The Fire Resistance Performance of Recycled Aggregate Concrete Columns with Different Concrete Compressive Strengths

Abstract

:1. Introduction

2. Experimental Details

2.1. Model Design

2.2. Aggregates, Concrete Mix Design, and Concrete Mechanical Properties

| Grade level | RCA replacement ratio (%) | Water-to-cement ratio | Water (kg·m−3) | Cement (kg·m−3) | FA (kg·m−3) | NA (kg·m−3) | RCA (kg·m−3) | HRWR (kg·m−3) |

|---|---|---|---|---|---|---|---|---|

| C20 | 0 | 0.56 | 107 | 152 | 906 | 1037 | - | 6.08 |

| C30 | 0 | 0.45 | 111 | 208 | 894 | 990 | - | 7.56 |

| C30 | 100 | 0.56 | 186 | 335 | 576 | - | 1116 | - |

| C40 | 100 | 0.37 | 178 | 482 | 464 | - | 1124 | - |

| Specimen | RCA replacement ratio (%) | Designed concrete level | Test cubic compressive strength (MPa) | Elastic modulus (MPa) |

|---|---|---|---|---|

| NCC-1 | 0 | C20 | 17.84 | 2.34 × 104 |

| NCC-2 | 0 | C30 | 30.85 | 3.03 × 104 |

| RCC-1 | 100 | C30 | 28.57 | 2.65 × 104 |

| RCC-2 | 100 | C40 | 40.70 | 3.15 × 104 |

2.3. Vertical Loading

| Specimen | Cross section (mm) | Vertical axial load (kN) | Axial force ratio | Real axial force ratio |

|---|---|---|---|---|

| NCC-1 | 450 × 450 | 3000 | 1.737 | 0.830 |

| NCC-2 | 5250 | 1.758 | 0.840 | |

| RCC-1 | 4800 | 1.736 | 0.830 | |

| RCC-2 | 6900 | 1.751 | 0.837 |

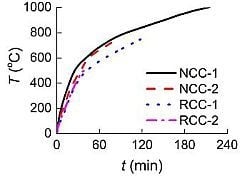

2.4. Loading Equipment and the Heating Curves

3. Results and Discussion

3.1. Test Results and Analysis

3.1.1. Fire Resistance Duration

| Specimen | Fire resistance duration (min) | Cubic compressive strength before fire test (MPa) | Residual cubic compressive strength after fire test (MPa) | Loss rate of cubic compressive strength after fire test (%) |

|---|---|---|---|---|

| NCC-1 | 227 | 17.84 | 0 | 100.0 |

| NCC-2 | 78 | 30.85 | 16.14 | 47.7 |

| RCC-1 | 118 | 28.57 | 10.06 | 64.8 |

| RCC-2 | 39 | 40.70 | 35.20 | 13.5 |

3.1.2. Temperature at the Measured Points

| Measure Point | TNCC-1 (°C) | TNCC-2 (°C) | TNCC-2/TNCC-1 | TRCC-1 (°C) | TRCC-2 (°C) | TRCC-2/TRCC-1 |

|---|---|---|---|---|---|---|

| Point 1 | 590.0 | 560.2 | 0.949 | 482.5 | 503.6 | 1.044 |

| Point 2 | 44.2 | 52.4 | 1.186 | 23.1 | 27.6 | 1.194 |

| Point 3 | 13.2 | 18.6 | 1.409 | 14.7 | 16.6 | 1.129 |

- (1)

- Before the 39 min of heating, the curves of “measured temperature to time” of the four specimens appear very similar. The temperature variation at the cross section for both the normal RC columns and the RAC columns shows no significant difference.

- (2)

- The heating rate is slower and the fire resistance duration is longer for RAC column RCC-1 compared to normal concrete column NCC-2, which has almost the same concrete strength rating. This could be attributed to the greater porosity and water absorption in RCAs, causing greater moisture content, which may in turn consume more heat through water evaporation [24].

- (3)

- The fire resistance performance of lower concrete strength columns with the same cross section is better than that of higher concrete strength columns under the same initial axial force ratio. Because of the lower permeability with increased strength of concrete, higher concrete strength is more susceptible to spalling and results in lower fire resistance [25].

- (4)

- The variation tendency of heating curves from Measure Point 1, which is very close to the outside of the columns, is similar to that from ISO834 [21] in Figure 3, while the curves from Measure Point 2, which is further from the outside of the columns, are significantly different from that of ISO834 [21]. As seen in Table 5, the temperatures at Point 3 were not affected by the fire at such a short heating time of 39 min because Point 3, which is in the center of the column section, is far from the fire.

- (5)

- Due to the rapid proliferation of internal cracks inside the columns through heating, at around 40 min heating, the heating rate at Measure Point 2 for normal concrete specimen NCC-1 and NCC-2 increases, while at Point 2 around 120 min and at Point 3 around 100 min for specimen NCC-1 the increase accelerates.

- (6)

- As shown in Table 5, there are six ratio values of TNCC-2/TNCC-1 and TRCC-2/TRCC-1 in total for four specimens, with five of them greater than 1. The temperature for higher concrete strength columns at the same measure points and same moment is slightly higher, but the difference is small.

3.1.3. Vertical Axial Displacement

- (1)

- The normal RC column NCC-2 shows axial extension before 48 min, while the columns NCC-1, RCC-1, and RCC-2 do not. The expansion of inner air voids in the vertical axial direction under the pressure of trapped expanding steam during heating made the axial extension for column NCC-2. Similar axial extension happened for columns under heating test in Miao’s paper [26]. The extension for NCC-2 reaches its maximum value of 1.1 mm at 27 min, corresponding to a strain of 0.00367, which is almost the ultimate strain of concrete. After the internal air was released from the microcrack, the value of axial extension for NCC-2 returns to 0 at about 48 min. The column started to shorten and cracks developed.

- (2)

- The RAC columns RCC-1 and RCC-2 exhibited no axial extension. The fire resistance performance of RCC-1 is better than that of RCC-2: Specimen RCC-2 deformed sharply and was seriously damaged at 39 min heating, while this happened 79 min later (at 118 min) for RCC-1. The cracks on the column with higher concrete strength started earlier because of its greater axial compression force N under the similar axial force ratio n; N can be seen in Table 3. Then the cracks led to a greater rate of temperature transmission to the interior of the columns, which resulted in a gradual deterioration of the inner concrete. During the test, the axial compression force remained unchanged, which means the axial force ratio N in Equation (1) remained constant. The actual area of the cross section of columns reduced during the test because the concrete started to crack and some material was shed under heating, which means fc and Ac in Equation (1) became smaller and the actual axial force ratio n became greater. This is the key factor in the sharp deformation of columns—the damage which occurred under the combined effect of heating and axial load.

- (3)

- The concrete strength of the normal RC column NCC-2 is very close to that of the RAC column RCC-1. The axial displacement was only 2.3 mm at 78 min for NCC-2, then the axial deformation increased sharply and the column exhibited sudden damage. The same occurred to RCC-1 at 118 min, with an axial displacement of 15 mm. The duration of effective fire resistance for specimen RCC-1 is therefore 51.28% longer than that of NCC-2. The greater porosity in the RCAs enables the column RCC-1 to exhibit greater deformation under heating. This clearly shows that the RAC column has better fire resistance performance than the normal RC column.

3.1.4. Lateral Deflection

| Specimen | NCC-1 | NCC-2 | RCC-1 | RCC-2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time-point (min) | 40 | 80 | 120 | 25 | 50 | 60 | 40 | 80 | 118 | 15 | 27 | 39 |

| f1 (mm) | 1.40 | 3.00 | 6.00 | 0.50 | 4.00 | 8.00 | 0.12 | 0.20 | 2.90 | 0.13 | 0.40 | 4.50 |

| f2 (mm) | 1.00 | 1.70 | 2.60 | 0.30 | 1.50 | 2.20 | 0.10 | 0.15 | 0.60 | 0.10 | 0.25 | 1.50 |

| f1/f2 | 1.40 | 1.76 | 2.31 | 1.67 | 2.67 | 3.64 | 1.20 | 1.33 | 4.83 | 1.30 | 1.60 | 3.00 |

- (1)

- The developing rate of lateral deflection of all the specimens became faster with the increase of heating time.

- (2)

- The ratio of f1 to f2 increased more quickly at the later period with the increase of heating time.

- (3)

- Compared to the normal RC column NCC-2 with a similar concrete strength, the lateral deflection of RAC column RCC-1 was smaller at the earlier heating and the deformation developing was relatively stable because more heat needed to be consumed by the greater moisture content in recycled aggregates; this induced less severe deformation in the specimen.

- (4)

- The concrete on the top part of column RCC-1 cracked and the column failed while there were no lateral displacements during the first 90 min of the fire at the bottom and middle part of the column.

3.1.5. Failure Characteristics

- (1)

- Specimen NCC-1. The observed cracks occurred at about 39 min. It could be observed through an observation port on the furnace that the dense cracks appeared at about 60 min. The bared coarse aggregate turned whiter and then the column failed at 227 min. There was a vertical crack with a maximum width of 2 mm running through the height of the column on the four sides. The concrete dropped from a large area, about 300 mm to 130 mm along the height from the top. The steel bars buckled to 50 mm at this position, which is 600 mm from the top.

- (2)

- Specimen NCC-2. The observed cracks occurred at about 28 min. Dense cracks appeared at about 40 min. The lateral deflection started to accelerate at 60 min and the column failed at 78 min. The maximum lateral deflection reached 198.5 mm. The concrete dropped at the area of 200 mm to 1110 mm from the bottom. The steel bars were exposed and buckled to 60 mm.

- (3)

- Specimen RCC-1. The observed cracks occurred at around 50 min. The cracks stretched visibly at about 90 min, and the specimen failed at 118 min. The concrete cover, which was 700 mm from the top, separated from the column and the inside steel bars were exposed. A vertical crack with a maximum width of 2 mm ran along the height of the column. The steel bars buckled to 50 mm, 350 mm down from the top of the column.

- (4)

- Specimen RCC-2. The observed cracks occurred at about 30 min. The cracks stretched visibly at about 35 min. At 36 min 51 s, concrete spalling occurred on the column over a large area, 50 mm to 1100 mm up from the bottom, and the inside steel bars were exposed. Figure 13 shows the concrete spalling process at different moments. Then the specimen failed at 39 min. A vertical crack with a maximum width of 2 mm ran through the height of the column and all the steel bars buckled to 50 mm.

3.2. Finite Element Method Analysis on Temperature Field of Concrete Columns

3.2.1. Thermal Performance Parameters

3.2.2. Finite Element Method

3.2.3. Finite Element Method Calculating and Analysis

| Specimen measure point | NCC-1 | NCC-2 | RCC-1 | RCC-2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |

| Test temperature (°C) | 590.0 | 44.2 | 13.2 | 560.2 | 52.4 | 18.6 | 482.5 | 23.1 | 14.7 | 503.6 | 27.6 | 16.6 |

| Calculated temperature (°C) | 543.7 | 43.4 | 12.8 | 478.9 | 48.2 | 18.0 | 429.9 | 22.3 | 14.5 | 539.8 | 26.2 | 16.5 |

| Relative error (%) | −7.8 | −1.8 | −3.0 | −14.5 | −8.0 | −3.2 | −10.9 | −3.5 | −1.4 | 7.2 | −5.1 | −0.6 |

4. Conclusions

- (1)

- The rate of heat transfer from the surface to the inside of the column increases with compressive strength for both RAC columns and normal RC columns during fire conditions.

- (2)

- Under the same initial axial force ratio, for both RAC columns and normal RC columns with the same cross section, those with lower concrete compressive strengths demonstrate better fire resistance performance. The fire resistance performance decreases as the concrete compressive strength increases, due to its higher density and lower porosity, which cause cracks to appear earlier and the material to degrade more rapidly.

- (3)

- The fire resistance performance of RAC columns is better than that of the normal concrete columns with the same concrete compressive strength. This is because the rate of temperature penetration for RAC columns is lower than that of normal RC columns under nominal fire condition heating.

- (4)

- Finite element method (FEM) analysis on the temperature fields of both the normal concrete columns and RAC columns, which showed almost the same results as the experiments, is able to be used to avoid the expensive test cost.

- (5)

- The RAC columns may be applied in practical projects.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lie, T.T.; Celikkol, B. Method to calculate the fire resistance of circular reinforced concrete columns. ACI Mater. J. 1991, 88, 84–91. [Google Scholar]

- Lie, T.T.; Irwin, R.J. Method to calculate the fire resistance of reinforced concrete columns with rectangular cross section. ACI Struct. J. 1993, 90, 52–60. [Google Scholar]

- Kodur, V.K.R.; Dwaikat, M. Performance-based fire safety design of reinforced concrete beams. J. Fire Prot. Eng. 2007, 17, 293–320. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Dwaikat, M. A numerical model for predicting the fire resistance of reinforced concrete beams. Cem. Concr. Compos. 2008, 30, 431–443. [Google Scholar] [CrossRef]

- Raut, N.; Kodur, V. Response of reinforced concrete columns under fire-induced biaxial bending. ACI Struct. J. 2011, 108, 610–619. [Google Scholar]

- Iguchi, S.; Hirashima, T.; Matsudo, M.; Shinozuka, W.; Kaneshiro, R. Fire performance of mixed structures composed of reinforced concrete columns and steel beams—Part 2—Influence of concrete spalling and forced horizontal displacement on the fire resistance of R/C columns. J. Struct. Constr. Eng. 2013, 78, 623–631. [Google Scholar] [CrossRef]

- Gernay, T.; Dimia, M.S. Structural behaviour of concrete columns under natural fires. Eng. Comput. 2013, 30, 854–872. [Google Scholar] [CrossRef]

- Hansen, T.C. Recycled aggregates and recycled aggregate concrete second state-of-the-art report developments 1945–1985. Mater. Struct. 1986, 19, 201–246. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M. Assessment of durability of recycled aggregate concrete produced by two-stage mixing approach. J. Mater. Sci. 2007, 42, 3592–3602. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- González-Fonteboa, B.; Martínez-Abella, F.; Herrador, M.F.; Seara-Paz, S. Structural recycled concrete: Behaviour under low loading rate. Constr. Build. Mater. 2012, 28, 111–116. [Google Scholar]

- Xiao, J.Z.; Li, W.G.; Poon, C.S. Recent studies on mechanical properties of recycled aggregate concrete in China—A review. Sci. China Technol. Sci. 2012, 55, 1463–1480. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Zhang, C.Z. Fire damage and residual strength of recycled aggregate concrete. Key Eng. Mater. 2007, 348–349, 937–940. [Google Scholar] [CrossRef]

- Vieira, J.P.B.; Correia, J.R.; de Brito, J. Post-fire residual mechanical properties of concrete made with recycled concrete coarse aggregates. Cem. Concr. Res. 2011, 41, 533–541. [Google Scholar] [CrossRef]

- Sarhat, S.R.; Sherwood, E.G. Residual mechanical response of recycled aggregate concrete after exposure to elevated temperatures. J. Mater. Civ. Eng. 2013, 25, 1721–1730. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, L. Significance of fire resistance performance on the recycled concrete-filled steel tube. Appl. Mech. Mater. 2012, 174–177, 881–884. [Google Scholar] [CrossRef]

- Dong, H.Y.; Cao, W.L.; Zhang, J.W. Study on fire resistant performance of recycled concrete tubular structures. Appl. Mech. Mater. 2013, 256–259, 2781–2785. [Google Scholar]

- Code for Design of Concrete Structures; GB50010-2010; China Architecture & Building Press: Beijing, China, 2011.

- Fire Resistance Tests—Elements of Building Construction; ISO-834; International Organization for Standardization (ISO): Geneva, Switzerland, 1975.

- Fire-Resistance Tests—Elements of Building Construction; GB/T 9978-2008; Standards Press of China: Beijing, China, 2008.

- Zi, W.; Yu, Z.W.; Liu, P.; Li, Z.S. Influences of temperature and time on concrete compressive strength after natural cooling. Appl. Mech. Mater. 2012, 204–208, 2990–2993. [Google Scholar] [CrossRef]

- Xu, M.; Gao, H.P.; Chen, Z.F. Experimental research on shear behaviors of recycled concrete beams exposed to fire. J. Build. Struct. 2014, 35, 42–52. (In Chinese) [Google Scholar]

- Kodur, V.K.R.; Sultan, M.A. Structural behaviour of high strength concrete columns exposed to fire. In Proceedings of the International Symposium on High Performance and Reactive Powder Concrete, Sherbrooke, QC, Canada, 29 June–2 July 1998; pp. 217–232.

- Miao, J.J.; Liu, C.W.; Liu, Y.C.; Li, W.J. Fire test on RC columns under axial load. J. Build. Struct. 2012, 2, 26–32. (In Chinese) [Google Scholar]

- Becker, J.M.; Bizri, H.; Bresler, B. Fires-T: A Computer Program for the Fire Response of Structures-Thermal; UCB FRG-74–1; University of California, Berkeley: Berkeley, CA, USA, 1974. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, H.; Cao, W.; Bian, J.; Zhang, J. The Fire Resistance Performance of Recycled Aggregate Concrete Columns with Different Concrete Compressive Strengths. Materials 2014, 7, 7843-7860. https://doi.org/10.3390/ma7127843

Dong H, Cao W, Bian J, Zhang J. The Fire Resistance Performance of Recycled Aggregate Concrete Columns with Different Concrete Compressive Strengths. Materials. 2014; 7(12):7843-7860. https://doi.org/10.3390/ma7127843

Chicago/Turabian StyleDong, Hongying, Wanlin Cao, Jianhui Bian, and Jianwei Zhang. 2014. "The Fire Resistance Performance of Recycled Aggregate Concrete Columns with Different Concrete Compressive Strengths" Materials 7, no. 12: 7843-7860. https://doi.org/10.3390/ma7127843

APA StyleDong, H., Cao, W., Bian, J., & Zhang, J. (2014). The Fire Resistance Performance of Recycled Aggregate Concrete Columns with Different Concrete Compressive Strengths. Materials, 7(12), 7843-7860. https://doi.org/10.3390/ma7127843