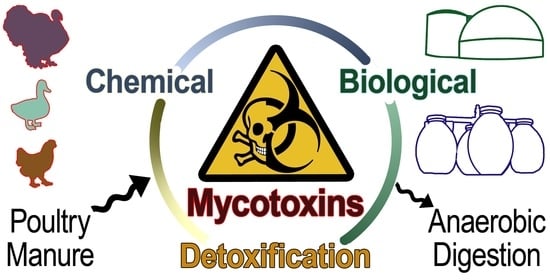

Destruction of Mycotoxins in Poultry Waste under Anaerobic Conditions within Methanogenesis Catalyzed by Artificial Microbial Consortia

Abstract

:1. Introduction

2. Mycotoxins in Poultry Manure

3. Prospects and Features of the Process of Detoxification of Mycotoxins in the Litter by Alkaline Pretreatment

4. Enzymes as Destructors of Mycotoxins in Poultry Manure under Conditions of Methanogenesis

5. Expected Potential in Development of Anaerobic Biocatalysts for AD of Poultry Manure Contaminated with Mycotoxins

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Awuchi, C.G.; Ondari, E.N.; Ogbonna, C.U.; Upadhyay, A.K.; Baran, K.; Okpala, C.O.R.; Korzeniowska, M.; Guiné, R.P.F. Mycotoxins affecting animals, foods, humans, and plants: Types, occurrence, toxicities, action mechanisms, prevention, and detoxification strategies—A revisit. Foods 2021, 10, 1279. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Guan, E.; Bian, K. Structure elucidation and toxicity analysis of the degradation products of deoxynivalenol by gaseous ozone. Toxins 2019, 11, 474. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luo, Y.; Liu, X.; Li, J. Updating techniques on controlling mycotoxins—A review. Food Control. 2018, 89, 123–132. [Google Scholar] [CrossRef]

- Shanakhat, H.; Sorrentino, A.; Raiola, A.; Romano, A.; Masi, P.; Cavella, S. Current methods for mycotoxins analysis and innovative strategies for their reduction in cereals: An overview. J. Sci. Food Agric. 2018, 98, 4003–4013. [Google Scholar] [CrossRef]

- Efremenko, E.; Maslova, O.; Stepanov, N.; Ismailov, A. Using cholinesterases and immobilized luminescent photobacteria for the express-analysis of mycotoxins and estimating the efficiency of their enzymatic hydrolysis. Toxins 2021, 13, 34. [Google Scholar] [CrossRef]

- Senko, O.; Stepanov, N.; Maslova, O.; Akhundov, R.; Ismailov, A.; Efremenko, E. Immobilized luminescent bacteria for the detection of mycotoxins under discrete and flow-through conditions. Biosensors 2019, 9, 63. [Google Scholar] [CrossRef] [Green Version]

- Hojnik, N.; Modic, M.; Tavčar-Kalcher, G.; Babič, J.; Walsh, J.L.; Cvelbar, U. Mycotoxin decontamination efficacy of atmospheric pressure air plasma. Toxins 2019, 11, 219. [Google Scholar] [CrossRef] [Green Version]

- Abbasi Pirouz, A.; Selamat, J.; Zafar Iqbal, S.; Iskandar Putra Samsudin, N. Efficient and simultaneous chitosan-mediated removal of 11 mycotoxins from palm kernel cake. Toxins 2020, 12, 115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Agriopoulou, S.; Stamatelopoulou, E.; Varzakas, T. Advances in occurrence, importance, and mycotoxin control strategies: Prevention and detoxification in foods. Foods 2020, 9, 137. [Google Scholar] [CrossRef]

- Lyagin, I.; Maslova, O.; Stepanov, N.; Efremenko, E. Degradation of mycotoxins in mixtures by combined proteinous nanobiocatalysts: In silico, in vitro and in vivo. Int. J. Biol. Macromol. 2022, 218, 866–877. [Google Scholar] [CrossRef]

- Manikandan, M.; Chun, S.; Kazibwe, Z.; Gopal, J.; Singh, U.B.; Oh, J.-W. Phenomenal bombardment of antibiotic in poultry: Contemplating the environmental repercussions. Int. J. Environ. Res. Public Health 2020, 17, 5053. [Google Scholar] [CrossRef] [PubMed]

- Chaump, K.; Preisser, M.; Shanmugam, S.R.; Prasad, R.; Adhikari, S.; Higgins, B.T. Leaching and anaerobic digestion of poultry litter for biogas production and nutrient transformation. Waste Manage. 2019, 84, 413–422. [Google Scholar] [CrossRef] [PubMed]

- Congilosi, J.L.; Aga, D.S. Review on the fate of antimicrobials, antimicrobial resistance genes, and other micropollutants in manure during enhanced anaerobic digestion and composting. J. Hazard. Mater. 2021, 405, 123634. [Google Scholar] [CrossRef] [PubMed]

- Maslova, O.; Senko, O.; Stepanov, N.; Gladchenko, M.; Gaydamaka, S.; Akopyan, A.; Eseva, E.; Anisimov, A.; Efremenko, E. Sulfur containing mixed wastes in anaerobic processing by new immobilized synthetic consortia. Bioresour. Technol. 2022, 362, 127794. [Google Scholar] [CrossRef] [PubMed]

- Mortola, N.; Romaniuk, R.; Cosentino, V.; Maximiliano, E.I.Z.A.; Carfagno, P.; Rizzo, P.; Bres, P.; Riera, N.; Roba, M.; Butti, M.; et al. Potential use of a poultry manure digestate as a biofertiliser: Evaluation of soil properties and Lactuca sativa growth. Pedosphere 2019, 29, 60–69. [Google Scholar] [CrossRef]

- Samoraj, M.; Mironiuk, M.; Izydorczyk, G.; Witek-Krowiak, A.; Szopa, D.; Moustakas, K.; Chojnacka, K. The challenges and perspectives for anaerobic digestion of animal waste and fertilizer application of the digestate. Chemosphere 2022, 295, 133799. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Liu, C.; Zhang, Z.; Li, H.; Song, T.; Liang, T.; Li, B.; Li, L.; Feng, S.; Su, Q.; et al. Research and Technological Advances Regarding the Study of the Spread of Antimicrobial Resistance Genes and Antimicrobial-Resistant bacteria related to animal husbandry. Int. J. Environ. Res. Public Health 2019, 16, 4896. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tacconi, C.; Cucina, M.; Pezzolla, D.; Zadra, C.; Gigliotti, G. Effect of the mycotoxin aflatoxin B1 on a semi-continuous anaerobic digestion process. Waste Manage. 2018, 78, 467–473. [Google Scholar] [CrossRef]

- Reyes, Y.A.; Barrera, E.L.; Cheng, K.K. A review on the prospective use of chicken manure leachate in high-rate anaerobic reactors. J. Environ. Chem. Eng. 2021, 9, 104695. [Google Scholar] [CrossRef]

- Kacprzak, M.; Malińska, K.; Grosser, A.; Sobik-Szołtysek, J.; Wystalska, K.; Dróżdż, D.; Jasińska, A.; Meers, E. Cycles of carbon, nitrogen and phosphorus in poultry manure management technologies—Environmental aspects. Crit. Rev. Env. Sci. Technol. 2023, 53, 914–938. [Google Scholar] [CrossRef]

- Chernysh, Y.; Balintova, M.; Shtepa, V.; Chubur, V.; Junakova, N. Effect of electrolysis on activated sludge during the hydrolysis and acidogenesis stages in the anaerobic digestion of poultry manure. Sustainability 2022, 14, 6826. [Google Scholar] [CrossRef]

- Khalifa, E.; Mohesien, M.T.; Mossa, M.I.; Piekutowska, M.; Alsuhaibani, A.M.; Abdel-Wahab, B.A.; Sotohy, S.A.; Ghosh, S.; Helmy, Y.A.; Hussein, M.; et al. Diversity of toxigenic fungi in livestock and poultry feedstuffs. Int. J. Environ. Res. Public Health 2022, 19, 7250. [Google Scholar] [CrossRef] [PubMed]

- Van Huis, A. Manure and flies: Biodegradation and/or bioconversion? J. Insects Food Feed 2019, 5, 55–58. [Google Scholar] [CrossRef]

- Ferrara, M.; Haidukowski, M.; D’Imperio, M.; Parente, A.; De Angelis, E.; Monaci, L.; Logrieco, A.F.; Mulè, G. New insight into microbial degradation of mycotoxins during anaerobic digestion. Waste Manage. 2021, 119, 215–225. [Google Scholar] [CrossRef] [PubMed]

- Juraschek, L.M.; Kappenberg, A.; Amelung, W. Mycotoxins in soil and environment. Sci. Total Environ. 2021, 814, 152425. [Google Scholar] [CrossRef]

- Varga, E.; Ladányi, M.; Fodor, P.; Soros, C. Comparison of QuEChERS and “dilute and shoot” extraction methods for multi-mycotoxin analysis of samples from button mushroom (Agaricus bisporus) cultivation. Int. J. Environ. Res. Public Health Part B. 2021, 56, 99–108. [Google Scholar] [CrossRef]

- Kiliszczyk, A.; Kierasińska, K.; Wróbel, B. Occurrence and concentration of mycotoxins in grass silage from selected farms. J. Res. Appl. Agric. Eng. 2019, 64, 20–24. [Google Scholar]

- Drakopoulos, D.; Sulyok, M.; Jenny, E.; Kägi, A.; Bänziger, I.; Logrieco, A.F.; Krska, R.; Vogelgsang, S. Fusarium head blight and associated mycotoxins in grains and straw of barley: Influence of agricultural practices. Agronomy 2021, 11, 801. [Google Scholar] [CrossRef]

- Abou Dib, A.; Assaf, J.C.; El Khoury, A.; El Khatib, S.; Koubaa, M.; Louka, N. Single, subsequent, or simultaneous treatments to mitigate mycotoxins in solid foods and feeds: A critical review. Foods 2022, 11, 3304. [Google Scholar] [CrossRef]

- Nunes, V.M.; Moosavi, M.; Khaneghah, A.M.; Oliveira, C.A. Innovative modifications in food processing to reduce the levels of mycotoxins. Curr. Opin. Food Sci. 2021, 38, 155–161. [Google Scholar] [CrossRef]

- Lyagin, I.; Efremenko, E. Enzymes for detoxification of various mycotoxins: Origins and mechanisms of catalytic action. Molecules 2019, 24, 2362. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khairullina, A.; Micic, N.; Jørgensen, H.J.L.; Bjarnholt, N.; Bülow, L.; Collinge, D.B.; Jensen, B. Biocontrol effect of Clonostachys rosea on Fusarium graminearum infection and mycotoxin detoxification in oat (Avena sativa). Plants 2023, 12, 500. [Google Scholar] [CrossRef] [PubMed]

- Śliżewska, K.; Cukrowska, B.; Smulikowska, S.; Cielecka-Kuszyk, J. The effect of probiotic supplementation on performance and the histopathological changes in liver and kidneys in broiler chickens fed diets with aflatoxin B1. Toxins 2019, 11, 112. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ogórek, R.; Borzęcka, J.; Kłosińska, K.; Piecuch, A.; Przymencki, M.; Litwiniak, K.; Suchodolski, J. A culture-based study of micromycetes isolated from the urban nests of grey heron (Ardea cinerea) in SW Poland. Animals 2022, 12, 676. [Google Scholar] [CrossRef]

- Hort, V.; Nicolas, M.; Travel, A.; Jondreville, C.; Maleix, C.; Baéza, E.; Engel, E.; Guérin, T. Carry-over assessment of fumonisins and zearalenone to poultry tissues after exposure of chickens to a contaminated diet-A study implementing stable-isotope dilution assay and UHPLC-MS/MS. Food Control 2020, 107, 106789. [Google Scholar] [CrossRef]

- Salako, A.O.; Atteh, J.O.; Akande, T.O.; Opowoye, I.O.; Aderibigbe, T.A. Mitigating potential of three phytogenic feed additives in broilers exposed to dietary aflatoxin. Iran J. Appl. Anim. Sci. 2022, 12, 571–581. [Google Scholar]

- Naseem, M.N.; Saleemi, M.K.; Khan, A.; Khatoon, A.; Gul, S.T.; Rizvi, F.; Ahmad, I.; Fayyaz, A. Pathological effects of concurrent administration of aflatoxin B1 and fowl adenovirus-4 in broiler chicks. Microb. Ppathog. 2018, 121, 147–154. [Google Scholar] [CrossRef]

- Ochieng, P.E.; Scippo, M.-L.; Kemboi, D.C.; Croubels, S.; Okoth, S.; Kang’ethe, E.K.; Doupovec, B.; Gathumbi, J.K.; Lindahl, J.F.; Antonissen, G. Mycotoxins in poultry feed and feed ingredients from Sub-Saharan Africa and their impact on the production of broiler and layer chickens: A review. Toxins 2021, 13, 633. [Google Scholar] [CrossRef]

- Jajić, I.; Dudaš, T.; Krstović, S.; Krska, R.; Sulyok, M.; Bagi, F.; Savić, Z.; Guljaš, D.; Stankov, A. Emerging Fusarium mycotoxins fusaproliferin, beauvericin, enniatins, and moniliformin in Serbian maize. Toxins 2019, 11, 357. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.; Applegate, T. Zearalenone (ZEN) in livestock and poultry: Dose, toxicokinetics, toxicity and estrogenicity. Toxins 2020, 12, 377. [Google Scholar] [CrossRef]

- Hubbard, L.E.; Givens, C.E.; Griffin, D.W.; Iwanowicz, L.R.; Meyer, M.T.; Kolpin, D.W. Poultry litter as potential source of pathogens and other contaminants in groundwater and surface water proximal to large-scale confined poultry feeding operations. Sci. Total Environ. 2020, 735, 139459. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.; Wang, T.; Wang, P.; Yin, Q.; Liu, C.; Zhu, Q.; Lu, F.; Gao, T. Compound probiotics alleviating aflatoxin B1 and zearalenone toxic effects on broiler production performance and gut microbiota. Ecotoxicol. Environ. Saf. 2020, 194, 110420. [Google Scholar] [CrossRef] [PubMed]

- Jurišić, N.; Schwartz-Zimmermann, H.E.; Kunz-Vekiru, E.; Moll, W.D.; Schweiger, W.; Fowler, J.; Berthiller, F. Determination of aflatoxin biomarkers in excreta and ileal content of chickens. Poult. Sci. 2019, 98, 5551–5561. [Google Scholar] [CrossRef] [PubMed]

- Riahi, I.; Marquis, V.; Pérez-Vendrell, A.M.; Brufau, J.; Esteve-Garcia, E.; Ramos, A.J. Effects of deoxynivalenol-contaminated diets on metabolic and immunological parameters in broiler chickens. Animals 2021, 11, 147. [Google Scholar] [CrossRef]

- Visconti, A.; Mirocha, C.J. Identification of various T-2 toxin metabolites in chicken excreta and tissues. Appl. Environ. Microbiol. 1985, 49, 1246–1250. [Google Scholar] [CrossRef] [Green Version]

- Rice, L.G.; Ross, P.F. Methods for detection and quantitation of Fumonisins in corn, cereal products and animal excreta. J. Food Prot. 1994, 57, 536–540. [Google Scholar] [CrossRef]

- Kochish, I.; Kapitonova, E.; Nikonov, I.; Shlykov, S.; Omarov, R. Results of using tripoli on zoohygienic indicators in the raising a parent herd of meat breed chickens. ITJEMAST 2020, 11, 11A. [Google Scholar] [CrossRef]

- Costello, B.; Chen, D.; Han, B.; Zhang, W.; Butterly, C.R. Lignite, dewatered lignite and modified subbituminous coal reduce nitrogen loss from broiler litter. Waste Manage. 2021, 136, 113–121. [Google Scholar] [CrossRef]

- Gałęcki, R.; Dąbrowski, M.; Bakuła, T.; Obremski, K.; Nowak, A.; Gutarowska, B. The influence of the mineral-microbial preparation on ammonia concentration and productivity in laying hens houses. Atmosphere 2019, 10, 751. [Google Scholar] [CrossRef] [Green Version]

- Peng, S.; Li, H.; Song, D.; Lin, X.; Wang, Y. Influence of zeolite and superphosphate as additives on antibiotic resistance genes and bacterial communities during factory-scale chicken manure composting. Bioresour. Technol. 2018, 263, 393–401. [Google Scholar] [CrossRef]

- Zhou, G.; Qiu, X.; Wu, X.; Lu, S. Horizontal gene transfer is a key determinant of antibiotic resistance genes profiles during chicken manure composting with the addition of biochar and zeolite. J. Hazard. Mater. 2021, 408, 124883. [Google Scholar] [CrossRef] [PubMed]

- Qiu, X.; Feng, M.; Zhou, G.; Wang, H. Effects of mineral additives on antibiotic resistance genes and related mechanisms during chicken manure composting. Bioresour. Technol. 2022, 346, 126631. [Google Scholar] [CrossRef] [PubMed]

- Prasai, T.P.; Walsh, K.B.; Midmore, D.J.; Jones, B.E.; Bhattarai, S.P. Manure from biochar, bentonite and zeolite feed supplemented poultry: Moisture retention and granulation properties. J. Environ. Manage. 2018, 216, 82–88. [Google Scholar] [CrossRef] [PubMed]

- Arak, H.; Karimi Torshizi, M.A.; Hedayati, M.; Rahimi, S. The first in vivo application of synthetic polymers based on methacrylic acid as an aflatoxin sorbent in an animal model. Mycotoxin Res. 2019, 35, 293–307. [Google Scholar] [CrossRef]

- Ghazalah, A.A.; Abd-Elsamee, M.O.; Moustafa, K.E.M.; Khattab, M.A.; Rehan, A.E.A. Effect of nanosilica and bentonite as mycotoxins adsorbent agent in broiler chickens’ diet on growth performance and hepatic histopathology. Animals 2021, 11, 2129. [Google Scholar] [CrossRef]

- Fouché, T.; Claassens, S.; Maboeta, M. Aflatoxins in the soil ecosystem: An overview of its occurrence, fate, effects and future perspectives. Mycotoxin Res. 2020, 36, 303–309. [Google Scholar] [CrossRef]

- Orlando, M.Q.; Borja, V.M. Pretreatment of animal manure biomass to improve biogas production: A review. Energies 2020, 13, 3573. [Google Scholar] [CrossRef]

- Rehman, K.U.; Rehman, R.U.; Somroo, A.A.; Cai, M.; Zheng, L.; Xiao, X.; Rehman, A.U.; Abdul Rehman, A.; Tomberlin, J.K.; Yu, Z.; et al. Enhanced bioconversion of dairy and chicken manure by the interaction of exogenous bacteria and black soldier fly larvae. J. Environ. Manage. 2019, 237, 75–83. [Google Scholar] [CrossRef]

- Khan, M.U.; Ahring, B.K. Anaerobic digestion of digested manure fibers: Influence of thermal and alkaline thermal pretreatment on the biogas yield. Bioenerg. Res. 2021, 14, 891–900. [Google Scholar] [CrossRef]

- Vigueras-Carmona, S.E.; Ramírez, F.; Noyola, A.; Monroy, O. Effect of thermal alkaline pretreatment on the anaerobic digestion of wasted activated sludge. Water Sci. Technol. 2011, 64, 953–959. [Google Scholar] [CrossRef]

- Chuenchart, W.; Logan, M.; Leelayouthayotin, C.; Visvanathan, C. Enhancement of food waste thermophilic anaerobic digestion through synergistic effect with chicken manure. Biomass Bioenergy 2020, 136, 105541. [Google Scholar] [CrossRef]

- Liu, M.; Zhao, L.; Gong, G.; Zhang, L.; Shi, L.; Dai, J.; Han, Y.; Wu, Y.; Khalil, M.M.; Sun, L. Invited review: Remediation strategies for mycotoxin control in feed. JASB 2022, 13, 1–16. [Google Scholar] [CrossRef]

- Schaarschmidt, S.; Fauhl-Hassek, C. Mycotoxins during the processes of nixtamalization and tortilla production. Toxins 2019, 11, 227. [Google Scholar] [CrossRef] [Green Version]

- Lyu, F.; Gao, F.; Zhou, X.; Zhang, J.; Ding, Y. Using acid and alkaline electrolyzed water to reduce deoxynivalenol and mycological contaminations in wheat grains. Food Control. 2018, 88, 98–104. [Google Scholar] [CrossRef]

- Ma, C.G.; Wang, Y.D.; Huang, W.F.; Liu, J.; Chen, X.W. Molecular reaction mechanism for elimination of zearalenone during simulated alkali neutralization process of corn oil. Food Chem. 2020, 307, 125546. [Google Scholar] [CrossRef] [PubMed]

- Schrenk, D.; Bignami, M.; Bodin, L.; Chipman, J.K.; del Mazo, J.; Grasl-Kraupp, B.; Hoogenboom, L.; Leblanc, J.; Nebbia, C.S.; Nielsen, E.; et al. Assessment of an application on a detoxification process of groundnut press cake for aflatoxins by ammoniation. EFSA J. 2021, 19, e07035. [Google Scholar] [CrossRef]

- Maureen, N.; Kaaya, A.N.; Kauffman, J.; Narrod, C.; Atukwase, A. Enhancing Nutritional Benefits and Reducing Mycotoxin Contamination of Maize through Nixtamalization. J. Biol. Sci. 2020, 20, 153–162. [Google Scholar] [CrossRef]

- Moreno-Pedraza, A.; Valdés-Santiago, L.; Hernández-Valadez, L.J.; Rodríguez-Sixtos Higuera, A.; Winkler, R.; Guzmán-de Peña, D.L. Reduction of aflatoxin B1 during tortilla production and identification of degradation by-products by direct-injection electrospray mass spectrometry (DIESI-MS). Salud Publica Mex. 2015, 57, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Borràs-Vallverdú, B.; Ramos, A.J.; Marín, S.; Sanchis, V.; Rodríguez-Bencomo, J.J. Deoxynivalenol degradation in wheat kernels by exposition to ammonia vapours: A tentative strategy for detoxification. Food Control. 2020, 118, 107444. [Google Scholar] [CrossRef]

- De Girolamo, A.; Lattanzio, V.M.T.; Schena, R.; Visconti, A.; Pascale, M. Effect of alkaline cooking of maize on the content of fumonisins B1 and B2 and their hydrolysed forms. Food Chem. 2016, 192, 1083–1089. [Google Scholar] [CrossRef]

- Zheng, X.; Wei, W.; Zhou, W.; Li, H.; Rao, S.; Gao, L.; Yang, Z. Prevention and detoxification of patulin in apple and its products: A review. Food Res. Int. 2021, 140, 110034. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Peng, X.; Li, X.; Meng, X.; Liu, B. Biodegradation of mycotoxin patulin in apple juice by calcium carbonate immobilized porcine pancreatic lipase. Food Control 2018, 88, 69–74. [Google Scholar] [CrossRef]

- Trivedi, A.B.; Doi, E.; Kitabatake, N. Detoxification of ochratoxin A on heating under acidic and alkaline conditions. Biosci. Biotechnol. Biochem. 1992, 56, 741–745. [Google Scholar] [CrossRef] [PubMed]

- Karlovsky, P.; Suman, M.; Berthiller, F.; De Meester, J.; Eisenbrand, G.; Perrin, I.; Oswald, I.P.; Speijers, G.; Chiodini, A.; Recker, T.; et al. Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Res. 2016, 32, 179–205. [Google Scholar] [CrossRef] [Green Version]

- Bazin, I.; Faucet-Marquis, V.; Monje, M.C.; El Khoury, M.; Marty, J.L.; Pfohl-Leszkowicz, A. Impact of pH on the stability and the cross-reactivity of ochratoxin A and citrinin. Toxins 2013, 5, 2324–2340. [Google Scholar] [CrossRef] [PubMed]

- Özcan, S.; Gökmen, V.U.R.A.L. Alkali-based pre-treatment may prevent ochratoxin A in grapes. World Mycotoxin J. 2016, 9, 517–523. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.; Li, Y.; Dai, C.; Ding, Q.; Hong, C.; He, Y.; He, R.; Ma, H. Effect of alkali concentration on digestibility and absorption characteristics of rice residue protein isolates and lysinoalanine. Food Chem. 2019, 289, 609–615. [Google Scholar] [CrossRef]

- Bogale, T.T. Microbial protein production from agro-industrial wastes as food and feed. AJLS 2020, 8, 121–126. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, D.; Su, Y.; Xie, B. Occurrence, influence and removal strategies of mycotoxins, antibiotics and microplastics in anaerobic digestion treating food waste and co-digestive biosolids: A critical review. Bioresour. Technol. 2021, 330, 124987. [Google Scholar] [CrossRef]

- Özmıhçı, S.; Hacıoğlu, İ.; Altındağ, E.E. Impacts of mycotoxin on biohydrogen production from waste dry fruits. J. Mater. Cycles Waste Manag. 2022, 24, 1736–1746. [Google Scholar] [CrossRef]

- De Gelder, L.; Audenaert, K.; Willems, B.; Schelfhout, K.; De Saeger, S.; De Boevre, M. Processing of mycotoxin contaminated waste streams through anaerobic digestion. Waste Manage. 2018, 71, 122–128. [Google Scholar] [CrossRef] [PubMed]

- Giorni, P.; Pietri, A.; Bertuzzi, T.; Soldano, M.; Piccinini, S.; Rossi, L.; Battilani, P. Fate of mycotoxins and related fungi in the anaerobic digestion process. Bioresour. Technol. 2018, 265, 554–557. [Google Scholar] [CrossRef] [PubMed]

- Salati, S.; D’Imporzano, G.; Panseri, S.; Pasquale, E.; Adani, F. Degradation of aflatoxin B1 during anaerobic digestion and its effect on process stability. Int. Biodeter. Biodegr. 2014, 94, 19–23. [Google Scholar] [CrossRef]

- Cucina, M.; Tacconi, C.; Gigliotti, G.; Zadra, C. Integration of anaerobic digestion and composting allows safety recovery of energy and nutrients from AFB1 contaminated corn. J. Environ. Chem. Eng. 2022, 10, 108356. [Google Scholar] [CrossRef]

- Tacconi, C.; Cucina, M.; Zadra, C.; Gigliotti, G.; Pezzolla, D. Plant nutrients recovery from aflatoxin B1 contaminated corn through co-composting. J. Environ. Chem. Eng. 2019, 7, 103046. [Google Scholar] [CrossRef]

- Varfolomeev, S.D.; Efremenko, E.N.; Krylova, L.P. Biofuels. Rus. Chem. Rev. 2010, 79, 491–509. [Google Scholar] [CrossRef]

- Bian, L.; Zheng, M.; Chang, T.; Zhou, J.; Zhang, C. Degradation of aflatoxin B1 by recombinant laccase extracellular produced from Escherichia coli. Ecotoxicol. Environ. Saf. 2022, 244, e114062. [Google Scholar] [CrossRef]

- Loi, M.; Renaud, J.B.; Rosini, E.; Pollegioni, L.; Vignali, E.; Haidukowski, M.; Sumarah, M.W.; Logrieco, A.F.; Mulè, G. Enzymatic transformation of aflatoxin B1 by Rh_DypB peroxidase and characterization of the reaction products. Chemosphere 2020, 250, e126296. [Google Scholar] [CrossRef]

- He, W.-J.; Shi, M.-M.; Yang, P.; Huang, T.; Zhao, Y.; Wu, A.-B.; Dong, W.-B.; Li, H.-P.; Zhang, J.-B.; Liao, Y.-C. A quinone-dependent dehydrogenase and two NADPH-dependent aldo/keto reductases detoxify deoxynivalenol in wheat via epimerization in a Devosia strain. Food Chem. 2020, 321, e126703. [Google Scholar] [CrossRef]

- Abraham, N.; Schroeter, K.L.; Zhu, Y.; Chan, J.; Evans, N.; Kimber, M.S.; Carere, J.; Zhou, T.; Seah, S.Y.K. Structure–function characterization of an aldo-keto reductase involved in detoxification of the mycotoxin, deoxynivalenol. Sci. Rep. 2022, 12, e14737. [Google Scholar] [CrossRef]

- Telmer, P.G.; Kelman, M.J.; Renaud, J.B.; Sumarah, M.W.; Garnham, C.P. Application of Aspergillus niger fumonisin amine oxidase (AnFAO) to detoxify fumonisin-contaminated maize. Toxins 2022, 14, 544. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qin, X.; Hao, Z.; Luo, H.; Yao, B.; Su, X. Degradation of four major mycotoxins by eight manganese peroxidases in presence of a dicarboxylic acid. Toxins 2019, 11, 566. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, L.; Sun, X.; Wan, X.; Li, H.; Yan, F.; Han, R.; Li, H.; Li, Z.; Tian, Y.; Liu, X.; et al. Identification of a Bacillus amyloliquefaciens H6 Thioesterase involved in zearalenone detoxification by transcriptomic analysis. J. Agric. Food Chem. 2020, 68, 10071–10080. [Google Scholar] [CrossRef] [PubMed]

- Efremenko, E.; Stepanov, N.; Senko, O.; Maslova, O.; Volikov, A.; Zhirkova, A.; Perminova, I. Strategies for variable regulation of methanogenesis efficiency and velocity. Appl. Microbiol. Biotechnol. 2022, 106, 6833–6845. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Zhou, S.; Yu, S.; Zhao, Y.; Wu, Y.; Wu, A. LC-MS/MS analysis of fumonisin B1, B2, B3, and their hydrolyzed metabolites in broiler chicken feed and excreta. Toxins 2022, 14, 131. [Google Scholar] [CrossRef] [PubMed]

- Bindari, Y.R.; Moore, R.J.; Van, T.T.H.; Hilliar, M.; Wu, S.-B.; Walkden-Brown, S.W.; Gerber, P.F. Microbial communities of poultry house dust, excreta and litter are partially representative of microbiota of chicken caecum and ileum. PLoS ONE 2021, 16, e0255633. [Google Scholar] [CrossRef]

- Qi, H.; Wang, J.; Zhang, L.; Chen, L.; Zhao, Y.; Wei, Z. Activation effect of catechol on biotic and abiotic factors of humus formation during chicken manure composting. Waste Manage. 2022, 149, 146–155. [Google Scholar] [CrossRef]

- Stepanov, N.; Senko, O.; Perminova, I.; Efremenko, E. A New Approach to assess the effect of various humic compounds on the metabolic activity of cells participating in methanogenesis. Sustainability 2019, 11, 3158. [Google Scholar] [CrossRef] [Green Version]

- Van Rensburg, C.J.; Van Rensburg, C.E.J.; Van Ryssen, J.B.J.; Casey, N.H.; Rottinghaus, G.E. In vitro and in vivo assessment of humic acid as an aflatoxin binder in broiler chickens. Poult. Sci. 2006, 85, 1576–1583. [Google Scholar] [CrossRef]

- Čolović, R.; Puvača, N.; Cheli, F.; Avantaggiato, G.; Greco, D.; Đuragić, O.; Kos, J.; Pinotti, L. Decontamination of mycotoxin-contaminated feedstuffs and compound feed. Toxins 2019, 11, 617. [Google Scholar] [CrossRef] [Green Version]

- Feng, H.; Liang, Y.N.; Hu, X. Natural organic matter (NOM), an underexplored resource for environmental conservation and remediation. Mater. Today Sustain. 2022, 19, 100159. [Google Scholar] [CrossRef]

- Lyagin, I.; Stepanov, N.; Maslova, O.; Senko, O.; Aslanli, A.; Efremenko, E. Not a mistake but a feature: Promiscuous activity of enzymes meeting mycotoxins. Catalysts 2022, 12, 1095. [Google Scholar] [CrossRef]

- Li, P.; Su, R.; Yin, R.; Lai, D.; Wang, M.; Liu, Y.; Zhou, L. Detoxification of mycotoxins through biotransformation. Toxins 2020, 12, 121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ben Taheur, F.; Kouidhi, B.; Al Qurashi, Y.M.A.; Ben Salah-Abbès, J.; Chaieb, K. Review: Biotechnology of mycotoxins detoxification using microorganisms and enzymes. Toxicon 2019, 160, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Nahle, S.; El Khoury, A.; Savvaidis, I.; Chokr, A.; Louka, N.; Atoui, A. Detoxification approaches of mycotoxins: By microorganisms, biofilms and enzymes. Food Contam. 2022, 9, 1–14. [Google Scholar] [CrossRef]

- Li, B.; Duan, J.; Ren, J.; Francis, F.; Li, G. Isolation and characterization of two new deoxynivalenol-degrading strains, Bacillus sp. HN117 and Bacillus sp. N22. Toxins 2022, 14, 781. [Google Scholar] [CrossRef]

- Aslanli, A.; Domnin, M.; Stepanov, N.; Efremenko, E. “Universal” antimicrobial combination of bacitracin and His6-OPH with lactonase activity, acting against various bacterial and yeast cells. Int. J. Mol. Sci. 2022, 23, 9400. [Google Scholar] [CrossRef] [PubMed]

- Jia, S.; Ren, C.; Yang, P.; Qi, D. Effects of intestinal microorganisms on metabolism and toxicity mitigation of zearalenone in broilers. Animals 2022, 12, 1962. [Google Scholar] [CrossRef] [PubMed]

- Yu., H.; Zhou, T.; Gong, J.; Young, C.; Su, X.; Li, X.Z.; Zhu, H.; Tsao, R.; Yang, R. Isolation of deoxynivalenol-transforming bacteria from the chicken intestines using the approach of PCR-DGGE guided microbial selection. BMC Microbiol. 2010, 10, 182. [Google Scholar] [CrossRef] [Green Version]

- Efremenko, E.; Stepanov, N.; Maslova, O.; Senko, O.; Aslanli, A.; Lyagin, I. “Unity and struggle of opposites” as a basis for the functioning of synthetic bacterial immobilized consortium that continuously degrades organophosphorus pesticides. Microorganisms 2022, 10, 1394. [Google Scholar] [CrossRef]

- Maslova, O.; Senko, O.; Stepanov, N.; Gladchenko, M.; Gaydamaka, S.; Akopyan, A.; Polikarpova, P.; Lysenko, S.; Anisimov, A.; Efremenko, E. Formation and use of anaerobic consortia for the biotransformation of sulfur-containing extracts from pre-oxidized crude oil and oil fractions. Bioresour. Technol. 2021, 319, 124248. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Zhang, Y.; Gong, A.; Liu, N.; Chen, S.; Zhao, X.; Li, X.; Chen, L.; Zhou, C.; Wang, J. Biodegradation of mycotoxin fumonisin B1 by a novel bacterial consortium SAAS79. Appl. Microbiol. Biotechnol. 2019, 103, 7129–7140. [Google Scholar] [CrossRef] [PubMed]

- Deepa, N.; Chennappa, G.; Deepthi, B.N.V.K.; Naik, M.K.; Ramesha, K.P.; Amaresh, Y.S.; Satish, S.; Sreenivasa, M.Y. Antifungal potential of Azotobacter species and its metabolites against Fusarium verticillioides and biodegradation of fumonisin. J. Appl. Microbiol. 2022, 133, 2430–2444. [Google Scholar] [CrossRef] [PubMed]

- Qu, L.; Wang, L.; Ji, H.; Fang, Y.; Lei, P.; Zhang, X.; Jin, L.; Sun, D.; Dong, H. Toxic mechanism and biological detoxification of fumonisins. Toxins 2022, 14, 182. [Google Scholar] [CrossRef] [PubMed]

- Efremenko, E.N. (Ed.) Immobilized Cells: Biocatalysts and Processes; RIOR: Moscow, Russia, 2018; p. 524. ISBN 978-5-369-02004-3. [Google Scholar] [CrossRef]

- Senko, O.; Gladchenko, M.; Maslova, O.; Efremenko, E. Long-term storage and use of artificially immobilized anaerobic sludge as a powerful biocatalyst for conversion of various wastes including those containing xenobiotics to biogas. Catalysts 2019, 9, 326. [Google Scholar] [CrossRef] [Green Version]

- Cavaleiro, A.J.; Salvador, A.F.; Martins, G.; Oliveira, C.C.; Liu, Y.; Martins, V.R.; Castro, A.R.; Soares, O.S.G.P.; Pereira, M.F.R.; Pereira, L.; et al. Multi-walled carbon nanotubes enhance methanogenesis from diverse organic compounds in anaerobic sludge and river sediments. Appl. Sci. 2020, 10, 8184. [Google Scholar] [CrossRef]

| Object of Analysis (Country) [Reference] | Mycotoxin | Concentration (μg/kg) | |

|---|---|---|---|

| in Feed | in Excreta | ||

| Leachates of broiler chickens (France) [35] | ZEN | 27 ± 9 400 ± 120 | 12 ± 6 270 ± 90 |

| Manure of broiler chickens (China) [42] | ZEN + AFB1 | 58.6 ZEN + 14.5 AFB1 | 38.8 ZEN + 2.3 AFB1 |

| Droppings of broiler chickens (Poland) [33] | AFB1 | 1000 5000 | 290 2740 |

| Chicken excreta (Austria) [43] | AFs (AFB1, FB2, AFG1, AFG2, AFM1) | 18 515 | 4 30 |

| Leachates of broiler chickens (Spain) [44] | DON | 5000 15,000 | 22.0 24.1 |

| Chicken excreta (USA) [45] | T-2 | 3500 | 682 |

| Fecal samples of rats and sheep (USA) [46] | FB1 | rats 1000 sheep 50 | 530 6 |

| Sorbent (Country) [Reference] | Main Purpose of the Sorbent Application | Procedure of Sorbent Addition | Dose of Sorbent Introduction |

|---|---|---|---|

| Brown coal (Australia) [48] | Ammonia sorption | Introduction of sorbent into the litter for broilers | 20% (w/w) of litter |

| Deodoric® (a mixture of zeolite and perlite with six bacterial strains) (Poland) [49] | Reducing humidity, preventing the appearance of ammonia in the air | Introduction of sorbent into the litter for chickens | 170 g/m2 of litter (once a week) |

| Natural Zeolite (China) [50] | Influence of the microbial society to reduce abundance of antibiotic resistance genes | Additives to compost with chicken manure | 50 g/kg of wet chicken manure |

| Zeolite and bio coal (China) [51] | Decrease in variety of antibiotic resistance genes | Additives to compost with chicken leachates | Sorbent ZL (5% w/w zeolite), BC (5% w/w bio coal), or ZB (per 5% w/w of both zeolite and bio coal) in compost mass |

| Diatomite and bentonite (Iran) [54] | Influence on the microbial community in order to reduce spreading of antibiotic resistance genes | Additives to compost with poultry manure | 5% (w/w) sorbent mixture (diatomite and bentonite) in composted mass |

| Biochar, bentonite, and zeolite (Australia) [53] | Influence on chemical and water-retaining properties of excrements and granulation characteristics of decomposed excrements | Additives to chicken feed | 2% (w/w) biochar, 2% (w/w) zeolite, or 4% (w/w) biochar in the broiler feed |

| Synthetic polymer based on methacrylic acid (TMU95) with macroporous structure (Iran) [54] | Binding of AFs | Additives to feed for ducklings | 5 g TMU95/kg diet when 200 µg of AFB1 is in 1 kg of feed |

| Mycotoxin (Country) [Reference] | Object of Contamination | Process under Alkaline Conditions | Degradation |

|---|---|---|---|

| ZEN (China) [65] | Crude corn oil 1178.7 μg ZEN/kg | 2 M NaOH, degumming | 100% ZEN |

| AFs (AFB1, AFB2, AFG1 and AFG2) (European Union) [66] | Groundnut press cake (286 μg AFs/kg) | 50 kg of the press cake, 0.6 L water, and 2 kg 25% w/w NH4OH were mixed for up to 3 h at a pressure of 10 kPa | 95% AFG1 93% AFG2 85% AFB1 83% AFB2 |

| AFs and FUM (Uganda) [67] | Maize | Soaking maize grains overnight in 1% slaked lime (Ca(OH)2) solution | Up to 90% AFs Up to 80% FUM |

| AFB1 (Mexico) [68] | Maize (125 µg AFB1/kg) | White maize (1 kg) was boiled for 45 min at 90 °C in 3 L of water with 10 g of lime (minimum content of Ca(OH)2 = 90%) and left to soak overnight (18 h at 24 °C, pH 10.2) | 100% AFB1 |

| DON (Spain) [69] | Wheat grains (2 mg DON/kg) | 4.8% NH4OH, 90 °C, 2 h | Up to 75% DON |

| DON (China) [64] | Wheat grains (1 mg DON /kg) | Treatment of grains with alkaline electrolyzed water (AlkEW) (pH 9.5) at room temperature for 45 min | 61.6% DON |

| FUMs: FB1 and FB2 (Germany) [63], (Italy) [70] | Maize (6480–8930 µg FUMs/kg) | 0.33% or 1.67% lime solution, 90 °C, 15–60 min | Up to 68% FB1 and FB2 |

| FB1 (USA) [46] | Model waste solution (10 mg/L) | 1 L of 1 N KOH, 60 °C, 1 h | 100% FB1 |

| PAT (China) [71] | Model laboratory wastes (0.1–10 mg/L PAT) | 1 mL of 5% ammonia was added to 100 mL of aqueous wastes with PAT and the resulting mixture was autoclaved at 120 °C for 15 min | 99.9% PAT |

| PAT (China) [72] | Apple juice (1 mg/L PAT) | Treatment of juice by porcine pancreatic lipase immobilized on CaCO3 at 40 °C for 18 h | 77.1% PAT |

| OTA (Japan) [73] | Model waste solution (100 mg/L) | 0.1 M NaOH, 100 °C for 10 min | 100% OTA |

| Substrate for AD (Country) [Reference] | Mycotoxins and Conditions of AD | Degradation |

|---|---|---|

| Milled grain corn (75%) (Belgium) [81] | AFB1, ergot alkaloids (40 µg/L) OTA (50 mg/L) FB1, DON (400 mg/L) ZEN, T-2 (100 µg/L) 37 °C, 25 days | 100% AFB1 100% ZEN 98% T-2 99% OTA 93% DON 70% FB1 67% ergot alkaloids |

| Cattle manure (45%), maize silage (45%), and maize flour (10%) (Italy) [82] | AFB1 (2–470 µg/kg) FUMs (115–3700 µg/kg) 38 °C, 50 days, pH 7.6–7.7 | 12–95% AFB1 15% FUMs |

| Corn grain (Italy) [83] | AFB1 (0.54–110 µg/kg) 37 °C, 60 days | 69–87% AFB1 |

| Corn (2.5%) and anaerobic sludge (97.5%) (1st medium) Corn (2.5%), pig slurry (22.5%), and anaerobic sludge (75%) (2nd medium) (Italy) [84] | AFB1 (100 µg/kg) 37 °C, 28 days, pH 7.4–7.6 | 69.7% AFB1 and 42% AFB1 in the 1st and 2nd medium, respectively |

| Corn (2%), pig slurry (40%), wood chips (40%), and cereal straw (8%) (Italy) [85] | AFB1 (100 µg/kg) 30–40 °C, 60 days | 85.7% AFB1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Efremenko, E.; Senko, O.; Maslova, O.; Lyagin, I.; Aslanli, A.; Stepanov, N. Destruction of Mycotoxins in Poultry Waste under Anaerobic Conditions within Methanogenesis Catalyzed by Artificial Microbial Consortia. Toxins 2023, 15, 205. https://doi.org/10.3390/toxins15030205

Efremenko E, Senko O, Maslova O, Lyagin I, Aslanli A, Stepanov N. Destruction of Mycotoxins in Poultry Waste under Anaerobic Conditions within Methanogenesis Catalyzed by Artificial Microbial Consortia. Toxins. 2023; 15(3):205. https://doi.org/10.3390/toxins15030205

Chicago/Turabian StyleEfremenko, Elena, Olga Senko, Olga Maslova, Ilya Lyagin, Aysel Aslanli, and Nikolay Stepanov. 2023. "Destruction of Mycotoxins in Poultry Waste under Anaerobic Conditions within Methanogenesis Catalyzed by Artificial Microbial Consortia" Toxins 15, no. 3: 205. https://doi.org/10.3390/toxins15030205

APA StyleEfremenko, E., Senko, O., Maslova, O., Lyagin, I., Aslanli, A., & Stepanov, N. (2023). Destruction of Mycotoxins in Poultry Waste under Anaerobic Conditions within Methanogenesis Catalyzed by Artificial Microbial Consortia. Toxins, 15(3), 205. https://doi.org/10.3390/toxins15030205