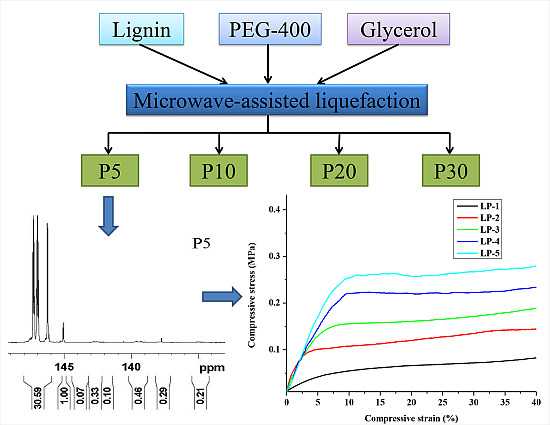

Producing Lignin-Based Polyols through Microwave-Assisted Liquefaction for Rigid Polyurethane Foam Production

Abstract

:1. Introduction

2. Results and Discussion

2.1. Liquefaction Yield and Viscosity of the Liquefied Products

| Sample | Microwave Heating Time (min) | Liquefaction Yield (%) | Viscosity (mPa·s) |

|---|---|---|---|

| P5 | 5 | 97.47% | 1035 |

| P10 | 10 | 98.34% | 1116 |

| P20 | 20 | 98.75% | 1161 |

| P30 | 30 | 97.19% | 1266 |

2.2. Molecular Weight of the Liquefied Products

| Entry | Lignin | Polyol Type a | |||

|---|---|---|---|---|---|

| P5 | P10 | P20 | P30 | ||

| Mw | 2792 | 525 | 673 | 725 | 1108 |

| Mn | 909 | 461 | 467 | 480 | 456 |

| Mw/Mn | 3.07 | 1.13 | 1.44 | 1.51 | 2.43 |

2.3. FT-IR Analysis for the Liquefied Products

2.4. 1H and 13C NMR Analysis for the Liquefied Products

2.5. 31P NMR Analysis for the Liquefied Products

| Polyol Type a | Aliphatic OH | Syringyl OH | Guaiacyl OH | p-Hydroxy Phenyl OH | Total OH | Carboxylic Group | ||

|---|---|---|---|---|---|---|---|---|

| Cb | N-Cc | C | N-Cc | |||||

| P5 | 8.289 | 0.019 | 0.089 | 0.027 | 0.125 | 0.079 | 8.628 | 0.057 |

| P10 | 8.187 | 0.033 | 0.114 | 0.041 | 0.146 | 0.095 | 8.616 | 0.068 |

| P20 | 8.011 | 0.038 | 0.114 | 0.046 | 0.152 | 0.098 | 8.459 | 0.062 |

| P30 | 7.780 | 0.041 | 0.111 | 0.043 | 0.146 | 0.092 | 8.213 | 0.049 |

2.6. Compressive Property of the Rigid PU Foam

3. Experimental Section

3.1. Materials

3.2. Microwave Heating Liquefaction Procedure

3.3. Characterization of the Liquefied Polyols

3.3.1. Determination of Liquefaction Yield

3.3.2. Viscosity and GPC Measurement

3.3.3. FT-IR Analysis

3.3.4. NMR Spectroscopy

3.4. Preparation of the Rigid PU Foam

3.5. Mechanical Properties of the Rigid PU Foams

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Belgacem, M.N.; Gandini, A. Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Chakar, F.S.; Ragauskas, A.J. Review of current and future softwood kraft lignin process chemistry. Ind. Crop. Prod. 2004, 20, 131–141. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.K.; Langan, M.P.; et al. Lignin valorization: Improving lignin processing in the biorefinery. Science 2014, 344. [Google Scholar] [CrossRef]

- Rials, T.G.; Glasser, W.G. Engineering plastics from lignin. XIII. Effect of lignin structure on polyurethane network formation. Holzforschung 1986, 40, 353–360. [Google Scholar] [CrossRef]

- Thring, R.W.; Vanderlaan, M.N.; Griffin, S.L. Polyurethanes from Alcell® lignin. Biomass Bioenergy 1997, 13, 125–132. [Google Scholar] [CrossRef]

- Evtuguin, D.V.; Andreolety, J.P.; Gandini, A. Polyurethanes based on oxygen-organosolv lignin. Eur. Polym. J. 1998, 34, 1163–1169. [Google Scholar] [CrossRef]

- Nadji, H.; Bruzzèse, C.; Belgacem, M.N.; Benaboura, A.; Gandini, A. Oxypropylation of lignins and preparation of rigid polyurethane foams from the ensuing polyols. Macromol. Mater. Eng. 2005, 290, 1009–1016. [Google Scholar] [CrossRef]

- Li, Y.; Ragauskas, A.J. Kraft lignin-based rigid polyurethane foam. J. Wood Chem. Technol. 2012, 32, 210–224. [Google Scholar] [CrossRef]

- Xue, B.L.; Wen, J.L.; Xu, F.; Sun, R.C. Polyols production by chemical modification of autocatalyzed ethanol-water lignin from betula alnoides. J. Appl. Polym. Sci. 2013, 129, 434–442. [Google Scholar] [CrossRef]

- Kurimoto, Y.; Takeda, M.; Koizumi, A.; Yamauchi, S.; Doi, S.; Tamura, Y. Mechanical properties of polyurethane films prepared from liquefied wood with polymeric MDI. Bioresour. Technol. 2000, 74, 151–157. [Google Scholar] [CrossRef]

- Lee, S.H.; Teramoto, Y.; Shiraishi, N. Biodegradable polyurethane foam from liquefied waste paper and its thermal stability, biodegradability, and genotoxicity. J. Appl. Polym. Sci. 2002, 83, 1482–1489. [Google Scholar] [CrossRef]

- Wang, H.; Chen, H.Z. A novel method of utilizing the biomass resource: Rapid liquefaction of wheat straw and preparation of biodegradable polyurethane foam (PUF). J. Chin. Inst. Chem. Eng. 2007, 38, 95–102. [Google Scholar] [CrossRef]

- Yip, J.; Chen, M.; Szeto, Y.S.; Yan, S. Comparative study of liquefaction process and liquefied products from bamboo using different organic solvents. Bioresour. Technol. 2009, 100, 6674–6678. [Google Scholar] [CrossRef] [PubMed]

- Hakim, A.A.A.; Nassar, M.; Emam, A.; Sultan, M. Preparation and characterization of rigid polyurethane foam prepared from sugarcane bagasse polyol. Mater. Chem. Phys. 2011, 129, 301–307. [Google Scholar] [CrossRef]

- Wang, T.P.; Zhang, L.H.; Li, D.; Yin, J.; Wu, S.; Mao, Z.H. Mechanical properties of polyurethane foams prepared from liquefied corn stover with PAPI. Bioresour. Technol. 2008, 99, 2265–2268. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.Q.; Ruan, X.M.; Cheng, X.S.; Lü, Q.F. Liquefaction of lignin by polyethyleneglycol and glycerol. Bioresour. Technol. 2011, 102, 3581–3583. [Google Scholar] [CrossRef] [PubMed]

- Hoz, A.; Diaz-Ortiz, A.; Moreno, A. Microwaves in organic synthesis. Thermal and non-thermal microwave effects. Chem. Soc. Rev. 2005, 34, 164–178. [Google Scholar] [CrossRef] [PubMed]

- Krzan, A.; Kunaver, M. Microwave heating in wood liquefaction. J. Appl. Polym. Sci. 2006, 101, 1051–1056. [Google Scholar] [CrossRef]

- Krzan, A.; Zagar, E. Microwave driven wood liquefaction with glycols. Bioresour. Technol. 2009, 100, 3143–3146. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.M.; Jiang, J.C.; Hse, C.Y.; Shupe, T.F. Renewable chemical feedstocks from integrated liquefaction processing of lignocellulosic materials using microwave energy. Green Chem. 2012, 14, 2821–2830. [Google Scholar] [CrossRef]

- Xie, J.L.; Hse, C.Y.; Shupe, T.F.; Qi, J.Q.; Pan, H. Liquefaction behaviors of bamboo residues in a glycerol-based solvent using microwave energy. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Bernardini, J.; Cinelli, P.; Anguillesi, I.; Coltelli, M.; Lazzeri, A. Flexible polyurethane foams green production employing lignin or oxypropylated lignin. Eur. Polym. J. 2015, 64, 147–156. [Google Scholar] [CrossRef]

- Xie, J.L.; Qi, J.Q.; Hse, C.Y.; Shupe, T.F. Effect of lignin derivatives in the bio-polyols from microwave liquefied bamboo on the properties of polyurethane foams. Bioresources 2014, 9, 578–588. [Google Scholar]

- Li, H.Q.; Qu, Y.S.; Xu, J. Microwave-assisted conversion of lignin. In Production of Biofuels and Chemicals with Microwave, 2nd ed.; Fang, Z., Smith, R.L., Qi, X.H., Eds.; Springer: Berlin, Germany, 2015; Volume 3, pp. 61–82. [Google Scholar]

- Sequeiros, A.; Serrano, L.; Briones, R.; Labidi, J. Lignin liquefaction under microwave heating. J. Appl. Polym. Sci. 2013, 130, 3292–3298. [Google Scholar] [CrossRef]

- Rezzoug, S.A.; Capart, R. Liquefaction of wood into successive steps: Solvolysis in ethylene glycol and catalytic hydrotreatment. Appl. Energy 2002, 72, 631–644. [Google Scholar] [CrossRef]

- Pan, H.; Zheng, Z.F.; Hse, C.Y. Microwave-assisted liquefaction of wood with polyhydric alcohols and its application in preparation of polyurethane (PU) foams. Eur. J. Wood Prod. 2012, 70, 461–470. [Google Scholar] [CrossRef]

- Pan, X.J.; Saddler, J.N. Effect of replacing polyol by organosolv and kraft lignin on the property and structure of rigid polyurethane foam. Biotechnol. Biofuel 2013, 6, 1–10. [Google Scholar]

- Jasiukaityte, E.; Kunaver, M.; Crestin, C. Lignin behaviour during wood liquefaction—Characterization by quantitative 31P, 13C NMR and size-exclusion chromatography. Catal. Today 2010, 156, 23–30. [Google Scholar] [CrossRef]

- Xiao, W.H.; Han, L.J.; Zhao, Y.Y. Comparative study of conventional and microwave-assisted liquefaction of corn stover in ethylene glycol. Ind. Crop. Prod. 2011, 34, 1602–1606. [Google Scholar] [CrossRef]

- D’Souza, J.; Yan, N. Producing bark-based polyols through liquefaction: Effect of liquefaction temperature. ACS Sustain. Chem. Eng. 2013, 1, 534–540. [Google Scholar] [CrossRef]

- Argyropoulos, D.S. Quantitative phosphorus-31 NMR analysis of lignin: A new tool for the lignin chemist. J. Wood Chem. Technol. 1994, 14, 45–63. [Google Scholar] [CrossRef]

- Archipov, Y.; Argyropoulos, D.S.; Bolker, H.; Heitner, C. 31P-NMR spectroscopy in wood chemistry. Phosphite derivatives of carbohydrates. Carbohyd. Res. 1991, 220, 49–61. [Google Scholar] [CrossRef]

- Granata, A.; Argyropoulos, D.S. 2-Chloro-4,4,5,5-tetramethyl-1,3,2-dioxaphospholate, a reagent for the accurate determination of the uncondensed and condensed phenolic moieties in lignins. J. Agric. Food Chem. 1995, 43, 1538–1544. [Google Scholar] [CrossRef]

- Nagy, M.; Kerr, B.J.; Ziemer, C.J.; Ragauskas, A.J. Phosphitylation and quantitative 31P NMR analysis of partially substituted biodiesel glycerols. Fuel 2009, 88, 1793–1797. [Google Scholar] [CrossRef]

- Ahvazi, B.; Wojciechowicz, O.; Ton-That, T.M.; Hawari, J. Preparation of lignopolyols from wheat straw soda lignin. J. Agric. Food Chem. 2011, 59, 10505–10516. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Zhang, L. Effects of [NCO]/[OH] molar ratio on structure and properties of graft-interpenetrating polymer networks from polyurethane and nitrolignin. Polymer 2002, 43, 2287–2294. [Google Scholar] [CrossRef]

- Nieuwenhuyse, A.E. Thermal Insulation Materials Made of Rigid Polyurethane Foam (Pur/Pir); PU Europe Report NO.1; Federation of European Rigid Polyurethane Foam Associations: Brussels, Belgium, 2006. [Google Scholar]

- Li, Y.; Ren, H.F.; Ragauskas, A.J. Rigid polyurethane foam/cellulose whisker nanocomposites: Preparation, characterization, and properties. J. Nanosci. Nanotechnol. 2011, 11, 6904–6911. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ragauskas, A.J. Ethanol organosolv lignin-based rigid polyurethane foam reinforced with cellulose nanowhiskers. RSC Adv. 2012, 2, 3347–3351. [Google Scholar] [CrossRef]

- Xue, B.L.; Wen, J.L.; Sun, R.C. Lignin-based rigid polyurethane foam reinforced with pulp fiber: Synthesis and characterization. ACS Sustain. Chem. Eng. 2014, 2, 1474–1480. [Google Scholar] [CrossRef]

- Standard Test Method for Compressive Properties of Rigid Cellular Plastics. Available online: http://www.astm.org/Standards/D1621.htm (accessed on 5 February 2014).

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, B.-L.; Wen, J.-L.; Sun, R.-C. Producing Lignin-Based Polyols through Microwave-Assisted Liquefaction for Rigid Polyurethane Foam Production. Materials 2015, 8, 586-599. https://doi.org/10.3390/ma8020586

Xue B-L, Wen J-L, Sun R-C. Producing Lignin-Based Polyols through Microwave-Assisted Liquefaction for Rigid Polyurethane Foam Production. Materials. 2015; 8(2):586-599. https://doi.org/10.3390/ma8020586

Chicago/Turabian StyleXue, Bai-Liang, Jia-Long Wen, and Run-Cang Sun. 2015. "Producing Lignin-Based Polyols through Microwave-Assisted Liquefaction for Rigid Polyurethane Foam Production" Materials 8, no. 2: 586-599. https://doi.org/10.3390/ma8020586

APA StyleXue, B. -L., Wen, J. -L., & Sun, R. -C. (2015). Producing Lignin-Based Polyols through Microwave-Assisted Liquefaction for Rigid Polyurethane Foam Production. Materials, 8(2), 586-599. https://doi.org/10.3390/ma8020586