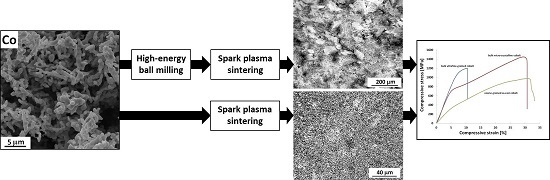

The Structure and Mechanical Properties of High-Strength Bulk Ultrafine-Grained Cobalt Prepared Using High-Energy Ball Milling in Combination with Spark Plasma Sintering

Abstract

:1. Introduction

2. Results

3. Discussion

4. Materials and Methods

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| SPD | Severe plastic deformation |

| HPT | High pressure torsion |

| ECAP | Equal channel angular pressing |

| SMAT | Surface mechanical attrition treatment |

| BM | Ball milling |

| SPS | Spark plasma sintering |

| SAED | Selected area electron diffraction |

| PIPS | Precision ion polishing system |

| XRD | X-ray diffraction |

| HV | Vickers hardness |

| CYS | Compressive yield strength |

| UCS | Ultimate compressive strength |

| PM | Powder metallurgy |

| RPM | Revolutions per minute |

| OM | Optical microscopy |

| SEM | Scanning electron microscopy |

| EDS | Energy dispersive spectroscopy |

| TEM | Transmission electron microscopy |

References

- Wang, Y.; Chen, M.; Zhou, F.; Ma, E. High tensile ductility in a nanostructured metal. Nature 2002, 419, 912–915. [Google Scholar] [CrossRef] [PubMed]

- Tjong, S.C. Deformation Characteristics of Nanocrystalline Metals. In Nanocrystalline Materials: Their Synthesis-Structure-Property Relationship and Applications, 1st ed.; Tjong, S.C., Ed.; Elsevier: Kidlington/Oxford, UK, 2006; pp. 241–274. [Google Scholar]

- Han, B.Q.; Lavernia, E.J.; Mohamed, F.A. Mechanical properties of nanostructured materials. Rev. Adv. Mater. Sci. 2005, 9, 1–16. [Google Scholar]

- Yan, W.; Liu, X.; Huang, J.; Chen, L. Strength and ductility in ultrafine-grained wrought aluminium alloys. Mater. Des. 2013, 49, 520–524. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Yu, H.-S.; Shin, D.H. Low sliding-wear resistance of ultrafine-grained Al alloys and stell having undergone severe plastic deformation. Int. J. Mater. Res. 2009, 100, 871–874. [Google Scholar] [CrossRef]

- Padap, A.K.; Chaudhari, G.P.; Nath, S.K. Mechanical and dry sliding wear behavior of ultrafine-grained AISI 1024 steel processed using multiaxial forging. J. Mater. Sci. 2010, 45, 4837–4845. [Google Scholar] [CrossRef]

- Wetscher, F.; Vorhauer, A.; Pippan, R. Strain hardening during high pressure torsion deformation. Mat. Sci. Eng. A 2005, 410–411, 213–216. [Google Scholar] [CrossRef]

- Langdon, T.G. The principle of grain refinement in equal-channel angular pressing. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Wu, X.; Tao, N.; Hong, Y.; Liu, G.; Xu, B.; Lu, J.; Lu, K. Strain-induced grain refinement of cobalt during surface mechanical attrition treatment. Acta Mater. 2005, 53, 681–691. [Google Scholar] [CrossRef]

- Fellah, F.; Schoenstein, F.; Dakhlaoui-Omrani, A.; Chérif, S.M.; Dirras, G.; Jouini, N. Nanostructured cobalt powders synthesised by polyol process and consolidated by Spark Plasma Sintering: Microstructure and mechanical poperties. Mater. Charact. 2012, 69, 1–8. [Google Scholar] [CrossRef]

- Abdellahi, M.; Bahmanpour, M. Rapid synthesis of nanopowders in high energy ball milling; Optimization of milling parameters. Ceram. Int. 2015, 41, 1631–1639. [Google Scholar] [CrossRef]

- Nazari, A.; Zakeri, M. Modeling the mean grain size of synthesized nanopowders produced by mechanical alloying. Ceram. Int. 2013, 39, 1587–1596. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. Introduction. In Mechanical Alloying: For Fabrication of Advanced Engineering Materials; University Press of Mississippi: Jackson, MS, USA, 2013; pp. 1–21. [Google Scholar]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Hellstern, E.; Fecht, H.J.; Garland, C.; Johnson, W.L. Mechanism of achieving nanocrystalline AIRu by ball milling. In Multicomponent Ultrafine Microstructures; McCandlish, L.E., Polk, D.E., Siegel, R.W., Kear, B.H., Eds.; Materials Research Society: Pittsburgh, PA, USA, 1989; pp. 137–142. [Google Scholar]

- Li, S.; Wang, K.; Sun, L.; Wang, Z. A simple model for the refinement of nanocrystalline grain size during ball milling. Scr. Metall. Mater. 1992, 27, 437–442. [Google Scholar] [CrossRef]

- Eckert, J.; Holzer, J.C.; Krill, C.E., III; Johnson, W.L. Structural and thermodynamic properties of nanocrystalline fcc metals prepared by mechanical attrition. J. Mater. Res. 1992, 7, 1751–1761. [Google Scholar] [CrossRef]

- Börner, I.; Eckert, J. Structural properties and compositional dependence of grain size in heavily mechanical deformed nanophase NiAl. Mater. Sci. Forum. 1996, 225–227, 377–382. [Google Scholar] [CrossRef]

- Koch, C.C. The synthesis and structure of nanocrystalline materials produced by mechanical attrition: A review. Nanostruct. Mater. 1993, 2, 109–129. [Google Scholar] [CrossRef]

- Koch, C.C. Synthesis of nanostructured materials by mechanical milling: Problems and opportunities. Nanostruct. Mater. 1997, 9, 13–22. [Google Scholar] [CrossRef]

- Vojtech, D.; Michalcova, A.; Pilch, J.; Sittner, P.; Serak, J.; Novak, P. Structural characteristics and thermal stability of Al-5.7Cr-2.5Fe-1.3Ti alloy produced by powder metallurgy. J. Alloys Compd. 2009, 475, 151–156. [Google Scholar] [CrossRef]

- Vojtech, D.; Prusa, F. Application of powder metallurgy in the processing of aluminium scraps with high-iron content. Mater. Tehnol. 2012, 46, 339–343. [Google Scholar]

- Vojtech, D.; Verner, J.; Serak, J.; Simancik, F.; Balog, M.; Nagy, J. Properties of thermally stable PM Al-Cr based alloys. Mat. Sci. Eng. A 2007, 458, 371–380. [Google Scholar] [CrossRef]

- Mendis, C.L.; Jhawar, H.P.; Sasaki, T.T.; Oh-ishi, K.; Sivaprasad, K.; Fleury, E.; Hono, K. Mechanical properties and microstructures of Al–1Fe–(0-1)Zr bulk nano-crystalline alloy processed by mechanical allying and spark plasma sintering. Mater. Sci. Eng. A 2012, 541, 152–158. [Google Scholar] [CrossRef]

- Li, X.P.; Yan, M.; Imai, H.; Kondoh, K.; Wang, J.Q.; Schaffer, G.B.; Qian, M. Fabrication of 10 mm diameter fully dense Al86Ni6Y4.5Co2La1.5 bulk metallic glass with high fracture strength. Mater. Sci. Eng. A 2013, 568, 155–159. [Google Scholar] [CrossRef]

- Le, G.M.; Godfrey, A.; Hansen, N. Structure and strength of aluminium with sub-micrometer/micrometer grain size prepared by spark plasma sintering. Mater. Des. 2013, 49, 360–367. [Google Scholar] [CrossRef]

- Zuniga, A.; Ajdelsztajn, L.; Lavernia, E.J. Spark plasma sintering of a nanocrystalline Al-Cu-Mg-Fe-Ni-Sc alloy. Metall. Mater. Trans. A 2006, 37, 1343–1352. [Google Scholar] [CrossRef]

- Ye, J.; Ajdelsztajn, L.; Schoenung, J.M. Bulk nanocrystalline aluminium 5083 alloy fabricated by a novel technique: Cryomilling and spark plasma sintering. Metall. Mater. Trans. A 2006, 37, 2569–2579. [Google Scholar] [CrossRef]

- Gu, J.; Gu, S.; Xue, L.; Wu, S.; Yan, Y. Microstructure and mechanical properties of in-situ Al13Fe4/Al composites prepared by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A 2012, 558, 684–691. [Google Scholar] [CrossRef]

- Zheng, B.; Ertorer, O.; Li, Y.; Zhou, Y.; Mathaudhu, S.N.; Tsao, C.Y.A.; Lavernia, E.J. High strength, nano-structured Mg-Al-Zn alloy. Mater. Sci. Eng. A 2011, 528, 2180–2191. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Ohkubo, T.; Hono, K. Microstructure and mechanical properties of bulk nanocrystalline Al-Fe alloy processed by mechanical alloying and spark plasma sintering. Acta Mater. 2009, 57, 3529–3538. [Google Scholar] [CrossRef]

- Akinrinlola, B.; Gauvin, R.; Brochu, M. Improving the mechanical reliability of cryomilled Al-Mg alloy using a two-stage spark plasma sintering cycle. Scr. Mater. 2012, 66, 455–458. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Liu, Z.-F.; Lu, J.-F.; Shen, Y.-B.; Wang, F.-C.; Wang, Y.-D. The sintering mechanism in spark plasma sintering—Proof of the occurrence of spark discharge. Scr. Mater. 2014, 81, 56–59. [Google Scholar] [CrossRef]

- Xiong, Y.; Liu, D.; Li, Y.; Zheng, B.; Haines, C.; Paras, J.; Martin, D.; Kapoor, D.; Lavernia, E.J.; Schoenung, J.M. Spark plasma sintering of cryomilled nanocrystalline Al alloy—Part I: Microstructure evolution. Metall. Mater. Trans. A 2012, 43, 327–339. [Google Scholar] [CrossRef]

- Liu, D.; Xiong, Y.; Topping, T.D.; Zhou, Y.; Haines, C.; Paras, J.; Martin, D.; Kapoor, D.; Schoenung, J.M.; Lavernia, E.J. Spark plasma sintering of cryomilled nanocrystalline Al alloy—Part II: Influence of processing conditions on densification and properties. Metall. Mater. Trans. A 2012, 43, 340–350. [Google Scholar] [CrossRef]

- Meng, Q.; Guo, S.; Zhao, X.; Veintemillas-Verdaguer, S. Bulk metastable cobalt in fcc crystal structure. J. Alloys Compd. 2013, 580, 187–190. [Google Scholar] [CrossRef]

- Toledano, P.; Krexner, G.; Prem, M.; Weber, H.-P.; Dmitriev, V.P. Theory of the martensitic transformation in cobalt. Phys. Rev. B 2001, 64, 144104–144121. [Google Scholar] [CrossRef]

- Christian, J.W. A theory of the transformation in pure cobalt. Proc. R. Soc. Lond. A 1951, 206, 51–64. [Google Scholar] [CrossRef]

- Owen, E.A.; Jones, D.M. Effect of grain size on the crystal structure of cobalt. Proc. Phys. Soc. Lond. B 1954, 67, 456–466. [Google Scholar] [CrossRef]

- Bollmann, W. On the phase transformation of cobalt. Acta Metall. Mater. 1961, 9, 972–975. [Google Scholar] [CrossRef]

- Ray, A.E.; Smith, S.R.; Scofield, J.D. Study of the phase transformation of cobalt. J. Phase Equilib. 1991, 12, 644–647. [Google Scholar] [CrossRef]

- Delaey, L. Diffusionless Transformations. Phase Transformations in Materials; WILEY-VCH: Weinheim, Germany, 2001. [Google Scholar]

- Plewes, J.T.; Bachmann, K.J. The effect of thermomechanical pretreatment on the allotropic transformation in cobalt. Metall. Trans. 1973, 4, 1729–1734. [Google Scholar] [CrossRef]

- Sarkar, S.; Bansal, C.; Chatterjee, A. Gibbs-Thomson effect in nanocrystalline Fe-Ge. Phys. Rev. B 2000, 62, 3218–3222. [Google Scholar] [CrossRef]

- Zhao, X.Q.; Veintemillas-Verdaguer, S.; Bomati-Miguel, O.; Morales, M.P.; Xu, H.B. Thermal history dependence of the crystal structure of Co fine particles. Phys. Rev. B 2005, 71. [Google Scholar] [CrossRef]

- Zhao, X.; Liang, Y.; Hu, Z.; Liu, B. Thermodynamic interpretation of the martensitic transformation in ultrafine γ-Fe(N) particles. Jpn. J. Appl. Phys. 1996, 35, 4468–4473. [Google Scholar] [CrossRef]

- Ma, G.; Zhao, X.; Veintemillas-Verdaguer, S. Size dependent allotropic transition of Co fine particles. J. Nanosci. Nanotechnol. 2009, 9, 4472–4477. [Google Scholar] [CrossRef] [PubMed]

- Karimpoor, A.A.; Erb, U.; Aust, K.T.; Palumbo, G. High-strength nanocrystalline cobalt with high tensile ductility. Scr. Mater. 2003, 49, 651–656. [Google Scholar] [CrossRef]

- Barry, A.H.; Dirras, G.; Schoenstein, F.; Tédart, F.; Jouini, N. Microstructure and mechanical properties of bulk highly faulted fcc/hcp nanostructured cobalt microstructures. Mater. Charact. 2014, 91, 26–33. [Google Scholar] [CrossRef]

- Ramesh, K.T. Nanomaterials: Mechanics and Mechanisms; Springer Science & Business Media: New York, NY, USA, 2009; p. 143. [Google Scholar]

- Wang, Y.M.; Ott, R.T.; van Buuren, T.; Willey, T.M.; Biener, M.M.; Hamza, A.V. Controlling factors in tensile deformation of nanocrystalline cobalt and nickel. Phys. Rev. B 2012, 85. [Google Scholar] [CrossRef]

- Fellah, F.; Dirras, G.; Gubicza, J.; Schoenstein, F.; Jouini, N.; Cherif, S.M.; Gatel, C.; Douin, J. Microstructure and mechanical properties of ultrafine-grained fcc/hcp cobalt processed by a bottom up approach. J. Alloys Compd. 2010, 489, 424–428. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ma, E. On the origin of ultrahigh cryogenic strength of nanocrystalline metals. Appl. Phys. Lett. 2004, 85, 2750–2752. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Li, B.; Liu, Q. Non-equlibrium basal stacking faults in hexagonal close-packed metals. Acta Mater. 2015, 90, 140–150. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ott, R.T.; Hamza, A.V.; Besser, M.F.; Almer, J.; Kramer, M.J. Achieving large uniform tensile duktility in nanocrystalline metals. Phys. Rev. Lett. 2010, 105. [Google Scholar] [CrossRef] [PubMed]

| Sample | HV | CYS (MPa) | UCS (MPa) | Max Deformation (%) | ρrel (%) |

|---|---|---|---|---|---|

| Ultrafine-grained | 310 ± 4 | 1030 | 1200 | 10 | 88.8 ± 0.6 |

| Micro-crystalline | 190 ± 5 | 640 | 1450 | 30 | 98.9 ± 0.4 |

| As-cast | 100 ± 3 | 340 | 980 | 31 | 97.8 ± 0.4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marek, I.; Vojtěch, D.; Michalcová, A.; Kubatík, T.F. The Structure and Mechanical Properties of High-Strength Bulk Ultrafine-Grained Cobalt Prepared Using High-Energy Ball Milling in Combination with Spark Plasma Sintering. Materials 2016, 9, 391. https://doi.org/10.3390/ma9050391

Marek I, Vojtěch D, Michalcová A, Kubatík TF. The Structure and Mechanical Properties of High-Strength Bulk Ultrafine-Grained Cobalt Prepared Using High-Energy Ball Milling in Combination with Spark Plasma Sintering. Materials. 2016; 9(5):391. https://doi.org/10.3390/ma9050391

Chicago/Turabian StyleMarek, Ivo, Dalibor Vojtěch, Alena Michalcová, and Tomáš František Kubatík. 2016. "The Structure and Mechanical Properties of High-Strength Bulk Ultrafine-Grained Cobalt Prepared Using High-Energy Ball Milling in Combination with Spark Plasma Sintering" Materials 9, no. 5: 391. https://doi.org/10.3390/ma9050391

APA StyleMarek, I., Vojtěch, D., Michalcová, A., & Kubatík, T. F. (2016). The Structure and Mechanical Properties of High-Strength Bulk Ultrafine-Grained Cobalt Prepared Using High-Energy Ball Milling in Combination with Spark Plasma Sintering. Materials, 9(5), 391. https://doi.org/10.3390/ma9050391