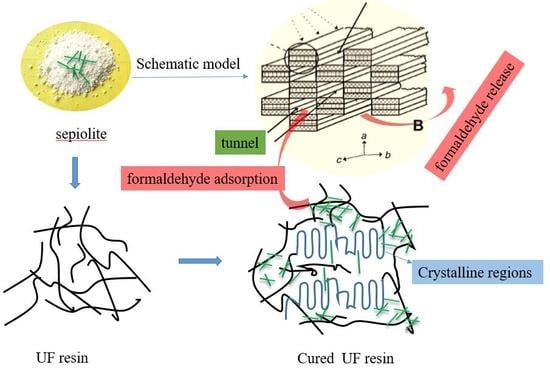

Urea Formaldehyde Resin Resultant Plywood with Rapid Formaldehyde Release Modified by Tunnel-Structured Sepiolite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of UF Resin

2.3. Preparation of Three-Ply Plywood

2.4. Wet Shear Strength Measurement

2.5. Formaldehyde Emission Measurement

2.6. Fourier-Transform Infrared (FTIR) Spectroscopy

2.7. Thermal Stability of Cured Resins

2.8. Scanning Electron Microscopy (SEM)

2.9. Water Contact Angle Tests

3. Results and Discussion

3.1. Wet Shear Strength Measurement

3.2. Formaldehyde Emission Measurement

3.3. FTIR Analysis

3.4. TG and DTG Analysis

3.5. SEM Analysis

3.6. Water Contact Angle Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jeong, B.; Park, B.D. Effect of molecular weight of urea-formaldehyde resins on their cure kinetics, interphase, penetration into wood, and adhesion in bonding wood. Wood Sci. Technol. 2019, 53, 665–685. [Google Scholar] [CrossRef]

- Pizzi, A.; George, B.; Zanetti, M.; Meausoone, P.J. Rheometry of aging of colloidal melamine-urea-formaldehyde polycondensates. J. Appl. Polym. Sci. 2005, 96, 655–659. [Google Scholar] [CrossRef]

- Jovanovic, V.; Samarzija-Jovanovic, S.; Petkovic, B.; Milicevic, Z.; Markovic, G.; Marinovic-Cincovic, M. Biocomposites based on cellulose and starch modified urea-formaldehyde resin: Hydrolytic, thermal, and radiation stability. Polym. Compos. 2019, 40, 1287–1294. [Google Scholar] [CrossRef]

- Park, B.D.; Jeong, H.W. Hydrolytic stability and crystallinity of cured urea-formaldehyde resin adhesives with different formaldehyde/urea mole ratios. Int. J. Adhes. Adhes. 2011, 31, 524–529. [Google Scholar] [CrossRef]

- Kim, M.G.; No, B.Y.; Lee, S.M.; Nieh, W.L. Examination of selected synthesis and room-temperature storage parameters for wood adhesive-type urea-formaldehyde resins by C-13-NMR spectroscopy. V. J. Appl. Polym. Sci. 2003, 89, 1896–1917. [Google Scholar] [CrossRef]

- Hse, C.Y.; Fu, F.; Pan, H. Melamine-modified urea formaldehyde resin for bonding particleboards. For. Prod. J. 2008, 58, 56–61. [Google Scholar]

- Kim, S.; Kim, H.J. Comparison of standard methods and gas chromatography method in determination of formaldehyde emission from MDF bonded with formaldehyde-based resins. Bioresour. Technol. 2005, 96, 1457–1464. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kaymakci, A. Reduction of formaldehyde emission from light MDF panels by adding chestnut shell flour. Holzforschung 2012, 66, 443–446. [Google Scholar] [CrossRef]

- Li, X.N.; Chen, M.S.; Zhang, J.Z.; Gao, Q.; Zhang, S.F.; Li, J.Z. Physico-Chemical Properties of Soybean Meal-Based Adhesives Reinforced by Ethylene Glycol Diglycidyl Ether and Modified Nanocrystalline Cellulose. Polymers 2017, 9, 463. [Google Scholar] [CrossRef]

- Liu, X.R.; Wang, K.L.; Gu, W.D.; Li, F.; Li, J.Z.; Zhang, S.F. Reinforcement of interfacial and bonding strength of soybean meal-based adhesive via kenaf fiber-CaCO3 anchored N-cyclohexyl-2-benzothiazole sulfenamide. Compos. Part B Eng. 2018, 155, 204–211. [Google Scholar] [CrossRef]

- Zheng, P.T.; Chen, N.R.; Islam, S.M.M.; Ju, L.K.; Liu, J.; Zhou, J.H.; Chen, L.Y.; Zeng, H.B.; Lin, Q.J. Development of Self-Cross-Linked Soy Adhesive by Enzyme Complex from Aspergillus niger for Production of All-Biomass Composite Materials. ACS Sustain. Chem. Eng. 2019, 7, 3909–3916. [Google Scholar] [CrossRef]

- Wu, Z.G.; Xi, X.D.; Lei, H.; Liang, J.K.; Liao, J.J.; Du, G.B. Study on Soy-Based Adhesives Enhanced by Phenol Formaldehyde Cross-Linker. Polymers 2019, 11, 365. [Google Scholar] [CrossRef]

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Mansouri, H.R.; Pizzi, A.; Leban, J.M. Improved water resistance of UF adhesives for plywood by small pMDI additions. Holz Roh-Und Werkst. 2006, 64, 218–220. [Google Scholar] [CrossRef]

- Doosthoseini, K.; Zarea-Hosseinabadi, H. Using Na+ MMT nanoclay as a secondary filler in plywood manufacturing. J. Indian Acad. Wood Sci. 2010, 7, 58–64. [Google Scholar] [CrossRef]

- Zhu, X.F.; Xu, E.G.; Lin, R.H.; Wang, X.B.; Gao, Z.Z. Decreasing the Formaldehyde Emission in Urea-Formaldehyde Using Modified Starch by Strongly Acid Process. J. Appl. Polym. Sci. 2014, 131, 40202. [Google Scholar] [CrossRef]

- Lei, H.; Du, G.; Pizzi, A.; Celzard, A.; Fang, Q. Influence of Nanoclay on Phenol-Formaldehyde and Phenol-Urea-Formaldehyde Resins for Wood Adhesives. J. Adhes. Sci. Technol. 2010, 24, 1567–1576. [Google Scholar] [CrossRef]

- Li, Z.F.; Wang, J.; Li, C.M.; Gu, Z.B.; Cheng, L.; Hong, Y. Effects of montmorillonite addition on the performance of starch-based wood adhesive. Carbohydr. Polym. 2015, 115, 394–400. [Google Scholar] [CrossRef]

- Kovacevic, Z.; Bischof, S.; Fan, M.Z. The influence of Spartium junceum L. fibres modified with montmorrilonite nanoclay on the thermal properties of PLA biocomposites. Compos. Part B Eng. 2015, 78, 122–130. [Google Scholar] [CrossRef]

- Li, X.N.; Luo, J.L.; Gao, Q.; Li, J.Z. A sepiolite-based united cross-linked network in a soybean meal-based wood adhesive and its performance. RSC Adv. 2016, 6, 45158–45165. [Google Scholar] [CrossRef]

- Li, H.Y.; Li, C.C.; Gao, Q.; Zhang, S.F.; Li, J.Z. Properties of soybean-flour-based adhesives enhanced by attapulgite and glycerol polyglycidyl ether. Ind. Crops Prod. 2014, 59, 35–40. [Google Scholar] [CrossRef]

- Kim, J.S.; Choi, M.C.; Jeong, K.M.; Kim, G.H.; Ha, C.S. Enhanced interaction in the polyimide/sepiolite hybrid films via acid activating and polydopamine coating of sepiolite. Polym. Adv. Technol. 2018, 29, 1404–1413. [Google Scholar] [CrossRef]

- Ruiz-Hitzky, E. Molecular access to intracrystalline tunnels of sepiolite. J. Mater. Chem. 2001, 11, 86–91. [Google Scholar] [CrossRef]

- Falco, G.; Giulieri, F.; Volle, N.; Pagnotta, S.; Sbirrazzuoli, N.; Disdier, E.P.; Mija, A. Self-organization of sepiolite fibbers in a biobased thermoset. Compos. Sci. Technol. 2019, 171, 226–233. [Google Scholar] [CrossRef]

- Chivrac, F.; Pollet, E.; Schmutz, M.; Averous, L. Starch nano-biocomposites based on needle-like sepiolite clays. Carbohydr. Polym. 2010, 80, 145–153. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Wang, X.M.; Zhang, S.F.; Gao, Q.; Li, J.Z. Effects of melamine addition stage on the performance and curing behavior of melamine-urea-formaldehyde (MUF) resin. Bioresources 2013, 8, 5500–5514. [Google Scholar] [CrossRef]

- Zhang, J. Synthesis, Structure, and Properties of Modified Urea-Formaldehyde Resins Based on Multiple Copolycondensation. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2015; pp. 34–45. [Google Scholar]

- Ding, W.B.; Li, W.Y.; Gao, Q.; Han, C.R.; Zhang, S.F.; Li, J.Z. The Effects of Sealing Treatment and Wood Species on Formaldehyde Emission of Plywood. Bioresources 2013, 8, 2568–2582. [Google Scholar] [CrossRef]

- He, Z.K.; Zhang, Y.P.; Wei, W.J. Formaldehyde and VOC emissions at different manufacturing stages of wood-based panels. Build. Environ. 2012, 47, 197–204. [Google Scholar] [CrossRef]

- Ye, J.; Qiu, T.; Wang, H.Q.; Guo, L.H.; Li, X.Y. Study of glycidyl ether as a new kind of modifier for urea-formaldehyde wood adhesives. J. Appl. Polym. Sci. 2013, 128, 4086–4094. [Google Scholar] [CrossRef]

- Tong, X.M.; Zhang, M.; Wang, M.S.; Fu, Y. Effects of surface modification of self-healing poly(melamine-urea-formaldehyde) microcapsules on the properties of unsaturated polyester composites. J. Appl. Polym. Sci. 2013, 127, 3954–3961. [Google Scholar] [CrossRef]

- Kandelbauer, A.; Despres, A.; Pizzi, A.; Taudes, I. Testing by Fourier transform infrared species variation during melamine-urea-formaldehyde resin preparation. J. Appl. Polym. Sci. 2007, 106, 2192–2197. [Google Scholar] [CrossRef]

- Zhao, Y.T.; He, M.; Zhao, L.; Wang, S.Q.; Li, Y.P.; Gan, L.; Li, M.M.; Xu, L.; Chang, P.R.; Anderson, D.P.; et al. Epichlorohydrin-cross-linked ydroxyethyl cellulose/soy protein isolate composite films as biocompatible and biodegradable implants for tissue engineering. ACS Appl. Mater. Interfaces 2016, 8, 2781–2795. [Google Scholar] [CrossRef]

- Roumeli, E.; Papadopoulou, E.; Pavlidou, E.; Vourlias, G.; Bikiaris, D.; Paraskevopoulos, K.M.; Chrissafis, K. Synthesis, characterization and thermal analysis of urea-formaldehyde/nanoSiO2 resins. Thermochim. Acta 2012, 527, 33–39. [Google Scholar] [CrossRef]

- Siimer, K.; Kaljuvee, T.; Pehk, T.; Lasn, I. Thermal behaviour of melamine-modified urea-formaldehyde resins. J. Therm. Anal. Calorim. 2010, 99, 755–762. [Google Scholar] [CrossRef]

- Turhan, Y.; Doǧan, M.; Alkan, M. Characterization and some properties of poly (vinyl chloride)/sepiolite nanocomposites. Adv. Polym. Technol. 2013, 32, E65–E82. [Google Scholar] [CrossRef]

- Can, M.F.; Avdan, L.; Bedeloglu, A.C. Properties of biodegradable PVA/sepiolite-based nanocomposite fiber mats. Polym. Compos. 2015, 36, 2334–2342. [Google Scholar] [CrossRef]

| Resin No. | SEP (%) | WF (g) | SEP (g) |

|---|---|---|---|

| A1 (0% SEP + 100% WF) | 0 | 25 | 0 |

| A2 (20% SEP + 80% WF) | 20 | 20 | 5 |

| A3 (40% SEP + 60% WF) | 40 | 15 | 10 |

| A4 (60% SEP + 40% WF) | 60 | 10 | 15 |

| A5 (80% SEP + 20% WF) | 80 | 5 | 20 |

| A6 (100% SEP + 0% WF) | 100 | 0 | 25 |

| Samples | Initial Formaldehyde Emission (mg/L) | After 30 Days (mg/L) | Decline Rate (%) |

|---|---|---|---|

| A1 | 1.24 | 1.03 | 16.9 |

| A2 | 0.79 | 0.65 | 17.7 |

| A3 | 0.82 | 0.63 | 23.2 |

| A4 | 0.95 | 0.69 | 27.4 |

| A5 | 1.50 | 0.58 | 61.3 |

| A6 | 1.71 | 1.44 | 15.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Gao, Q.; Xia, C.; Li, J.; Zhou, X. Urea Formaldehyde Resin Resultant Plywood with Rapid Formaldehyde Release Modified by Tunnel-Structured Sepiolite. Polymers 2019, 11, 1286. https://doi.org/10.3390/polym11081286

Li X, Gao Q, Xia C, Li J, Zhou X. Urea Formaldehyde Resin Resultant Plywood with Rapid Formaldehyde Release Modified by Tunnel-Structured Sepiolite. Polymers. 2019; 11(8):1286. https://doi.org/10.3390/polym11081286

Chicago/Turabian StyleLi, Xiaona, Qiang Gao, Changlei Xia, Jianzhang Li, and Xiaoyan Zhou. 2019. "Urea Formaldehyde Resin Resultant Plywood with Rapid Formaldehyde Release Modified by Tunnel-Structured Sepiolite" Polymers 11, no. 8: 1286. https://doi.org/10.3390/polym11081286

APA StyleLi, X., Gao, Q., Xia, C., Li, J., & Zhou, X. (2019). Urea Formaldehyde Resin Resultant Plywood with Rapid Formaldehyde Release Modified by Tunnel-Structured Sepiolite. Polymers, 11(8), 1286. https://doi.org/10.3390/polym11081286