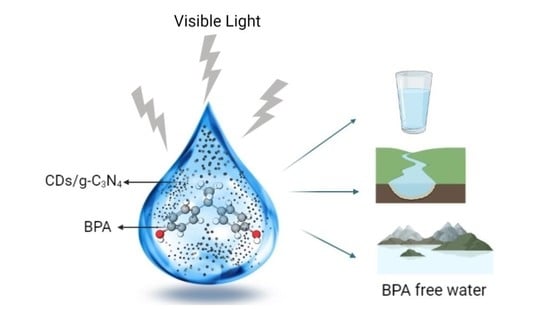

Photoreactive Carbon Dots Modified g-C3N4 for Effective Photooxidation of Bisphenol-A under Visible Light Irradiation

Abstract

:1. Introduction

2. Results

2.1. X-ray Diffraction (XRD) and Fourier Transform Infrared Spectroscopy (FT-IR) Analyses

2.2. Morphological Study

2.3. Nitrogen Adsorption-Desorption Analysis

2.4. UV-Vis Absorption Analysis

2.5. Photoluminescence (PL) Analysis

2.6. X-ray Photoelectron Spectroscopy (XPS) Analysis

2.7. Photocatalytic Performance

3. Materials and Methods

3.1. Synthesis of g-C3N4

3.2. Preparation of Carbon Dots (CDs)

3.3. Synthesis of Carbon Dots Doped Graphitic Carbon Nitride (CDs/g-C3N4)

3.4. Characterization

3.5. Photocatalytic Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Colborn, T.; Clement, C. Chemically-Induced Alterations in Sexual and Functional Development: The Wildlife/Human Connection; Wingspread Consensus Statement; Princeton Scientific Publishing Company: Princeton, NJ, USA, 1992. [Google Scholar]

- Zoeller, R.T.; Brown, T.R.; Doan, L.L.; Gore, A.C.; Skakkebaek, N.E.; Soto, A.M.; Woodruff, T.J.; Vom Saal, F.S. Endocrine-Disrupting Chemicals and Public Health Protection: A Statement of Principles from The Endocrine Society. Endocrinology 2012, 153, 4097–4110. [Google Scholar] [CrossRef] [PubMed]

- Gore, A.C. Environmental Toxicant Effects on Neuroendocrine Function. Endocrine 2001, 14, 235–246. [Google Scholar] [CrossRef]

- Carpenter, D.O. (Ed.) Effects of Persistent and Bioactive Organic Pollutants on Human Health; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Yilmaz, B.; Terekeci, H.; Sandal, S.; Kelestimur, F. Endocrine Disrupting Chemicals: Exposure, Effects on Human Health, Mechanism of Action, Models for Testing and Strategies for Prevention. Rev. Endocr. Metab. Disord. 2020, 21, 127–147. [Google Scholar] [CrossRef] [PubMed]

- Welshons, W.V.; Nagel, S.C.; vom Saal, F.S. Large Effects from Small Exposures. III. Endocrine Mechanisms Mediating Effects of Bisphenol A at Levels of Human Exposure. Endocrinology 2006, 147, s56–s69. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohapatra, D.P.; Brar, S.K.; Tyagi, R.D.; Surampalli, R.Y. Physico-Chemical Pre-Treatment and Biotransformation of Wastewater and Wastewater Sludge—Fate of Bisphenol A. Chemosphere 2010, 78, 923–941. [Google Scholar] [CrossRef]

- Jugan, M.L.; Oziol, L.; Bimbot, M.; Huteau, V.; Tamisier-Karolak, S.; Blondeau, J.P.; Lévi, Y. In Vitro Assessment of Thyroid and Estrogenic Endocrine Disruptors in Wastewater Treatment Plants, Rivers and Drinking Water Supplies in the Greater Paris Area (France). Sci. Total Environ. 2009, 407, 3579–3587. [Google Scholar] [CrossRef]

- Moreman, J.; Takesono, A.; Trznadel, M.; Winter, M.J.; Perry, A.; Wood, M.E.; Rogers, N.J.; Kudoh, T.; Tyler, C.R. Estrogenic Mechanisms and Cardiac Responses Following Early Life Exposure to Bisphenol A (BPA) and Its Metabolite 4-Methyl-2,4-Bis( p-Hydroxyphenyl)Pent-1-Ene (MBP) in Zebrafish. Environ. Sci. Technol. 2018, 52, 6656–6665. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Jiang, Z.; An, T.; Li, G.; Zhao, H.; Wong, P.K. Enhanced Visible-Light-Driven Photocatalytic Bacterial Inactivation by Ultrathin Carbon-Coated Magnetic Cobalt Ferrite Nanoparticles. Environ. Sci. Technol. 2018, 52, 4774–4784. [Google Scholar] [CrossRef]

- Serrà, A.; Philippe, L.; Perreault, F.; Garcia-Segura, S. Photocatalytic Treatment of Natural Waters. Reality or Hype? The Case of Cyanotoxins Remediation. Water Res. 2021, 188, 116543. [Google Scholar] [CrossRef]

- Inagaki, M.; Tsumura, T.; Kinumoto, T.; Toyoda, M. Graphitic Carbon Nitrides (g-C3N4) with Comparative Discussion to Carbon Materials. Carbon 2019, 141, 580–607. [Google Scholar] [CrossRef]

- Liu, H.; Liang, J.; Fu, S.; Li, L.; Cui, J.; Gao, P.; Zhao, F.; Zhou, J. N Doped Carbon Quantum Dots Modified Defect-Rich g-C3N4 for Enhanced Photocatalytic Combined Pollutions Degradation and Hydrogen Evolution. Colloids Surf. A Physicochem. Eng. Asp. 2020, 591, 124552. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, J.; Dong, X.; Fu, H.; Zhang, X.; Lv, X.; Li, Y.; Jiang, G. Defective Borate-Decorated Polymer Carbon Nitride: Enhanced Photocatalytic NO Removal, Synergy Effect and Reaction Pathway. Appl. Catal. B Environ. 2019, 249, 266–274. [Google Scholar] [CrossRef]

- Wypych, G. Functional Fillers—Structure. In Functional Fillers; Elsevier: Amsterdam, The Netherlands, 2018; pp. 101–151. [Google Scholar] [CrossRef]

- Sun, J.; Hui, S.; Lin, X.; Xie, J.; Wang, Q.; Li, Y.; Ying, Z. Novel g-C3N4–Carbon Dots-Aggregation/Ferrite Hybrid Heterojunction Photocatalyst with Excellent Visible-Light-Driven Photodegradation Performance toward Organic Pollutants. Opt. Mater. 2020, 109, 110242. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, Z.; Ji, T.; Jv, D.; Guan, P. The Critical Role of Surface Area Optimization in Carbon Quantum Dots Modified g-C3N4 for Photocatalytic Enhancement. Mater. Lett. 2022, 309, 131273. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Lei, W.; Zhu, B.; Yang, J. Novel Carbon Quantum Dot Modified g-C3N4 Nanotubes on Carbon Cloth for Efficient Degradation of Ciprofloxacin. Appl. Surf. Sci. 2021, 559, 149967. [Google Scholar] [CrossRef]

- Sim, L.C.; Tai, J.Y.; Leong, K.H.; Saravanan, P.; Tan, S.T.; Chong, W.C.; Aziz, A.A. Metal Free and Sunlight Driven g-C3N4 Based Photocatalyst Using Carbon Quantum Dots from Arabian Dates: Green Strategy for Photodegradation of 2,4-Dichlorophenol and Selective Detection of Fe3+. Diam. Relat. Mater. 2021, 120, 108679. [Google Scholar] [CrossRef]

- Liu, W.; Li, Y.; Liu, F.; Jiang, W.; Zhang, D.; Liang, J. Visible-Light-Driven Photocatalytic Degradation of Diclofenac by Carbon Quantum Dots Modified Porous g-C3N4: Mechanisms, Degradation Pathway and DFT Calculation. Water Res. 2019, 151, 8–19. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.; Feng, Y.; Xie, Z.; Zhang, Q.; Jin, X.; Liu, H.; Liu, Y.; Lv, W.; Liu, G. Facile Synthesis of Carbon Quantum Dots Loaded with Mesoporous g-C3N4 for Synergistic Absorption and Visible Light Photodegradation of Fluoroquinolone Antibiotics. Dalton Trans. 2018, 47, 1284–1293. [Google Scholar] [CrossRef]

- Duan, B.; Dong, C.; Yuan, X.; Yao, K. Electrospinning of Chitosan Solutions in Acetic Acid with Poly(Ethylene Oxide). J. Biomater. Sci. Polym. Ed. 2004, 15, 797–811. [Google Scholar] [CrossRef]

- Jiang, X.-H.; Wang, L.-C.; Yu, F.; Nie, Y.-C.; Xing, Q.-J.; Liu, X.; Pei, Y.; Zou, J.-P.; Dai, W.-L. Photodegradation of Organic Pollutants Coupled with Simultaneous Photocatalytic Evolution of Hydrogen Using Quantum-Dot-Modified g-C3N4 Catalysts under Visible-Light Irradiation. ACS Sustain. Chem. Eng. 2018, 6, 12695–12705. [Google Scholar] [CrossRef]

- Zhao, C.; Liao, Z.; Liu, W.; Liu, F.; Ye, J.; Liang, J.; Li, Y. Carbon Quantum Dots Modified Tubular g-C3N4 with Enhanced Photocatalytic Activity for Carbamazepine Elimination: Mechanisms, Degradation Pathway and DFT Calculation. J. Hazard. Mater. 2020, 381, 120957. [Google Scholar] [CrossRef] [PubMed]

- Hak, C.H.; Leong, K.H.; Chin, Y.H.; Saravanan, P.; Tan, S.T.; Chong, W.C.; Sim, L.C. Water Hyacinth Derived Carbon Quantum Dots and g-C3N4 Composites for Sunlight Driven Photodegradation of 2,4-Dichlorophenol. SN Appl. Sci. 2020, 2, 1030. [Google Scholar] [CrossRef]

- Puvvada, N.; Kumar, B.N.P.; Konar, S.; Kalita, H.; Mandal, M.; Pathak, A. Synthesis of Biocompatible Multicolor Luminescent Carbon Dots for Bioimaging Applications. Sci. Technol. Adv. Mater. 2012, 13, 045008. [Google Scholar] [CrossRef] [PubMed]

- Ruz, P.; Banerjee, S.; Pandey, M.; Sudarsan, V.; Sastry, P.U.; Kshirsagar, R.J. Structural Evolution of Turbostratic Carbon: Implications in H2 Storage. Solid State Sci. 2016, 62, 105–111. [Google Scholar] [CrossRef]

- Cao, J.; Qin, C.; Wang, Y.; Zhang, H.; Sun, G.; Zhang, Z. Solid-State Method Synthesis of SnO2-Decorated g-C3N4 Nanocomposites with Enhanced Gas-Sensing Property to Ethanol. Materials 2017, 10, 604. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Zhang, X.; Wu, X.; Tang, D.; Cai, K.; Zhang, Q. Carbon Quantum Dots/Ni-Al Layered Double Hydroxide Composite for High-Performance Supercapacitors. RSC Adv. 2016, 6, 39317–39322. [Google Scholar] [CrossRef]

- Fang, S.; Xia, Y.; Lv, K.; Li, Q.; Sun, J.; Li, M. Effect of Carbon-Dots Modification on the Structure and Photocatalytic Activity of g-C3N4. Appl. Catal. B Environ. 2016, 185, 225–232. [Google Scholar] [CrossRef]

- Lin, H.; Huang, J.; Ding, L. Preparation of Carbon Dots with High-Fluorescence Quantum Yield and Their Application in Dopamine Fluorescence Probe and Cellular Imaging. J. Nanomater. 2019, 2019, 5037243. [Google Scholar] [CrossRef]

- Yang, Y.; Cui, J.; Zheng, M.; Hu, C.; Tan, S.; Xiao, Y.; Yang, Q.; Liu, Y. One-Step Synthesis of Amino-Functionalized Fluorescent Carbon Nanoparticles by Hydrothermal Carbonization of Chitosan. Chem. Commun. 2012, 48, 380–382. [Google Scholar] [CrossRef]

- Andrade, P.F.; Nakazato, G.; Durán, N. Additive Interaction of Carbon Dots Extracted from Soluble Coffee and Biogenic Silver Nanoparticles against Bacteria. J. Phys. Conf. Ser. 2017, 838, 012028. [Google Scholar] [CrossRef]

- Jian, X.; Liu, X.; Yang, H.M.; Li, J.G.; Song, X.L.; Dai, H.Y.; Liang, Z.H. Construction of Carbon Quantum Dots/Proton-Functionalized Graphitic Carbon Nitride Nanocomposite via Electrostatic Self-Assembly Strategy and Its Application. Appl. Surf. Sci. 2016, 370, 514–521. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, L.; Geng, F.; Guo, L.H.; Wan, B.; Yang, Y. Carbon Dots Decorated Graphitic Carbon Nitride as an Efficient Metal-Free Photocatalyst for Phenol Degradation. Appl. Catal. B Environ. 2016, 180, 656–662. [Google Scholar] [CrossRef]

- Li, S.; Hu, C.; Peng, Y.; Chen, Z. One-Step Scalable Synthesis of Honeycomb-like g-C3N4 with Broad Sub-Bandgap Absorption for Superior Visible-Light-Driven Photocatalytic Hydrogen Evolution. RSC Adv. 2019, 9, 32674–32682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, Y.; Yoo, J.; Lim, B.; Kwon, W.; Rhee, S.-W. Improving the Functionality of Carbon Nanodots: Doping and Surface Functionalization. J. Mater. Chem. A 2016, 4, 11582–11603. [Google Scholar] [CrossRef]

- Ayinla, R.T.; Dennis, J.O.; Zaid, H.M.; Sanusi, Y.K.; Usman, F.; Adebayo, L.L. A Review of Technical Advances of Recent Palm Bio-Waste Conversion to Activated Carbon for Energy Storage. J. Clean. Prod. 2019, 229, 1427–1442. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Peng, S.; Lu, G.; Li, S. Eosin Y-Sensitized Graphitic Carbon Nitride Fabricated by Heating Urea for Visible Light Photocatalytic Hydrogen Evolution: The Effect of the Pyrolysis Temperature of Urea. Phys. Chem. Chem. Phys. 2013, 15, 7657. [Google Scholar] [CrossRef]

- John, B.K.; John, N.; Mathew, S.; Korah, B.K.; Punnoose, M.S.; Mathew, B. Fluorescent Carbon Quantum Dots as a Novel Solution and Paper Strip-Based Dual Sensor for the Selective Detection of Cr(VI) Ions. Diam. Relat. Mater. 2022, 126, 109138. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, X.; Shi, X.; Han, Y.; Guo, Z.; Liu, Y. Development of Carbon Quantum Dot–Labeled Antibody Fluorescence Immunoassays for the Detection of Morphine in Hot Pot Soup Base. Food Anal. Methods 2020, 13, 1042–1049. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, L.; Cao, F.; Leng, Y. Thermal Treatment of Hair for the Synthesis of Sustainable Carbon Quantum Dots and the Applications for Sensing Hg2+. Sci. Rep. 2016, 6, 35795. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Wu, M.; Wang, Y.; Yang, Q.; Li, X.; Zhang, B.; Yang, D. Novel P-n Li2SnO3/g-C3N4 Heterojunction With Enhanced Visible Light Photocatalytic Efficiency Toward Rhodamine B Degradation. Front. Chem. 2020, 8, 75. [Google Scholar] [CrossRef] [Green Version]

- Alwin, E.; Kočí, K.; Wojcieszak, R.; Zieliński, M.; Edelmannová, M.; Pietrowski, M. Influence of High Temperature Synthesis on the Structure of Graphitic Carbon Nitride and Its Hydrogen Generation Ability. Materials 2020, 13, 2756. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Cheng, H.; Hu, Y.; Song, L.; Zhang, Z.; Jiang, L.; Qu, L. Functionalized Graphitic Carbon Nitride for Metal-Free, Flexible and Rewritable Nonvolatile Memory Device via Direct Laser-Writing. Sci. Rep. 2014, 4, 5882. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, P.; Sun, S.; Zhang, X.; Ge, X.; Lü, W. Efficient Degradation of Organic Pollutants and Hydrogen Evolution by g-C3N4 Using Melamine as the Precursor and Urea as the Modifier. RSC Adv. 2016, 6, 33589–33598. [Google Scholar] [CrossRef]

- Jin, X.; Zhong, Y.; Chen, L.; Xu, L.; Wu, Y.; Fu, F.F. A Palladium-Doped Graphitic Carbon Nitride Nanosheet with High Peroxidase-Like Activity: Preparation, Characterization, and Application in Glucose Detection. Part. Part. Syst. Charact. 2018, 35, 1700359. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, Y.; Liu, X.; Zeng, G.; Shao, B.; Liu, Y.; Liu, Y.; Zhang, W.; Yan, M.; He, X. Silver Chromate Modified Sulfur Doped Graphitic Carbon Nitride Microrod Composites with Enhanced Visible-Light Photoactivity towards Organic Pollutants Degradation. Compos. Part B Eng. 2019, 173, 106918. [Google Scholar] [CrossRef]

- Huang, J.; Li, D.; Li, R.; Zhang, Q.; Chen, T.; Liu, H.; Liu, Y.; Lv, W.; Liu, G. An Efficient Metal-Free Phosphorus and Oxygen Co-Doped g-C3N4 Photocatalyst with Enhanced Visible Light Photocatalytic Activity for the Degradation of Fluoroquinolone Antibiotics. Chem. Eng. J. 2019, 374, 242–253. [Google Scholar] [CrossRef]

- Ji, S.; Yang, Y.; Li, X.; Liu, H.; Zhou, Z. Facile Production of a Fenton-like Photocatalyst by Two-Step Calcination with a Broad PH Adaptability. Nanomaterials 2020, 10, 676. [Google Scholar] [CrossRef] [Green Version]

- Gu, L.; Dong, G.; Yu, H.; Qiao, X.; Zhang, K.; Lu, X.; Wen, H. Graphitic Carbon Nitride–Doped Sewage Sludge as a Novel Material for Photodegradation of Eriochrome Black T. Environ. Sci. Pollut. Res. 2020, 27, 27971–27983. [Google Scholar] [CrossRef]

- Wang, A.; Wang, C.; Fu, L.; Wong-Ng, W.; Lan, Y. Recent Advances of Graphitic Carbon Nitride-Based Structures and Applications in Catalyst, Sensing, Imaging, and LEDs. Nano-Micro Lett. 2017, 9, 47. [Google Scholar] [CrossRef]

- Ju, H.; Yu, D.; Xu, J.; Yu, L.; Geng, Y.; Gao, T.; Yi, G.; Bian, S. Microstructure, Mechanical, and Tribological Properties of Niobium Vanadium Carbon Nitride Films. J. Vac. Sci. Technol. A Vac. Surf. Film. 2018, 36, 031511. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, X.; Chen, H.S.; Hu, X.; Yang, P. Formation of g-C3N4 Nanotubes towards Superior Photocatalysis Performance. ChemCatChem 2019, 11, 4558–4567. [Google Scholar] [CrossRef]

- Tang, R.; Ding, R.; Xie, X. Preparation of Oxygen-Doped Graphitic Carbon Nitride and Its Visible-Light Photocatalytic Performance on Bisphenol A Degradation. Water Sci. Technol. 2018, 78, 1023–1033. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Q.; Chen, C.; Zhang, Q.; Zhang, Z.; Fang, X. Molecular Engineering of Supramolecular Precursor to Modulate g-C3N4 for Boosting Photocatalytic Hydrogen Evolution. Carbon 2020, 164, 337–348. [Google Scholar] [CrossRef]

- Yin, J.-T.; Li, Z.; Cai, Y.; Zhang, Q.-F.; Chen, W. Ultrathin Graphitic Carbon Nitride Nanosheets with Remarkable Photocatalytic Hydrogen Production under Visible LED Irradiation. Chem. Commun. 2017, 53, 9430–9433. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; He, T.; Wang, Y.; Ning, G.; Xu, Z.; Chen, X.; Hu, X.; Wu, Y.; Zhao, Y. Synergistic Adsorption-Photocatalytic Degradation Effect and Norfloxacin Mechanism of ZnO/ZnS@BC under UV-Light Irradiation. Sci. Rep. 2020, 10, 11903. [Google Scholar] [CrossRef]

- Abdi, J.; Vossoughi, M.; Mahmoodi, N.M.; Alemzadeh, I. Synthesis of Metal-Organic Framework Hybrid Nanocomposites Based on GO and CNT with High Adsorption Capacity for Dye Removal. Chem. Eng. J. 2017, 326, 1145–1158. [Google Scholar] [CrossRef]

- Mahmoodi, N.M.; Hayati, B.; Arami, M.; Mazaheri, F. Single and Binary System Dye Removal from Colored Textile Wastewater by a Dendrimer as a Polymeric Nanoarchitecture: Equilibrium and Kinetics. J. Chem. Eng. Data 2010, 55, 4660–4668. [Google Scholar] [CrossRef]

- Tzeng, J.-H.; Weng, C.-H.; Chang, C.-J.; Yen, L.-T.; de Luna, M.D.G.; Huang, J.-W.; Lin, Y.-T. N-Schorl TiO2 Nanocomposite for Visible-Light Photocatalysis Deactivation Yeast Exemplified by Candida Albicans. Chem. Eng. J. 2022, 435, 134294. [Google Scholar] [CrossRef]

- Huang, S.-M.; Weng, C.-H.; Tzeng, J.-H.; Huang, Y.-Z.; Anotai, J.; Yen, L.-T.; Chang, C.-J.; Lin, Y.-T. Photocatalytic Inactivation of Klebsiella Pneumoniae by Visible-Light-Responsive N/C-Doped and N-Tourmaline/Palladium-C-Codoped TiO2. Chem. Eng. J. 2020, 379, 122345. [Google Scholar] [CrossRef]

- Oh, W.-D.; Lok, L.-W.; Veksha, A.; Giannis, A.; Lim, T.-T. Enhanced Photocatalytic Degradation of Bisphenol A with Ag-Decorated S-Doped g-C3N4 under Solar Irradiation: Performance and Mechanistic Studies. Chem. Eng. J. 2018, 333, 739–749. [Google Scholar] [CrossRef]

- Naya, S.; Yamauchi, J.; Okubo, T.; Tada, H. Rapid Removal and Mineralization of Bisphenol A by Heterosupramolecular Plasmonic Photocatalyst Consisting of Gold Nanoparticle-Loaded Titanium(IV) Oxide and Surfactant Admicelle. Langmuir 2017, 33, 10468–10472. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Yue, M.; Natarajan, V.; Kong, L.; Ma, L.; Zhang, Y.; Zhao, Q.; Zhan, J. Efficient Activation of Persulfate by Fe3O4 @β-Cyclodextrin Nanocomposite for Removal of Bisphenol A. RSC Adv. 2018, 8, 14879–14887. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, Y.; Zhou, P.; Tang, H. Visible-Light Photocatalytic Degradation of Bisphenol A on NaBiO3 Nanosheets in a Wide PH Range: A Synergistic Effect between Photocatalytic Oxidation and Chemical Oxidation. Chem. Eng. J. 2016, 291, 149–160. [Google Scholar] [CrossRef]

- Sharma, J.; Mishra, I.M.; Kumar, V. Mechanistic Study of Photo-Oxidation of Bisphenol-A (BPA) with Hydrogen Peroxide (H2O2) and Sodium Persulfate (SPS). J. Environ. Manag. 2016, 166, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Poerschmann, J.; Trommler, U.; Górecki, T. Aromatic Intermediate Formation during Oxidative Degradation of Bisphenol A by Homogeneous Sub-Stoichiometric Fenton Reaction. Chemosphere 2010, 79, 975–986. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.Q.; Zhang, W.D. Facile Synthesis of Nitrogen Deficient g-C3N4 by Copolymerization of Urea and Formamide for Efficient Photocatalytic Hydrogen Evolution. Mol. Catal. 2018, 453, 85–92. [Google Scholar] [CrossRef]

- Fan, L.; Yu, Q.; Chen, J.; Khan, U.; Wang, X.; Gao, J. Achievements and Perspectives in Metal–Organic Framework-Based Materials for Photocatalytic Nitrogen Reduction. Catalysts 2022, 12, 1005. [Google Scholar] [CrossRef]

| Photocatalyst | Application | Outcome and Role of CDs/CQDs | Ref |

|---|---|---|---|

| C−dots/g-C3N4 | Photodegradation of Rhodamine B (RhB) dye under UV light irradiation. |

| [17] |

| Zero−dimensional carbon quantum dots (CQDs) immobilized within one-dimensional porous tubular graphitic carbon nitride (g-C3N4) on carbon cloth (CC). | Photodegradation of ciprofloxacin under visible light irradiation. |

| [18] |

| Carbon quantum dots (CQDs) from Arabian dates coupled with graphitic carbon nitride (AD-CQDs/ g-C3N4) | Photodegradation of 2,4-dicholorophenol (4-DCP)under sunlight irradiation. |

| [19] |

| Carbon quantum dots-modified reduced ultrathin g-C3N4 (RUCN/CQD) | Photodegradation of diclofenac (DCF) under visible light irradiation. |

| [20] |

| Carbon quantum dots loaded with mesoporous g-C3N4 (mpg-C3N4 /CQDs) | Photodegradation of fluoroquinolone antibiotics under visible light irradiation. |

| [21] |

| g-C3N4/carbon dots nanosheets calcined at 500 °C (C–CN–NS500) | Photodegradation of sulfadiazine (SDZ) under visible light. |

| [22] |

| Carbon quantum dots/CdS quantum dots/g-C3N4 (CDs/CdS/GCN) | Simultaneous photocatalytic production of hydrogen coupled with degradation of bisphenol A (BPA). |

| [23] |

| g-C3N4 modified with carbon quantum dots (CQDs) | Photodegradation of carbamazepine (CBZ) under visible light irradiation. |

| [24] |

| g-C3N4 incorporated with water hyacinth leaves derived CQDs | Photodegradation of 2,4-dichlorophenol (2,4-DCP) under UV light irradiation. |

| [25] |

| Samples | BET (m2 g−1) | Pore Volume (cm3 g−1) |

|---|---|---|

| Pure g-C3N4 | 62.8 | 0.14 |

| 0.5CDs/g-C3N4 | 38.5 | 0.06 |

| 1.0CDs/g-C3N4 | 48.2 | 0.07 |

| 1.5CDs/g-C3N4 | 50.08 | 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqbal, A.; Shittu, F.B.; Ibrahim, M.N.M.; Bakar, N.H.H.A.; Yahaya, N.; Rajappan, K.; Hussin, M.H.; Danial, W.H.; Wilson, L.D. Photoreactive Carbon Dots Modified g-C3N4 for Effective Photooxidation of Bisphenol-A under Visible Light Irradiation. Catalysts 2022, 12, 1311. https://doi.org/10.3390/catal12111311

Iqbal A, Shittu FB, Ibrahim MNM, Bakar NHHA, Yahaya N, Rajappan K, Hussin MH, Danial WH, Wilson LD. Photoreactive Carbon Dots Modified g-C3N4 for Effective Photooxidation of Bisphenol-A under Visible Light Irradiation. Catalysts. 2022; 12(11):1311. https://doi.org/10.3390/catal12111311

Chicago/Turabian StyleIqbal, Anwar, Fatimah Bukola Shittu, Mohamad Nasir Mohamad Ibrahim, N. H. H. Abu Bakar, Noorfatimah Yahaya, Kalaivizhi Rajappan, M. Hazwan Hussin, Wan Hazman Danial, and Lee D. Wilson. 2022. "Photoreactive Carbon Dots Modified g-C3N4 for Effective Photooxidation of Bisphenol-A under Visible Light Irradiation" Catalysts 12, no. 11: 1311. https://doi.org/10.3390/catal12111311

APA StyleIqbal, A., Shittu, F. B., Ibrahim, M. N. M., Bakar, N. H. H. A., Yahaya, N., Rajappan, K., Hussin, M. H., Danial, W. H., & Wilson, L. D. (2022). Photoreactive Carbon Dots Modified g-C3N4 for Effective Photooxidation of Bisphenol-A under Visible Light Irradiation. Catalysts, 12(11), 1311. https://doi.org/10.3390/catal12111311