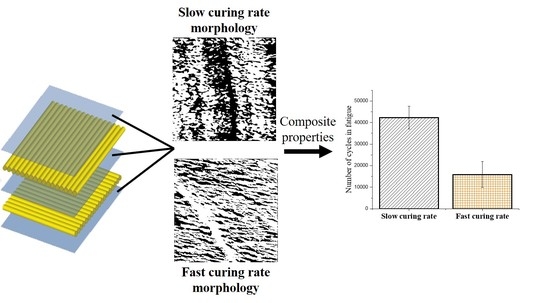

Effect of Curing Rate on the Microstructure and Macroscopic Properties of Epoxy Fiberglass Composites

Abstract

:1. Introduction

- Microgel particles, made up of uniformly cross-linked networks, nucleate and grow from the reacting polymeric network.

- These microgels begin to coalesce, to form less coherent clusters, which continue to interact with other microgel clusters.

- At gelation, the microgel clusters pack together to form a non-uniform, incoherent gel network with the partially reacted networks having a lower cross-link density, forming the dispersed phase.

2. Experimental

2.1. Materials

2.2. Instrumental Methods

2.2.1. Soxhlet Extraction

2.2.2. Differential Scanning Calorimetry (DSC)

2.2.3. Atomic Force Microscopy (AFM)

2.2.4. Thermal Gravimetric Analysis (TGA)

2.2.5. Dynamic Mechanical Analysis (DMA)

2.2.6. Static and Dynamic Flexural Testing

3. Results and Discussion

3.1. Probing the Microstructure

3.2. Composite Characterization

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fan, Z.; Santare, M.H.; Advani, S.G. Interlaminar shear strength of glass fiber reinforced epoxy composites enhanced with multi-walled carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2008, 39, 540–554. [Google Scholar] [CrossRef]

- Brøndsted, P.; Lilholt, H.; Lystrup, A. Composite Materials for Wind Power Turbine Blades. Annu. Rev. Mater. Res. 2005, 35, 505–538. [Google Scholar] [CrossRef]

- Pilato, L.A.; Michno, M.J. Phenolic Resins: A century of progress. In Advanced Composite Materials; Springer: Berlin/Heidelberg, Germany, 1994. [Google Scholar]

- Thwe, M.M.; Liao, K. Effects of environmental aging on the mechanical properties of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 43–52. [Google Scholar] [CrossRef]

- Latha, P.S.; Rao, M.V.; Kumar, V.K.; Raghavendra, G.; Ojha, S.; inala, R. Evaluation of mechanical and tribological properties of bamboo–glass hybrid fiber reinforced polymer composite. J. Ind. Text. 2016, 46, 3–18. [Google Scholar] [CrossRef]

- Akinyede, O.; Mohan, R.; Kelkar, A.; Sankar, J. Static and Fatigue Behavior of Epoxy/Fiberglass Composites Hybridized with Alumina Nanoparticles. J. Compos. Mater. 2009, 43, 769–781. [Google Scholar] [CrossRef]

- Birger, S.; Moshonov, A.; Kenig, S. Failure mechanisms of graphite-fabric epoxy composites subjected to flexural loading. Composites 1989, 20, 136–144. [Google Scholar] [CrossRef]

- Lucas, J.P. Delamination fracture: Effect of fiber orientation on fracture of a continuous fiber composite laminate. Eng. Fract. Mech. 1992, 42, 543–561. [Google Scholar] [CrossRef]

- Patel, A.; Maiorana, A.; Yue, L.; Gross, R.A.; Manas-Zloczower, I. Curing Kinetics of Biobased Epoxies for Tailored Applications. Macromolecules 2016, 49, 5315–5324. [Google Scholar] [CrossRef]

- Mijovic, J.; Fishbain, A.; Wijaya, J. Mechanistic modeling of epoxy-amine kinetics. 2. Comparison of kinetics in thermal and microwave fields. Macromolecules 1992, 25, 986–989. [Google Scholar] [CrossRef]

- Pascault, J.P.; Moschiar, S.M.; Williams, R.J.J. Buildup of Epoxycycloaliphatic Amine Networks. Kinetics, Vitrification, and Gelation. Macromelecules 1990, 23, 725–731. [Google Scholar] [CrossRef]

- Mijovic, J.; Fishbain, A.; Wijaya, J. Mechanistic modeling of epoxy-amine kinetics. 1. Model compound study. Macromolecules 1992, 25, 979–985. [Google Scholar] [CrossRef]

- Mijovic, J.; Wijayat, J. Reaction Kinetics of Epoxy/Amine Model Systems. The Effect of Electrophilicity of Amine Molecule. Macromolecules 1994, 27, 7589–7600. [Google Scholar] [CrossRef]

- Pollard, M.; Kardos, J.L. Analysis of epoxy resin curing kinetics using the Avrami theory of phase change. Polym. Eng. Sci. 1987, 27, 829–836. [Google Scholar] [CrossRef]

- Ivankovic, M.; Incarnato, L.; Kenny, J.M.; Nicolais, L. Curing kinetics and chemorheology of epoxy/anhydride system. J. Appl. Polym. Sci. 2003, 90, 3012–3019. [Google Scholar] [CrossRef]

- Cheng, K.C.; Chiu, W.Y.; Hsieh, K.H.; Ma, C.C.M. Chemorheology of epoxy resin Part I epoxy resin cured with tertiary amine. J. Mater. Sci. 1994, 29, 721–727. [Google Scholar] [CrossRef]

- Bogetti, T.A.; Gillespie, J.W., Jr. Process-Induced Stress and Deformation in Thick-Section Thermoset Composite Laminates. J. Compos. Mater. 1992, 26, 626–660. [Google Scholar] [CrossRef]

- Kravchenko, O.G.; Kravchenko, S.G.; Pipes, R.B. Chemical and thermal shrinkage in thermosetting prepreg. Compos. Part A Appl. Sci. Manuf. 2016, 80, 72–81. [Google Scholar] [CrossRef]

- Kravchenko, O.G.; Kravchenko, S.G.; Pipes, R.B. Cure history dependence of residual deformation in a thermosetting laminate. Compos. Part A Appl. Sci. Manuf. 2017, 99, 186–197. [Google Scholar] [CrossRef]

- Madhukar, M.S.; Genidy, M.S.; Russell, J.D. A New Method to Reduce Cure-Induced Stresses in Thermoset Polymer Composites, Part I: Test Method. J. Compos. Mater. 2000, 34, 1882–1904. [Google Scholar] [CrossRef]

- Morgan, R.J.; O’Neal, J.E. The microscopic failure processes and their relation to the structure of amine-cured bisphenol-A-diglycidyl ether epoxies. J. Mater. Sci. 1977, 12, 1966–1980. [Google Scholar] [CrossRef]

- Vanlandingham, M.R.; Eduljee, R.F.; Gillespie, J.W., Jr. Relationships between Stoichiometry, Microstructure, and Properties for Amine-Cured Epoxies. J. Appl. Polym. Sci. 1999, 71, 699–712. [Google Scholar] [CrossRef]

- Cuthrell, R.E. Epoxy polymers. II. Macrostructure. J. Appl. Polym. Sci. 1968, 12, 1263–1278. [Google Scholar] [CrossRef]

- Vanlandingham, M.R.; Eduljee, R.F.; Gillespie, J.W., Jr. Moisture diffusion in epoxy systems. J. Appl. Polym. Sci. 1999, 71, 787–798. [Google Scholar] [CrossRef]

- Palmese, G.R.; McCullough, R.L. Effect of epoxy-amine stoichiometry on cured resin material properties. J. Appl. Polym. Sci. 1992, 46, 1863–1873. [Google Scholar] [CrossRef]

- Palmese, G.R.; McCullough, R.L. Kinetic and thermodynamic considerations regarding interphase formation in thermosetting composite systems. J. Adhes. 1994, 44, 29–49. [Google Scholar] [CrossRef]

- Hale, A.; Macosko, C.W.; Bair, H.E. Glass transition temperature as a function of conversion in thermosetting polymers. Macromolecules 1991, 24, 2610–2621. [Google Scholar] [CrossRef]

- Gillham, J.K. Formation and Properties of Thermosetting and High Tg Polymeric Materials. Polym. Eng. Sci. 1986, 26, 1429–1433. [Google Scholar] [CrossRef]

- López, J.; Ramírez, C.; Torres, A.; Abad, M.J.; Barral, L.; Cano, J.; Díez, F.J. Isothermal curing by dynamic mechanical analysis of three epoxy resin systems: Gelation and vitrification. J. Appl. Polym. Sci. 2002, 83, 78–85. [Google Scholar] [CrossRef]

- Lange, J.; Altmann, N.; Kelly, C.T.; Halley, P.J. Understanding vitrification during cure of epoxy resins using dynamic scanning calorimetry and rheological techniques. Polymer 2000, 41, 5949–5955. [Google Scholar] [CrossRef]

- Chiou, P.-L.; Letton, A. Modelling the chemorheology of an epoxy resin system exhibiting complex curing behaviour. Polym. Eng. Sci. 1992, 33, 3925–3931. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Sbirrazzuoli, N. Mechanism and Kinetics of Epoxy-Amine Cure Studied by Differential Scanning Calorimetry. Macromolecules 1996, 29, 1867–1873. [Google Scholar] [CrossRef]

- Yue, L.; Maiorana, A.; Patel, A.; Gross, R.; Manas-Zloczower, I. A sustainable alternative to current epoxy resin matrices for vacuum infusion molding. Compos. Part A Appl. Sci. Manuf. 2017, 100, 269–274. [Google Scholar] [CrossRef]

- Nightingale, C.; Day, R.J. Flexural and interlaminar shear strength properties of carbon fibre/epoxy composites cured thermally and with microwave radiation. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1021–1030. [Google Scholar] [CrossRef]

| Curing Cycle | Weight before Drying (mg) | Weight after Drying (mg) | Percent Change in Weight (%) |

|---|---|---|---|

| Room temperature (RT) sample | 258.6 | 258.4 | 0.077 ± 0.002 |

| 70 sample | 176.7 | 176.2 | 0.275 ± 0.024 |

| 140 sample | 294.8 | 286.1 | 2.886 ± 0.212 |

| Sample | Storage Modulus at 40 °C (GPa) | Storage Modulus at 200 °C (GPa) | Tg (°C) | Flexural Modulus at 25 °C (GPa) | Flexural Strength at 25 °C (MPa) | Strain at Break (%) |

|---|---|---|---|---|---|---|

| RT + 70 + 140 | 13.8 ± 0.1 | 3.8 ± 0.3 | 165 | 20.6 ± 1.4 | 354 ± 17.7 | 1.9 ± 0.1 |

| 70 + 140 | 13.4 ± 0.1 | 3.7 ± 0.2 | 164 | 20.1 ± 0.6 | 350.4 ± 35.1 | 2 ± 0.2 |

| 140 | 12.5 ± 0.3 | 3.6 ± 0.4 | 165 | 20.2 ± 1.2 | 343.1 ± 41.0 | 2.1 ± 0.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, A.; Kravchenko, O.; Manas-Zloczower, I. Effect of Curing Rate on the Microstructure and Macroscopic Properties of Epoxy Fiberglass Composites. Polymers 2018, 10, 125. https://doi.org/10.3390/polym10020125

Patel A, Kravchenko O, Manas-Zloczower I. Effect of Curing Rate on the Microstructure and Macroscopic Properties of Epoxy Fiberglass Composites. Polymers. 2018; 10(2):125. https://doi.org/10.3390/polym10020125

Chicago/Turabian StylePatel, Ammar, Oleksandr Kravchenko, and Ica Manas-Zloczower. 2018. "Effect of Curing Rate on the Microstructure and Macroscopic Properties of Epoxy Fiberglass Composites" Polymers 10, no. 2: 125. https://doi.org/10.3390/polym10020125

APA StylePatel, A., Kravchenko, O., & Manas-Zloczower, I. (2018). Effect of Curing Rate on the Microstructure and Macroscopic Properties of Epoxy Fiberglass Composites. Polymers, 10(2), 125. https://doi.org/10.3390/polym10020125