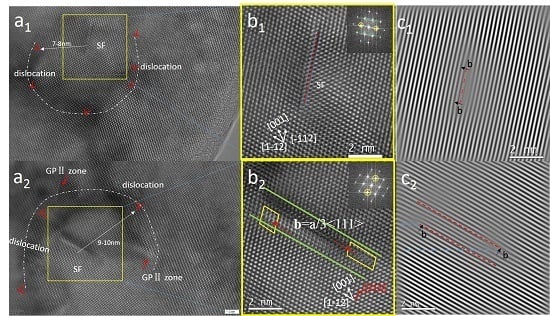

Stable Stacking Faults Bounded by Frank Partial Dislocations in Al7075 Formed through Precipitate and Dislocation Interactions

Abstract

:1. Introduction

2. Experimental Details

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liao, X.Z.; Zhou, F.; Lavernia, E.J.; He, D.W.; Zhu, Y.T. Deformation twins in nanocrystalline Al. Appl. Phys. Lett. 2003, 83, 5062–5064. [Google Scholar] [CrossRef]

- Yamakov, V.; Wolf, D.; Phillpot, S.R.; Gleiter, H. Deformation twinning in nanocrystalline Al by molecular dynamics simulation. Acta Mater. 2002, 50, 5005–5020. [Google Scholar] [CrossRef]

- Jin, S.B.; Zhang, K.; Bjorge, R.; Tao, N.R.; Marthinsen, K.; Lu, K.; Li, Y.J. Formation of incoherent deformation twin boundaries in a coarse-grained Al-7Mg alloy. Appl. Phys. Lett. 2015, 107, 091901. [Google Scholar] [CrossRef]

- Cao, B.; Daphalapurkar, N.P.; Ramesh, K.T. Ultra-high-strain-rate shearing and deformation twinning in nanocrystalline aluminum. Meccanica 2015, 50, 561–574. [Google Scholar] [CrossRef]

- Li, B.Q.; Sui, M.L.; Li, B.; Ma, E.; Mao, S.X. Reversible Twinning in Pure Aluminum. Phys. Rev. Lett. 2009, 102, 205504. [Google Scholar] [CrossRef] [PubMed]

- Han, W.Z.; Cheng, G.M.; Li, S.X.; Wu, S.D.; Zhang, Z.F. Deformation induced microtwins and stacking faults in aluminum single crystal. Phys. Rev. Lett. 2008, 101, 115505. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Wang, L.; Fan, D.; Bie, B.X.; Zhou, X.M.; Suo, T.; Li, Y.L.; Chen, M.W.; Liu, C.L.; Qi, M.L.; et al. Macrodeformation Twins in Single-Crystal Aluminum. Phys. Rev. Lett. 2016, 116. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.B.; Sui, M.L. Atomic-scale in situ observation of lattice dislocations passing through twin boundaries. Appl. Phys. Lett. 2009, 94, 021909. [Google Scholar] [CrossRef]

- Liao, X.Z.; Zhou, F.; Lavernia, E.J.; Srinivasan, S.G.; Baskes, M.I.; He, D.W.; Zhu, Y.T. Deformation mechanism in nanocrystalline Al: Partial dislocation slip. Appl. Phys. Lett. 2003, 83, 632–634. [Google Scholar] [CrossRef]

- Wu, X.L.; Li, B.; Ma, E. Vacancy clusters in ultrafine grained Al by severe plastic deformation. Appl. Phys. Lett. 2007, 91, 141908. [Google Scholar] [CrossRef]

- Yang, W.; Dong, R.; Jiang, L.; Wu, G.; Hussain, M. Unstable stacking faults in submicron/micron Al grammins in multi-SiCp/multi-Al nanocomposite. Vacuum 2015, 122, 1–5. [Google Scholar] [CrossRef]

- Monnet, G. New insights into radiation hardening in face-centered cubic alloys. Scr. Mater. 2015, 100, 24–27. [Google Scholar] [CrossRef]

- Zheng, Y.; Luo, B.; Bai, Z.; Wang, J.; Yin, Y. Study of the Precipitation Hardening Behaviour and Intergranular Corrosion of Al-Mg-Si Alloys with Differing Si Contents. Metals 2017, 7, 387. [Google Scholar] [CrossRef]

- Hu, T.; Ma, K.; Topping, T.D.; Schoenung, J.M.; Lavernia, E.J. Precipitation phenomena in an ultrafine-grained Al alloy. Acta Mater. 2013, 61, 2163–2178. [Google Scholar] [CrossRef]

- Berg, L.K.; Gjonnes, J.; Hansen, V.; Li, X.Z.; Knutson-Wedel, M.; Waterloo, G.; Schryvers, D.; Wallenberg, L.R. GP-zones in Al-Zn-Mg alloys and their role in artificial aging. Acta Mater. 2001, 49, 3443–3451. [Google Scholar] [CrossRef]

- Xu, P.; Luo, H. Improving the ductility of nanostructured Al alloy using strongly textured nano-laminated structure combined with nano-precipitates. Mater. Sci. Eng. A Struct. 2016, 675, 323–337. [Google Scholar] [CrossRef]

- Sha, G.; Cerezo, A. Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050). Acta Mater. 2004, 52, 4503–4516. [Google Scholar] [CrossRef]

- Kelly, A.; Nicholson, R.B. Precipitation hardening. Prog. Mater. Sci. 1963, 10, 151–391. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Luo, H.; Wang, H.; Xu, P.; Luo, J.; Liu, C.; Zhang, T. Stable Stacking Faults Bounded by Frank Partial Dislocations in Al7075 Formed through Precipitate and Dislocation Interactions. Crystals 2017, 7, 375. https://doi.org/10.3390/cryst7120375

Li S, Luo H, Wang H, Xu P, Luo J, Liu C, Zhang T. Stable Stacking Faults Bounded by Frank Partial Dislocations in Al7075 Formed through Precipitate and Dislocation Interactions. Crystals. 2017; 7(12):375. https://doi.org/10.3390/cryst7120375

Chicago/Turabian StyleLi, Sijie, Hongyun Luo, Hui Wang, Pingwei Xu, Jun Luo, Chu Liu, and Tao Zhang. 2017. "Stable Stacking Faults Bounded by Frank Partial Dislocations in Al7075 Formed through Precipitate and Dislocation Interactions" Crystals 7, no. 12: 375. https://doi.org/10.3390/cryst7120375

APA StyleLi, S., Luo, H., Wang, H., Xu, P., Luo, J., Liu, C., & Zhang, T. (2017). Stable Stacking Faults Bounded by Frank Partial Dislocations in Al7075 Formed through Precipitate and Dislocation Interactions. Crystals, 7(12), 375. https://doi.org/10.3390/cryst7120375