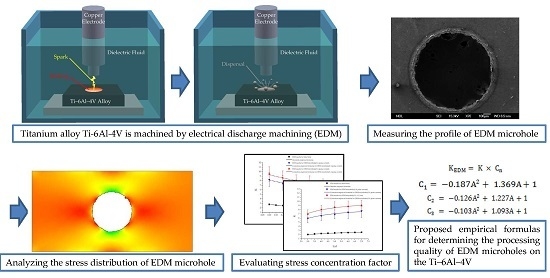

Effect of Electrical Discharge Machining on Stress Concentration in Titanium Alloy Holes

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Experimental Setup

2.3. Data Analysis Instrument and Method

2.4. Prediction of Stress Concentration Factor

3. Results and Discussion

3.1. EDM Results and Stress Distribution

3.2. Stress Concentration Factor of Specimens with EDM Holes

3.3. Proposed Empirical Formulas for Stress Concentration Factor of Specimen with EDM Holes

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Davies, D.P.; Jenkins, S.L. Influence of forming method on the tensile and fatigue properties of Ti-6Al-4V sheet for helicopter erosion shield applications. Mater. Des. 2012, 33, 254–263. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Markhoff, J.; Wieding, J.; Weissmann, V.; Pasold, J.; Jonitz-Heincke, A.; Bader, R. Influence of different three-dimensional open porous titanium scaffold designs on human osteoblasts behavior in static and dynamic cell investigations. Materials 2015, 8, 5490–5507. [Google Scholar] [CrossRef]

- Weißmann, V.; Wieding, J.; Hansmann, H.; Laufer, N.; Wolf, A.; Bader, R. Specific yielding of selective laser-melted Ti6Al4V open-porous scaffolds as a function of unit cell design and dimensions. Metals 2016, 6, 166. [Google Scholar] [CrossRef]

- Che-Haron, C.H.; Jawaid, A. The effect of machining on surface integrity of titanium alloy Ti-6% Al-4% V. J. Mater. Process. Technol. 2005, 166, 188–192. [Google Scholar] [CrossRef]

- Cantero, J.L.; Tardio, M.M.; Canteli, J.A.; Marcos, M.; Miguélez, M.H. Dry drilling of alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2005, 45, 1246–1255. [Google Scholar] [CrossRef]

- Rahman, M.; Wang, Z.-G.; Wong, Y.-S. A review on high-speed machining of titanium alloys. JSME Int. J. Ser. C 2006, 49, 11–20. [Google Scholar] [CrossRef]

- Yang, D.; Liu, Z. Quantification of microstructural features and prediction of mechanical properties of a dual-phase Ti-6Al-4V alloy. Materials 2016, 9, 628. [Google Scholar] [CrossRef]

- Guu, Y.H.; Hou, M.T.-K. Effect of machining parameters on surface textures in EDM of Fe-Mn-Al alloy. Mater. Sci. Eng. A 2007, 466, 61–67. [Google Scholar] [CrossRef]

- Fonda, P.; Wang, Z.; Yamazaki, K.; Akutsu, Y. A fundamental study on Ti-6Al-4V’s thermal and electrical properties and their relation to EDM productivity. J. Mater. Process. Technol. 2008, 202, 583–589. [Google Scholar] [CrossRef]

- Ramulu, M.; Spaulding, M. Drilling of hybrid titanium composite laminate (HTCL) with electrical discharge machining. Materials 2016, 9, 746. [Google Scholar] [CrossRef]

- Hascalik, A.; Caydas, U. Electrical discharge machining of titanium alloy (Ti-6Al-4V). Appl. Surf. Sci. 2007, 253, 9007–9016. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Chow, H.-M.; Yan, B.-H.; Tzeng, H.-J. Effects of finishing in abrasive fluid machining on microholes fabricated by EDM. Int. J. Adv. Manuf. Technol. 2007, 33, 489–497. [Google Scholar] [CrossRef]

- Pradhan, B.B.; Masanta, M.; Sarkar, B.R.; Bhattacharyya, B. Investigation of electro-discharge micro-machining of titanium super alloy. Int. J. Adv. Manuf. Technol. 2009, 41, 1094–1106. [Google Scholar] [CrossRef]

- Harcuba, P.; Bacakova, L.; Strasky, J.; Bacakova, M.; Novotna, K.; Janecek, M. Surface treatment by electric discharge machining of Ti-6Al-4V alloy for potential application in orthopaedics. J. Mech. Behav. Biomed. Mater. 2012, 7, 96–105. [Google Scholar] [CrossRef] [PubMed]

- D’Urso, G.; Longo, M.; Maccarini, G.; Ravasio, C. Electrical discharge machining of micro holes on titanium sheets. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011; pp. 417–424.

- Yan, X. Cracks emanating from circular hole or square hole in rectangular plate in tension. Eng. Fract. Mech. 2006, 73, 1743–1754. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, W.; Jiang, S. Fatigue life prediction based on crack closure and equivalent initial flaw size. Materials 2015, 8, 7145–7160. [Google Scholar] [CrossRef]

- Kubair, D.V.; Bhanu-Chandar, B. Stress concentration factor due to a circular hole in functionally graded panels under uniaxial tension. Int. J. Mech. Sci. 2008, 50, 732–742. [Google Scholar] [CrossRef]

- Yang, Z.; Kim, C.-B.; Cho, C.; Beom, H.G. The concentration of stress and strain in finite thickness elastic plate containing a circular hole. Int. J. Solids Struct. 2008, 45, 713–731. [Google Scholar] [CrossRef]

- Peterson, R.E. Stress Concentration Factors: Charts and Relations Useful in Making Strength Calculations for Machine Parts and Structural Elements; Wiley: New York, NY, USA, 1974. [Google Scholar]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 8th ed.; McGraw-Hill: Boston, MA, USA, 2008. [Google Scholar]

- D’Urso, G.; Maccarini, G.; Ravasio, C. Influence of electrode material in micro-EDM drilling of stainless steel and tungsten carbide. Int. J. Adv. Manuf. Technol. 2016, 85, 2013–2025. [Google Scholar] [CrossRef]

- Hibbeler, R.C. Mechanics of Materials, 7th ed.; Pearson/Prentice Hall: Upper Saddle River, NJ, USA, 2008. [Google Scholar]

| Property | Value |

|---|---|

| Density | 5010 kg/m3 |

| Young’s modulus | 110.3 GPa |

| Poisson’s ratio | 0.33 |

| Yield strength | 1.57 GPa |

| Thermal conductivity | 7 W/(m·K) |

| Electrical conductivity | 1.01% IACS |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, W.-H.; Chien, W.-T. Effect of Electrical Discharge Machining on Stress Concentration in Titanium Alloy Holes. Materials 2016, 9, 957. https://doi.org/10.3390/ma9120957

Hsu W-H, Chien W-T. Effect of Electrical Discharge Machining on Stress Concentration in Titanium Alloy Holes. Materials. 2016; 9(12):957. https://doi.org/10.3390/ma9120957

Chicago/Turabian StyleHsu, Wei-Hsuan, and Wan-Ting Chien. 2016. "Effect of Electrical Discharge Machining on Stress Concentration in Titanium Alloy Holes" Materials 9, no. 12: 957. https://doi.org/10.3390/ma9120957

APA StyleHsu, W. -H., & Chien, W. -T. (2016). Effect of Electrical Discharge Machining on Stress Concentration in Titanium Alloy Holes. Materials, 9(12), 957. https://doi.org/10.3390/ma9120957