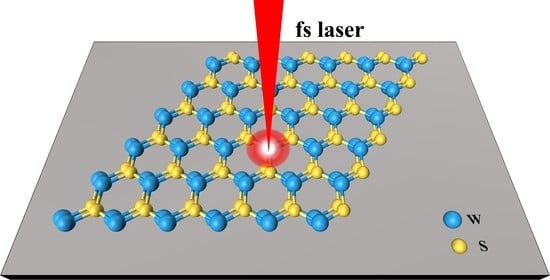

Ultrafast Mechanism of Material Removal in the Femtosecond Laser Ablation of WS2 and Its Diode Rectification Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Methods

2.2. Computational Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Falin, A.; Holwill, M.; Lv, H.; Gan, W.; Cheng, J.; Zhang, R.; Qian, D.; Barnett, M.R.; Santos, E.J.G.; Novoselov, K.S. Mechanical Properties of Atomically Thin Tungsten Dichalcogenides: WS2, WSe2, and WTe2. ACS Nano 2021, 15, 2600–2610. [Google Scholar] [CrossRef]

- Sang, Y.; Zhao, Z.; Zhao, M.; Hao, P.; Leng, Y.; Liu, H. From UV to Near-infrared, WS2 Nanosheet: A Novel Photocatalyst for Full Solar Light Spectrum Photodegradation. Adv. Mater. 2015, 27, 363–369. [Google Scholar] [CrossRef] [PubMed]

- Ashraf, W.; Fatima, T.; Srivastava, K.; Khanuja, M. Superior Photocatalytic Activity of Tungsten Disulfide Nanostructures: Role of Morphology and Defects. Appl. Nanosci. 2019, 9, 1515–1529. [Google Scholar] [CrossRef]

- Kim, J.; Lee, E.; Mehta, G.; Choi, W. Stable and High-Performance Piezoelectric Sensor via CVD Grown WS2. Nanotechnology 2020, 31, 445203. [Google Scholar] [CrossRef]

- Afzal, A.M.; Iqbal, M.Z.; Dastgeer, G.; Nazir, G.; Mumtaz, S.; Usman, M.; Eom, J. WS2/GeSe/WS2 Bipolar Transistor-Based Chemical Sensor with Fast Response and Recovery Times. ACS Appl. Mater. Interfaces 2020, 12, 39524–39532. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Liu, J.; Gu, X.; Gong, H.; Shi, X.; Liu, T.; Wang, C.; Wang, X.; Liu, G.; Xing, H. PEGylated WS2 Nanosheets as a Multifunctional Theranostic Agent for in Vivo Dual-modal CT/Photoacoustic Imaging Guided Photothermal Therapy. Adv. Mater. 2014, 26, 1886–1893. [Google Scholar] [CrossRef]

- Khalil, H.M.W.; Khan, M.F.; Eom, J.; Noh, H. Highly Stable and Tunable Chemical Doping of Multilayer WS2 Field Effect Transistor: Reduction in Contact Resistance. ACS Appl. Mater. Interfaces 2015, 7, 23589–23596. [Google Scholar] [CrossRef] [PubMed]

- Caigas, S.P.; Cheng, M.-C.; Lin, T.-N.; Santiago, S.R.M.S.; Yuan, C.-T.; Yang, C.-C.; Chou, W.-C.; Shen, J.-L. P-Type Doping of WS2 Quantum Dots via Pulsed Laser Ablation. ACS Photonics 2018, 5, 4828–4837. [Google Scholar] [CrossRef]

- Kim, H.-C.; Kim, H.; Lee, J.-U.; Lee, H.-B.; Choi, D.-H.; Lee, J.-H.; Lee, W.H.; Jhang, S.H.; Park, B.H.; Cheong, H. Engineering Optical and Electronic Properties of WS2 by Varying the Number of Layers. ACS Nano 2015, 9, 6854–6860. [Google Scholar] [CrossRef]

- Ma, S.; Zeng, L.; Tao, L.; Tang, C.Y.; Yuan, H.; Long, H.; Cheng, P.K.; Chai, Y.; Chen, C.; Fung, K.H. Enhanced Photocatalytic Activity of WS2 Film by Laser Drilling to Produce Porous WS2/WO3 Heterostructure. Sci. Rep. 2017, 7, 3125. [Google Scholar] [CrossRef]

- Yang, X.; Tang, S.; Ding, G.; Xie, X.; Jiang, M.; Huang, F. Layer-by-Layer Thinning of Graphene by Plasma Irradiation and Post-Annealing. Nanotechnology 2011, 23, 25704. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Lu, J.H.; Liu, H.; Liu, B.; Chan, K.X.; Lin, J.; Chen, W.; Loh, K.P.; Sow, C.H. Improved Photoelectrical Properties of MoS2 Films after Laser Micromachining. ACS Nano 2014, 8, 6334–6343. [Google Scholar] [CrossRef]

- Rani, R.; Dimple; Rani, R.; Jena, N.; Kundu, A.; De Sarkar, A.; Hazra, K.S. Controlled Formation of Nanostructures on MoS2 Layers by Focused Laser Irradiation. Appl. Phys. Lett. 2017, 110, 83101. [Google Scholar] [CrossRef]

- Xu, C.; Jiang, L.; Li, X.; Li, C.; Shao, C.; Zuo, P.; Liang, M.; Qu, L.; Cui, T. Miniaturized High-Performance Metallic 1T-Phase MoS2 Micro-Supercapacitors Fabricated by Temporally Shaped Femtosecond Pulses. Nano Energy 2020, 67, 104260. [Google Scholar] [CrossRef]

- Venkatakrishnan, A.; Chua, H.; Tan, P.; Hu, Z.; Liu, H.; Liu, Y.; Carvalho, A.; Lu, J.; Sow, C.H. Microsteganography on WS2 Monolayers Tailored by Direct Laser Painting. ACS Nano 2017, 11, 713–720. [Google Scholar] [CrossRef]

- Zuo, P.; Jiang, L.; Li, X.; Tian, M.; Xu, C.; Yuan, Y.; Ran, P.; Li, B.; Lu, Y. Maskless Micro/Nanopatterning and Bipolar Electrical Rectification of MoS2 Flakes through Femtosecond Laser Direct Writing. ACS Appl. Mater. Interfaces 2019, 11, 39334–39341. [Google Scholar] [CrossRef]

- Mahjouri-Samani, M.; Lin, M.-W.; Wang, K.; Lupini, A.R.; Lee, J.; Basile, L.; Boulesbaa, A.; Rouleau, C.M.; Puretzky, A.A.; Ivanov, I.N. Patterned Arrays of Lateral Heterojunctions within Monolayer Two-Dimensional Semiconductors. Nat. Commun. 2015, 6, 7749. [Google Scholar] [CrossRef]

- Zuo, P.; Jiang, L.; Li, X.; Ran, P.; Li, B.; Song, A.; Tian, M.; Ma, T.; Guo, B.; Qu, L. Enhancing Charge Transfer with Foreign Molecules through Femtosecond Laser Induced MoS2 Defect Sites for Photoluminescence Control and SERS Enhancement. Nanoscale 2019, 11, 485–494. [Google Scholar] [CrossRef]

- Zhang, L.; Nan, H.; Zhang, X.; Liang, Q.; Du, A.; Ni, Z.; Gu, X.; Ostrikov, K.; Xiao, S. 2D Atomic Crystal Molecular Superlattices by Soft Plasma Intercalation. Nat. Commun. 2020, 11, 5960. [Google Scholar] [CrossRef]

- Castellanos-Gomez, A.; Barkelid, M.; Goossens, A.M.; Calado, V.E.; van der Zant, H.S.J.; Steele, G.A. Laser-Thinning of MoS2: On Demand Generation of a Single-Layer Semiconductor. Nano Lett. 2012, 12, 3187–3192. [Google Scholar] [CrossRef]

- Alrasheed, A.; Gorham, J.M.; Tran Khac, B.C.; Alsaffar, F.; DelRio, F.W.; Chung, K.-H.; Amer, M.R. Surface Properties of Laser-Treated Molybdenum Disulfide Nanosheets for Optoelectronic Applications. ACS Appl. Mater. Interfaces 2018, 10, 18104–18112. [Google Scholar] [CrossRef] [PubMed]

- Ardekani, H.; Younts, R.; Yu, Y.; Cao, L.; Gundogdu, K. Reversible Photoluminescence Tuning by Defect Passivation via Laser Irradiation on Aged Monolayer MoS2. ACS Appl. Mater. Interfaces 2019, 11, 38240–38246. [Google Scholar] [CrossRef]

- Hu, L.; Shan, X.; Wu, Y.; Zhao, J.; Lu, X. Laser Thinning and Patterning of MoS2 with Layer-by-Layer Precision. Sci. Rep. 2017, 7, 15538. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, A.-D.; Li, B.; Cui, T.-H.; Lu, Y.-F. Electrons Dynamics Control by Shaping Femtosecond Laser Pulses in Micro/Nanofabrication: Modeling, Method, Measurement and Application. Light Sci. Appl. 2018, 7, 17134. [Google Scholar] [CrossRef]

- Han, G.H.; Chae, S.J.; Kim, E.S.; Gunes, F.; Lee, I.H.; Lee, S.W.; Lee, S.Y.; Lim, S.C.; Jeong, H.K.; Jeong, M.S. Laser Thinning for Monolayer Graphene Formation: Heat Sink and Interference Effect. ACS Nano 2011, 5, 263–268. [Google Scholar] [CrossRef]

- Gu, E.; Wang, Q.; Zhang, Y.; Cong, C.; Hu, L.; Tian, P.; Liu, R.; Zhang, S.-L.; Qiu, Z.-J. A Real-Time Raman Spectroscopy Study of the Dynamics of Laser-Thinning of MoS2 Flakes to Monolayers. AIP Adv. 2017, 7, 125329. [Google Scholar] [CrossRef]

- Sundaram, S.K.; Mazur, E. Inducing and Probing Non-Thermal Transitions in Semiconductors Using Femtosecond Laser Pulses. Nat. Mater. 2002, 1, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Vaidyanathan, A.; Mitra, S.S.; Narducci, L.M.; Shatas, R.A. One-Photon Absorption in Direct Gap Semiconductors. Solid State Commun. 1977, 21, 405–407. [Google Scholar] [CrossRef]

- Jing, X.; Tian, Y.; Zhang, J.; Chen, S.; Jin, Y.; Shao, J.; Fan, Z. Modeling Validity of Femtosecond Laser Breakdown in Wide Bandgap Dielectrics. Appl. Surf. Sci. 2012, 258, 4741–4749. [Google Scholar] [CrossRef]

- Jiang, L.; Tsai, H.-L. Energy Transport and Material Removal in Wide Bandgap Materials by a Femtosecond Laser Pulse. Int. J. Heat Mass Transf. 2005, 48, 487–499. [Google Scholar] [CrossRef]

- Liu, J.M. Simple Technique for Measurements of Pulsed Gaussian-Beam Spot Sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef]

- Siegel, J.; Puerto, D.; Gawelda, W.; Bachelier, G.; Solis, J.; Ehrentraut, L.; Bonse, J. Plasma Formation and Structural Modification below the Visible Ablation Threshold in Fused Silica upon Femtosecond Laser Irradiation. Appl. Phys. Lett. 2007, 91, 82902. [Google Scholar] [CrossRef]

- Hernandez-Rueda, J.; Puerto, D.; Siegel, J.; Galvan-Sosa, M.; Solis, J. Plasma Dynamics and Structural Modifications Induced by Femtosecond Laser Pulses in Quartz. Appl. Surf. Sci. 2012, 258, 9389–9393. [Google Scholar] [CrossRef]

- Pan, C.; Jiang, L.; Sun, J.; Wang, Q.; Wang, F.; Wang, K.; Lu, Y.; Wang, Y.; Qu, L.; Cui, T. Ultrafast Optical Response and Ablation Mechanisms of Molybdenum Disulfide under Intense Femtosecond Laser Irradiation. Light Sci. Appl. 2020, 9, 80. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Rueda, J.; Siegel, J.; García-Lechuga, M.; Solis, J. Femtosecond Laser-Induced Refractive Index Changes at the Surface of Dielectrics: Quantification Based on Newton Ring Analysis. JOSA B 2014, 31, 1676–1683. [Google Scholar] [CrossRef]

- Berkdemir, A.; Gutiérrez, H.R.; Botello-Méndez, A.R.; Perea-López, N.; Elías, A.L.; Chia, C.-I.; Wang, B.; Crespi, V.H.; López-Urías, F.; Charlier, J.-C. Identification of Individual and Few Layers of WS2 Using Raman Spectroscopy. Sci. Rep. 2013, 3, 1755. [Google Scholar] [CrossRef]

- Zhou, P.; Xu, Q.; Li, H.; Wang, Y.; Yan, B.; Zhou, Y.; Chen, J.; Zhang, J.; Wang, K. Fabrication of Two-Dimensional Lateral Heterostructures of WS2/WO3 H2O Through Selective Oxidation of Monolayer WS2. Angew. Chemie 2015, 127, 15441–15445. [Google Scholar] [CrossRef]

- Sundberg, J.; Lindblad, R.; Gorgoi, M.; Rensmo, H.; Jansson, U.; Lindblad, A. Understanding the Effects of Sputter Damage in W–S Thin Films by HAXPES. Appl. Surf. Sci. 2014, 305, 203–213. [Google Scholar] [CrossRef]

- Gutiérrez, H.R.; Perea-López, N.; Elías, A.L.; Berkdemir, A.; Wang, B.; Lv, R.; López-Urías, F.; Crespi, V.H.; Terrones, H.; Terrones, M. Extraordinary Room-Temperature Photoluminescence in Triangular WS2 Monolayers. Nano Lett. 2013, 13, 3447–3454. [Google Scholar] [CrossRef]

- Sze, S.M.; Li, Y.; Ng, K.K. Physics of Semiconductor Devices; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Aftab, S.; Khan, M.F.; Min, K.-A.; Nazir, G.; Afzal, A.M.; Dastgeer, G.; Akhtar, I.; Seo, Y.; Hong, S.; Eom, J. Van Der Waals Heterojunction Diode Composed of WS2 Flake Placed on P-Type Si Substrate. Nanotechnology 2017, 29, 45201. [Google Scholar] [CrossRef]

- Lan, C.; Li, C.; Wang, S.; He, T.; Jiao, T.; Wei, D.; Jing, W.; Li, L.; Liu, Y. Zener Tunneling and Photoresponse of a WS2/Si van Der Waals Heterojunction. ACS Appl. Mater. Interfaces 2016, 8, 18375–18382. [Google Scholar] [CrossRef]

- Hao, L.; Liu, Y.; Gao, W.; Han, Z.; Xue, Q.; Zeng, H.; Wu, Z.; Zhu, J.; Zhang, W. Electrical and Photovoltaic Characteristics of MoS2/Si Pn Junctions. J. Appl. Phys. 2015, 117, 114502. [Google Scholar] [CrossRef]

- Iqbal, M.W.; Iqbal, M.Z.; Khan, M.F.; Shehzad, M.A.; Seo, Y.; Park, J.H.; Hwang, C.; Eom, J. High-Mobility and Air-Stable Single-Layer WS2 Field-Effect Transistors Sandwiched between Chemical Vapor Deposition-Grown Hexagonal BN Films. Sci. Rep. 2015, 5, 10699. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Chen, Z.; Wu, X.; Pan, C.; Wang, F.; Wang, J.; Zhang, K.; Yang, Y.; Sun, J. Ultrafast Mechanism of Material Removal in the Femtosecond Laser Ablation of WS2 and Its Diode Rectification Characteristics. Crystals 2023, 13, 832. https://doi.org/10.3390/cryst13050832

Wang K, Chen Z, Wu X, Pan C, Wang F, Wang J, Zhang K, Yang Y, Sun J. Ultrafast Mechanism of Material Removal in the Femtosecond Laser Ablation of WS2 and Its Diode Rectification Characteristics. Crystals. 2023; 13(5):832. https://doi.org/10.3390/cryst13050832

Chicago/Turabian StyleWang, Kai, Zhicheng Chen, Xu Wu, Changji Pan, Feifei Wang, Jiaxing Wang, Ke Zhang, Yang Yang, and Jingya Sun. 2023. "Ultrafast Mechanism of Material Removal in the Femtosecond Laser Ablation of WS2 and Its Diode Rectification Characteristics" Crystals 13, no. 5: 832. https://doi.org/10.3390/cryst13050832

APA StyleWang, K., Chen, Z., Wu, X., Pan, C., Wang, F., Wang, J., Zhang, K., Yang, Y., & Sun, J. (2023). Ultrafast Mechanism of Material Removal in the Femtosecond Laser Ablation of WS2 and Its Diode Rectification Characteristics. Crystals, 13(5), 832. https://doi.org/10.3390/cryst13050832