Heterogeneous Catalysis with the Participation of Ionic Liquids

Abstract

:1. Introduction

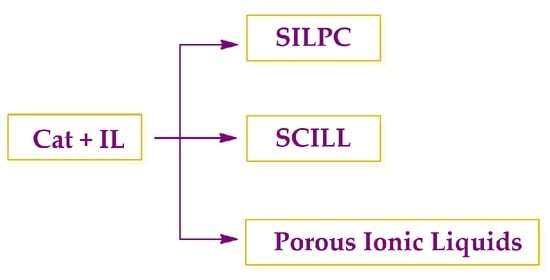

2. Ionic Liquids in Catalysis

2.1. Supported Ionic Liquid Phase Catalysts (SILPCs)

2.2. Solid Catalyst with Ionic Liquid Layer (SCILL)

2.3. Porous Ionic Liquids

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- The New Material. The Twenty Most Potential New Materials in the Future. 2014. Available online: https://new.qq.com/omn/20191105/20191105A098C000.html (accessed on 21 October 2020).

- ISI Web of Science Search. Available online: https://clarivate.com/webofsciencegroup/solutions/web-of-science/ (accessed on 21 October 2020).

- Wasserscheid, P.; Welton, T. Ionic Liquids in Synthesis; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Adams, D.J.; Dyson, P.J.; Tavener, S.J. Chemistry in Alternative Reaction Media; Wiley: Chichester, UK, 2004. [Google Scholar]

- Vekariya, R.L. A review of ionic liquids: Applications towards catalytic transfromations. J. Mol. Liq. 2017, 227, 44–60. [Google Scholar] [CrossRef]

- Javed, F.; Ullah, F.; Zakaria, M.R.; Akil, H.M. An approach to classification and hi-tech applications of room-temperature ionic liquids (RTILs): A review. J. Mol. Liq. 2018, 271, 403–420. [Google Scholar] [CrossRef]

- Singh, S.K.; Savoy, A.W. Ionic liquids synthesis and applications: An overview. J. Mol. Liq. 2020, 297, 112038. [Google Scholar] [CrossRef]

- Walden, P. Über die Molekulargrösse und elektrische Leitfähigkeit einiger geschmolzener Salze. Bull. Acad. Imp. Sci. 1914, 8, 405–422. [Google Scholar]

- Hurley, F.H.; Weir, T.P. Electrodeposition of metals from fused quaternary ammonium salts. J. Electrochem. Soc. 1951, 98, 203–206. [Google Scholar] [CrossRef] [Green Version]

- Wilkes, J.S.; Zaworotko, M.J. Air and water stable 1-ethyl-3-methylimidazolium based ionic liquids. J. Chem. Soc. Chem. Commun. 1992, 965–967. [Google Scholar] [CrossRef]

- Wierzbicki, A.; Davis, J.H., Jr. Envisioning the second generation of ionic liquid technology: Design and synthesis of Task-specific Ionic Liquids (TSILs). In Proceedings of the Symposium on Advances in Solvent Selection and Substitution for Extraction, Atlanta, Georgia, 5–9 March 2000; AIChE: New York, NY, USA, 2000. [Google Scholar]

- Welton, T. Ionic Liquids: A brief history. Biophys. Rev. 2018, 10, 691–706. [Google Scholar] [CrossRef] [Green Version]

- Earle, M.J.; Esperanca, J.M.S.S.; Gilea, M.A.; Lopes, J.N.C.; Rebelo, L.P.N.; Magee, J.W.; Seddon, K.R.; Widegren, J.A. The distillation and volatility of ionic liquids. Nature 2006, 439, 831–834. [Google Scholar] [CrossRef]

- Clark, J.H.; Tavener, S.J. Alternative solvents: Shades of green. Org. Proc. Res. Dev. 2007, 11, 149–155. [Google Scholar] [CrossRef]

- Jessop, P.G. Searching for green solvents. Green Chem. 2011, 13, 1391–1398. [Google Scholar] [CrossRef]

- Cevasco, G.; Chiappe, C. Are ionic liquids a proper solution to current environmental challenges? Green Chem. 2014, 16, 2375–2385. [Google Scholar] [CrossRef]

- Frade, R.F.; Alonso, C.A. Impact of Ionic Liquids in environment and humans: An overview. Hum. Exp. Toxicol. 2010, 29, 1038–1054. [Google Scholar] [CrossRef] [PubMed]

- Kunz, W.; Hackl, K. The hype with ionic liquids as solvents. Chem. Phys. Lett. 2016, 661, 6–12. [Google Scholar] [CrossRef]

- Anastas, P. (Ed.) Green Solvents; Wiley-VCH: Weinheim, Germany, 2010. [Google Scholar]

- Ameta, G.; Pathak, A.K.; Ameta, C.; Punjabi, P.B. Sonochemical synthesis and imidazolium based ionic liquids: A green pathway. J. Mol. Liq. 2015, 211, 934–937. [Google Scholar] [CrossRef]

- Naeimi, H.; Nazifi, Z.S. A facile one-pot ultrasound assisted synthesis of 1,8-dioxooctahydroxanthene derivatives catalysed by Bronsted acidic ionic liquid (BAIL) under green conditions. J. Ind. Eng. Chem. 2014, 20, 1043–1049. [Google Scholar] [CrossRef]

- Martinez-Palou, R. Microwave-assisted synthesis using ionic liquids. Mol. Divers. 2010, 14, 3–25. [Google Scholar] [CrossRef]

- Itoh, T.; Koo, Y.-M. (Eds.) Application of Ionic Liquids in Biotechnology; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Ozokwelu, D.; Zhang, S.; Okafor, O.C.; Cheng, W.; Litombe, N. Novel Catalytic and Separation Processes Based on Ionic Liquids; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Saha, B.; Fan, M.; Wang, J. (Eds.) Sustainable Catalytic Process; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Dupont, J.; Itoh, T.; Lozano, P.; Malhotra, S.V. (Eds.) Environmentally Friendly Syntheses Using Ionic Liquids; CRC Press: New York, NY, USA, 2015. [Google Scholar]

- Lozano, P. Sustainable Catalysis in Ionic Liquids; CRC Press: New York, NY, USA, 2019. [Google Scholar]

- Alvarez, M.S.; Zhang, Y. Sketching neoteric solvents for boosting drugs bioavailability. J. Controll. Release 2019, 311, 225–232. [Google Scholar] [CrossRef]

- Villa, R.; Alvarez, E.; Porcar, R.; Garcia-Verdugo, E.; Luis, S.V.; Lozano, P. Ionic Liquids as an enabling tool to integrate reaction and separation processes. Green Chem. 2019, 21, 6527–6544. [Google Scholar] [CrossRef]

- Gaida, B.; Brzęczek-Szafran, A. Insights into the Properties and Potential Applications of Renewable Carbohydrate-Based Ionic Liquids: A Review. Molecules 2020, 25, 3285. [Google Scholar] [CrossRef]

- Gomes, J.M.; Silva, S.S.; Reis, R.L. Biocompatible ionic liquids: Fundamental behaviors and applications. Chem. Soc. Rev. 2019, 48, 4317–4335. [Google Scholar] [CrossRef]

- Welton, T. Solvents and sustainable chemistry. Proc. R. Soc. A Mat. 2015, 471, 50502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olivier-Bourbigou, H.; Magna, L.; Morvan, D. Ionic Liquids and Catalysis: Recent progress from knowledge to applications. Appl. Catal. A 2010, 373, 1–56. [Google Scholar] [CrossRef]

- Hajipour, A.R.; Rafiee, F. Recent progress in ionic liquids and their applications in organic synthesis. Org. Prep. Proced. Int. 2015, 47, 249–308. [Google Scholar] [CrossRef]

- Sahin, S. Tailor-designed deep eutectic liquids as a sustainable extraction media: An alternative to ionic liquids. J. Pharm. Biomed. Anal. 2019, 174, 324–329. [Google Scholar] [CrossRef]

- Kalhor, P.; Ghandi, K. Deep Eutectic Solvents for Pretreatment, Extraction and Catalysis of Biomas and Food Waste. Molecules 2019, 24, 4012. [Google Scholar] [CrossRef] [Green Version]

- Unli, A.E.; Arikaya, A.; Takac, S. Use of deep eutectic solvents as catalyst: A mini-review. Green Process Synth. 2019, 8, 355–372. [Google Scholar] [CrossRef]

- Eyckens, D.J.; Henderson, L.C. A review of Solvate Ionic liquids: Physical Parameters and Synthetic Applications. Front. Chem. 2019, 7, 263. [Google Scholar] [CrossRef]

- Salar-García, M.J.; Ortiz-Martínez, V.M.; Hernández-Fernández, F.J.; de los Ríos, A.P.; Quesada-Medina, J. Ionic liquid technology to recover volatile organic compounds (VOCs). J. Hazard. Mater. 2017, 321, 484–499. [Google Scholar] [CrossRef]

- Watanabe, M.; Thomas, M.L.; Zhang, S.G.; Ueno, K.; Yasuda, T.; Dokko, K. Application of ionic liquids to energy storage and conversion materials and devices. Chem. Rev. 2017, 117, 7190–7239. [Google Scholar] [CrossRef] [Green Version]

- Balducci, A. Ionic liquids in Lithium-ion batteries. Top. Curr. Chem. 2017, 375, 20. [Google Scholar] [CrossRef]

- Itoh, T. Ionic liquids as tool to improve enzymatic organic synthesis. Chem. Rev. 2017, 117, 10567–10607. [Google Scholar] [CrossRef]

- Ventura, S.P.M.; Silva, F.A.E.; Quental, M.V.; Monda, D.; Freire, M.G.; Coutinho, J.A.P. Ionic-liquid-mediated extraction and separation processes for bioactive compounds: Past, present, and future trends. Chem. Rev. 2017, 117, 6984–7052. [Google Scholar] [CrossRef] [PubMed]

- Kristfikova, D.; Modrocka, V.; Meciarova, M.; Sebsta, R. Green Asymetric Organocatalysis. ChemSusChem 2020, 13, 2828–2858. [Google Scholar] [CrossRef] [PubMed]

- Egorova, K.S.; Gordeev, E.G.; Ananikov, V.P. Biological activity of ionic liquids and their application in pharmaceutics and medicine. Chem. Rev. 2017, 117, 7132–7189. [Google Scholar] [CrossRef] [PubMed]

- Nancarrow, P.; Mohammed, H. Ionic liquids in space technology—Current and future trends. Chembioeng Rev. 2017, 4, 106–119. [Google Scholar] [CrossRef]

- Dyson, P.J.; Geldbach, T.J. Metal Catalysed Reactions in Ionic Liquids; Springer: Dordrecht, The Netherlands, 2005. [Google Scholar]

- Dupont, J.; Kollar, L. Ionic Liquids (ILs) in Organometallic Catalysis; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar]

- Hardacre, C.; Parvulescu, V. Catalysis in Ionic Liquids. In Catalysts Synthesis to Applications; RS: Cambridge, UK, 2014. [Google Scholar]

- Domingez de Maria, P. (Ed.) Ionic Liquids in Biotransformations and Organocatalysis. Solvent and Beyond; John Wiley&Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Stevens, J.C.; Shi, J. Biocatalysis in ionic liquids for lignin valorization: Opportunities and recent developments. Biotech. Adv. 2019, 37, 107418. [Google Scholar] [CrossRef]

- Quiroz, N.R.; Norton, A.M.; Nguyen, H.; Vasileiadou, E.; Vlachos, D.G. Homogeneous metal salt solutions for biomass upgrading and other select organic reactions. ACS Catal. 2019, 9, 9923–9952. [Google Scholar] [CrossRef]

- Hejazifar, M.; Lanaridi, O.; Bica-Schroder, K. Ionic liquid based microemulsions: A review. J. Mol. Liq. 2020, 303, 112264. [Google Scholar] [CrossRef]

- Qiao, Y.; Ma, W.; Theyssen, N.; Chen, C.; Hou, Z. Temperature-responsive ionic liquids: Fundamental behaviors and catalytic applications. Chem. Rev. 2017, 117, 6881–6928. [Google Scholar] [CrossRef]

- Fehrmann, R.; Riisager, A.; Haumann, M. Supported Ionic Liquids. Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2014. [Google Scholar]

- Gu, Y.; Li, G. Ionic liquids-based catalysis with solids. State of the art. Adv. Synth. Catal. 2009, 351, 817–847. [Google Scholar] [CrossRef]

- Kaur, P.; Chopra, H. Recent Advances of Supported Ionic Liquids. Curr. Org. Chem. 2019, 23, 2881–2915. [Google Scholar] [CrossRef]

- Feher, C.; Papp, M.; Urban, B.; Skoda-Foldes, R. Catalytic Applications of Supported Ionic Liquid Phases. In Advances in Asymmetric Autocatalysis and Related Topics; Academic Press: London, UK, 2017. [Google Scholar]

- Kuhmann, E.; Haumann, M.; Jess, A.; Seeberger, A.; Wasserscheid, P. Ionic liquids in refinery desulfurization: Comparison between biphasic and supported ionic liquid phase suspension processes. ChemSusChem 2009, 2, 969–977. [Google Scholar] [CrossRef] [PubMed]

- Marinkovic, J.M.; Riisager, A.; Franke, R.; Wasserscheid, P.; Haumann, M. Fifteen years of Supported Ionic Liquid Phase—Catalysed hydroformylation: Material and process developments. Ind. Eng. Chem. Res. 2019, 58, 2409–2420. [Google Scholar] [CrossRef]

- Mehnert, C.P.; Cook, R.A.; Dispenziere, N.C.; Afeworki, M. Supported Ionic Liquid Catalysis—A New Concept for Homogeneous Hydroformylation Catalysis. J. Am. Chem. Soc. 2002, 124, 12932–12933. [Google Scholar] [CrossRef]

- Hintermair, U.; Gong, Z.; Serbanovic, A.; Muldoon, M.J.; Santini, C.C.; Cole-Hamilton, D.J. Continuous flow hydroformylation using Supported Ionic Liquid Phase catalysts with carbon dioxide as a carrier. Dlton Trans. 2010, 39, 8501–8510. [Google Scholar] [CrossRef]

- Illner, M.; Mulller, D.; Esche, E.; Pogrzeba, T.; Schmidt, M.; Schomacker, R.; Wony, G.; Repke, J.U. Hydroformylation in microemulsions: Proof of concept in a miniplant. Ind. Eng. Chem. Res. 2016, 55, 8616–8626. [Google Scholar] [CrossRef]

- Romanovsky, B.V.; Tarhanova, I.G. Supported ionic liquids in catalysis. Russ. Chem. Rev. 2017, 86, 444–458. [Google Scholar] [CrossRef]

- Li, M.; Zhang, M.; Wei, A.; Zhus, W.; Xun, S.; Li, Y.; Li, H.; Li, H. Facile synthesis of amphiphilic polyoxometalate-based ionic liquid supported silica induced efficient performance in oxidative desulfurization. J. Mol. Catal. A Chem. 2015, 406, 23–30. [Google Scholar] [CrossRef]

- Navalon, S.; Alvaro, M.; Garcia, H. Heterogeneous Fenton catalysts based on clays, silicas and zeolites. Appl. Catal. B. 2010, 99, 1–26. [Google Scholar] [CrossRef]

- Kim, D.W.; Chi, D.Y. Polymer-Supported Ionic Liquids: Imidazolium Salts as Catalysts for Nucleophilic Substitution Reactions Including Fluorinations. Angew. Chem. Int. Ed. 2004, 43, 483–485. [Google Scholar] [CrossRef]

- Kim, D.W.; Hong, D.J.; Jang, K.S.; Chi, D.Y. Structural Modification of Polymer-Supported Ionic Liquids as Catalysts for Nucleophilic Substitution Reactions Including Fluorination. Adv. Synth. Catal. 2006, 348, 1719–1727. [Google Scholar] [CrossRef]

- Termirbulatova, M.G.; Moskovskaya, I.F.; Romanovsky, B.V.; Yatsenko, A.V. MCM-41 mesoporous molecular sieves modified with a base or a palladium-containing ionic liquid as catalysts for certain organic synthesis reactions. Petrol. Chem. 2009, 49, 7–10. [Google Scholar] [CrossRef]

- Trilla, M.; Borja, G.; Pleixats, R.; Man, M.W.C.; Bied, C.; Moreau, J.J.E. Recoverable Palladium Catalysts for Suzuki–Miyaura Cross- Coupling Reactions Based on Organic-Inorganic Hybrid Silica Materials Containing Imidazolium and Dihydroimidazolium Salts. Adv. Synth. Catal. 2008, 350, 2566–2574. [Google Scholar] [CrossRef]

- Isaeva, V.I.; Prokudina, N.I.; Kozlova, L.M.; Kustov, L.M.; Glukhov, L.M.; Tarasov, D.L.; Beletskaya, I.P. Hydroamination of phenylacetylene in the presence of gold-containing catalytic systems supported on carriers modified by ionic liquids. Russ. Chem. Bull. Int. Ed. 2015, 64, 2811–2815. [Google Scholar] [CrossRef]

- Sigeev, A.S.; Beletskaya, I.P.; Petrovskii, P.V.; Peregudov, A.S. Cu(I)/Cu(II)/TMEDA, new effective available catalyst of sandmeyer reaction. Russ. J. Org. Chem. 2012, 48, 1055–1058. [Google Scholar] [CrossRef]

- Zavalinskaya, I.S.; Malikov, I.V.; Yas’yan, Y.P. Conversion of Straight-Run Gasoline Fraction on Combined Zeolite-Containing Catalysts. Chem. Technol. Fuels Oils 2015, 51, 154–159. [Google Scholar] [CrossRef]

- More, S.; Jadhav, S.; Salunkhe, R.; Kumbhar, A. Palladium supported ionic liquid phase catalyst (Pd@SIPL-PS) for room temperature Suzuki-Miyaura cross-coupling reaction. Mol. Catal. 2017, 442, 126–132. [Google Scholar] [CrossRef]

- Li, Y.; Dong, Y.; Li, W.; Han, Y.; Zhang, J. Impovement of imidazolium-based ionic liquids on the activity of ruthenium catalyst for acetylene hydrochlorination. Mol. Catal. 2017, 443, 220–227. [Google Scholar] [CrossRef]

- Sonawane, B.D.; Rashinkar, G.S.; Sonawane, K.D.; Dhanavade, M.J.; Sonawane, V.D.; Patil, S.V. Aerosil-Supported Ionic Liquid Phase (ASILP) mediated synthesis of 2-substituted benzimidazole derivatives as AChE inhibitors. Chem. Sel. 2018, 3, 5544–5551. [Google Scholar] [CrossRef]

- Brunig, J.; Csendes, Z.; Weber, S.; Gorgas, N.; Bittner, R.W.; Limbeck, A.; Bica, K.; Hoffmann, H.; Kirchner, K. Chemoselective Supported Ionic Liquid Phase (SILP) aldehyde hydrogenation catalysed by an Fe(II) PNP Pincer Complex. ACS Catal. 2018, 8, 1048–1051. [Google Scholar] [CrossRef]

- Castro-Amoedo, R.; Csendes, Z.; Brunig, J.; Sauer, M.; Foelske-Schmitz, A.; Yigit, N.; Rupprechter, G.; Gupta, T.; Martins, A.M.; Bica, K.; et al. Carbon-based SILP catalysis for the selective hydrogenation of aldehydes using a well-defined Fe (II) PNP complex. Catal. Sci. Technol. 2018, 8, 4812–4820. [Google Scholar] [CrossRef] [Green Version]

- Gajare, S.; Audumbar, P.; Kale, D.; Bansode, P.; Patil, P.; Rashinkar, G. Graphene oxide-supported ionic Liquid Phase catalysed synthesis of 3,4-dihydro-2H-naphtho[2,3-e][1,3]oxazine-5,10-diones. Chem. Lett. 2019, 150, 243–255. [Google Scholar]

- Urban, B.; Skoda-Foldes, R. Development of palladium catalysts immobilized on supported phosphonium ionic liquid phases. Phosphorus Sulfur. 2019, 194, 302–306. [Google Scholar] [CrossRef]

- Lee, C.; Sanding, B.; Buchmeiser, M.R.; Haumann, M. Supported Ionic Liquid Phase (SILP) facilitated gas-phase enzyme catalysis- CALB catalysed trensestrification of vinyl propionate. Catal. Sci. Technol. 2018, 8, 2460–2466. [Google Scholar] [CrossRef]

- Wolf, P.; Logemann, M.; Schorner, M.; Keller, L.; Haaumann, M.; Wessling, M. Multi-walled carbo nanotube-based composite materials as catalyst support for water-gas shift and hydroformylation reactions. RSC Adv. 2019, 9, 27732–27742. [Google Scholar] [CrossRef] [Green Version]

- Wolf, P.; Aubermann, M.; Wolf, M.; Bauer, T.; Blaumeiser, D.; Stepic, R.; Wick, C.R.; Smith, D.M.; Smith, A.S.; Wasserscheid, P.; et al. Improving the performance of supported ionic liquid phase (SILP) catalysts for the ultra-low-temperature water-gas shift reaction using metal salt additives. Green Chem. 2019, 21, 5008–5018. [Google Scholar] [CrossRef]

- Bryzhin, A.A.; Gantman, M.G.; Buryak, A.K.; Tarkhanova, I.G. Brönsted acidic SILP-based catalysts with H3PMo12O40 i H3PW12O40 in the oxidative desulfurization of fuels. Appl. Catal. B Env. 2019, 257, 117938–117945. [Google Scholar] [CrossRef]

- El Sayed, S.; Bordet, A.; Weidenthaler, C.; Hetaba, W.; Luska, K.L.; Leitner, W. Selective hydrogenation of benzofurans using ruthenium nanoparticles in Lewis acid-modifies Ruthenium-Supported Ionic Liquid Phase. ACS Catal. 2020, 10, 2124–2130. [Google Scholar] [CrossRef] [Green Version]

- Kukawka, R.; Pawlowska-Zygarowicz, A.; Dzialkowska, J.; Pietrowski, M.; Maciejewski, H.; Bica, K.; Smiglak, M. Highly effective Supported Ionic Liquid-Phase (SILP) catalysts: Characterization and application to the hydrosilylation reaction. Sustain. Chem. Eng. 2019, 7, 4699–4706. [Google Scholar] [CrossRef]

- Steinruck, H.P.; Wasserscheid, P. Ionic liquids in catalysis. Catal. Lett. 2015, 145, 380–397. [Google Scholar] [CrossRef]

- Kernchen, U.; Etzold, B.; Korth, W.; Jess, A. Solid Catalyst with Ionic Liquid Layer (SCILL)- a new concept to improve the selectivity investigated for the example of hydrogenation of cyclooctadiene. Chem. Eng. Technol. 2007, 79, 807–819. [Google Scholar]

- Werner, S.; Szesni, N.; Kaiser, M.; Haumann, M.; Wasserscheid, P. A scalable preparation method for SILP and SCILL ionic liquid thin-film materials. Chem. Eng. Technol. 2012, 11, 1962–1967. [Google Scholar] [CrossRef]

- Miller, S.F.; Friedrich, H.B.; Holzapfel, C.W. The effects of SCILL catalyst modification on the competitive hydrogenation of 1-octyne and 1,7-octadiene versus 1-octene. ChemCatChem 2012, 4, 1337–1344. [Google Scholar] [CrossRef]

- Antonels, N.C.; Meijboom, R. Preparation of well-defined dendrimer encapsulated ruthenium nanoparticles and their application as catalyst and enhancement of activity when utilised as SCILL catalysts in the hydrogenation of citral. Catal. Commun. 2014, 57, 148–152. [Google Scholar] [CrossRef]

- Antonels, N.C.; Williams, M.B.; Mejboom, R.; Haumann, M. Well-defined dendrimer encapsulated ruthenium SCILL catalysts for partial hydrogenation of toluene in liquid-phase. J. Mol. Catal. A Chem. 2016, 421, 156–160. [Google Scholar] [CrossRef]

- Jalal, A.; Uzun, A. An exceptional selectivity for partial hydrogenation on a supported nickel catalyst coated with [BMIM][BF4]. J. Catal. 2017, 350, 86–96. [Google Scholar] [CrossRef]

- Lijewski, M.; Hogg, J.M.; Swadzba-Kwasny, M.; Wasserscheid, P.; Haumann, M. Coating of PD/C catalysts with Lewis-acidic ionic liquids and liquid coordination complexes—SCILL induced activity enhancement in arene hydrogenation. RSC Adv. 2017, 7, 27558–27563. [Google Scholar] [CrossRef] [Green Version]

- Bart, T.; Korth, W.; Jess, A. Selectivity-enhancing effect of a SCILL catalyst in butadiene hydrogenation. Chem. Eng. Technol. 2017, 40, 395–404. [Google Scholar] [CrossRef]

- Hu, S.; Wang, L.; Chen, X.; Wei, X.; Tong, Z.; Yin, L. The conversion of α-pinene to cis-pinane using a nickel catalyst supported on a discarded fluid catalytic cracking catalyst with an ionic liquid layer. RSC Adv. 2019, 9, 5978–5986. [Google Scholar] [CrossRef] [Green Version]

- Bauer, T.; Hager, V.; Williams, M.B.; Laurin, M.; Dopper, T.; Gorling, A.; Szesni, N.; Wassercheid, P.; Haumann, M.; Libuda, J. Palladium-mediated ethylation of the imidazolium cation monitored in-operando on a SCILL-type catalyst. ChemCatChem 2017, 9, 109–113. [Google Scholar] [CrossRef]

- Perdikaki, A.V.; Vangeli, O.C.; Karanikolos, G.N.; Stefanopoulos, K.L.; Beltsios, K.G.; Alexandridis, P.; Kanellopoulus, N.K.; Romanos, G.E. Ionic liquid-modified porous materials for gas separation and heterogenous catalysis. J. Phys. Chem. C 2012, 31, 16398–16411. [Google Scholar] [CrossRef]

- Podolean, I.; Pavel, O.D.; Manyar, H.G.; Taylor, S.F.R.; Ralphs, K.; Goodrich, P.; Parvulescu, V.I.; Hardacre, C. SCILLs as selective catalysts for oxidation of aromatic alcohols. Catal. Today 2019, 333, 140–146. [Google Scholar] [CrossRef] [Green Version]

- Pavel, O.D.; Podolean, I.; Parvulescu, V.I.; Taylor, S.F.R.; Manyar, H.; Ralphs, K.; Goodrich, P.; Hardacre, C. Impact of SCILL catalysts for the S-S coupling of thiols to disulfides. Faraday Discuss. 2018, 206, 535–547. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mayer, C.; Hager, V.; Schwieger, W.; Wasserscheid, P. Enhanced activity and selectivity in n-octane isomerization using a bifunctional SCILL catalyst. J. Catal. 2012, 292, 157–165. [Google Scholar] [CrossRef]

- Li, T.; Zhang, W.; Chen, W.; Miras, H.N.; Song, Y.F. Layered double hydroxide anchored ionic liquids as amphiphilic heterogeneous catalysts for the Knoevenagel condensation reaction. Dalton Trans. 2018, 47, 3059–3067. [Google Scholar] [CrossRef] [Green Version]

- O’Reilly, N.; Giri, N.; James, S.L. Porous liquids. Chem. Eur. J. 2007, 13, 3020–3025. [Google Scholar] [CrossRef]

- Zhang, S.; Dokko, K.; Watanabe, M. Porous ionic liquids: Synthesis and application. Chem. Sci. 2015, 6, 3684–3691. [Google Scholar] [CrossRef] [Green Version]

- Wilke, A.; Yuan, J.; Antonietti, M.; Weber, J. Enhanced Carbon Dioxide Adsorption by a Mesoporous Poly(ionic liquid). ACS Macro Lett. 2012, 1, 1028–1031. [Google Scholar] [CrossRef]

- Huang, J.; Tao, C.; An, Q.; Zhang, W.; Wu, Y.; Li, X.; Shen, D.; Li, G. Visual indication of enviromental humidity by using poly(ionic liquid) photonic crystals. Chem. Commun. 2010, 46, 4103–4105. [Google Scholar] [CrossRef]

- Eftekhari, A. Polymerized Ionic Liquids. R. Soc. Chem. 2018, 2, 23–82. [Google Scholar]

- Jang, J.; Bae, J. Fabrication of mesoporous polymer using soft template method. Chem. Commun. 2005, 1200–1202. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Wang, L.; Sun, Q.; Zhu, L.; Meng, X.; Xiao, F.S. Transesterification Catalysed by Ionic Liquids on Superhydrophobic Mesoporous Polymers: Heterogeneous Catalysts That Are Faster than Homogeneous Catalysts. J. Am. Chem. Soc. 2012, 134, 16948–16950. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Dunlop, J.W.C.; Qiu, X.; Huang, F.; Zhang, Z.; Heyda, J.; Dziubiella, J.; Antonielli, M.; Yuan, J. An instant multi-responsive porous polymer actuator driven by solvent molecule sorption. Nat. Commun. 2014, 5, 4293–4300. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Q.; Heyda, J.; Dziubiella, J.; Tauber, K.; Dunlop, J.W.C.; Yuan, J. Sensing solvents with ultrasensitive porous poly(ionic liquid) actuators. Adv. Mater. 2015, 27, 2913–2917. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, Y.; Hu, T.; Chen, X.; Xu, K.; Zhang, J.; Huang, J. Pd nanoparticles on a porous ionic copolymer: A highly active and recyclable catalyst for Suzuki-Miyaura reaction under air in water. Chem. Commun. 2011, 47, 3592–3594. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Leng, Y.; Wang, J. Heteropolyanion-paired cross-linked ionic copolymer: An efficient heterogeneous catalyst for hydroxylation of benzene with hydrogen peroxide. Chem. Eng. J. 2012, 204–206, 72–78. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, P.; Antonielli, M.; Yuan, J. Poly(ionic liquid) complex with spontaneous micro-mesoporosity: Template-free synthesis and application as catalyst support. J. Am. Chem. Soc. 2012, 134, 11852–11855. [Google Scholar] [CrossRef]

- Gao, C.; Chen, G.; Wang, X.; Li, J.; Zhou, Y.; Wang, J. Hierarchical meso-macroporous poly(ionic liquid) monolith derived from single soft template. Chem. Commun. 2015, 51, 4969–4972. [Google Scholar] [CrossRef]

- Wang, B.; Sheng, X.; Zhou, Y.; Zhu, Z.; Liu, Y.; Sha, X.; Zhang, C.; Gao, H. Functional mesoporous poly(ionic liquid) derived from P123: From synthesis to catalysis and alkylation of styrene and o-xylene. Appl. Organomet. Chem. 2019, 33, 4719–4730. [Google Scholar] [CrossRef]

- Sheng, X.; Gao, H.; Zhou, Y.; Wang, B.; Sha, X. Stable poly (ionic liquids) with unique cross-linked mesoporous-macroporous structure as efficient catalyst for alkylation of o-xylene and styrene. Appl. Organomet. Chem. 2019, 33, 4979–4989. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Chen, G.; Guo, Z.; Zhou, Y.; Wang, J. Hydrophobic mesoporous poly(ionic liquid)s towards highly efficient and contamination-resistant solid-base catalyst. ChemCatChem 2015, 6, 993–1003. [Google Scholar] [CrossRef]

- Tao, D.J.; Liu, F.; Wang, L.; Jiang, L. A green and efficient hydration of alkynes catalysed by hierarchically porous poly(ionic liquid)s solid strong acids. Appl. Catal. A Gen. 2018, 564, 56–63. [Google Scholar] [CrossRef]

- Hui, W.; Heb, X.M.; Xua, X.Y.; Chen, Y.M.; Zhou, Y.; Li, Z.M.; Zhang, L.; Tao, D.J. Highly efficient cycloaddition of diluted and waste CO2 into cyclic carbonates catalyzed by porous ionic copolymers. J. CO₂ Util. 2020, 36, 169–176. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, L.; Yin, L. Progress in the Heterogeneous Catalytic Cyclization of CO2 with Epoxides Using Immobilized Ionic Liquids. Catal. Lett. 2019, 149, 985–997. [Google Scholar] [CrossRef]

- Fujie, K.; Yamada, T.; Ikeda, R.; Kitagawa, H. Introduction of an ionic liquid into the micropores of a metal–organic framework and its anomalous phase behavior. Angew. Chem. Int. Ed. 2014, 53, 11302–11305. [Google Scholar] [CrossRef]

- Luo, Q.X.; An, B.W.; Ji, M.; Park, S.E.; Hao, C.; Li, Y.Q. Metal–organic frameworks HKUST-1 as porous matrix for encapsulation of basic ionic liquid catalyst: Effect of chemical behaviour of ionic liquid in solvent. J. Porous Mater. 2015, 22, 247–259. [Google Scholar] [CrossRef]

- Luo, Q.; Song, X.; Ji, M.; Park, S.E.; Hao, C.; Li, Y. Molecular size- and shape-selective Knoevenagel condensation over microporous Cu3(BTC)2 immobilized amino-functionalized basic ionic liquid catalyst. Appl. Catal. A 2014, 478, 81–90. [Google Scholar] [CrossRef]

- Fujie, K.; Kitagawa, H. Ionic liquid transported into metal–organic frameworks. Coord. Chem. Rev. 2016, 307, 382–390. [Google Scholar] [CrossRef]

- Khan, N.A.; Hasan, Z.; Jhung, S.H. Ionic liquid@MIL-101 prepared via the ship-in-bottle technique: Remarkable adsorbents for the removal of benzothiophene from liquid fuel. Chem. Commun. 2016, 52, 2561–2564. [Google Scholar] [CrossRef]

- Fujie, K.; Otsubo, K.; Ikeda, R.; Yamada, T.; Kitagawa, H. Low temperature ionic conductor: Ionic liquid incorporated within a metal–organic framework. Chem. Sci. 2015, 6, 4306–4310. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Jia, X.; Huang, H.; Guo, X.; Qiao, Z.; Zhong, C. Solvent-free mechanochemical route for the construction of ionic liquid and mixed-metal MOF composites for synergistic CO2 fixation. J. Mater. Chem. A 2020, 8, 3180–3185. [Google Scholar] [CrossRef]

- Gomes, M.C.; Pison, L.; Cervinka, C.; Padua, A. Porous Ionic Liquids or Liquid Metal-Organic Frameworks? Angew. Chem. Int. Ed. 2018, 57, 11909–11912. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, T.J.; Ribeiro, R.P.P.L.; Mota, J.P.B.; Rebelo, L.P.N.; Esperança, J.M.S.S.; Esteves, I.A.A.C. Ionic Liquid-Impregnated Metal−Organic Frameworks for CO2/CH4 Separation. ACS Appl. Nano Mater. 2019, 2, 7933–7950. [Google Scholar] [CrossRef]

- Liu, S.; Liu, J.; Hou, X.; Xu, T.; Tong, J.; Zhang, J.; Ye, B.; Liu, B. Porous Liquid: A Stable ZIF-8 Colloid in Ionic Liquid with Permanent Porosity. Langmuir 2018, 34, 3654–3660. [Google Scholar] [CrossRef]

- Ma, L.; Haynes, C.J.E.; Grommet, A.B.; Walczak, A.; Parkins, C.C.; Doherty, C.M.; Longley, L.; Tron, A.; Stefankiewicz, A.R.; Bennett, T.D.; et al. Coordination cages as permanently porous ionic liquids. Nat. Chem. 2020, 12, 270–275. [Google Scholar] [CrossRef]

- Prechtl, M.H.G. (Ed.) Nanocatalysis in Ionic Liquids; Wiley-VCH: Weinheim, Germany, 2017. [Google Scholar]

- Verma, C.; Ebenso, E.E.; Quraishi, M.A. Transition metal nanoparticles in ionic liquids: Synthesis and stabilization. J. Mol. Liq. 2019, 276, 826–849. [Google Scholar] [CrossRef]

- Hesemann, P. Applications of ionosilicas in heterogeneous catalysis: Opportunities for the elaboration of new functional catalytic phases. Curr. Opin. Green Sustain. Chem. 2018, 10, 21–26. [Google Scholar] [CrossRef]

- Rajendran, A.; Rajendiran, M.; Yang, Z.F.; Fan, H.X.; Cui, T.Y.; Zhang, Y.G.; Li, W.Y. Functionalized Silicas for Metal-Free and Metal-Based Catalytic Applications: A Review in Perspective of Green Chemistry. Chem. Rec. 2019, 19, 1–29. [Google Scholar] [CrossRef]

- Mecerreyes, D. (Ed.) Applications of Ionic Liquids in Polymer Science and Technology; Springer: Heidelberg, Germany, 2015. [Google Scholar]

- Li, P.; Cheng, F.-F.; Xiong, W.-W.; Zhang, Q. New synthetic strategies to prepare metal-organic frameworks. Inorg. Chem. Front. 2018, 5, 2693–2708. [Google Scholar] [CrossRef]

- Kore, R.; Berton, P.; Kelley, S.P.; Aduri, P.; Katti, S.S.; Rogers, R.D. Group IIIA halometallate ionic liquids: Speciation and applications in catalysis. ACS Catal. 2017, 7, 7014–7028. [Google Scholar] [CrossRef]

- Jankowska-Wajda, M.; Bartlewicz, O.; Walczak, A.; Stefankiewicz, A.R.; Maciejewski, H. Highly efficient hydrosilylation catalysts based on chloroplatinate “ionic liquids”. J. Catal. 2019, 374, 266–275. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, C.C.; Yang, S. Heterogeneously chemo/enzyme-functionalized porous polymeric catalysts of high-performance for efficient biodiesel production. ACS Catal. 2019, 9, 10990–11029. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartlewicz, O.; Dąbek, I.; Szymańska, A.; Maciejewski, H. Heterogeneous Catalysis with the Participation of Ionic Liquids. Catalysts 2020, 10, 1227. https://doi.org/10.3390/catal10111227

Bartlewicz O, Dąbek I, Szymańska A, Maciejewski H. Heterogeneous Catalysis with the Participation of Ionic Liquids. Catalysts. 2020; 10(11):1227. https://doi.org/10.3390/catal10111227

Chicago/Turabian StyleBartlewicz, Olga, Izabela Dąbek, Anna Szymańska, and Hieronim Maciejewski. 2020. "Heterogeneous Catalysis with the Participation of Ionic Liquids" Catalysts 10, no. 11: 1227. https://doi.org/10.3390/catal10111227

APA StyleBartlewicz, O., Dąbek, I., Szymańska, A., & Maciejewski, H. (2020). Heterogeneous Catalysis with the Participation of Ionic Liquids. Catalysts, 10(11), 1227. https://doi.org/10.3390/catal10111227