Structure Mediation and Properties of Poly(l-lactide)/Poly(d-lactide) Blend Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PLLA/PDLA Blend Fibers

2.3. Measurements

3. Results

3.1. The Initial Structure of PLLA/PDLA As-Spun Fibers

3.2. Crystal Formation of Fibers with Different Initial Structures during Heating and Cooling Process

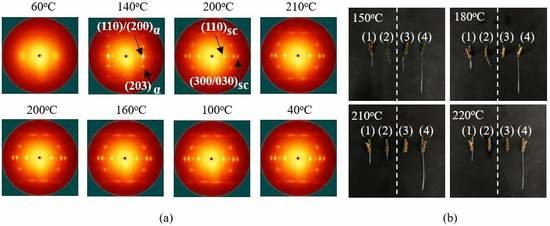

3.3. Effect of Annealing Temperature on Crystallization of PLLA/PDLA Blend Fibers

3.4. Heat-Resistant Properties of PLLA/PDLA Blend Fibers

4. Conclusions

Reference

Author Contributions

Funding

Conflicts of Interest

References

- Wang, D.Y.; Gohs, U.; Kang, N.J.; Leuteritz, A.; Boldt, R.; Wagenknecht, U.; Heinrich, G. Method for simultaneously improving the thermal stability and mechanical properties of poly(lactic acid): Effect of high-energy electrons on the morphological, mechanical, and thermal properties of PLA/MMT nanocomposites. Langmuir 2012, 28, 12601–12608. [Google Scholar] [CrossRef]

- Zhao, X.M.; Guerrero, F.R.; Llorca, J.; Wang, D.Y. A new super-efficiently flame-retardant bioplastic-poly (lactic acid): Flammability, thermal decomposition behavior and tensile properties. ACS Sustain. Chem. Eng. 2016, 4, 201–209. [Google Scholar] [CrossRef]

- Liu, G.M.; Zhang, X.Q.; Wang, D.J. Tailoring crystallization: Towards high-performance poly(lactic acid). Adv. Mater. 2014, 26, 6905–6911. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Q.; Jiang, X.Z.; Liu, G.M.; Liu, Y.A.; Wang, R.; Wang, D.J. Effcet of orientation on crystallization behavior of poly(l-lactide acid)/poly(d-lactide acid) fibers. Acta Polym. Sin. 2014, 1048–1055. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkarc, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Desanties, P.; Kovacs, A.J. Oligoethylene-end-capped polylactides. Biopolymers 1968, 6, 299–306. [Google Scholar] [CrossRef]

- Pan, P.; Liang, Z.; Cao, A.; Inoue, Y. Layered metal phosphonate reinforced poly(l-lactide) composites with a highly enhanced crystallization rate. ACS Appl. Mater. Interfaces 2009, 1, 402–411. [Google Scholar] [CrossRef]

- Bibi, G.; Jung, Y.M.; Lim, J.C.; Kim, S.H. Fully biobased robust biocomposites of PLA with assisted nucleation by monodispersed stereocomplexed polylactide particles. RSC Adv. 2016, 6, 111129–111138. [Google Scholar] [CrossRef]

- Mitomo, H.; Kaneda, A.; Quynh, T.M.; Nagasawa, N.; Yoshii, F. Improvement of heat stability of poly(l-lactic acid) by radiation-induced crosslinking. Polymer 2005, 46, 4695–4703. [Google Scholar] [CrossRef]

- Bai, H.; Liu, H.; Bai, D.; Zhang, Q.; Wang, K.; Deng, H.; Chen, F.; Fu, Q. Enhancing the melt stability of polylactide stereocomplexes using a solid-state cross-linking strategy during a melt-blending process. Polym. Chem. 2014, 5, 5985–5993. [Google Scholar] [CrossRef]

- Rahman, N.; Kawai, T.; Matsuba, G.; Nishida, K.; Kanaya, T.; Watanabe, H.; Okamoto, H.; Kato, M.; Usuki, A.; Matsuda, M. Effect of polylactide stereocomplex on the crystallization behavior of poly(l-lactic acid). Macromolecules 2009, 42, 4739–4745. [Google Scholar] [CrossRef]

- Schmidt, S.C.; Hillmyer, M.A. Morphological behavior of model poly(ethylene-alt-propylene)-b-polylactide diblock copolymers. J. Polym. Sci. Polym. Phys. 2015, 39, 300–313. [Google Scholar] [CrossRef]

- Ikada, Y.; Jamshidi, K.; Tsuji, H.; Hyon, S.H. Stereocomplex formation between enantiomeric poly(lactides). Macromolecules 1987, 20, 904–906. [Google Scholar] [CrossRef]

- Tsuji, H. Poly(lactide) stereocomplexes: Formation, structure, properties, degradation, and applications. Macromol. Biosci. 2005, 5, 569–597. [Google Scholar] [CrossRef] [PubMed]

- Fukushima, K.; Kimura, Y. Stereocomplexed polylactides (Neo-PLA) as high-performance bio-based polymers: Their formation, properties, and application. Polym. Int. 2006, 55, 626–642. [Google Scholar] [CrossRef]

- Zhu, J.; Na, B.; Lv, R.; Li, C. Enhanced stereocomplex formation of high-molecular-weight polylactides by gelation in an ionic liquid. Polym. Int. 2014, 63, 1101–1104. [Google Scholar] [CrossRef]

- Shao, J.; Xiang, S.; Bian, X.; Sun, J.; Li, G.; Chen, X. Remarkable melting behavior of PLA stereocomplex in linear PLLA/PDLA blends. Ind. Eng. Chem. Res. 2015, 54, 2246–2253. [Google Scholar] [CrossRef]

- Ahmed, J.; Varshney, S.K.; Janvier, F. Rheological and thermal properties of stereocomplexed polylactide films. J. Therm. Anal. Calorim. 2013, 115, 2053–2061. [Google Scholar] [CrossRef]

- Takasaki, M.; Ito, H.; Kikutani, T. Development of stereocomplex crystal of polylactide in high-speed melt spinning and subsequent drawing and annealing processes. J. Macromol. Sci. B 2003, 42, 403–420. [Google Scholar] [CrossRef]

- Furuhashi, Y.; Kimura, Y.; Yamane, H. Higher order structural analysis of stereocomplex-type poly(lactic acid) melt-spun fibers. J. Polym. Sci. B Polym. Phys. 2007, 45, 218–228. [Google Scholar] [CrossRef]

- Furuhashi, Y.; Kimura, Y.; Yoshie, N.; Yamane, H. Higher-order structures and mechanical properties of stereocomplex-type poly(lactic acid) melt spun fibers. Polymer 2006, 47, 5965–5972. [Google Scholar] [CrossRef]

- Tsuji, H.; Tezuka, Y. Stereocomplex formation between enantiomeric poly(lactic acid)s. 12. spherulite growth of low-molecular-weight poly(lactic acid)s from the melt. Biomacromolecules 2004, 5, 1181–1186. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Lian, F.; Ma, Z.K.; Liang, J.Y. Effects of deformation-induced orientation on cyclization and oxidation of polyacrylonitrile fibers during stabilization process. Chinese. J. Polym. Sci. 2012, 30, 786–795. [Google Scholar] [CrossRef]

- Tsuji, H.; Nakano, M.; Hashimoto, M.; Takashima, K.; Katsura, S.; Mizuno, A. Electrospinning of poly(lactic acid) stereocomplex nanofibers. Biomacromolecules 2006, 7, 3316–3320. [Google Scholar] [CrossRef] [PubMed]

- Tsuji, H.; Ikada, Y.; Hyon, S.H.; Kimura, Y.; Kitao, T. Stereocomplex formation between enantiomeric poly(lactic acid). VIII. complex fibers spun from mixed solution of poly(d-lactic acid) and poly(l-lactic acid). J. Appl. Polym. Sci. 1994, 51, 337–344. [Google Scholar] [CrossRef]

- Zhang, J.M.; Tashiro, K.; Tsuji, H.; Domb, A.J. Investigation of phase transitional behavior of poly(l-lactide)/poly(d-lactide) blend used to prepare the highly-oriented stereocomplex. Macromolecules 2007, 40, 1049–1054. [Google Scholar] [CrossRef]

- Fujita, M.; Sawayanagi, T.; Abe, H.; Tanaka, T.; Iwata, T.; Ito, K.; Fujisawa, T.; Maeda, M. Stereocomplex formation through reorganization of poly(l-lactic acid) and poly(d-lactic acid) crystals. Macromolecules 2008, 41, 2852–2858. [Google Scholar] [CrossRef]

- Na, B.; Zhu, J.; Lv, R.; Ju, Y.H.; Tian, R.P.; Chen, B. Stereocomplex formation in enantiomeric polylactides by melting recrystallization of homocrystals: Crystallization kinetics and crystal morphology. Macromolecules 2013, 47, 347–352. [Google Scholar] [CrossRef]

- Barbosa, P.; Campos, J.M.; Turygin, A.; Shur, V.Y. Piezoelectric poly (lactide) stereocomplexes with a cholinium organic ionic plastic crystal. J. Mater. Chem. C 2017, 46, 12134–12142. [Google Scholar] [CrossRef]

- Li, W.; Wu, X.M.; Chen, X.Y.; Fan, Z.Y. The origin of memory effect in stereocomplex poly (lactic acid) crystallization from melt state. Eur. Polym. J. 2017, 89, 241–248. [Google Scholar] [CrossRef]

- Xie, Y.; Lan, X.R.; Bao, R.Y.; Lei, Y.; Cao, Z.Q.; Yang, M.B.; Yang, W.; Wang, Y.B. High-performance porous polylactide stereocomplex crystallite scaffolds prepared by solution blending and salt leaching. Mater. Sci. Eng. C-Mater. 2018, 90, 602–609. [Google Scholar] [CrossRef] [PubMed]

- Tsuji, H.; Yamamoto, S. Enhanced stereocomplex crystallization of biodegradable enantiomeric poly(lactic acid)s by repeated casting. Macromol. Mater. Eng. 2011, 296, 583–589. [Google Scholar] [CrossRef]

- Hermans, P.H.; Platzek, P. Beiträge zur Kenntnis des Deformations mechanismus und der Feinstruktur von hydratzellulose. Colloid Polym. Sci. 1939, 88, 68–72. [Google Scholar] [CrossRef]

- Zhang, J.M.; Tashiro, K.; Tsuji, H.; Domb, A.J. Disorder-to-order Phase transition and multiple melting behavior of poly(l-lactide) investigated by simultaneous measurements of WAXD and DSC. Macromolecules 2008, 41, 1352–1357. [Google Scholar] [CrossRef]

- Xiang, S.; Jun, S.; Li, G.; Bian, X.C.; Feng, L.D.; Chen, X.S.; Liu, F.Q.; Huang, S.Y. Effects of molecular weight on the crystallization and melting behaviors of poly(l-lactide). Chin. J. Polym. Sci. 2016, 34, 69–76. [Google Scholar] [CrossRef]

- Pan, P.J.; Kai, W.H.; Zhu, B.; Dong, T.; Inoue, Y. Polymorphous crystallization and multiple melting behavior of poly(l-lactide): Molecular weight dependence. Macromolecules 2007, 40, 6898–6905. [Google Scholar] [CrossRef]

- Sawai, D.; Tsugane, Y.; Tamada, M.; Kanamoto, T.; Sungil, M.; Hyon, S.H. Crystal density and heat of fusion for a stereo-complex of poly(l-lactic acid) and poly(d-lactic acid). J. Polym. Sci. Polym. Phys. 2007, 45, 2632–2639. [Google Scholar] [CrossRef]

- Yin, Y.A.; Song, Y.; Xiong, Z.J.; Zhang, X.Q.; Vos, S.D.; Wang, R.Y.; Joziasse, C.A.P.; Liu, G.M.; Wang, D.J. Effect of the melting temperature on the crystallization behavior of a poly(l-lactide)/poly(d-lactide) equimolar mixture. J. Appl. Polym. Sci. 2016, 133, 1301–1309. [Google Scholar] [CrossRef]

- Sun, J.; Yu, H.; Zhuang, X.; Chen, X.; Jing, X. Crystallization behavior of asymmetric PLLA/PDLA blends. J. Phys. Chem. B 2011, 115, 2864–2869. [Google Scholar] [CrossRef]

- Bao, R.Y.; Yang, W.; Jiang, W.R.; Liu, Z.Y.; Xie, B.H.; Yang, M.B.; Fu, Q. Stereocomplex formation of high-molecular-weight polylactide: A low temperature approach. Polymer 2012, 53, 5449–5454. [Google Scholar] [CrossRef]

| Conditions | Code |

|---|---|

| 60 °C undrawn | PLLA/PDLA-60 |

| 60 °C drawn up to 2 times | PLLA/PDLA-60-2 |

| 80 °C undrawn | PLLA/PDLA-80 |

| 80 °C drawn up to 2 times | PLLA/PDLA-80-2 |

| 60 °C drawn up to 2 times, annealed at 210 °C | PLLA/PDLA-60-2-210 |

| 60 °C drawn up to 2 times, annealed at 215 °C | PLLA/PDLA-60-2-215 |

| Sample | X0min-A | X10min-A | X20min-A | Xα | Xsc |

|---|---|---|---|---|---|

| PLLA/PDLA-60 | 21 | 24 | 24 | 1.4 | 25 |

| PLLA/PDLA-60-2 | 20 | 21 | 20 | 4.9 | 32 |

| PLLA/PDLA-80 | 21 | 24 | 23 | 4.1 | 29 |

| PLLA/PDLA-80-2 | 19 | 22 | 21 | 5.2 | 29 |

| Sample | f(110)/(200)α | f(110)sc |

|---|---|---|

| PLLA/PDLA-60 | / | −0.15 |

| PLLA/PDLA-60-2 | −0.25 | −0.40 |

| PLLA/PDLA-80 | / | −0.13 |

| PLLA/PDLA-80-2 | −0.13 | −0.21 |

| T (°C) | Xα (%) | Xsc (%) | f(110)sc |

|---|---|---|---|

| 200 | 7.4 | 32 | −0.40 |

| 210 | 2.0 | 51 | −0.39 |

| 215 | 0.93 | 51 | −0.36 |

| Temperature (°C) | PLLA-130 (%) | PLLA/PDLA-60-2-210 (%) |

|---|---|---|

| 130 | 2.3 ± 0.4 | 0 |

| 140 | 9.3 ± 0.4 | 0 |

| 150 | 48 ± 0.6 | 0 |

| 160 | 71 ± 1.2 | 0 |

| 170 | 91 ± 1.2 | 0 |

| 180 | melt | 0 |

| 190 | melt | 0 |

| 200 | melt | 0 |

| 210 | melt | 27 ± 0.5 |

| 220 | melt | melt |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Wang, R.; Ma, H.-L.; Li, X.; Brünig, H.; Dong, Z.; Qi, Y.; Zhang, X. Structure Mediation and Properties of Poly(l-lactide)/Poly(d-lactide) Blend Fibers. Polymers 2018, 10, 1353. https://doi.org/10.3390/polym10121353

Yang B, Wang R, Ma H-L, Li X, Brünig H, Dong Z, Qi Y, Zhang X. Structure Mediation and Properties of Poly(l-lactide)/Poly(d-lactide) Blend Fibers. Polymers. 2018; 10(12):1353. https://doi.org/10.3390/polym10121353

Chicago/Turabian StyleYang, Bo, Rui Wang, Hui-Ling Ma, Xiaolu Li, Harald Brünig, Zhenfeng Dong, Yue Qi, and Xiuqin Zhang. 2018. "Structure Mediation and Properties of Poly(l-lactide)/Poly(d-lactide) Blend Fibers" Polymers 10, no. 12: 1353. https://doi.org/10.3390/polym10121353

APA StyleYang, B., Wang, R., Ma, H. -L., Li, X., Brünig, H., Dong, Z., Qi, Y., & Zhang, X. (2018). Structure Mediation and Properties of Poly(l-lactide)/Poly(d-lactide) Blend Fibers. Polymers, 10(12), 1353. https://doi.org/10.3390/polym10121353