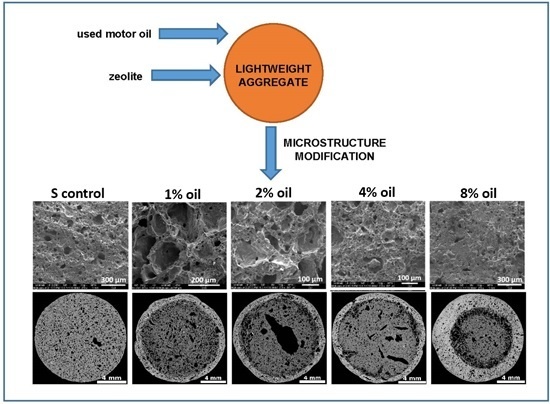

Modification of Lightweight Aggregates’ Microstructure by Used Motor Oil Addition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrates

2.2. Lightweight Aggregates’ Preparation

2.3. Methods of Characterization

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Riley, C.M. Relation of chemical properties to the bloating of clays. J. Am. Ceram. Soc. 1951, 41, 74–80. [Google Scholar] [CrossRef]

- Volland, S.; Brötz, J. Lightweight aggregates produced from sand sludge and zeolitic rocks. Constr. Build. Mater. 2015, 85, 22–29. [Google Scholar] [CrossRef]

- González-Corrochano, B.; Alonso-Azcárate, J.; Rodas, M. Characterization of lightweight aggregates manufactured from washing aggregate sludge and fly ash. Resour. Conserv. Recycl. 2009, 53, 571–581. [Google Scholar] [CrossRef]

- González-Corrochano, B.; Alonso-Azcárate, J.; Rodas, M.; Luque, F.J.; Barrenechea, J.F. Microstructure and mineralogy of lightweight aggregates produced from washing aggregate sludge, fly ash and used motor oil. Cem. Concr. Compos. 2010, 32, 694–707. [Google Scholar] [CrossRef] [Green Version]

- Olmeda, J.; Frías, M.; Olaya, M.; Frutos, B.; Sánchez de Rojas, M.I. Recycling petroleum coke in blended cement mortar to produce lightweight material for Impact Noise Reduction. Cem. Concr. Compos. 2012, 34, 1194–1201. [Google Scholar] [CrossRef]

- Topçu, I.B.; Işikdaǧ, B. Effect of expanded perlite aggregate on the properties of lightweight concrete. J. Mater. Process. Technol. 2008, 204, 34–38. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Strength and elastic properties of structural lightweight concretes. Mater. Des. 2011, 32, 2396–2403. [Google Scholar] [CrossRef]

- Korat, L.; Ducman, V.; Legat, A.; Mirtič, B. Characterisation of the pore-forming process in lightweight aggregate based on silica sludge by means of X-ray micro-tomography (micro-CT) and mercury intrusion porosimetry (MIP). Ceram. Int. 2013, 39, 6997–7005. [Google Scholar] [CrossRef]

- Fragoulis, D.; Stamatakis, M.G.; Chaniotakis, E.; Columbus, G. Characterization of lightweight aggregates produced with clayey diatomite rocks originating from Greece. Mater. Charact. 2004, 53, 307–316. [Google Scholar] [CrossRef]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Go, C.G.; Tang, J.R.; Chi, J.H.; Chen, C.T.; Huang, Y.L. Fire-resistance property of reinforced lightweight aggregate concrete wall. Constr. Build. Mater. 2012, 30, 725–733. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Liu, X. Effect of nano-silica on the mechanical and transport properties of lightweight concrete. Constr. Build. Mater. 2015, 82, 114–122. [Google Scholar] [CrossRef]

- Bernhardt, M.; Justnes, H.; Tellesbø, H.; Wiik, K. The effect of additives on the properties of lightweight aggregates produced from clay. Cem. Concr. Compos. 2014, 53, 233–238. [Google Scholar] [CrossRef]

- Huang, S.-C.; Chang, F.-C.; Lo, S.-L.; Lee, M.-Y.; Wang, C.-F.; Lin, J.-D. Production of lightweight aggregates from mining residues, heavy metal sludge, and incinerator fly ash. J. Hazard. Mater. 2007, 144, 52–58. [Google Scholar] [CrossRef] [PubMed]

- Chang, F.-C.; Lo, S.-L.; Lee, M.-Y.; Ko, C.-H.; Lin, J.-D.; Huang, S.-C.; Wang, H.-F. Leachability of metals from sludge-based artificial lightweight aggregate. J. Hazard. Mater. 2007, 146, 98–105. [Google Scholar] [CrossRef] [PubMed]

- González-Corrochano, B.; Alonso-Azcárate, J.; Rodas, M. Chemical partitioning in lightweight aggregates manufactured from washing aggregate sludge, fly ash and used motor oil. J. Environ. Manag. 2012, 109, 43–53. [Google Scholar] [CrossRef] [PubMed]

- González-Corrochano, B.; Alonso-Azcárate, J.; Rodas, M. Effect of prefiring and firing dwell times on the properties of artificial lightweight aggregates. Constr. Build. Mater. 2014, 53, 91–101. [Google Scholar] [CrossRef]

- Verbinnen, B.; Block, C.; Van Caneghem, J.; Vandecasteele, C. Recycling of spent adsorbents for oxyanions and heavy metal ions in the production of ceramics. Waste Manag. 2015, 45, 407–411. [Google Scholar] [CrossRef] [PubMed]

- Quina, M.J.; Bordado, J.M.; Quinta-Ferreira, R.M. Recycling of air pollution control residues from municipal solid waste incineration into lightweight aggregates. Waste Manag. 2014, 34, 430–438. [Google Scholar] [CrossRef] [PubMed]

- Quijorna, N.; de Pedro, M.; Romero, M.; Andrés, A. Characterisation of the sintering behaviour of Waelz slag from electric arc furnace (EAF) dust recycling for use in the clay ceramics industry. J. Environ. Manag. 2014, 132, 278–286. [Google Scholar] [CrossRef] [PubMed]

- Latosinska, J.; Zygadlo, M. Effect of Sewage Sludge Addition on Porosity of Lightweight Expanded Clay Aggregate (Leca) and Level of Heavy Metals Leaching From Ceramic Matrix. Environ. Prot. Eng. 2009, 35, 189–196. [Google Scholar]

- Sarabèr, A.; Overhof, R.; Green, T.; Pels, J. Artificial lightweight aggregates as utilization for future ashes—A case study. Waste Manag. 2012, 32, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Franus, M.; Barnat-Hunek, D.; Wdowin, M. Utilization of sewage sludge in the manufacture of lightweight aggregate. Environ. Monit. Assess. 2016, 188, 10. [Google Scholar] [CrossRef] [PubMed]

- Suchorab, Z.; Barnat-Hunek, D.; Franus, M.; Łagód, G. Mechanical and Physical Properties of Hydrophobized Lightweight Aggregate Concrete with Sewage Sludge. Materials 2016, 9, 317. [Google Scholar] [CrossRef]

- Franus, W.; Franus, M.; Latosińska, J.; Wójcik, R. The use of spent glauconite in lightweight aggregate production. Bol. Soc. Esp. Ceram. Vidr. 2011, 50, 193–200. [Google Scholar] [CrossRef]

- Moreira, A.; António, J.; Tadeu, A. Lightweight screed containing cork granules: Mechanical and hygrothermal characterization. Cem. Concr. Compos. 2014, 49, 1–8. [Google Scholar] [CrossRef]

- Anagnostopoulos, I.M.; Stivanakis, V.E. Utilization of lignite power generation residues for the production of lightweight aggregates. J. Hazard. Mater. 2009, 163, 329–336. [Google Scholar] [CrossRef] [PubMed]

- Ducman, V.; Mirtic, B. The applicability of different waste materials for the production of lightweight aggregates. Waste Manag. 2009, 29, 2361–2368. [Google Scholar] [CrossRef] [PubMed]

- Franus, M.; Wdowin, M.; Bandura, L.; Franus, W. Removal of environmental pollutions using zeolites from fly ash: A review. Fresenius Environ. Bull. 2015, 24, 854–866. [Google Scholar]

- Bandura, L.; Franus, M.; Józefaciuk, G.; Franus, W. Synthetic zeolites from fly ash as effective mineral sorbents for land-based petroleum spills cleanup. Fuel 2015, 147, 100–107. [Google Scholar] [CrossRef]

- Bandura, L.; Franus, M.; Panek, R.; Woszuk, A.; Franus, W. Characterization of zeolites and their use as adsorbents of petroleum substances. Przemysl Chemiczny 2015, 94, 323–327. [Google Scholar]

- Bandura, L.; Panek, R.; Rotko, M.; Franus, W. Synthetic zeolites from fly ash for an effective trapping of BTX in gas stream. Microporous Mesoporous Mater. 2016, 223, 1–9. [Google Scholar] [CrossRef]

- Franus, W.; Wiatros-Motyka, M.M.; Wdowin, M. Coal fly ash as a resource for rare earth elements. Environ. Sci. Pollut. Res. 2015, 94, 64–74. [Google Scholar] [CrossRef] [PubMed]

- Wdowin, M.; Franus, M.; Panek, R.; Badura, L.; Franus, W. The conversion technology of fly ash into zeolites. Clean Technol. Environ. Policy 2014, 16, 1217–1223. [Google Scholar] [CrossRef]

- Kyziol-Komosinska, J.; Rosik-Dulewska, C.; Franus, M.; Antoszczyszyn-Szpicka, P.; Czupiol, J.; Krzyzewska, I. Sorption capacities of the natural and synthetic zeolites for the Cu(II) ions. Pol. J. Environ. Stud. 2015, 24, 1111–1123. [Google Scholar] [CrossRef]

- Muir, B.; Bajda, T. Organically modified zeolites in petroleum compounds spill cleanup—Production, efficiency, utilization. Fuel Process. Technol. 2016, 149, 153–162. [Google Scholar] [CrossRef]

- Dong, H.; Blunt, M.J. Pore-network extraction from micro-computerized-tomography images. Phys. Rev. E 2009, 80, 036307. [Google Scholar] [CrossRef] [PubMed]

- Sridharan, A.; Venkatappa Rao, G. Pore size distribution of soils from mercury intrusion porosimetry data. Soil Sci. Soc. Am. Proc. 1972, 36, 980–981. [Google Scholar] [CrossRef]

- Pachepsky, Y.A.; Polubesova, T.A.; Hajnos, M.; Sokolowska, Z.; Jozefaciuk, G. Fractal parameters of pore surface area as influences by simulated soil degradation. Soil Sci. Soc. Am. J. 1995, 59, 68–75. [Google Scholar] [CrossRef]

- Yokoya, N.; Yamamoto, K.; Funakubo, N. Fractal-based analysis and interpolation of 3D natural surface shapes and their application to terrain modeling. Comput. Vis. Graph Image Process. 1989, 46, 284–302. [Google Scholar] [CrossRef]

- Wang, X.; Jin, Y.; Wan, Z.; Nie, Y.; Huang, Q.; Wang, Q. Development of lightweight aggregate from dry sewage sludge and coal ash. Waste Manag. 2009, 29, 1330–1335. [Google Scholar] [CrossRef] [PubMed]

| Structural Parameter | S | S + Clin | S + NAP |

|---|---|---|---|

| Solid phase density from helium pycnometry, SPD(He), g/cm3 | 2.20 | 2.29 | 2.19 |

| Bulk density from aggregate mass and volume, BD, g/cm3 | 1.39 | 1.37 | 1.21 |

| Data from mercury intrusion porosimetry (MIP) | |||

| Total pore volume, V(MIP), cm3/g | 0.25 | 0.28 | 0.38 |

| Average pore radius, R(MIP), μm | 5.9 | 7.7 | 6.5 |

| Bulk density, BD(MIP), g/cm3 | 1.44 | 1.39 | 1.22 |

| Solid phase density, SPD(MIP), g/cm3 | 2.26 | 2.27 | 2.23 |

| Porosity, P(MIP), % | 36.3 | 38.7 | 45.6 |

| Fractal dimension, DL, for 40–1 μm large (L) pores | 6.31 | 4.86 | 5.09 |

| Fractal dimension, DM, for 0.7–0.1 μm medium (M) pores | 3.50 | 3.23 | 2.71 |

| Fractal dimension, DS, for 0.02–0.001 μm small (S) pores | 3.71 | 3.51 | 3.47 |

| Data from microtomography (MT) | |||

| * Pore volume, V(MT), mm3/g | 17.4 | 27.6 | 44.2 |

| Porosity, P(MT), %, including all pores | 15.5 | 19.6 | 27.4 |

| * Average pore radius, R(MT), μm | 10 | 15 | 16 |

| Fractal dimension, D(MT) | 2.75 | 2.76 | 2.76 |

| Bulk density, BD(MT), g/cm3 | 1.39 | 1.39 | 1.17 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franus, M.; Jozefaciuk, G.; Bandura, L.; Lamorski, K.; Hajnos, M.; Franus, W. Modification of Lightweight Aggregates’ Microstructure by Used Motor Oil Addition. Materials 2016, 9, 845. https://doi.org/10.3390/ma9100845

Franus M, Jozefaciuk G, Bandura L, Lamorski K, Hajnos M, Franus W. Modification of Lightweight Aggregates’ Microstructure by Used Motor Oil Addition. Materials. 2016; 9(10):845. https://doi.org/10.3390/ma9100845

Chicago/Turabian StyleFranus, Małgorzata, Grzegorz Jozefaciuk, Lidia Bandura, Krzysztof Lamorski, Mieczysław Hajnos, and Wojciech Franus. 2016. "Modification of Lightweight Aggregates’ Microstructure by Used Motor Oil Addition" Materials 9, no. 10: 845. https://doi.org/10.3390/ma9100845

APA StyleFranus, M., Jozefaciuk, G., Bandura, L., Lamorski, K., Hajnos, M., & Franus, W. (2016). Modification of Lightweight Aggregates’ Microstructure by Used Motor Oil Addition. Materials, 9(10), 845. https://doi.org/10.3390/ma9100845