Thermal and Mechanical Characterization of Coir Fibre–Reinforced Polypropylene Biocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- Polypropylene: 6.7 dtex linear density, 27 cN/tex tenacity, 100% breaking elongation; 60 mm length; 7.5 g/10 min (230 °C/2.16 kg) melting flow index = 0.9 g/cm3 density; 160 °C melting temperature—produced by Beauileu International Group, Kruisem, Belgium;

- Coir fibres: 0.25 mm diameter, 102 MPa tensile strength, 23% breaking elongation and a length that ranged between 50 and 100 mm—purchased from Madras, India.

2.2. Methods

2.2.1. Experimental Variants

2.2.2. Composite Manufacturing Process

2.2.3. Mechanical Properties

2.2.4. Thermogravimetric Analysis

2.2.5. Differential Scanning Calorimetry (DSC)

2.2.6. Fourier Transform Infrared Spectroscopy

2.2.7. Scanning Electron Microscopy

2.2.8. Chromatic Measurements

3. Results and Discussions

3.1. Mechanical Properties

3.2. TG and DTG Analysis

- In the first stage, in the temperature range between 48.86 °C and 91.67 °C, there is a loss of mass due to the removal of moisture from coir fibres (4.8%). The maximum degradation rate is recorded at a temperature of 64.71 °C.

- In the second stage, for the temperature range between 250.19 °C and 342.26 °C the mass losses are higher, reaching a maximum value at the temperature of 278.07 °C, a temperature that can be attributed to cellulose and hemicellulose degradation. The peak at 328.31 °C is assigned to both the degradation of hemicellulose and cellulose and the degradation of PP fibres [48].

- In the last temperature zone, between 391.99 °C and 477.66 °C, the maximum degradation rate is recorded at a temperature of 451 °C and corresponds both to the degradation of lignin and cellulose, but also to the degradation of PP.

3.3. DSC Analysis

3.4. ATR-FTIR Analysis

3.5. SEM Analysis

3.6. Chromatic Measurements

4. Conclusions

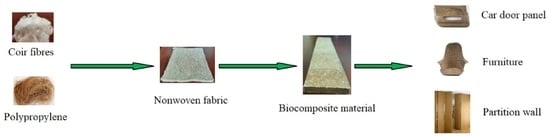

- Coir fibre-reinforced polypropylene biocomposite materials were obtained in various reinforcement agent–matrix mixing ratios.

- The tensile and bending strength of biocomposites decreased when the coir fibre content increased due to the weak bonds from the fibre–matrix interface.

- The analysis of the TG and DTG diagrams showed that the mass losses of biocomposite materials increased with increasing temperature. Moreover, for the same mass loss, the degradation temperature increases with increasing coir content. For mass losses greater than 15%, the biocomposite materials with a maximum coir fibre content of 50% had a higher temperature resistance compared to the 100% PP fibres.

- The DSC diagrams confirmed that the values of melting enthalpies (ΔHm) of biocomposites are lower than those obtained for the PP matrix and therefore, a decrease in the overall crystallinity of the biocomposites with increasing coir fibre content was registered.

- The FTIR spectra confirmed the presence of the two fibres and the changes that occur with the variation of the ratio between the two components used to obtain the studied biocomposites. From the analysis of SEM microelectrophotographs, it has been observed that with the increase of coir fibre content the degree of coverage of fibres with PP matrix decreased, so for 25Co75PP biocomposites, it appeared as a total coverage, while for 75Co25PP biocomposites, a series of holes appeared which confirms the above statement.

- From the analysis of the spectra, the colour intensity of the samples increased with the increase in the content of coir fibres which have a slightly brown colour.

- Due to its properties and low cost, coconut fibres are increasingly used to obtain composite materials containing thermoplastic polymer matrices.

- The biocomposite materials obtained from pp fibres and coconut fibres can be used in various fields such as the furniture industry, cars, constructions, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zwawi, M. A Review on Natural Fiber Bio-Composites, Surface Modifications and Applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef] [PubMed]

- Manu, T.; Nazmi, A.R.; Shahri, B.; Emerson, N.; Huber, T. Biocomposites: A Review of Materials and Perception. Mater. Today Commun. 2022, 31, 103308. [Google Scholar] [CrossRef]

- Abdulkhani, A.; Echresh, Z.; Allahdadi, M. Chapter 15. Effect of nanofibers on the structure and properties of biocomposites. In Micro and Nano Technologies, Fiber-Reinforced Nanocomposites: Fundamentals and Applications; Han, B., Sharma, S., Nguyen, T.A., Longbiao, L., Subrahmanya Bhat, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 321–357. [Google Scholar] [CrossRef]

- Shanmugam, V.; Mensah, R.A.; Försth, M.; Sas, G.; Restás, A.; Addy, C.; Xu, Q.; Jiang, L.; Neisiany, R.E.; Singha, S.; et al. Circular economy in biocomposite development: State-of-the-art, challenges and emerging trends. Compos. Part C Open Access 2021, 5, 100138. [Google Scholar] [CrossRef]

- Edebali, S. Methods of engineering of biopolymers and biocomposites. In Advanced Green Materials; Shakeel, A., Ed.; Woodhead Publishing: Cambridge, UK, 2021; pp. 351–357. ISBN 9780128199886. [Google Scholar] [CrossRef]

- Christian, S.J. Natural fibre-reinforced noncementitious composites (biocomposites). In Nonconventional and Vernacular Construction Materials; Harries, K.A., Sharma, B., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 111–126. ISBN 9780081008713. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable biobased composites for advanced applications: Recent trends and future opportunities—A critical review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Drzal, L.T.; Mohanty, A.K.; Misra, M. Bio-composite materials as alternatives to petroleum-based composites for automotive applications. Magnesium 2001, 40, 1–3. [Google Scholar]

- Jawaid, M.; Sapuan, S.M.; Alothman, O.Y. Green Biocomposites: Manufacturing and Properties; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Chisholm, H. Encyclopædia Britannica 6, 11th ed.; Cambridge University Press: Cambridge, UK, 1911; p. 654. [Google Scholar]

- Yan, Y. Developments in fibers for technical nonwovens. In Advances in Technical Nonwovens; Kellie, G., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 19–96. ISBN 9780081005750. [Google Scholar] [CrossRef]

- Bongarde, U.S.; Khot, B.K. A Review on Coir Fiber Reinforced Polymer Composite. Int. Res. J. Eng. Technol. 2019, 6, 793–795. [Google Scholar]

- Goyat, V.; Ghangas, G.; Sirohi, S.; Kumar, A.; Nain, J. A review on mechanical properties of coir based composites. Mater. Today Proc. 2022, 62, 1738–1745. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers and Biocomposites; Taylor & Francis: Boca Ranton, FL, USA, 2005; p. 875. [Google Scholar]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. B Eng. 2019, 176, 107305. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Kóczán, Z.; Alpár, T. Thermo-mechanical properties of pretreated coir fiber and fibrous chips reinforced multilayered composites. Sci. Rep. 2021, 11, 3618. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.R.; Siengchin, S.; Fouad, H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. Express Polym. Lett. 2020, 14, 717–730. [Google Scholar] [CrossRef]

- Guerrica-Echevarria, G.; Eguiazábal, J.; Nazábal, J. Effects of reprocessing conditions on the properties of unfilled and talc-filled polypropylene. Polym. Degrad. Stab. 1996, 53, 1–8. [Google Scholar] [CrossRef]

- Bourmaud, A.; Baley, C. Investigations on the recycling of hemp and sisal fibre reinforced polypropylene composites. Polym. Degrad. Stab. 2007, 92, 1034–1045. [Google Scholar] [CrossRef]

- Bourmaud, A.; Le Duigou, A.; Baley, C. What is the technical and environmental interest in reusing a recycled polypropylene—hemp fibrecomposite? Polym. Degrad. Stab. 2011, 96, 1732–1739. [Google Scholar] [CrossRef]

- Ichim, M.; Ailenei, E.C.; Sava, C.; Filip, I.; Cionca, I.; Stelea, L. Investigations on the Recycling of Polypropylene Matrix Composites Reinforced with Hemp Fibres. In Proceedings of the 7th International Symposium “Technical Textiles—Present and Future”, Iași, Romania, 12 November 2021; Sciendo: Warsaw, Poland, 2022; pp. 149–154, ISBN 978-83-66675-73-5. [Google Scholar] [CrossRef]

- Mukhopadhyay, S. Natural and synthetic fibres for composite nonwovens. In Composite Nonwoven Materials: Structure, Properties and Applications; Das, D., Pourdeyhimi, B., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2014; pp. 20–29. [Google Scholar] [CrossRef]

- Samuel, O.D.; Agbo, S.; Adekanye, T.A. Assessing Mechanical Properties of Natural Fibre Reinforced Composites for Engineering Applications. J. Miner. Mater. Charact. Eng. 2012, 11, 780–784. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, Mechanical and Thermal Properties of Green Composites Reinforced with Natural Fibers Waste. Polymers 2020, 12, 654. [Google Scholar] [CrossRef] [Green Version]

- Naik, M.K. Coconut fiber reinforced polymer composite for partition wall. Int. J. Adv. Res. Ideas Innov. Technol. 2018, 4, 607–611. [Google Scholar]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P.; White, R.H. Coir fiber reinforced polypropylene composite panel for automotive interior applications. Fibers Polym. 2011, 12, 919–926. [Google Scholar] [CrossRef]

- Gelfuso, M.V.; da Silva, P.V.G.; Thomazini, D. Polypropylene matrix composites reinforced with coconut fibers. Mater. Res. 2011, 14, 360–365. [Google Scholar] [CrossRef]

- Kumar, S.; Shamprasad, M.S.; Varadarajan, Y.S.; Sangamesha, M.A. Coconut coir fiber reinforced polypropylene composites: Investigation on fracture toughness and mechanical properties. Mater. Today Proc. 2021, 46, 2471–2476. [Google Scholar] [CrossRef]

- Naveen, P.N.E.; Dharma Raju, T. Evaluation of Mechanical Properties of Coconut Coir Fiber Reinforced Polymer Matrix Composites. J. Nano Res. 2013, 24, 34–45. [Google Scholar] [CrossRef]

- Hasan, M.; Hoque, M.E.; Mir, S.S.; Saba, N.; Sapuan, S. Manufacturing of Coir Fibre-Reinforced Polymer Composites by Hot Compression Technique. In Manufacturing of Natural Fibre Reinforced Polymer Composites, 1st ed.; Sapuan, S.M., Jawaid, M., Yusoff, N., EnamulHoque, M., Eds.; Springer: Cham, Switzerland, 2015; pp. 309–328. [Google Scholar] [CrossRef]

- Obele, C.; Ishidi, E. Mechanical Properties of Coir Fiber Reinforced Epoxy Resin Composites for Helmet Shell. Ind. Eng. Lett. 2015, 5, 67–73. [Google Scholar]

- Kumar, S.; Deka, K.; Suresh, P. Mechanical Properties of Coconut Fiber Reinforced Epoxy Polymer Composites. Int. Res. J. Eng. Technol. 2016, 3, 1334–1336. [Google Scholar]

- Pani, D.; Mishra, P. Analysis of Mechanical Properties of Coir composites with varied compositions. Int. J. Mater. Sci. Technol. 2019, 9, 2249–3077. [Google Scholar]

- Nam, T.H.; Ogihara, S.; Kobayashi, S. Interfacial, Mechanical and Thermal Properties of Coir Fiber-Reinforced Poly(Lactic Acid) Biodegradable Composites. Adv. Compos. Mater. 2012, 21, 103–122. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Effect of fiber content on thermal behavior and viscoelastic properties of PALF/Epoxy and COIR/Epoxy composites. Mater. Res. Express 2018, 5, 125305. [Google Scholar] [CrossRef]

- Ball, P. Manufacturing Processes. In Handbook of Polymer Composites for Engineers; Hollaway, L., Ed.; Woodhead Publishing Limited: Cambridge, UK, 1994; pp. 73–94. [Google Scholar]

- Salazar-Cru, B.A.; Chávez-Cinco, M.I.; Morales-Cepeda, A.B.; Ramos-Galván, C.E.; Rivera-Armenta, J.L. Evaluation of Thermal Properties of Composites Prepared from Pistachio Shell Particles Treated Chemically and Polypropylene. Molecules 2022, 27, 426. [Google Scholar] [CrossRef]

- Ingamells, W. Colour for Textiles: A User’s Handbook; Society of Dyers and Colourists: Bradford, UK, 1993; p. 154. ISBN1 0901956562. ISBN2 9780901956569. [Google Scholar]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Schirp, A.; Stender, J. Properties of extruded wood-plastic composites based on refiner wood fibres (TMP fibres) and hemp fibres. Eur. J. Wood Wood Prod. 2010, 68, 219. [Google Scholar] [CrossRef] [Green Version]

- Nourbakhsh, A.; Ashori, A. Highly Fiber-Loaded Composites: Physical and Mechanical Properties. Polym. Polym. Compos. 2008, 16, 283–287. [Google Scholar] [CrossRef]

- Stelea, L.; Filip, I.; Lisa, G.; Ichim, M.; Drobotă, M.; Sava, C.; Mureșan, A. Characterisation of Hemp Fibres Reinforced Composites Using Thermoplastic Polymers as Matrices. Polymers 2022, 14, 481. [Google Scholar] [CrossRef]

- Nguyen, T.; Zavarin, E.; Barral, E.M. Thermal Analysis of Lignocellulosic Materials. J. Macromol. Sci.-Part C 1981, 20, 1–65. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Patnaik, S.; Singh, B.C.; Misra, M. Graft copolymerization of acrylonitrile onto acetylated jute fibers. J. Appl. Polym. Sci. 1989, 37, 1171–1181. [Google Scholar] [CrossRef]

- Sabaa, M.W. Thermal degradation behaviour of sisal fibers grafted with various vinyl monomers. Polym. Degrad. Stab. 1991, 32, 209–217. [Google Scholar] [CrossRef]

- Yap, M.G.S.; Que, Y.T.; Chia, L.H.L.; Chan, H.S.O. Thermal properties of tropical wood–polymer composites. J. Appl. Polym. Sci. 1991, 43, 2057–2065. [Google Scholar] [CrossRef]

- Santafé, H.P., Jr.; Rodriguez, R.J.; Monteiro, S.N.; Castillo, T.E. Characterization of thermogravimetric behavior of polyester composites reinforced with coir fiber. In Proceedings of the Characterization of Minerals, Metals and Materials Symposium—TMS 2011, Annual Conference, San Diego, CA, USA, 27 February–3 March 2011; pp. 1–6. [Google Scholar]

- Sergio, N.M.; Calado, V.; Ruben, J.S.R.; Frederico, M.M. Thermogravimetric behavior of natural fibres reinforced polymer compozites—An overview. Mater. Sci. Eng. A 2012, 557, 17–28. [Google Scholar]

- Mark, H.F.; Bikales, N.M.; Overberger, C.G.; Menges, G. Encyclopedia of Polymer Science and Engineering; John Wiley & Sons: New York, NY, USA, 1988; Volume 14. [Google Scholar]

- Anderson, K.S.; Hillmyer, M.A. Melt preparation and nucleation efficiency of polylactide stereocomplex crystallites. Polymer 2006, 47, 2030–2035. [Google Scholar] [CrossRef]

- Xu, H.; Liu, C.Y.; Chen, C.; Hsiao, B.S.; Zhong, G.J.; Li, Z.M. Easy alignment and effective nucleation activity of ramie fibers in injection-molded poly(lactic acid) biocompozites. Biopolymers 2012, 97, 825–839. [Google Scholar] [CrossRef]

- Naruedee, P.; Amnouy, L. Wollastonite and talc reinforced polypropylene hybrid compozites: Mechanical, morphological and thermal properties. J. Met. Mater. Miner. 2021, 31, 92–99. [Google Scholar]

- Lee, L.-T.; Tseng, H.-Y.; Wu, T.-Y. Crystallization Behaviors of Composites Comprising Biodegradable Polyester and Functional Nucleation Agent. Crystals 2021, 11, 1260. [Google Scholar] [CrossRef]

- Techawinyutham, L.; Frick, A.; Siengchin, S. Polypropylene/Maleic Anhydride Grafted Polypropylene (MAgPP)/Coconut Fiber Composites. Adv. Mech. Eng. 2016, 8, 1687814016645446. [Google Scholar] [CrossRef] [Green Version]

- Karsli, N.G.; Aytac, A. Effects of maleated polypropylene on the morphology, thermal and mechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Des. 2011, 32, 4069–4073. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Bak, M.; Alpár, T. A state-of-the-art review on coir fiber-reinforced biocomposites. RSC Adv. 2021, 11, 10548–10571. [Google Scholar] [CrossRef] [PubMed]

- Jung, M.R.; Horgen, F.D.; Orski, S.V.; Rodriguez, V.; Beers, K.L.; Balazs, G.H.; Jones, T.T.; Work, T.M.; Brignac, K.C.; Royer, S.-J.; et al. Validation of ATR FT-IR to identify polymers of plastic marine debris, including those ingested by marine organisms. Mar. Pollut. Bull. 2018, 127, 704–716. [Google Scholar] [CrossRef] [PubMed]

- Mir, S.S.; Hasan, S.M.N.; Hossain, J.; Hasan, M. Chemical Modification Effect on the Mechanical Properties of Coir Fiber. Eng. J. 2012, 16, 73–84. [Google Scholar] [CrossRef]

- Moosavinejad, S.M.; Madhoushi, M.; Vakili, M.; Rasouli, D. Evaluation of degradation in chemical compounds of wood in historical buildings using FT-IR and FT-Raman vibrational spectroscopy. Maderas Cienc. Tecnol. 2019, 21, 381–392. [Google Scholar] [CrossRef]

- Shi, J.; Xing, D.; Lia, J. FTIR Studies of the Changes in Wood Chemistry from Wood Forming Tissue under Inclined Treatment. Energy Procedia 2012, 16, 758–762. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Oktiani, R.; Ragadhita, R. How to Read and Interpret FTIR Spectroscope of Organic Material. Indones. J. Sci. Technol. 2019, 4, 97–118. [Google Scholar] [CrossRef]

- Traoré, M.; Kaal, J.; Martínez Cortizas, A. Differentiation between pine woods according to species and growing location using FTIR-ATR. Wood Sci. Technol. 2018, 52, 487–504. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Sutton, D.; Wang, X.; Lin, T. Needleless Melt-Electrospinning of Polypropylene Nanofibres. J. Nanomater. 2012, 2012, 382639. [Google Scholar] [CrossRef]

- Javier-Astete, R.; Jimenez-Davalos, J.; Zolla, G. Determination of hemicellulose, cellulose, holocellulose and lignin content using FTIR in Calycophyllum spruceanum (Benth.) K. Schum. and Guazuma crinita Lam. PLoS ONE 2021, 16, e0256559. [Google Scholar] [CrossRef]

- Célino, A.; Gonçalves, O.; Jacquemin, F.; Fréour, S. Qualitative and quantitative assessment of water sorption in natural fibres using ATR-FTIR spectroscopy. Carbohydr. Polym. 2014, 101, 163–170. [Google Scholar] [CrossRef] [PubMed]

- Annandarajah, C.; Li, P.; Michel, M.; Chen, Y.; Jamshidi, R.; Kiziltas, A.; Hoch, R.; Grewell, D.; Montazami, R. Study of Agave Fiber-Reinforced Biocomposite Films. Materials 2019, 12, 99. [Google Scholar] [CrossRef] [PubMed]

- Chércoles Asensio, R.; San Andrés Moya, M.; de la Roja, J.M.; Gómez, M. Analytical characterization of polymers used in conservation and restoration by ATR-FTIR spectroscopy. Anal. Bioanal. Chem. 2009, 395, 2081–2096. [Google Scholar] [CrossRef]

- Pisanu, L.; Barbosa, J.; Souza, R.; Nascimento, M. Evaluating the influence of coupling agents in the structural properties of polypropylene coconut fiber compozites. Mater. Res. Express 2019, 6, 115320. [Google Scholar] [CrossRef]

| Blend | Variant Code |

|---|---|

| 100% Polypropylene | 100PP |

| 25% Coir fibres/75% Polypropylene | 25Co75PP |

| 50% Coir fibres/50% Polypropylene | 50Co50PP |

| 75% Coir fibres/25% Polypropylene | 75Co25PP |

| 100% Coir fibres | 100Co |

| Variant | Tensile Strength (MPa) | Breaking Elongation (%) | Bending Strength (MPa) | Bending Modulus (MPa) |

|---|---|---|---|---|

| 100PP | 20.33 ± 0.96 | 14.1 ± 0.73 | 37.3 ± 4.17 | 1123.8 ± 142.7 |

| 25Co75PP | 15.02 ± 1.06 | 3.6 ± 0.29 | 29.2 ± 4.35 | 1332.6 ± 215.88 |

| 50Co50PP | 10.6 ± 1.16 | 4.4 ± 0.53 | 21.5 ± 3.95 | 980.7 ± 185.35 |

| 75Co25PP | 8.06 ± 1.22 | 5.2 ± 0.87 | 14.4 ± 2.82 | 720.5 ± 146.9 |

| 100Co | 0.86 ± 0.08 | 64.5 ± 7.32 | – | – |

| Mass Loss (%) | Process Temperature (°C) | ||||

|---|---|---|---|---|---|

| 100Co | 75Co25PP | 50Co50PP | 25Co75PP | 100PP | |

| 2.5 | 67 | 222.8 | 223.1 | 290.89 | 366 |

| 5 | 222.7 | 256.9 | 284.2 | 324.7 | 372.1 |

| 10 | 249.9 | 284.1 | 324.9 | 378.9 | 385.6 |

| 15 | 263.6 | 304.5 | 358.7 | 411.9 | 394.1 |

| 20 | 278.2 | 321.2 | 406.1 | 426 | 405.1 |

| 25 | 284.1 | 330.8 | 419.4 | 435.1 | 410.5 |

| 50 | 332.3 | 432.8 | 452.9 | 454.3 | 433.1 |

| Sample | First Heating | Cooling | Second Heating | |||||

|---|---|---|---|---|---|---|---|---|

| Tm (°C) | ∆Hm (J/g) * | Tc (°C) | ∆HC (J/g) | χcomp (%) | Tm (°C) | ∆Hm (J/g) ** | χcomp % | |

| 100Co | – | – | – | – | – | – | – | |

| 75Co25PP | 165.28 | 35.8 | 115.99 | 42.33 | 20.44 | 162.62 | 37.82 | 18.27 |

| 50Co50PP | 166.99 | 50.32 | 116 | 58.04 | 28.03 | 163.66 | 52.84 | 25.52 |

| 25Co75PP | 167.18 | 59.64 | 114.46 | 72.12 | 34.84 | 164.36 | 61.33 | 29.62 |

| 100PP | 164.74 | 74.40 | 112.5 | 93.56 | 45.19 | 167.54 | 81.67 | 39.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ichim, M.; Stelea, L.; Filip, I.; Lisa, G.; Muresan, E.I. Thermal and Mechanical Characterization of Coir Fibre–Reinforced Polypropylene Biocomposites. Crystals 2022, 12, 1249. https://doi.org/10.3390/cryst12091249

Ichim M, Stelea L, Filip I, Lisa G, Muresan EI. Thermal and Mechanical Characterization of Coir Fibre–Reinforced Polypropylene Biocomposites. Crystals. 2022; 12(9):1249. https://doi.org/10.3390/cryst12091249

Chicago/Turabian StyleIchim, Mariana, Lucia Stelea, Ioan Filip, Gabriela Lisa, and Emil Ioan Muresan. 2022. "Thermal and Mechanical Characterization of Coir Fibre–Reinforced Polypropylene Biocomposites" Crystals 12, no. 9: 1249. https://doi.org/10.3390/cryst12091249

APA StyleIchim, M., Stelea, L., Filip, I., Lisa, G., & Muresan, E. I. (2022). Thermal and Mechanical Characterization of Coir Fibre–Reinforced Polypropylene Biocomposites. Crystals, 12(9), 1249. https://doi.org/10.3390/cryst12091249