Industrial Wastes-Cum-Strength Enhancing Additives Incorporated Lightweight Aggregate Concrete (LWAC) for Energy Efficient Building: A Comprehensive Review

Abstract

:1. Introduction

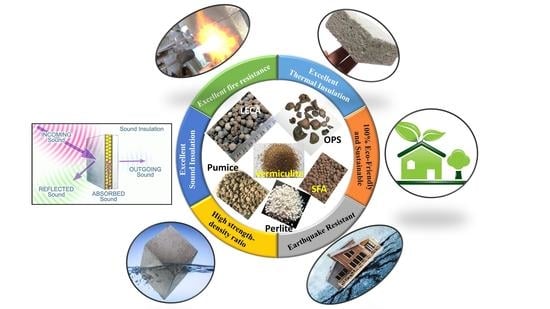

2. Types of LWAs

2.1. Natural Aggregate

2.2. Manufactured/Artificial Aggregate

3. Different LWAs and Their Use to Develop Green Building Materials

3.1. OPS Concrete (OPSC)

3.2. LECA Concrete

3.3. Vermiculite Concrete

3.4. Perlite Concrete

3.5. Pumice Concrete

3.6. Sintered Fly Ash Concrete

4. The Comparisons among Different LWAs/LWACs on the Basis of Various Parameters

5. Research and Development at CSIR-CBRI

6. Conclusions

7. Recommendations for the Further Research

- Studies of hardened, durable and functional properties for different LWACs in various Indian climatic conditions;

- Comprehensive studies of different durability attributes of high-performance LWAC containing different SCMs, fibers and polymers;

- Statistical modeling for durability properties based on theoretical and empirical studies along with their validation in the fields;

- Field studied for fire resistance of LWA concrete incorporated with SCMs, fibers, fire-resistant admixtures, etc.;

- Study investigating the toughness and fracture energy of LWACs (LECA, OPS, sintered fly ash, pumice, perlite, vermiculite) is needed as these properties are necessary while modeling their mechanical behavior.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Koksal, F.; Gencel, O.; Kaya, M. Combined effect of silica fume and expanded vermiculite on properties of lightweight mortars at ambient and elevated temperatures. Constr. Build. Mater. 2015, 88, 175–187. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Al Muhit, B.A.; Jumaat, M.Z. Utilization of oil palm kernel shell as lightweight aggregate in concrete–A review. Constr. Build. Mater. 2013, 38, 161–172. [Google Scholar] [CrossRef]

- Olanipekun, E.; Olusola, K.; Ata, O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- Teo, D.C.L.; Mannan, M.A.; Kurian, V.J.; Ganapathy, C. Lightweight concrete made from oil palm shell (OPS): Structural bond and durability properties. Build. Environ. 2007, 42, 2614–2621. [Google Scholar] [CrossRef]

- Zach, J.; Hubertova, M.; Hroudova, J. Possibilities of determination of thermal conductivity of lightweight concrete with utilization of nonstationary hot-wire method. In The 10th International Conference of the Slovenian Society for Non-Destructive Testing; Application of Contemporary Non-Destructive Testing in Engineering: Ljubljana, Slovenia, 2009; pp. 207–213. [Google Scholar]

- Grabois, T.M.; Cordeiro, G.C.; Filho, R.D.T. Fresh and hardened-state properties of self-compacting lightweight concrete reinforced with steel fibers. Constr. Build. Mater. 2016, 104, 284–292. [Google Scholar] [CrossRef]

- Nirmal, C.; Jaiswal, D.S. Dynamic Analysis of High Rise Building Structure with Lightweight concrete. Int. Res. J. Eng. Technol. 2018, 05, 368–372. [Google Scholar]

- Omar, W.; Mohamed, R.N. The performance of pretensioned prestressed concrete beams made with lightweight concrete. Malays. J. Civ. Eng. 2002, 14. [Google Scholar] [CrossRef]

- Lo, T.; Cui, H.; Li, Z. Influence of aggregate pre-wetting and fly ash on mechanical properties of lightweight concrete. Waste Manag. 2004, 24, 333–338. [Google Scholar] [CrossRef] [PubMed]

- Guide for Structural Lightweight-Aggregate Concrete; ACI Committee: Farmington Hills, MI, USA, 1999; p. 213.

- Bogas, J.A.; Cunha, D. Non-structural lightweight concrete with volcanic scoria aggregates for lightweight fill in building’s floors. Constr. Build. Mater. 2017, 135, 151–163. [Google Scholar] [CrossRef]

- Karatas, M.; Balun, B.; Benli, A. High temperature resistance of self-compacting lightweight mortar incorporating expanded perlite and pumice. Comput. Concr. 2017, 19, 121–126. [Google Scholar] [CrossRef]

- Parhizkar, T.; Najimi, M.; Pourkhorshidi, A.R. Application of Pumice Aggregate in Structural Lightweight Concrete. Asian J. Civ. Eng. 2012, 13, 43–54. [Google Scholar]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Oil palm shell as a lightweight aggregate for production high strength lightweight concrete. Constr. Build. Mater. 2011, 25, 1848–1853. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Effects of lightweight fly ash aggregate properties on the behavior of lightweight concretes. J. Hazard. Mater. 2010, 179, 954–965. [Google Scholar] [CrossRef] [PubMed]

- Dinakar, P. Properties of fly-ash lightweight aggregate concretes. Proc. Inst. Civ. Eng.-Constr. Mater. 2013, 166, 133–140. [Google Scholar] [CrossRef]

- Sahoo, S.; Selvaraju, A.K.; Prakash, S.S. Mechanical characterization of structural lightweight aggregate concrete made with sintered fly ash aggregates and synthetic fibres. Cem. Concr. Compos. 2020, 113, 103712. [Google Scholar] [CrossRef]

- Youssf, O.; Hassanli, R.; Mills, J.; Elrahman, M.A. An experimental investigation of the mechanical performance and structural application of LECA-Rubcrete. Constr. Build. Mater. 2018, 175, 239–253. [Google Scholar] [CrossRef]

- Karakoç, M.B.; Demirboga, R. HSC with Expanded Perlite Aggregate at Wet and Dry Curing Conditions. J. Mater. Civ. Eng. 2010, 22, 1252–1259. [Google Scholar] [CrossRef]

- Mo, K.H.; Lee, H.J.; Liu, M.Y.J.; Ling, T.-C. Incorporation of expanded vermiculite lightweight aggregate in cement mortar. Constr. Build. Mater. 2018, 179, 302–306. [Google Scholar] [CrossRef]

- Eziefula, U.G.; Opara, H.E.; Anya, C.U. Mechanical Properties of Palm Kernel Shell Concrete In Comparison with Periwinkle Shell Concrete. Mal. J. Civil Eng. 2017, 29, 1–14. [Google Scholar]

- Mannan, M.; Ganapathy, C. Engineering properties of concrete with oil palm shell as coarse aggregate. Constr. Build. Mater. 2002, 16, 29–34. [Google Scholar] [CrossRef]

- Sobuz, H.R.; Hasan, N.M.S.; Tamanna, N.; Islam, S. Structural Lightweight Concrete Production by Using Oil Palm Shell. J. Mater. 2014, 2014, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Real, S.; Bogas, J.A.; Pontes, J. Chloride migration in structural lightweight aggregate concrete produced with different binders. Constr. Build. Mater. 2015, 98, 425–436. [Google Scholar] [CrossRef]

- Shafigh, P.; Chai, L.J.; Bin Mahmud, H.; Nomeli, M.A. A comparison study of the fresh and hardened properties of normal weight and lightweight aggregate concretes. J. Build. Eng. 2018, 15, 252–260. [Google Scholar] [CrossRef]

- Schackow, A.; Effting, C.; Folgueras, M.V.; Güths, S.; Mendes, G.A. Mechanical and thermal properties of lightweight concretes with vermiculite and EPS using air-entraining agent. Constr. Build. Mater. 2014, 57, 190–197. [Google Scholar] [CrossRef]

- Divya, M.R.; Rajalingam, M.; George, S. Study on Concrete with Replacement of Fine Aggregates by Vermiculite. Int. J. New Tech. Res. 2016, 2, 87–89. [Google Scholar]

- Arun, L.; Kowsalya, K.; Madhumathi, S.; Preethi, K.; Pradheepa, R. An experimental study on concrete with partial replacement of fine aggregate by vermiculite and silica fume as a mineral admixture. Int. J. Intell. Adv. Res. Eng. Comput. 2018, 06, 224–227. [Google Scholar]

- Demirboğa, R.; Gül, R. The effects of expanded perlite aggregate, silica fume and fly ash on the thermal conductivity of lightweight concrete. Cem. Concr. Res. 2003, 33, 723–727. [Google Scholar] [CrossRef]

- Oktay, H.; Yumrutaş, R.; Akpolat, A. Mechanical and thermophysical properties of lightweight aggregate concretes. Constr. Build. Mater. 2015, 96, 217–225. [Google Scholar] [CrossRef]

- Zulkifeli, M.F.; Saman, H.M. Compressive and Flexural Strength of Expanded Perlite Aggregate Mortar Subjected to High Temperatures; AIP: New York, NY, USA, 2016. [Google Scholar]

- Hossain, K.M.A. Properties of volcanic pumice based cement and lightweight concrete. Cem. Concr. Res. 2004, 34, 283–291. [Google Scholar] [CrossRef]

- Sari, D.; Pasamehmetoglu, A. The effects of gradation and admixture on the pumice lightweight aggregate concrete. Cem. Concr. Res. 2005, 35, 936–942. [Google Scholar] [CrossRef]

- Gündüz, L.; Uğur, I. The effects of different fine and coarse pumice aggregate/cement ratios on the structural concrete properties without using any admixtures. Cem. Concr. Res. 2005, 35, 1859–1864. [Google Scholar] [CrossRef]

- Binici, H.; Durgun, M.Y.; Rızaoğlu, T.; Koluçolak, M. Investigation of durability properties of concrete pipes incorporating blast furnace slag and ground basaltic pumice as fine aggregates. Sci. Iran. 2012, 19, 366–372. [Google Scholar] [CrossRef] [Green Version]

- Güneyisi, E.; Gesoglu, M.; Pürsünlü, Ö.; Mermerdaş, K. Durability aspect of concretes composed of cold bonded and sintered fly ash lightweight aggregates. Compos. Part B Eng. 2013, 53, 258–266. [Google Scholar] [CrossRef]

- Gomathi, P.; Sivakumar, A. Accelerated curing effects on the mechanical performance of cold bonded and sintered fly ash aggregate concrete. Constr. Build. Mater. 2015, 77, 276–287. [Google Scholar] [CrossRef]

- Foong, K.Y.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Enhancement of the mechanical properties of lightweight oil palm shell concrete using rice husk ash and manufactured sand. J. Zhejiang Univ. A 2015, 16, 59–69. [Google Scholar] [CrossRef] [Green Version]

- Al-Bahar, S.; Bogahawatta, T. Development of lightweight aggregate in Kuwait. Arab. J. Sci. Eng. 2006, 31, 231–239. [Google Scholar] [CrossRef]

- Sajedi, F.; Shafigh, P. High-strength lightweight concrete using Leca, silica fume, and limestone. Arab. J. Sci. Eng. 2012, 37, 1885–1893. [Google Scholar] [CrossRef]

- Masoud, Z.; Shahram, S.; Nezamedin, H.S. Photocatalytic degradation of ammonia by light expanded clay aggregate (LECA)-coating of TiO2 nanoparticles. Korean J. Chem. Eng. 2013, 30, 574–579. [Google Scholar]

- Abidi, S.; Nait-Ali, B.; Joliff, Y.; Favotto, C. Impact of perlite, vermiculite and cement on the thermal conductivity of a plaster composite material: Experimental and numerical approaches. Compos. Part B Eng. 2015, 68, 392–400. [Google Scholar] [CrossRef]

- Sayadi, A.; Neitzert, T.R.; Clifton, G.C.; Han, M.C. Assessment of Vermiculite Concrete Containing Bio-polymer Aggregate, World Acad. Sci. Eng. Tech. Int. J. Civ. Env. Eng. 2016, 10, 1180–1187. [Google Scholar] [CrossRef]

- Türkmen, I.; Kantarcı, A. Effects of expanded perlite aggregate and different curing conditions on the physical and mechanical properties of self-compacting concrete. Build. Environ. 2007, 42, 2378–2383. [Google Scholar] [CrossRef]

- Demirel, B.; Keleştemur, O. Effect of elevated temperature on the mechanical properties of concrete produced with finely ground pumice and silica fume. Fire Saf. J. 2010, 45, 385–391. [Google Scholar] [CrossRef] [Green Version]

- Onoue, K.; Tamai, H.; Suseno, H. Shock-absorbing capability of lightweight concrete utilizing volcanic pumice aggregate. Constr. Build. Mater. 2015, 83, 261–274. [Google Scholar] [CrossRef]

- Kayali, O. Fly ash lightweight aggregates in high performance concrete. Constr. Build. Mater. 2008, 22, 2393–2399. [Google Scholar] [CrossRef]

- Mannan, M.; Ganapathy, C. Concrete from an agricultural waste-oil palm shell (OPS). Build. Environ. 2004, 39, 441–448. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014, 72, 238–245. [Google Scholar] [CrossRef]

- Mo, K.H.; Yap, K.K.Q.; Alengaram, U.J.; Jumaat, M.Z. The effect of steel fibres on the enhancement of flexural and compressive toughness and fracture characteristics of oil palm shell concrete. Constr. Build. Mater. 2014, 55, 20–28. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Visintin, P.; Goh, S.H.; Jumaat, M.Z. Influence of lightweight aggregate on the bond properties of concrete with various strength grades. Constr. Build. Mater. 2015, 84, 377–386. [Google Scholar] [CrossRef] [Green Version]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Liu, M.Y.J.; Lim, J. Assessing some durability properties of sustainable lightweight oil palm shell concrete incorporating slag and manufactured sand. J. Clean. Prod. 2016, 112, 763–770. [Google Scholar] [CrossRef]

- Khankhaje, E.; Rafieizonooz, M.; Salim, M.R.; Mirza, J.; Salmiati; Hussin, M.W. Comparing the effects of oil palm kernel shell and cockle shell on properties of pervious concrete pavement. Int. J. Pavement Res. Technol. 2017, 10, 383–392. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z. Enhancement and prediction of modulus of elasticity of palm kernel shell concrete. Mater. Des. 2011, 32, 2143–2148. [Google Scholar] [CrossRef]

- Campione, G.; Miraglia, N.; Papia, M. Mechanical properties of steel fibre reinforced lightweight concrete with pumice stone or expanded clay aggregates. Mater. Struct. 2001, 34, 201–210. [Google Scholar] [CrossRef]

- Nkansah, M.A.; Christy, A.A.; Barth, T.; Francis, G.W. The use of lightweight expanded clay aggregate (LECA) as sorbent for PAHs removal from water. J. Hazard. Mater. 2012, 217–218, 360–365. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maghsoudi, A.A.; Mohamadpour, S.; Maghsoudi, M. Mix design and mechanical properties of self-compacting lightweight concrete. Int. J. Civ. Eng. 2011, 9, 230–236. [Google Scholar]

- Zohrabi, M.; Zohrabi, A.; Chermahini, A.G. Investigation of the Mechanical Properties of Lightweight Concrete Containing LECA with Metakaoline Pozzolan Using Polypropylene and Steel Fibers. J. Appl. Environ. Biol. Sci. 2015, 5, 11–15. [Google Scholar]

- Vijayalakshmi, R.; Ramanagopal, S. Structural concrete using expanded clay aggregate: A review. Indian J. Sci. Technol. 2018, 11, 1–12. [Google Scholar] [CrossRef]

- Heiza, K.M.; Eid, F.M.; Masoud, T. Lightweight self-compacting concrete with light expanded clay aggregate (LECA). ERJ Eng. Res. J. 2017, 40, 65–71. [Google Scholar] [CrossRef] [Green Version]

- Reddy, S.R.; Swetha, N.; Desai, V.B. Flexural Study on Slab Specimens with Partial to Fully Replacement of Natural Coarse Aggregate by Light Weight Expandable Clay Aggregate (LECA). Int. J. Tech. Innov. Mod. Eng. Sci. 2018, 4, 2935–2942. [Google Scholar]

- Sundhakumar, J. Studies on the thermal performance of ferrocement roofs. In Proceedings of the 26th Conference on Our World in Concrete & Structures, Singapore, 27–28 August 2001; pp. 599–604. [Google Scholar]

- Lorenzon, M.C.A.; Cidreira, R.G.; Rodrigues, E.H.V.; Dornelles, M.S.; Pereira, G., Jr. Langstroth Hive Construction with Cement-Vermiculite. Sci. Agric. 2004, 61, 573–578. [Google Scholar] [CrossRef] [Green Version]

- Al-Jabri, K.S.; Hago, A.W.; Taha, R.; Alnuaimi, A.; Al-Saidy, A.H. Strength and Insulating Properties of Building Blocks Made from Waste Materials. J. Mater. Civ. Eng. 2009, 21, 191–197. [Google Scholar] [CrossRef]

- Gunasekaran, M.; Priyalakshmi, A.; Anudevi, C.; Premachandar, H. Study on Vermiculite Incorporate in Mortar. Int. J. Innov. Res. Sci. Tech. 2016, 2, 36–42. [Google Scholar]

- Sairam, A.V.V.; Sailaja, K. An Experimental Study on Strength Properties of Vermiculite Concrete Using Fly ash as Partially Replacement of Cement and Silica Fume as Mineral Admixture. Int. Res. J. Eng. Tech. 2017, 4, 659–664. [Google Scholar]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Gandage, A.S.; Rao, V.V.; Sivakumar, M.; Vasan, A.; Venu, M.; Yaswanth, A. Effect of Perlite on Thermal Conductivity of Self Compacting Concrete. Procedia-Soc. Behav. Sci. 2013, 104, 188–197. [Google Scholar] [CrossRef] [Green Version]

- Kotwica, Ł.; Pichór, W.; Kapeluszna, E.; Różycka, A. Utilization of waste expanded perlite as new effective supplementary cementitious material. J. Clean. Prod. 2017, 140, 1344–1352. [Google Scholar] [CrossRef]

- Polat, R.; Demirboğa, R.; Karagöl, F. The influence of expanded perlite aggregate on compressive strength, linear autogenous shrinkage, restrained shrinkage, heat of hydration of cement-based materials. Struct. Concr. 2018, 19, 1771–1781. [Google Scholar] [CrossRef]

- Law Yim Wan, D.S.; Aslani, F.; Ma, G. Lightweight Self-Compacting Concrete Incorporating Perlite, Scoria, and Polystyrene Aggregates. J. Mater. Civ. Eng. 2018, 30, 04018178. [Google Scholar] [CrossRef]

- Demir, I.; Baspinar, M.S. Effect of silica fume and expanded perlite addition on the technical properties of the fly ash–lime–gypsum mixture. Constr. Build. Mater. 2008, 22, 1299–1304. [Google Scholar] [CrossRef]

- Gündüz, L. The effects of pumice aggregate/cement ratios on the low-strength concrete properties. Constr. Build. Mater. 2008, 22, 721–728. [Google Scholar] [CrossRef]

- Tasdemir, C.; Sengul, O.; Tasdemir, M.A. A comparative study on the thermal conductivities and mechanical properties of lightweight concretes. Energy Build. 2017, 151, 469–475. [Google Scholar] [CrossRef]

- Kilincarslan, Ş.; Davraz, M.; Akça, M. The effect of pumice as aggregate on the mechanical and thermal properties of foam concrete. Arab. J. Geosci. 2018, 11, 1–6. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Structural concrete using sintered flyash lightweight aggregate: A review. Constr. Build. Mater. 2017, 154, 928–944. [Google Scholar] [CrossRef]

- Swamy, R.N.; Lambert, G.H. The microstructure of LytagTM aggregates. Int. J. Cem. Compos. Lightweight Concr. 1981, 3, 273–285. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Durability of lightweight concretes with lightweight fly ash aggregates. Constr. Build. Mater. 2011, 25, 1430–1438. [Google Scholar] [CrossRef]

- Kumar, A.; Prakash, P. Studies on Structural Light Weight Concrete by Blending Light Weight Aggregates. Int. J. Innov. Res. Eng. Manag. 2015, 2, 48–52. [Google Scholar] [CrossRef]

| Type of Aggregate | References | Specific Gravity | Water Absorption for 24 h (%) | Fineness Modulus (FM) | Bulk Density (Compacted) (kg/m3) |

|---|---|---|---|---|---|

| OPS | Mannan and Ganapathy [22]; Teo et al. [4]; Shafigh et al. [14]; Sobuz et al. [23]; Eziefula et al. [21] | 1.17–1.30 | 33.0–19.6 | 5.64–6.24 | 572–656 |

| LECA | Maghsoudi et al. [5]; Real et al. [24]; Bogas and Cunha [11]; Shafigh et al. [25] | 0.51–1.18 | 16.42–26.5 | 15.8–5.96 | 273–667 |

| Vermiculite | Schackow et al. [26]; Divya et al. [27]; Arun et al. [28] | 1.10–3.0 | 2.65 | 2.46 | - |

| Perlite | Demirbog and Gul [29]; Karakoc and Demirboga [19]; Oktay et al. [30]; Zulkifeli and Saman [31] | 0.12–0.42 | 82.5 | - | 200 |

| Pumice | Hossain [32]; Sari and Pasamehmetoglu [33]; Gunduz and Ugur [34]; Binici et al. [35]; Kockal and Ozturan [15] | 1.57–3.10 | - | - | 870 |

| Sintered Fly ash | Guneyisi et al. [36]; Gomathi and Sivakumar [37] | 2.10–2.25 | 0.14 | 6.24 | - |

| Type of Aggregate | References | Chemical Components (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Main | Minor | |||||||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | LOI | ||

| OPS | Shafigh et al. [14]; Foong et al. [38] | 18.47–21.32 | 4.27–6.20 | 2.06–3.62 | 64.09–65.41 | 2.08–2.43 | 4.25–5.50 | 0.28–0.73 | 0.21–0.25 | 1.41–1.80 |

| LECA | Al-Bahar and Bogahawatta [39]; Sajedi and Shafigh [40]; Masoud et al. [41] | 53.3–66.05 | 15.05–19.78 | 6.2–9.52 | 1.05–2.98 | 0.78–3.67 | 0.23–0.25 | 2.55–4.1 | 0.17–1.54 | 1.37–15.11 |

| Vermiculite | Koksal et al. [1]; Abidi et al. [42]; Sayadi et al. [43] | 36.9–46 | 10–17.7 | 5.50–11.2 | 1–3.5 | 16–35 | 0.02–0.10 | 1–6 | 0.13–0.2 | 7.5–9.2 |

| Perlite | Turkmen and Kantarci [44] | 71–76 | 9.91–16 | 0.40–1.57 | 0.5–2.19 | 0.01–0.28 | 0.04–0.10 | 4–5 | 2.9–4 | 1.48–2.0 |

| Pumice | Demirel and Kelestemur [45]; Binici et al. [35]; Onoue et al. [46] | 41.41–63.4 | 12.97–21.9 | 1.26–11.41 | 1.8–13.73 | 0.3–15 | 0.44–0.50 | 1.73–5.40 | 1.80–5.20 | 1.60–7.32 |

| Sintered Fly ash | Kayali [47]; Kockal and Ozturan [15]; Guneyisi et al. [36] | 56.2–64.60 | 19.58–28.5 | 4.0–7.23 | 0.54–4.24 | 0.66–4.64 | 0.30–0.69 | 0.01–5.95 | 0.32–2.06 | 0.49–5.10 |

| Aggregate Type | References | Compressive Strength | Splitting Tensile Strength | Flexural Strength | Thermal Conductivity | Modulus of Elasticity | Water Absorption |

|---|---|---|---|---|---|---|---|

| OPS | Mannan and Ganapathy [22] | ✓ | ✓ | ✓ | ✓ | ||

| Sobuz et al. [23] | ✓ | ✓ | ✓ | ✓ | |||

| Mo et al. [51] | ✓ | ✓ | ✓ | ||||

| Mo et al. [52] | ✓ | ✓ | |||||

| LECA | Maghsoudi et al. [57] | ✓ | ✓ | ||||

| Zohrabi et al. [58] | ✓ | ✓ | |||||

| Kumar and Prakash [79] | ✓ | ✓ | |||||

| Heiza et al. [60] | ✓ | ✓ | |||||

| Reddy et al. [61] | ✓ | ||||||

| Al-Jabri et al. [64] | ✓ | ✓ | |||||

| Vermiculite | Schackow et al. [26] | ✓ | |||||

| Koksal et al. [1] | ✓ | ✓ | ✓ | ✓ | |||

| Divya et al. [27] | ✓ | ✓ | ✓ | ||||

| Mo et al. [20] | ✓ | ✓ | |||||

| Arun et al. [28] | ✓ | ✓ | ✓ | ||||

| Karakoc and Demirboga [19] | ✓ | ✓ | |||||

| Perlite | Sengul et al. [67] | ✓ | ✓ | ✓ | ✓ | ||

| Gandage et al. [68] | ✓ | ✓ | ✓ | ||||

| Polat et al. [70] | ✓ | ||||||

| Wan et al. [71] | ✓ | ✓ | |||||

| Gunduz and Ugur [34] | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Pumice | Gunduz [73] | ✓ | ✓ | ✓ | ✓ | ||

| Parhizkar et al. [13] | ✓ | ✓ | ✓ | ||||

| Tasdemir et al. [74] | ✓ | ✓ | ✓ | ||||

| Kilincarslan et al. [75] | ✓ | ✓ | |||||

| Sintered fly ash | Kockal and Ozturan [78] | ✓ | ✓ | ✓ | |||

| Kockal and Ozturan [15] | ✓ | ✓ | ✓ | ✓ | |||

| Nadesan and Dinakar [76] | ✓ | ✓ | ✓ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, R.; Srivastava, A.; Lakhani, R. Industrial Wastes-Cum-Strength Enhancing Additives Incorporated Lightweight Aggregate Concrete (LWAC) for Energy Efficient Building: A Comprehensive Review. Sustainability 2022, 14, 331. https://doi.org/10.3390/su14010331

Kumar R, Srivastava A, Lakhani R. Industrial Wastes-Cum-Strength Enhancing Additives Incorporated Lightweight Aggregate Concrete (LWAC) for Energy Efficient Building: A Comprehensive Review. Sustainability. 2022; 14(1):331. https://doi.org/10.3390/su14010331

Chicago/Turabian StyleKumar, Rajesh, Abhishek Srivastava, and Rajni Lakhani. 2022. "Industrial Wastes-Cum-Strength Enhancing Additives Incorporated Lightweight Aggregate Concrete (LWAC) for Energy Efficient Building: A Comprehensive Review" Sustainability 14, no. 1: 331. https://doi.org/10.3390/su14010331

APA StyleKumar, R., Srivastava, A., & Lakhani, R. (2022). Industrial Wastes-Cum-Strength Enhancing Additives Incorporated Lightweight Aggregate Concrete (LWAC) for Energy Efficient Building: A Comprehensive Review. Sustainability, 14(1), 331. https://doi.org/10.3390/su14010331