Application of Combining YOLO Models and 3D GPR Images in Road Detection and Maintenance

Abstract

:1. Introduction

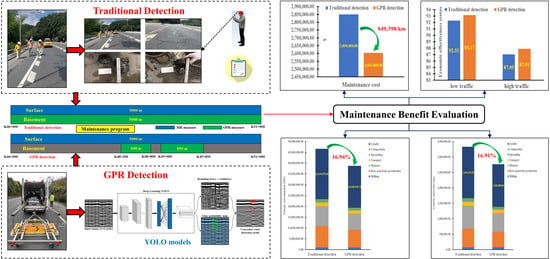

2. Traditional Pavement Detection

2.1. Tested Road Sections

2.2. Testing Process and Results

3. Nondestructive Testing of Pavement Based on GPR

3.1. Testing Equipment

3.2. Testing Scheme

3.3. Data Processing

3.3.1. Filtering for GPR Data

3.3.2. Recognizing for GPR Data

3.3.3. Capturing for GPR Data

3.3.4. Labeling for GPR Data

3.4. Testing Results

4. Discussion of Maintenance Benefits

4.1. Disease Characteristics and Analysis

4.1.1. Traditional Detection

4.1.2. GPR Detection

- The up and down cracking (the pumping defect had emerged, Figure 10a).

- The top-down developing cracking (the cracking had emerged on the surface but not at the basement, Figure 10b).

- The bottom-up developing cracking (the cracking had emerged on the basement but not at the surface, Figure 10c).

4.2. Maintenance Program

4.3. Benefits Analysis

4.3.1. Economic Benefits

4.3.2. Environmental Benefits

5. Conclusions

- The internal defects in asphalt pavement, including cracking, void zones, raveling, and settlement, were detected by 3D GPR. However, the conventional method detected only the surface conditions. Furthermore, 3D GPR detection is more nondestructive relative to the coring validation.

- The final converged loss value of YOLOv3 was approximately 2, whereas that of YOLOv5 was lower than 0.2. Thus, the YOLOv5 models are suitable for the detection of internal defects in asphalt road, and these models provide a good training result even for a small dataset condition. The mAP values of the YOLOv5m, YOLOv5l, and YOLOv5x models were higher than 90% and the maximum was 94.45% in YOLOv5-x. It was also found with regularity that the larger a model’s weights are, the higher the model’s mAP will be, which suggests that an appropriate increase in model depth favors the enhancement of the training performance. Most importantly, the YOLOv5m models are the most balanced deep-learning models in terms of detection speed and actual performance of the six YOLO series models.

- In the evaluation of the economic benefits of maintenance programs, the maintenance cost based on GPR detection was reduced by $49,398/km compared to that of traditional detection, and the economic scores based on GPR detection were higher than those of traditional detection in low-traffic and high-traffic road sections. As for environmental benefits, the energy consumption and carbon emissions of the maintenance program based on GPR detection was less than those of traditional detection by 792,106 MJ/km and 56,289 kg/km or 16.94 and 16.91 percentage points, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zou, Q.; Cao, Y.; Mao, Q.; Wang, S. Crack Tree: Automatic crack detection from pavement images. Pattern Recogn. Lett. 2012, 33, 227–238. [Google Scholar] [CrossRef]

- Brown, S.F. Accelerated pavement testing in highway engineering. Transport 2004, 157, 173–180. [Google Scholar] [CrossRef]

- Lai, W.L.; Dérobert, X.; Annan, P. A review of ground penetrating radar application in civil engineering: A 30-year journey from locating and testing to imaging and diagnosis. NDT E Int. 2017, 96, 58–78. [Google Scholar]

- Zhao, S.; Al-Qadi, I.L. Development of regularization methods on simulated ground-penetrating radar signals to predict thin asphalt overlay thickness. Signal Process. 2017, 132, 261–271. [Google Scholar] [CrossRef]

- Zhao, S.; Al-Qadi, I.L. Super-Resolution of 3-D GPR Signals to Estimate Thin Asphalt Overlay Thickness Using the XCMP Method. IEEE Trans. Geosci. Remote Sens. 2019, 57, 893–901. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, X.; Li, W.; Zhang, S.; Jia, Y. Automatic detection of moisture damages in asphalt pavements from GPR data with deep CNN and IRS method. Autom. Constr. 2020, 113, 103119. [Google Scholar] [CrossRef]

- Zhao, S.; Al-Qadi, I.L. Algorithm development for real-time thin asphalt concrete overlay compaction monitoring using ground-penetrating radar. NDT E Int. 2019, 104, 114–123. [Google Scholar] [CrossRef]

- Zhao, S.; Al-Qadi, I.L.; Wang, S. Prediction of thin asphalt concrete overlay thickness and density using nonlinear optimization of GPR data. NDT E Int. 2018, 100, 20–30. [Google Scholar] [CrossRef]

- Liu, Y.; Qiao, J.; Han, T.; Li, L.; Xu, T. A 3D Image Reconstruction Model for Long Tunnel Geological Estimation. J. Adv. Transp. 2020, 2020, 8846955. [Google Scholar] [CrossRef]

- Rasol, M.A.; Gracia, V.P.; Fernandes, F.M.; Pais, J.C.; Assuncao, S.S.; Santos, C.; Sossa, V. GPR laboratory tests and numerical models to characterize cracks in cement concrete specimens, exemplifying damage in rigid pavement. Measurement 2020, 158, 107662. [Google Scholar] [CrossRef]

- Rodes, P.J.; Reguero, A.M.; Perez-Gracia, V. GPR Spectra for Monitoring Asphalt Pavements. Remote Sens. 2020, 12, 1749. [Google Scholar] [CrossRef]

- Gao, J.; Yuan, D.; Tong, Z.; Yang, J.; Yu, D. Autonomous pavement distress detection using ground penetrating radar and region-based deep learning. Measurement 2020, 164, 108077. [Google Scholar] [CrossRef]

- Kang, M.S.; Kim, N.; Im, S.B.; Lee, J.J.; An, Y.K. 3D GPR Image-based UcNet for Enhancing Underground Cavity Detectability. Remote Sens. 2019, 11, 2545. [Google Scholar] [CrossRef] [Green Version]

- Gong, Z.; Zhang, H. Research on GPR image recognition based on deep learning. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2020; Volume 309, p. 03027. [Google Scholar]

- Tong, Z.; Gao, J.; Zhang, H. Innovative method for recognizing subgrade defects based on a convolutional neural network. Constr. Build. Mater. 2018, 169, 69–82. [Google Scholar] [CrossRef]

- Tong, Z.; Yuan, D.; Gao, J.; Wang, Z. Pavement defect detection with fully convolutional network and an uncertainty framework. Comput. Aided Civ. Infrastruct. Eng. 2020, 35, 832–849. [Google Scholar] [CrossRef]

- Tong, Z.; Yuan, D.; Gao, J.; Wei, Y.; Dou, H. Pavement-distress detection using ground-penetrating radar and network in networks. Constr. Build. Mater. 2019, 233, 117352. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the Computer Vision & Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLO9000: Better, Faster, Stronger. In Proceedings of the IEEE Conference on Computer Vision & Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLOv3: An Incremental Improvement. arXiv 2018, arXiv:1804.02767. [Google Scholar]

- Lin, T.Y.; Gaoyal, P.; Girshick, R.; He, K.; Dollár, P. Focal Loss for Dense Object Detection. In Proceedings of the 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017. [Google Scholar]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C. SSD: Single Shot MultiBox Detector. In Computer Vision—ECCV 2016, ECCV 2016; Lecture Notes in Computer Science; Springer: Cham, Switzerland; Glasgow, UK, 2016. [Google Scholar]

- Shen, Z.; Zhuang, L.; Li, J.; Jiang, Y.; Xue, X. DSOD: Learning Deeply Supervised Object Detectors from Scratch. In Proceedings of the 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017. [Google Scholar]

- Duan, K.; Bai, S.; Xie, L.; Qi, H.; Huang, Q.; Tian, Q. CenterNet: Keypoint Triplets for Object Detection. In Proceedings of the 2019 IEEE/CVF International Conference on Computer Vision (ICCV), Seoul, South Korea, 27 October–2 November 2019. [Google Scholar]

- Zhou, J.; Tian, Y.; Yuan, C.; Yin, K.; Wen, M. Improved UAV Opium Poppy Detection Using an Updated YOLOv3 Model. Sensors 2019, 19, 4851. [Google Scholar] [CrossRef] [Green Version]

- Pang, L.; Liu, H.; Chen, Y.; Miao, J. Real-time Concealed Object Detection from Passive Millimeter Wave Images Based on the YOLOv3 Algorithm. Sensors 2020, 20, 1678. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.; Wang, X. Early recognition of tomato gray leaf spot disease based on MobileNetv2-YOLOv3 model. Plant Methods 2020, 16, 1–16. [Google Scholar] [CrossRef]

- Sunjay, S. GPR Applications in Energy Resources Exploration. In All India Seminar on “Sources of Planet Energy, Environmental and Disaster Science: Challenges & Strategies” (SPEEDS-2013) on Sep’ 07–08, 2013; The Institution of Engineers (India) State Centre, Lucknow&School of Management Sciences, Technical Campus: Lucknow, India, 2019. [Google Scholar]

- Ukhwah, E.N.; Yuniarno, E.M.; Suprapto, Y.K. Asphalt Pavement Pothole Detection using Deep learning method based on YOLO Neural Network. In Proceedings of the 2019 International Seminar on Intelligent Technology and Its Applications (ISITIA), Surabaya, Indonesia, 28–29 August 2019. [Google Scholar]

- Du, Y.C.; Pan, N.; Xu, Z.; Deng, F.; Shen, Y.; Kang, H. Pavement distress detection and classification based on YOLO network. Int. J. Pavement Eng. 2020, 1–14. [Google Scholar] [CrossRef]

- Bochkovskiy, A.; Wang, C.Y.; Liao, H.Y.M. YOLOv4: Optimal Speed and Accuracy of Object Detection. arXiv 2020, arXiv:2004.10934. [Google Scholar]

- Arya, D.; Maeda, H.; Ghosh, S.K.; Toshniwal, D.; Sekimoto, Y. Global Road Damage Detection: State-of-the-art Solutions. arXiv 2020, arXiv:2011,08740. Available online: https://github.com/USC-InfoLab/rddc2020 (accessed on 26 September 2020).

- Liu, Z.; Gu, X.; Dong, Q.; Tu, S.; Li, S. 3D Visualization of Airport Pavement Quality Based on BIM and WebGL Integration. Forthcoming. J. Transp. Eng. Part B Pavements 2021. [Google Scholar] [CrossRef]

- Yao, L.; Dong, Q.; Jiang, J.W.; Ni, F.J. Deep reinforcement learning for long-term pavement maintenance planning. Comput.-Aided Civ. Infrastruct. Eng. 2020, 35, 1230–1245. [Google Scholar] [CrossRef]

- China Highway and Transportation Society, Chts. Technical Guideline for Ground Penetrating Radar Detection for Internal Conditions of Highway Asphalt Pavement. China. 2020. Available online: http://www.chts.cn/upload/file/20201027/6373939111170418695360217.pdf (accessed on 20 October 2020).

- Li, S.; Gu, X.; Xu, X.; Xu, D.; Zhang, T.; Liu, Z.; Dong, Q. Detection of concealed cracks from ground penetrating radar images based on deep learning algorithm. Constr. Build. Mater. 2021, 273, 121949. [Google Scholar] [CrossRef]

- Tzutalin. LabelImg. Git Code. 2015. Available online: https://github.com/tzutalin/labelImg (accessed on 27 October 2017).

- YOLOv5. 2020. Available online: https://github.com/ultralytics/yolov5 (accessed on 30 May 2020).

- Rezatofighi, H.; Tsoi, N.; Gwak, J.Y.; Sadeghian, A.; Reid, I.; Savarese, S. Generalized Intersection Over Union: A Metric and a Loss for Bounding Box Regression. In Proceedings of the 2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition, Long Beach, CA, USA, 15–20 June 2019; pp. 658–666. [Google Scholar]

- Yosinski, J.; Clune, J.; Bengio, Y.; Lipson, H. How transferable are features in deep neural networks? In Proceedings of the 27th International Conference on Neural Information Processing Systems, Montreal, QC, Canada, 8–13 December 2014. [Google Scholar]

- Yao, L.; Dong, Q.; Ni, F.; Jiang, J.; Lu, X.; Du, Y. Effectiveness and Cost-Effectiveness Evaluation of Pavement Treatments Using Life-Cycle Cost Analysis. J. Transp. Eng. Part B Pavements 2019, 145, 04019006. [Google Scholar] [CrossRef]

- Yu, B.; Meng, X.; Liu, Q. Multi-objective optimisation of hot in-place recycling of asphalt pavement considering environmental impact, cost and construction quality. Int. J. Pavement Eng. 2018, 21, 1576–1584. [Google Scholar] [CrossRef]

- Yu, B.; Wang, S.; Gu, X. Estimation and uncertainty analysis of energy consumption and CO2 emission of asphalt pavement maintenance. J. Clean. Prod. 2018, 189, 326–333. [Google Scholar] [CrossRef]

- Lei, M. Research on Comprehensive Evaluation System of Highway Maintenance Cost Benefit. Master’s Thesis, School of Transportation, Southeast University, Nanjing, China, 2019. (In Chinese). [Google Scholar]

- Xie, S. Research on Evaluation Method of Maintenance Benefit of Highway Asphalt Pavement. Master’s Thesis, School of Transportation, Southeast University, Nanjing, China, 2016. (In Chinese). [Google Scholar]

| Disease | Cracking | Settlement | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Structural Layer | N l | L l | D l | N r | L r | D r | N l | A l | N r | A r | |

| Asphalt surface | 126 | 337.6 | 1.4 | 84 | 174.1 | 0.7 | 1 | 4.5 | 2 | 7.3 | |

| Base | – | – | – | – | – | – | – | – | – | – | |

| Subbase | – | – | – | – | – | – | – | – | – | – | |

| GeoScopeTM MKIV Data Acquisition | DXGTM 1820 Ground-Coupled Antenna Array | ||

|---|---|---|---|

| Indicators | Parameters | Indicators | Parameters |

| Antennas | Compatible with all 3D-RADAR DX and DXG antenna array models | Width | 1.8 m |

| Number of channels | 0~21 | Frequency range | 200–3000 MHz |

| Scan pattern | Liner scan, multi-offset, and common mid-point | Number of channels | 21 |

| Frequency bandwidth | 2.9 GHz (100–300 MHz) | Channels spacing (Crpss-line) | 75 mm |

| Resolution (time) | ≥0.34 ns | Effective scan width | 1.5 m |

| Time range | ≤250 ns | Direct wave suppression | >50 dB |

| Scan rate | 13,000 A-scans per second | Polarization (in-line direction) | Linear |

| Location | Stake Number of Starting Point | Stake Number of Ending Point | Breadth of Road | Length/m | Number of Lines | Testing Content | Number of Repeated Scans | Testing Mileage/m |

|---|---|---|---|---|---|---|---|---|

| S210 | K46 + 000 | K51 + 000 | Full width | 5000 | 2 | disease | 1 | 10,000 |

| Typical Images of Abnormal GPR Signals | Judgement | Excavation for Verifying | |||

|---|---|---|---|---|---|

| B-Scan | Description | C-Scan | Description | ||

| Both sides of the waveform in-phase axial near horizontal distribution accompanied interruption or dislocation |  | Similar to the shape pf cracking (long strip) | Cracking |  |

| Reflected waves of in-phase axial clearly protrude toward the top |  | Irregular bright-spots | Void |  |

| Model | Backbone | Neck | Head | Main Improvement |

|---|---|---|---|---|

| YOLOv3 | Darknet | Feature Pyramid Network | YOLOv3 | – |

| YOLOv5s | Cross-stage Partial Darknet | Path Aggregation Network | Mosaic (Data Augmentation) GIoU (estimating the bounding box loss) Auto-learning bounding box anchors (adjusting and optimize the choice of anchors) |

| Model | P | R | F1 | mAP/% | FPS | Inference Time/ms | Weights/MB |

|---|---|---|---|---|---|---|---|

| YOLOv3 | 0.73 | 0.86 | 0.79 | 80.11 | 0.52 | 1920.65 | 235 |

| YOLOv3-tiny | 0.66 | 0.65 | 0.69 | 67.59 | 4.52 | 221.48 | 33.1 |

| YOLOv5s | 0.79 | 0.87 | 0.85 | 87.53 | 3.45 | 289.81 | 26.4 |

| YOLOv5m | 0.76 | 0.94 | 0.82 | 91.61 | 1.36 | 735.54 | 83.2 |

| YOLOv5l | 0.77 | 0.95 | 0.86 | 91.59 | 0.66 | 1526.37 | 190 |

| YOLOv5x | 0.75 | 0.95 | 0.85 | 94.45 | 0.37 | 2735.15 | 364 |

| Disease | Cracking | Void | Raveling | Settlement | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Structural Layer | N 1 | L 2 | D 3 | N | A 4 | N | A | N | A | |

| Asphalt surface | 132 | 354.9 | 1.5 | 4 | 13 | – | – | 1 | 4.5 | |

| Base | 103 | 238.5 | 1.0 | 5 | 16 | 1 | 3.8 | 2 | 8.2 | |

| Subbase | – | – | – | – | – | – | – | – | – | |

| Disease | Cracking | Void | Raveling | Settlement | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Structural Layer | N 1 | L 2 | D 3 | N | A 4 | N | A | N | A | |

| Asphalt surface | 92 | 189 | 0.8 | – | – | – | – | 2 | 7.3 | |

| Base | 86 | 151.6 | 0.6 | 13 | 52 | – | – | 1 | 4.2 | |

| Subbase | – | – | – | – | – | – | – | – | – | |

| Maintenance Measures | Thickness of Treatment (m) | Average Cost ($/m2) | Economic Effectiveness 1 | Economic Effectiveness 2 |

|---|---|---|---|---|

| MR | 0.04 | 11.12 | 93.88 | 88.62 |

| OPR | 0.01 | 4.64 | 90.73 | 85.47 |

| Maintenance Measures | Maintenance Measures | ||||||

|---|---|---|---|---|---|---|---|

| Maintenance Sessions | MR | OPR | Maintenance Sessions | MR | OPR | ||

| Milling | 1770.83 | Milling | 131.22 | ||||

| Raw materials production | 12,298.53 | 12,298.53 | Raw materials production | 756.05 | 756.05 | ||

| Mixture | 11,469.15 | 11,469.15 | Mixture | 925.58 | 925.58 | ||

| Transport | 2146.60 | 2146.60 | Transport | 159.06 | 159.06 | ||

| Spreading | 681.09 | 681.09 | Spreading | 50.47 | 50.47 | ||

| Compaction | 1225.96 | 1225.96 | Compaction | 90.84 | 90.84 | ||

| Totally | 29,592.17 | 27,821.34 | Totally | 2113.23 | 1982.01 | ||

| Thickness of treatment (m) | 0.04 | 0.04 | Thickness of treatment (m) | 0.04 | 0.04 | ||

| Energy consumption (MJ/m2) | 78.91 | 74.19 | CO2 emissions (kg/m2) | 5.64 | 5.29 | ||

| —— | —— | —— | Carbon emissions (kg/m2) | 1.54 | 1.44 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wu, W.; Gu, X.; Li, S.; Wang, L.; Zhang, T. Application of Combining YOLO Models and 3D GPR Images in Road Detection and Maintenance. Remote Sens. 2021, 13, 1081. https://doi.org/10.3390/rs13061081

Liu Z, Wu W, Gu X, Li S, Wang L, Zhang T. Application of Combining YOLO Models and 3D GPR Images in Road Detection and Maintenance. Remote Sensing. 2021; 13(6):1081. https://doi.org/10.3390/rs13061081

Chicago/Turabian StyleLiu, Zhen, Wenxiu Wu, Xingyu Gu, Shuwei Li, Lutai Wang, and Tianjie Zhang. 2021. "Application of Combining YOLO Models and 3D GPR Images in Road Detection and Maintenance" Remote Sensing 13, no. 6: 1081. https://doi.org/10.3390/rs13061081

APA StyleLiu, Z., Wu, W., Gu, X., Li, S., Wang, L., & Zhang, T. (2021). Application of Combining YOLO Models and 3D GPR Images in Road Detection and Maintenance. Remote Sensing, 13(6), 1081. https://doi.org/10.3390/rs13061081