Control of Macromolecule Chains Structure in a Nanofiber

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Instrumentation

2.3. Solution Preparation

2.4. Electrospinning Process

3. Results and Discussion

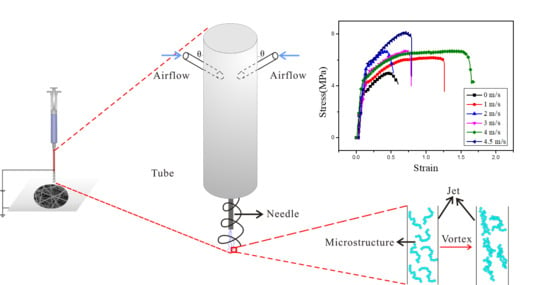

3.1. Air Vortex Electrospinning

3.1.1. Morphological Characterization (SEM)

3.1.2. Mechanical Property

3.1.3. Fourier Transform Infrared (FTIR) Spectroscopy

3.1.4. Gas Permeability

3.2. Different Air Vortex Strength

3.2.1. Morphological Characterization

3.2.2. Mechanical Property Test

3.2.3. Gas Permeability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Su, X. Research on flow field in a modified ring spinning system with the air nozzle. J. Text. Inst. 2016, 108, 1–12. [Google Scholar] [CrossRef]

- Zeng, Y.C.; Wan, Y.-Q.; Yu, C.W.; He, J.-H. Controlling the air vortex twist in air-jet spinning. Text. Res. J. 2005, 75, 175–177. [Google Scholar] [CrossRef]

- Zeng, Y.C.; Wang, K.F.; Yu, C.W. Predicting the tensile properties of air-jet spun yarns. Text. Res. J. 2004, 74, 689–694. [Google Scholar] [CrossRef]

- Basal, G.; Oxenham, W. Vortex spun yarn vs. air-jet spun yarn. Autex Res. J. 2003, 3, 96–101. [Google Scholar]

- Kim, H.A.; Kim, S.J. Mechanical properties of micro modal air vortex yarns and the tactile wear comfort of knitted fabrics. Fibers Polym. 2018, 19, 211–218. [Google Scholar] [CrossRef]

- Mo, Z.; Zhu, W.; Sun, Y.; Xiang, Q.; Zheng, M.; Chen, M.; Li, Z. One novel representation of DNA sequence based on the global and local position information. Sci. Rep. 2018, 8, 7592. [Google Scholar] [CrossRef]

- Galletto, R.; Jezewska, M.J.; Bujalowski, W. Unzipping mechanism of the double-stranded DNA unwinding by a hexameric helicase: Quantitative analysis of the rate of the dsDNA unwinding, processivity and kinetic step-size of the Escherichia coli DnaB helicase using rapid quench-flow method. J. Mol. Biol. 2004, 343, 83–99. [Google Scholar] [CrossRef]

- Tian, D.; Li, X.; He, J.-H. Self-assembly of macromolecules in a long and narrow tube. Science 2018, 22, 1659–1664. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, L.; Liu, B.; Zhu, L.; Shi, S.; Wang, X. Flexible, controllable, and high-strength near-infrared reflective Y2O3 nanofiber membrane by electrospinning a polyacetylacetone-yttrium precursor. Mater. Des. 2018, 160, 918–925. [Google Scholar] [CrossRef]

- Yu, D.-N.; Tian, D.; He, J.-H. Snail-based nanofibers. Mater. Lett. 2018, 220, 5–7. [Google Scholar] [CrossRef]

- Hai, T.; Wan, X.; Yu, D.-G.; Wang, K.; Yang, Y.; Liu, Z.-P. Electrospun lipid-coated medicated nanocomposites for an improved drug sustained-release profile. Mater. Des. 2019, 162, 70–79. [Google Scholar] [CrossRef]

- Jin, C.; Liu, X.; Liu, C.; Wang, Y.; Hwang, H.; Wang, Q. High-performance BCTZ nanowires-based energy harvesting device and self-powered bio-compatible flexion sensor. Mater. Des. 2018, 144, 55–63. [Google Scholar] [CrossRef]

- Seeram, R.; Fujihara, K.; Teo, W.E.; Yong, T.; Ma, Z.; Ramaseshan, R. Electrospun nanofibers: Solving global issues. Mater. Today 2006, 9, 40–50. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, J.; Huang, Z.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 2018, 126, 360–371. [Google Scholar] [CrossRef]

- Yao, Q.; Cosme, J.G.; Xu, T.; Miszuk, J.M.; Picciani, P.H.; Fong, H.; Sun, H. Three dimensional electrospun PCL/PLA blend nanofibrous scaffolds with significantly improved stem cells osteogenic differentiation and cranial bone formation. Biomaterials 2017, 115, 115–127. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.-Y.; Chang, C.-H.; Wang, C.-M.; Li, Y.-J.; Chu, H.-Y.; Chan, H.-H.; Huang, Y.-W.; Liao, W.-S. Large Area Nanoparticle Alignment by Chemical Lift-Off Lithography. Nanomaterials 2018, 8, 71. [Google Scholar] [CrossRef] [Green Version]

- Tian, D.; He, C.-H.; He, J.-H. Macromolecule Orientation in Nanofibers. Nanomaterials 2018, 8, 918. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kasahara, S.; Sato, Y.; Licciardello, S.; Čulo, M.; Arsenijević, S.; Ottenbros, T.; Tominaga, T.; Böker, J.; Eremin, I.; Shibauchi, T.; et al. Evidence for an Fulde-Ferrell-Larkin-Ovchinnikov State with Segmented Vortices in the BCS-BEC-Crossover Superconductor FeSe. Phys. Rev. Lett. 2020, 124, 107001. [Google Scholar] [CrossRef] [Green Version]

- Erdumlu, N.; Ozipek, B.; Oxenham, W. Vortex spinning technology. Text. Prog. 2012, 44, 141–174. [Google Scholar] [CrossRef]

- Yan, L.; Zou, Z.; Cheng, L.; Wei, G.; Tang, P. Numerical simulation of flow field in the twisting chamber of Murata vortex spinning based on the hollow spindle with different structures. Text. Res. J. 2018, 89, 645–656. [Google Scholar] [CrossRef]

- Shang, S.; Yang, J.; Yu, C. Numerical simulation of the airflow field in vortex spinning processing. Text. Res. J. 2018, 89, 1113–1127. [Google Scholar] [CrossRef]

- McKee, M.G.; Wilkes, G.L.; Colby, R.H.; Long, T.E. Correlations of solution rheology with electrospun fiber formation of linear and branched polyesters. Macromolecules 2004, 37, 1760–1767. [Google Scholar] [CrossRef]

- Gupta, P.; Elkins, C.; Long, T.E.; Wilkes, G.L. Electrospinning of linear homopolymers of poly(methyl methacrylate): Exploring relationships between fiber formation, viscosity, molecular weight and concentration in a good solvent. Polymers 2005, 46, 4799–4810. [Google Scholar] [CrossRef]

- Shenoy, S.L.; Bates, W.D.; Frisch, H.L.; Wnek, G.E. Role of chain entanglements on fiber formation during electrospinning of polymer solutions: Good solvent, non-specific polymer–polymer interaction limit. Polymers 2005, 46, 3372–3384. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, H.; Jia, R.; Dai, Y.; Dong, H.; Hou, H.; Guo, Q. High performance extrusion blown starch/polyvinyl alcohol/clay nanocomposite films. Food Hydrocoll. 2018, 79, 534–543. [Google Scholar] [CrossRef]

- Hadad, S.; Goli, S.A.H. Fabrication and characterization of electrospun nanofibers using flaxseed (Linum usitatissimum) mucilage. Int. J. Biol. Macromol. 2018, 114, 408–414. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Zhang, Y.; Gu, Y.; Zeng, Q. Flame retardant polyacrylonitrile fabrics prepared by organic-inorganic hybrid silica coating via sol-gel technique. Prog. Org. Coat. 2017, 112, 225–233. [Google Scholar] [CrossRef]

- Tsai, H.-A.; Wang, T.-Y.; Huang, S.-H.; Hu, C.-C.; Hung, W.-S.; Lee, K.-R.; Lai, J.-Y. The preparation of polyamide/polyacrylonitrile thin film composite hollow fiber membranes for dehydration of ethanol mixtures. Sep. Purif. Technol. 2017, 187, 221–232. [Google Scholar] [CrossRef]

- Song, Y.; Sun, Z.; Xu, L.; Shao, Z. Preparation and characterization of highly aligned carbon nanotubes/polyacrylonitrile composite nanofibers. Polymers 2017, 9, 1. [Google Scholar] [CrossRef] [Green Version]

- Li, X.W.; Kong, H.Y.; He, J.H. Study on highly filtration efficiency of electrospun polyvinyl alcohol micro-porous webs. Indian J. Phys. 2014, 89, 175–179. [Google Scholar] [CrossRef]

- Zhu, M.; Han, J.; Wang, F.; Shao, W.; Xiong, R.; Zhang, Q.; Pan, H.; Yang, Y.; Keshari Samal, S.; Zang, F.; et al. Electrospun nanofibers membranes for effective air filtration. Macromol. Mater. Eng. 2017, 302, 1600353. [Google Scholar] [CrossRef]

- Al-Attabi, R.; Morsi, Y.; Schütz, J.A.; Dumee, L.F. One-pot synthesis of catalytic molybdenum based nanocomposite nano-fiber membranes for aerosol air remediation. Sci. Total Environ. 2019, 647, 725–733. [Google Scholar] [CrossRef] [PubMed]

| Sample | Average Diameter (nm) | Standard Deviation (σ) (nm) | Confidence Interval (nm) |

|---|---|---|---|

| PVA | 178 | 21.8 | ±4.3 |

| PVA (vortex) | 163 | 24.5 | ±4.9 |

| PAN | 190 | 26.4 | ±7.1 |

| PAN (vortex) | 178 | 26.1 | ±9.0 |

| Sample | Pore Number | ||

|---|---|---|---|

| PVA | 1.17–1.4 | 1.27 | |

| PVA (vortex) | 0.817–4.83 | 0.907 | |

| PAN | 0.817–3.9 | 0.952 | |

| PAN (vortex) | 0.727–4.83 | 0.817 |

| Airflow Speed (m/s) | Average Diameter (nm) | Standard Deviation (σ) (nm) | Confidence Interval (nm) |

|---|---|---|---|

| 0 | 178 | 21.8 | ±4.3 |

| 1 | 163 | 24.5 | ±4.9 |

| 2 | 156 | 23.2 | ±4.5 |

| 3 | 137 | 19.6 | ±3.8 |

| 4 | 130 | 19.4 | ±3.8 |

| 4.5 | 107 | 15.4 | ±3.0 |

| Air Vortex Speed (m/s) | Pore Size | Average Pore Size | Pore Number |

|---|---|---|---|

| 0 | 1.17–1.4 | 1.27 | |

| 1 | 0.817–4.83 | 0.907 | |

| 2 | 0.637–4.83 | 0.817 | |

| 3 | 0.952–1.17 | 1.04 | |

| 4 | 1.14–1.42 | 1.27 | |

| 4.5 | 0.952–3.9 | 1.28 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, D.; He, J.-H. Control of Macromolecule Chains Structure in a Nanofiber. Polymers 2020, 12, 2305. https://doi.org/10.3390/polym12102305

Tian D, He J-H. Control of Macromolecule Chains Structure in a Nanofiber. Polymers. 2020; 12(10):2305. https://doi.org/10.3390/polym12102305

Chicago/Turabian StyleTian, Dan, and Ji-Huan He. 2020. "Control of Macromolecule Chains Structure in a Nanofiber" Polymers 12, no. 10: 2305. https://doi.org/10.3390/polym12102305

APA StyleTian, D., & He, J. -H. (2020). Control of Macromolecule Chains Structure in a Nanofiber. Polymers, 12(10), 2305. https://doi.org/10.3390/polym12102305