1. Introduction

Porous asphalt concrete (PAC) has been widely studied in recent years because it can better cope with the adverse effects of rainfall on traffic [

1,

2,

3,

4]. In addition to greatly reducing the risk of driving in rainy days [

5,

6,

7,

8], PAC also has good noise reduction performance [

9,

10,

11,

12] and heat absorption performance [

13,

14,

15,

16]. Although the permeable pavement paved by PAC has many good service performances, its comprehensive mechanical properties are worse than traditional dense graded asphalt mixtures (such as AC, SMA, etc.) due to its inherent large void structure characteristics [

17,

18]. Zeng et al. [

19] studied the effects of different aggregates and different modifiers on the performance of different asphalt mixtures (AC, SMA, PAC); their results showed that PACs are more prone to stripping. Wu et al. [

20] summarized the research results on open-graded friction course (OGFC) in recent years; they pointed out the reasons for the limited application of OGFC in a large range, and proposed future research directions. Xu et al. [

21] studied the permeability of different types of asphalt mixtures (AC, SMA, OGFC) under freeze-thaw cycles, and the results show that OGFC exhibits the worst water stability.

Aggregate is an important part of the solid phase of asphalt mixture, and its properties directly affect the performance of the mixture [

22,

23,

24,

25]. The natural stones commonly used in asphalt mixture aggregates include basalt, limestone, granite and so on [

26,

27,

28,

29]. Natural stones with excellent mechanical properties are good aggregates for preparing asphalt mixtures. However, the over-exploitation of natural stone in some areas has also caused some problems, such as a shortage of natural stone, environmental pollution and so on [

30,

31,

32]. Therefore, researchers began to seek a new type of pavement material with excellent engineering characteristics that can replace natural stones, such as industrial waste steel slag, oil shale, cinder, fly ash. It is worth noting that steel slag has been extensively studied due to its unique formation process and excellent engineering characteristics among alternative materials.

Liu et al. [

33] studied the feasibility of using steel slag in the pavement base, as well as the mechanical properties and durability of concrete with different steel slag content. In addition, the microstructure and element distribution of concrete were studied by scanning electron microscope (SEM) and energy dispersive X-ray spectroscopy (EDS). The results showed that concrete with 50% steel slag content had the best performance. Zhu et al. [

34] discussed the low-temperature crack resistance of PAC with different steel slag content, and used acoustic emission technology to monitor the splitting process of specimens in real time. It was found that the low-temperature crack resistance of PAC is significantly improved after using 100% steel slag. Hasita et al. [

35] studied the fatigue properties and creep properties of asphalt mixtures made of steel slag and the test results revealed that the fatigue life, elastic modulus and rut depth resistance of asphalt mixture made of steel slag are 1.6, 1.4, and 1.4 times higher than those of asphalt mixture made of natural aggregate, respectively. The above studies have shown that the application of steel slag in pavement materials has good engineering performance and has a large application space.

PAC has higher requirements for the viscosity of bitumen. High-viscosity bitumen can make aggregate and bitumen bond better, greatly increasing the mechanical properties of the mixture and the Cantabro particle loss resistance of pavement surface. As an excellent binder, SBS polymer modified bitumen has higher viscosity and better high temperature stability. In addition, the properties of PAC can be further improved by adding modifiers [

36,

37,

38]. Among commonly used modifiers, fibers and rubber powder modifiers have been extensively studied. Wang et al. [

39] studied the various properties of basalt fiber modified PACs; the analysis of a series of pavement performance experiments and micro-experiment results showed that the three-dimensional network system formed by basalt fibers in PAC significantly improves the mechanical properties of PAC. Cheng et al. [

40] optimized the amount of basalt fiber and rubber powder in PAC by the response surface method, and verified the improvement effect of basalt fiber and crumb rubber on the performance of the mixture through pavement performance experiments; its results paved the way for environmentally friendly road construction. Jiao et al. [

41] used acoustic emission technology to study the cracking characteristics of crumb rubber modified PAC. Their work showed that the crumb rubber and styrene–butadiene–styrene modified PAC has a more uniform force and a more stable internal structure; these results were found through the analysis of the results of splitting, compression experiments and acoustic emission parameters. The above studies have shown that fibers and crumb rubber are potentially good modifiers for asphalt mixtures.

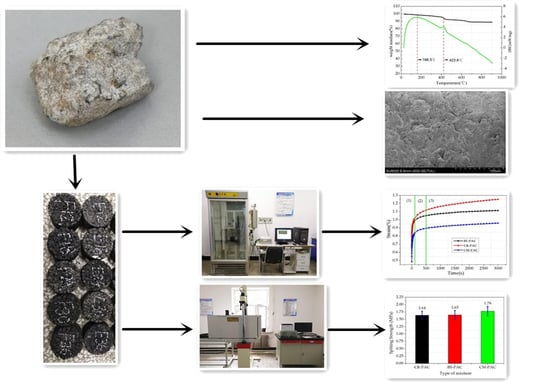

In summary, the purpose of this study is to analyze the mechanical properties of a new type of composite-modified PAC. First of all, from the perspective of environmental protection, steel slag was selected as an aggregate, and its physical and chemical properties were explored with modern instruments. Furthermore, the applicability of steel slag as aggregate is also discussed. Then, from the perspective of using modifiers, crumb rubber and basalt fiber were used as modifiers to further study the mechanical properties of SBS-modified PAC. Finally, a comprehensive study of the modified PAC is carried out through pavement performance experiments.

3. Results and Discussion

3.1. Analysis of Crush Value and Abrasion Value Results

Table 6 shows the results of the crush value and abrasion value of steel slag. It can be seen from the experimental results that the crush value and abrasion value are 15.1% and 13.5%, respectively; this meet the requirements of the specification [

44], which are less than 26% and 28%, respectively. This shows that the steel slag has good strength and wear resistance and can be used as the aggregate of the mixture for further research.

3.2. Analysis of SEM Test Results

Figure 7 shows the SEM results of different magnifications on the surface of the crude steel slag. It can be seen from

Figure 7a,b that when the minimum accurate identification length in the figure is 100 and 50.0 μm, the surface of the steel slag presents a very obvious disordered “peak and valley” shape, which is consistent with the macroscopic observation. Different from the smooth surface of natural aggregate, the surface of steel slag is very rough and uneven.

As shown in

Figure 7c,d, the minimum accurate identification lengths in the figure are 20.0 and 5 μm. It can be seen in

Figure 7c that the surface of the steel slag presents a fine porous structure, and the radius of the holes is about 10 μm.

Figure 7d shows the further enlargement effect of

Figure 7c.

It can be seen that the surface of the steel slag is uneven and exhibits obvious porous characteristics through the SEM pictures with different magnifications, which provides the basis for a good bonding effect with bitumen.

3.3. XRF Test Result Analysis

Table 7 shows the results of XRF of the steel slag used in this experiment. Among all the elements, the top five proportions from high to low are Ca (53.9%), Fe (21.2%), Mg (9.1%), Si (7.7%), and Al (2.3%). These five elements are mainly metal elements and account for 94.2% of all elements. From the perspective of oxides, the top five oxides are CaO (48.4%), Fe

2O

3 (17.7%), SiO

2 (12.2%), MgO (11.7%), and Al

2O

3 (3.3%). These five oxides also accounted for 93.3%. From the perspective of oxide composition, the steel slag has stable chemical properties, and chemical reactions are not prone to occur under normal temperature.

3.4. Analysis of SAT Test Results

Figure 8 shows the TG-DSC (thermogravimetric analysis-differential scanning calorimetry) curve of steel slag. It can be seen from the figure that when the experimental temperature reaches 166.5 °C, a large exothermic peak appears in the DSC curve, while the corresponding TG curve does not show a significant quality change, which shows that from the room temperature to 166.5 °C, the liquid water inside the steel slag was gradually evaporating, resulting in a slow decline in the quality of the sample. The evaporation continues until the temperature reaches 400 °C. When the experimental temperature reached 423.6 °C, another small exothermic peak appeared in the DSC curve, and the quality of the sample also appeared to undergo a more obvious drop at this time. This may be caused by the decomposition of crystal water inside the sample.

In summary, the chemical properties of steel slag are very stable before 400 °C. Generally, the mixing temperature of asphalt mixture does not exceed 180 °C. Therefore, from the perspective of thermal stability, steel slag is suitable as an aggregate of the asphalt mixture.

3.5. Analysis of Marshall Test Result

According to the Marshall test results in

Table 8, the air voids of the three types of PAC are all within 20%–22%. The air voids of CM-PAC are the smallest, with a value of 20.4%. The Marshall stability of the three modified PACs all meet the requirements of the specification, and the stability of CM-PAC is largest with a value of 8.94 kN. At the same time, the flow value of CM-PAC is also the largest.

The addition of crumb rubber and basalt fiber reduces the air voids of the CM-PAC. This is because the crumb rubber and the basalt fiber used in this experiment have smaller sizes, which occupy the voids of PAC to a certain extent. In addition, under the combined effect of crumb rubber viscosity increasing and basalt fiber structural bridging, the Marshall stability of CM-PAC has been significantly improved, and the flow value is the same.

3.6. Analysis of Freeze-Thaw Splitting Test Result

Table 9 shows the results of the freeze-thaw splitting test; it is found that these three modified PACs are all have values greater than 85%, which shows that all three PACs meet the minimum requirements of the specification. Specifically, the freeze-thaw splitting strength ratios of CR-PAC and BF-PAC are 88% and 89%, respectively. For CM-PAC, the freeze-thaw splitting strength ratio reached 92%, which reveals that under the combined action of crumb rubber and basalt fiber, the combination of bitumen and aggregate in PAC further improves the water stability of the mixture.

3.7. Analysis of Low-Temperature Splitting Test Result

Figure 9 shows the results of the low-temperature splitting test. Compared with CR-PAC and BF-PAC, the low-temperature splitting strength of CM-PAC is slightly improved. This shows that under the joint action of crumb rubber and basalt fiber, the low-temperature splitting load resistance of CM-PAC has been improved.

In addition, the failure stiffness modulus of BF-PAC and CM-PAC is significantly lower than that of CR-PAC, and their failure strain is obviously increased. This reveals that both of them are easier to deform under the condition of low-temperature splitting, and their ultimate deformation values have been significantly improved. The main reason is that the basalt fiber forms a three-dimensional network structure in PAC, which makes the force of the mixture more uniform. This reinforcement effect of this basalt fiber effectively improves the tensile properties of the mixture.

3.8. Analysis of Water Permeability Test Results

Table 10 shows water permeability test results of three PACs. It can be seen that the water permeability coefficient of CM-PAC is 0.287, which is somewhat reduced compared to the values of CR-PAC and BF-PAC, but still meets the requirements of the specification.

This difference in water permeability results occurs because the crumb rubber and basalt fiber are in powder form and fine crumb form, respectively. After being added to PAC, they fill in the voids to a certain extent.

3.9. Analysis of Creep Test Results

Figure 10 shows the creep test results of three PACs. From the “time–strain” diagram, these three types of PAC can be divided into three stages. The first stage is the rapid growth stage of strain. This stage is approximately from the beginning of the experiment to 120 s. In the second stage, the rate of strain gradually slowed down and this stage is mainly for the experiment to be carried out between 120 and 500 s. The third stage is the stable growth stage of strain; during this stage the deformation rate tends to be constant, and the strain shows a steady increasing trend. This stage continues until the end of the experiment. In addition, it can be seen from

Figure 10 that the strain of CM-PAC in all three stages is the smallest, and it can be considered that CM-PAC has the best high-temperature deformation resistance.

In order to quantify the deformation characteristics of the three PACs in the creep stage from the parameters, the creep results were fitted by a four-parameter Burgers model. The fitting results are shown in

Table 11.

It can be seen that the fitting coefficients of the three groups of PAC samples are not less than 0.94, which shows that the fitting effect is better. For the parameters E1 and η1, CM-PAC’s values are 0.43 and 4455.16, respectively, which are the largest among the three groups of PAC samples. This shows that under the same temperature and load conditions, the instantaneous deformation and permanent deformation of CM-PAC are the smallest. For the parameter τ, the value of CM-PAC is 17.72, which is the smallest among the three groups of PAC, which shows that the CM-PAC needs the shortest time during elastic deformation recovery process.

It can be seen that the high-temperature deformation resistance of CM-PAC is the best through the analysis of experimental results and Burgers fitting parameters. The application of crumb rubber can improve the elastic properties of the mixture to a certain extent. In addition, the “bridging” structure formed by basalt fiber in the mixture has a better force–transmission effect. The high- temperature performance of CM-PAC has been significantly improved under the joint modification of crumb rubber and basalt fiber.