaqus, G. Abaqus, version 6.11; Dassault Systemes Simulia Corporation: Providence, RI, USA, 2011.

- Fatigue Technology. Available online: www.fatiguetech.com (accessed on 4 December 2022).

- Gong, P.; Zheng, L.B. Effects of hole cold-expansion on microstructure and fatigue property of 7B50-T7451 aluminum alloy plate. J. Aeronaut. Mater. 2011, 31, 45–50. [Google Scholar]

- Chakherlou, T.N.; Vogwell, J. The effect of cold expansion on improving the fatigue life of fastener holes. Eng. Fail. Anal 2003, 10, 13–24. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, X.; Liu, J.; Yue, Z. Finite element method and experimental investigation on the residual stress fields and fatigue performance of cold expansion hole. Meas. Sci. 2010, 31, 1208–1215. [Google Scholar] [CrossRef]

- Shi, G.; Yanishevsky, M. A Parametric Study on Modeling of Residual Stress Profiles Induced by the Hole Cold Expansion Process. Proc. Aging Aircr. 2007. Available online: http://ir.fy.edu.tw/ir/handle/987654321/13398 (accessed on 4 December 2022).

- Mann, J.Y.; Sparrow, J.G.; Beaver, P. Fatigue characteristics of joints with holes cold-expanded in a multi-layer stack. Int. J. Fatigue 1989, 11, 214–220. [Google Scholar] [CrossRef]

- Yanishevsky, M.; Li, G.; Shi, G.; Backman, D. Fractographic examination of coupons representing aircraft structural joints with and without hole cold expansion. Eng. Fail. Anal. 2013, 30, 74–90. [Google Scholar] [CrossRef]

- Houghton, S.J.; Campbell, S.K.; James, A.D. Investigations into the fatigue enhancement provided by the hole cold expansion process using accurate 3D FEA simulations and fatigue testing. In ICAF 2011 Structural Integrity: Influence of Efficiency and Green Imperatives, Proceedings of the 26th Symposium of the International Committee on Aeronautical Fatigue, Montreal, QC, Canada, 1–3 June 2011; Springer: Dordrecht, The Netherlands, 2011; pp. 839–853. [Google Scholar]

- Amjad, K. Study of Residual Stresses Around Cold-Expanded Holes. Ph.D. Thesis, The University of Liverpool, Liverpool, UK, 2018. [Google Scholar]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Quality Score/% | 0.03 | 0.22 | 1.55 | 0.09 | 2.38 | 0.19 | 5.4 | 0.02 | remainder |

| Material | Thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 7075-T6 | 4 | 556–566 | 506–509 | 11.5–12.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Dong, M.; Zhang, T.; Wang, C.; Hou, B.; Li, C. Finite Element Analysis of Split Sleeve Cold Expansion Process on Multiple Hole Aluminum Alloy. Materials 2023, 16, 1109. https://doi.org/10.3390/ma16031109

Lv Y, Dong M, Zhang T, Wang C, Hou B, Li C. Finite Element Analysis of Split Sleeve Cold Expansion Process on Multiple Hole Aluminum Alloy. Materials. 2023; 16(3):1109. https://doi.org/10.3390/ma16031109

Chicago/Turabian StyleLv, Yuan, Meng’en Dong, Teng Zhang, Changkai Wang, Bo Hou, and Changfan Li. 2023. "Finite Element Analysis of Split Sleeve Cold Expansion Process on Multiple Hole Aluminum Alloy" Materials 16, no. 3: 1109. https://doi.org/10.3390/ma16031109

APA StyleLv, Y., Dong, M., Zhang, T., Wang, C., Hou, B., & Li, C. (2023). Finite Element Analysis of Split Sleeve Cold Expansion Process on Multiple Hole Aluminum Alloy. Materials, 16(3), 1109. https://doi.org/10.3390/ma16031109