Development of MEMS Multi-Mode Electrostatic Energy Harvester Based on the SOI Process

Abstract

:1. Introduction

2. Materials and Methods

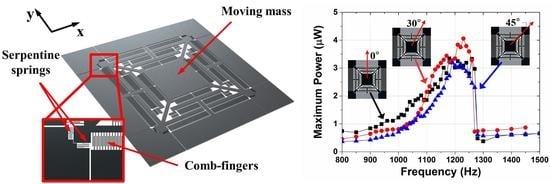

2.1. Design and Working Principle

2.2. Fabrication

3. Results and Discussion

3.1. Multi-Directional Energy Harvester

3.2. Multi-Frequency Energy Harvester

3.3. Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Paradiso, J.A.; Starner, T. Energy scavenging for mobile and wireless electronics. IEEE Pervasive Comput. 2005, 4, 18–27. [Google Scholar] [CrossRef]

- Beeby, S.P.; Tudor, M.J.; White, N. Energy harvesting vibration sources for microsystems applications. Meas. Sci. Technol. 2006, 17, R175. [Google Scholar] [CrossRef]

- Mateu, L.; Moll, F. Review of energy harvesting techniques and applications for microelectronics (Keynote Address). VLSI Circuits Syst. II Proc. SPIE 2005, 5837, 359–373. [Google Scholar]

- Liu, J.-Q.; Fang, H.-B.; Xu, Z.-Y.; Mao, X.-H.; Shen, X.-C.; Chen, D.; Liao, H.; Cai, B.-C. A MEMS-based piezoelectric power generator array for vibration energy harvesting. Microelectron. J. 2008, 39, 802–806. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.K.; Rabaey, J. A study of low level vibrations as a power source for wireless sensor nodes. Comput. Commun. 2003, 26, 1131–1144. [Google Scholar] [CrossRef]

- Sterken, T.; Fiorini, P.; Baert, K.; Puers, R.; Borghs, G. An electret-based electrostatic μ-generator. In Proceedings of the 12th International Conference on TRANSDUCERS, Solid-State Sensors, Actuators and Microsystems, Boston, MA, USA, 8–12 June 2003; pp. 1291–1294.

- Bartsch, U.; Gaspar, J.; Paul, O. A 2D electret-based resonant micro energy harvester. In Proceedings of the IEEE 22nd International Conference on Micro Electro Mechanical Systems, Sorrento, Italy, 25–29 January 2009; pp. 1043–1046.

- Roundy, S.; Wright, P.K.; Pister, K.S. Micro-electrostatic vibration-to-electricity converters. In Proceedings of the ASME 2002 International Mechanical Engineering Congress and Exposition, New Orleans, LO, USA, 17–22 November 2002; pp. 487–496.

- Shen, D.; Park, J.-H.; Ajitsaria, J.; Choe, S.-Y.; Wikle, H.C., III; Kim, D.-J. The design, fabrication and evaluation of a MEMS PZT cantilever with an integrated Si proof mass for vibration energy harvesting. J. Micromech. Microeng. 2008, 18, 055017. [Google Scholar] [CrossRef]

- Park, J.C.; Park, J.Y.; Lee, Y.-P. Modeling and characterization of piezoelectric-mode MEMS energy harvester. J. Microelectromech. Syst. 2010, 19, 1215–1222. [Google Scholar] [CrossRef]

- Sheu, G.-J.; Yang, S.-M.; Lee, T. Development of a low frequency electrostatic comb-drive energy harvester compatible to SoC design by CMOS process. Sens. Actuators A Phys. 2011, 167, 70–76. [Google Scholar] [CrossRef]

- Bartsch, U.; Gaspar, J.; Paul, O. Low-frequency two-dimensional resonators for vibrational micro energy harvesting. J. Micromech. Microeng. 2010, 20, 035016. [Google Scholar] [CrossRef]

- Yang, B.; Lee, C.; Kotlanka, R.K.; Xie, J.; Lim, S.P. A MEMS rotary comb mechanism for harvesting the kinetic energy of planar vibrations. J. Micromech. Microeng. 2010, 20, 065017. [Google Scholar] [CrossRef]

- Zhu, Y.; Moheimani, S.R.; Yuce, M.R. A 2-DOF MEMS ultrasonic energy harvester. IEEE Sens. J. 2011, 11, 155–161. [Google Scholar]

- Ferrari, M.; Ferrari, V.; Guizzetti, M.; Marioli, D.; Taroni, A. Piezoelectric multifrequency energy converter for power harvesting in autonomous microsystems. Sens. Actuators A Phys. 2008, 142, 329–335. [Google Scholar] [CrossRef]

- Roundy, S.; Leland, E.S.; Baker, J.; Carleton, E.; Reilly, E.; Lai, E.; Otis, B.; Rabaey, J.M.; Wright, P.K.; Sundararajan, V. Improving power output for vibration-based energy scavengers. IEEE Pervasive Comput. 2005, 4, 28–36. [Google Scholar] [CrossRef]

- Yang, B.; Lee, C.; Xiang, W.; Xie, J.; He, J.H.; Kotlanka, R.K.; Low, S.P.; Feng, H. Electromagnetic energy harvesting from vibrations of multiple frequencies. J. Micromech. Microeng. 2009, 19, 035001. [Google Scholar] [CrossRef]

- Chiu, Y.; Kuo, C.-T.; Chu, Y.-S. MEMS design and fabrication of an electrostatic vibration-to-electricity energy converter. Microsyst. Technol. 2007, 13, 1663–1669. [Google Scholar] [CrossRef]

- Despesse, G.; Chaillout, J.; Jager, T.; Cardot, F.; Hoogerwerf, A. In Innovative structure for mechanical energy scavenging. In Proceedings of the TRANSDUCERS 2007—2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 895–898.

- Barillaro, G.; Molfese, A.; Nannini, A.; Pieri, F. Analysis, simulation and relative performances of two kinds of serpentine springs. J. Micromech. Microeng. 2005, 15, 736. [Google Scholar] [CrossRef]

- Fukuta, Y.; Fujita, H.; Toshiyoshi, H. Vapor hydrofluoric acid sacrificial release technique for micro electro mechanical systems using labware. Jpn. J. Appl. Phys. 2003, 42, 3690. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.K.; Rabaey, J.M. Energy Scavenging for Wireless Sensor Networks; Springer: Norwell, MA, USA, 2003; p. 159. [Google Scholar]

- Zhao, Y.; Tay, F.E.H.; Zhou, G.; Chau, F.-S. A study of electrostatic spring softening for dual-axis micromirror. Optik 2006, 117, 367–372. [Google Scholar] [CrossRef]

- Wu, C.-C.; Zhong, Z. Capacitive spring softening in single-walled carbon nanotube nanoelectromechanical resonators. Nano Lett. 2011, 11, 1448–1451. [Google Scholar] [CrossRef] [PubMed]

- Ramlan, R.; Brenna, M.J.; Mace, B.R.; Kovacic, I. Potential benefits of a non-linear stiffness in an energy harvesting device. Nonlinear Dyn. 2010, 59, 545–558. [Google Scholar] [CrossRef]

- Cho, H.; Yu, M.-F.; Vakakis, A.F.; Bergman, L.A.; McFarland, D.M. Tunable, broadband nonlinear nanomechanical resonator. Nano Lett. 2010, 10, 1793–1798. [Google Scholar] [CrossRef] [PubMed]

- Jeong, B.; Cho, H.; Yu, M.-F.; Vakakis, A.; McFarland, D.M.; Bergman, L.A. Modeling and measurement of geometrically nonlinear damping in a microcantilever-nanotube system. ACS Nano 2013, 10, 8547–8553. [Google Scholar] [CrossRef] [PubMed]

- Arakawa, Y.; Suzuki, Y.; Kasagi, N. Micro seismic power generator using electret polymer film. In Proceedings of the 4th International Workshop on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (Power MEMS 2004), Kyoto, Japan, 28–30 November 2004; pp. 187–190.

- Despesse, G.; Chaillout, J.J.; Dekkaki, I.; Jager, T.; Léger, J.M.; Vassilev, A.; Basrour, S.; Charlot, B. High damping electrostatic system for vibration energy scavenging. In Proceedings of the Joint Conference on Smart Objects and Ambient Intelligence: Innovative Context-Aware Services: Usages and Technologies, Grenoble, France, 12–14 October 2005; pp. 283–286.

- Jia, Y.; Yan, J.; Soga, K.; Seshia, A.A. Multi-frequency operation of a MEMS vibration energy harvester by accessing five orders of parametric resonance. J. Phys. Conf. Ser. 2013, 476, 012126. [Google Scholar] [CrossRef]

- Tao, K.; Liu, S.W.; Miao, J.M.; Lye, S.W. A three-dimensional electrostatic/electret micro power generator for low acceleration and low frequency vibration energy harvesting. In Proceedings of the IEEE 27th International Conference on Micro Electro Mechanical Systems, San Francisco, CA, USA, 26–30 January 2014; pp. 366–369.

- Chiu, Y.; Tseng, V.F.G. A capacitive vibration-to-electricity energy converter with integrated mechanical switches. J. Micromech. Microeng. 2010, 20, 104004. [Google Scholar] [CrossRef]

- Basset, P.; Galayko, D.; Paracha, A.M.; Marty, F.; Dudka, A.; Bourouina, T. A batch-fabricated and electret-free silicon electrostatic vibration energy harvester. J. Micromech. Microeng. 2009, 19, 115025. [Google Scholar] [CrossRef]

| Comb Length | Gap | Initial Overlapping Length | Thickness | Total No. of Pairs | Effective No. of Pairs for a Single Axis |

|---|---|---|---|---|---|

| 450 µm | 11 µm | 400 µm | 50 µm | 888 | 444 |

| 250 µm | 11 µm | 200 µm | 50 µm | 96 | 48 |

| Type | N | w | lo | lp | Iz | kx.sn | ky.sn |

|---|---|---|---|---|---|---|---|

| Spring A | 3 | 5 µm | 325 µm | 10.5 µm | 5.21 × 10−22 m4 | 3.85 N/m | 10.1 N/m |

| Spring B | 3 | 6 µm | 325 µm | 9.5 µm | 9.0 × 10−22 m4 | 6.65 N/m | 21.3 N/m |

| Type | m | kx | ky | fx | fy |

|---|---|---|---|---|---|

| Multi-directional (Spring A only) | 1.45 × 10−6 kg | 55.66 N/m | 55.66 N/m | 986.0 Hz | 986.0 Hz |

| Multi-frequency (Spring A and B) | 1.45 × 10−6 kg | 66.85 N/m | 100.4 N/m | 1081 Hz | 1324 Hz |

| Ref. No. | Power (μW) | Frequency (Hz) | Input Acceleration (g) | Volume (cm3) | Power Density Per Acceleration (μW/cm3·g) | Capability to Harvest Random Vibration |

|---|---|---|---|---|---|---|

| Our work | 3.28 | 1272 | 6 | 0.0041 | 133.3 | O |

| Arakawa [28] | 6 | 10 | 0.4 | 0.8 | 18.75 | X |

| Despesse [29] | 70 | 50 | 0.8 | 0.0324 | 2700 | X |

| Sheu [11] | 0.0924 | 105 | 0.1 | 0.0045 | 205 | X |

| Yang [13] | 0.35 | 110 | 2.5 | 0.0394 | 3.55 | O |

| Jia [30] | 0.166 | 200 | 0.5 | 0.000278 | 1200 | O |

| Tao [31] | 0.0048 | 66 | 0.05 | 0.0588 | 1.64 | O |

| Chiu [32] | 1.2 | 1870 | 3.3 | 0.6 | 0.606 | X |

| Basset [33] | 0.061 | 250 | 0.25 | 0.06149 | 3.96 | X |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, B.; Kim, M.-O.; Lee, J.-I.; Eun, Y.; Choi, J.; Kim, J. Development of MEMS Multi-Mode Electrostatic Energy Harvester Based on the SOI Process. Micromachines 2017, 8, 51. https://doi.org/10.3390/mi8020051

Jeong B, Kim M-O, Lee J-I, Eun Y, Choi J, Kim J. Development of MEMS Multi-Mode Electrostatic Energy Harvester Based on the SOI Process. Micromachines. 2017; 8(2):51. https://doi.org/10.3390/mi8020051

Chicago/Turabian StyleJeong, Bongwon, Min-Ook Kim, Jae-Ik Lee, Youngkee Eun, Jungwook Choi, and Jongbaeg Kim. 2017. "Development of MEMS Multi-Mode Electrostatic Energy Harvester Based on the SOI Process" Micromachines 8, no. 2: 51. https://doi.org/10.3390/mi8020051

APA StyleJeong, B., Kim, M. -O., Lee, J. -I., Eun, Y., Choi, J., & Kim, J. (2017). Development of MEMS Multi-Mode Electrostatic Energy Harvester Based on the SOI Process. Micromachines, 8(2), 51. https://doi.org/10.3390/mi8020051