In Situ Strain and Damage Monitoring of GFRP Laminates Incorporating Carbon Nanofibers under Tension

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Specimens

2.2. Measurement

2.2.1. Electrical Measurement

2.2.2. In Situ Monitoring Measurement

2.2.3. Microstructure Characterization

3. Results and Discussions

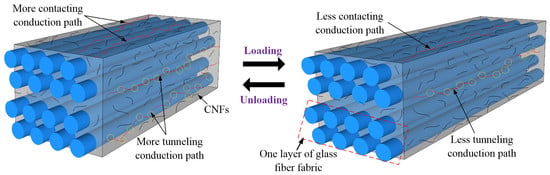

3.1. Electrical Properties of CNF/GFRP Laminates

3.2. In Situ Monitoring of CNF/GFRP Laminates

3.2.1. In Situ Damage Monitoring under Monotonic Tensile Loading

3.2.2. In Situ Strain Monitoring under Constant Amplitude Cyclic Tensile Loading

3.2.3. In Situ Monitoring under Incremental Amplitude Cyclic Tensile Loading

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Al-Sabagh, A.; Taha, E.; Kandil, U.; Awadallah, A.; Nasr, G.M.; Taha, M.R. Monitoring moisture damage propagation in GFRP composites using carbon nanoparticles. Polymers 2017, 9, 94. [Google Scholar] [CrossRef]

- Li, W.; He, D.; Dang, Z.; Bai, J. In-situ damage sensing in the glass fabric reinforced epoxy composites containing CNT-Al2O3 hybrids. Compos. Sci. Technol. 2014, 99, 8–14. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Ou, J. Mechanical behavior of BFRP-steel composite plate under axial tension. Polymers 2014, 6, 1862–1876. [Google Scholar] [CrossRef]

- Bai, Y.; Dai, J.; Teng, J. Buckling of steel reinforcing bars in FRP-confined RC columns: An experimental study. Constr. Build. Mater. 2017, 140, 403–415. [Google Scholar] [CrossRef]

- Mohammadi, T.; Wan, B.; Harries, K.A.; Sweriduk, M.E. Bond Behavior of FRP–Concrete in Presence of Intermediate Crack Debonding Failure. J. Compos. Constr. 2017, 21, 4017018. [Google Scholar] [CrossRef]

- Zhang, D.; Gu, X.; Yu, Q.; Huang, H.; Wan, B.; Jiang, C. Fully probabilistic analysis of FRP-to-concrete bonded joints considering model uncertainty. Compos. Struct. 2018, 185, 786–806. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, G.; Wan, B.; Lin, H.; Zhang, J. Behavior of innovative circular ice filled steel tubular stub columns under axial compression. Constr. Build. Mater. 2018, 171, 680–689. [Google Scholar] [CrossRef]

- Dai, J.; Bai, Y.; Teng, J. Behavior and Modeling of Concrete Confined with FRP Composites of Large Deformability. J. Compos. Constr. 2011, 15, 963–973. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saadie, S. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars. Corros. Sci. 2018, 138, 200–218. [Google Scholar] [CrossRef]

- Loutas, T.H.; Kostopoulos, V. Health monitoring of carbon/carbon, woven reinforced composites. Damage assessment by using advanced signal processing techniques. Part I: Acoustic emission monitoring and damage mechanisms evolution. Compos. Sci. Technol. 2009, 69, 265–272. [Google Scholar] [CrossRef]

- Hatta, H.; Aly-Hassan, M.S.; Hatsukade, Y.; Wakayama, S.; Suemasu, H.; Kasai, N. Damage detection of C/C composites using ESPI and SQUID techniques. Compos. Sci. Technol. 2005, 65, 1098–1106. [Google Scholar] [CrossRef]

- Gao, S.; Zhuang, R.; Zhang, J.; Liu, J.; Mader, E. Glass Fibers with Carbon Nanotube Networks as Multifunctional Sensors. Adv. Funct. Mater. 2010, 20, 1885–1893. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D.; Zhang, H.; Huang, L.; Yao, Y.; Li, G.; Mobasher, B. Mechanical characterization of the tensile properties of glass fiber and its reinforced polymer (GFRP) composite under varying strain rates and temperatures. Polymers 2016, 8, 196. [Google Scholar] [CrossRef]

- Shateri, M.; Ghaib, M.; Svecova, D.; Thomson, D. On acoustic emission for damage detection and failure prediction in fiber reinforced polymer rods using pattern recognition analysis. Smart Mater. Struct. 2017, 26, 1–24. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Ran, J.; Cao, M. Experimental investigation of a self-sensing hybrid GFRP-concrete bridge superstructure with embedded FBG sensors. Int. J. Distrib. Sens. Netw. 2012, 2012, 902613. [Google Scholar] [CrossRef]

- Ma, X.; Wei, G. Numerical prediction of effective electro-elastic properties of three-dimensional braided piezoelectric ceramic composites. Compos. Struct. 2017, 180, 420–428. [Google Scholar] [CrossRef]

- Wang, Y.; Chang, R.; Chen, G. Strain and damage self-sensing properties of carbon nanofibers/carbon fiber-reinforced polymer laminates. Adv. Mech. Eng. 2017, 9, 1–11. [Google Scholar] [CrossRef]

- Schueler, R.; Joshi, S.P.; Schulte, K. Damage detection in CFRP by electrical conductivity mapping. Compos. Sci. Technol. 2001, 61, 921–930. [Google Scholar] [CrossRef]

- Wang, X.; Chung, D.D.L. Continuous carbon fibre epoxy-matrix composite as a sensor of its own strain. Smart Mater. Struct. 1996, 5, 796–800. [Google Scholar] [CrossRef]

- Wang, S.; Chung, D.D.L. Self-sensing of flexural strain and damage in carbon fiber polymer-matrix composite by electrical resistance measurement. Carbon N. Y. 2006, 44, 2739–2751. [Google Scholar] [CrossRef]

- Wang, X.; Chung, D.D.L. Real-time monitoring of fatigue damage and dynamic strain in carbon fiber polymer-matrix composite by electrical resistance measurement. Smart Mater. Struct. 1997, 6, 504–508. [Google Scholar] [CrossRef]

- Xiao, H.; Song, G.; Li, H.; Sun, L. Improved Tensile Properties of Carbon Nanotube Modified Epoxy and Its Continuous Carbon Fiber Reinforced Composites. Polym. Compos. 2015, 36, 1664–1668. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.; Li, H.; Sun, L.; Pi, Z.; Waqar, G.Q.; Du, T.; Yu, L. Effects of nano-SiO2 on the permeability-related properties of cement-based composites with different water/cement ratios. J. Mater. Sci. 2018, 53, 4974–4986. [Google Scholar] [CrossRef]

- Li, W.; Long, C.; Tam, V.W.Y.; Poon, C.S.; Hui Duan, W. Effects of nano-particles on failure process and microstructural properties of recycled aggregate concrete. Constr. Build. Mater. 2017, 142, 42–50. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, M.; Wang, G. Anisotropic electrical and abrasion-sensing properties of cement-based composites containing aligned nickel powder. Cem. Concr. Compos. 2018, 87, 130–136. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Jaillet, C.; Zakri, C.; Poulin, P.; Kourkoulis, S.K. Improved strain sensing performance of glass fiber polymer composites with embedded pre-stretched polyvinyl alcohol-carbon nanotube fibers. Carbon 2013, 59, 65–75. [Google Scholar] [CrossRef]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Chou, T.-W. Sensing of Damage Mechanisms in Fiber-Reinforced Composites under Cyclic Loading using Carbon Nanotubes. Adv. Funct. Mater. 2009, 19, 123–130. [Google Scholar] [CrossRef]

- Gao, L.; Chou, T.W.; Thostenson, E.T.; Zhang, Z. A comparative study of damage sensing in fiber composites using uniformly and non-uniformly dispersed carbon nanotubes. Carbon 2010, 48, 3788–3794. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Wan, B.; Han, B.; Cai, G.; Li, Z. Properties and mechanisms of self-sensing carbon nanofibers/epoxy composites for structural health monitoring. Compos. Struct. 2018, 200, 669–678. [Google Scholar] [CrossRef]

- Nam, I.W.; Park, S.M.; Lee, H.K.; Zheng, L. Mechanical properties and piezoresistive sensing capabilities of FRP composites incorporating CNT fibers. Compos. Struct. 2017, 178, 1–8. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Bartholome, C.; Poulin, P.; Marioli-Riga, Z. Structural health monitoring of glass fiber reinforced composites using embedded carbon nanotube (CNT) fibers. Compos. Sci. Technol. 2010, 70, 260–271. [Google Scholar] [CrossRef]

- Nisha, M.S.; Singh, D. Manufacturing of Smart Nano Materials for structural Health Monitoring (SHM) in Aerospace application using CNT and CNF. J. Nano Res. 2016, 37, 42–50. [Google Scholar] [CrossRef]

- Kim, Y.K.; Lim, S.K.; Park, H.; Hoffmann, M.R.; Kim, S. Trilayer CdS/carbon nanofiber (CNF) mat/Pt-TiO2composite structures for solar hydrogen production: Effects of CNF mat thickness. Appl. Catal. B Environ. 2016, 196, 216–222. [Google Scholar] [CrossRef]

- Monteiro, A.O.; Loredo, A.; Costa, P.M.F.J.; Oeser, M.; Cachim, P.B. A pressure-sensitive carbon black cement composite for traffic monitoring. Constr. Build. Mater. 2017, 154, 1079–1086. [Google Scholar] [CrossRef]

- Yu, X. Intelligent Pavement for Traffic Flow Detection-Phase II. Resistivity Method; Intelligent Transportation Systems Institute, Center for Transportation Studies, University of Minnesota: Minneapolis, MN, USA, 2012. [Google Scholar]

- Allaoui, A.; Hoa, S.V.; Pugh, M.D. The electronic transport properties and microstructure of carbon nanofiber/epoxy composites. Compos. Sci. Technol. 2008, 68, 410–416. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.J.; Yu, W.R.; Lee, J.S.; Gao, L.; Thostenson, E.T.; Chou, T.W.; Byun, J.H. Damage characterization of 3D braided composites using carbon nanotube-based in situ sensing. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1531–1537. [Google Scholar] [CrossRef]

- Li, W.; Yuan, J.; Dichira, A.; Lin, Y.; Bai, J. The use of vertically aligned carbon nanotubes grown on SiC for in situ sensing of elastic and plastic deformation in electrically percolative epoxy composites. Carbon 2012, 50, 4291–4301. [Google Scholar] [CrossRef]

| Constant B | Critical Weight Fraction φc (wt %) | Critical Exponent t |

|---|---|---|

| 7.69 | 0.86 | 1.606 |

| Parameters | Input Range (%) | Output Range (%) | Gauge Factor | Linearity (%) | Repeatability (%) | Hysteresis (%) |

|---|---|---|---|---|---|---|

| L1.0 | 0–0.5 | 0–8.7 | 17.4 | 14.2 | 7.9 | 18.5 |

| L1.5 | 0–0.5 | 0–5.5 | 11.0 | 11.7 | 5.1 | 6.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, Y.; Han, B.; Wan, B.; Cai, G.; Chang, R. In Situ Strain and Damage Monitoring of GFRP Laminates Incorporating Carbon Nanofibers under Tension. Polymers 2018, 10, 777. https://doi.org/10.3390/polym10070777

Wang Y, Wang Y, Han B, Wan B, Cai G, Chang R. In Situ Strain and Damage Monitoring of GFRP Laminates Incorporating Carbon Nanofibers under Tension. Polymers. 2018; 10(7):777. https://doi.org/10.3390/polym10070777

Chicago/Turabian StyleWang, Yanlei, Yongshuai Wang, Baoguo Han, Baolin Wan, Gaochuang Cai, and Ruijuan Chang. 2018. "In Situ Strain and Damage Monitoring of GFRP Laminates Incorporating Carbon Nanofibers under Tension" Polymers 10, no. 7: 777. https://doi.org/10.3390/polym10070777

APA StyleWang, Y., Wang, Y., Han, B., Wan, B., Cai, G., & Chang, R. (2018). In Situ Strain and Damage Monitoring of GFRP Laminates Incorporating Carbon Nanofibers under Tension. Polymers, 10(7), 777. https://doi.org/10.3390/polym10070777