On the Use of Biobased Waxes to Tune Thermal and Mechanical Properties of Polyhydroxyalkanoates–Bran Biocomposites

Abstract

:1. Introduction

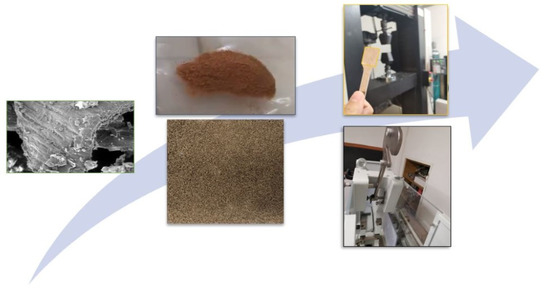

2. Materials and Methods

2.1. Materials and Processing

- PHBV (PHI002), by NaturePlast® (Caen, France), was used as matrix for the biocomposites. It is a polyhydroxybutyrate having 5 wt % of valerate content with a density of 1.25 g/cm3. It is a thermoplastic polymer with high crystallinity, due to his isotactic structure. Supplier data sheet reports a glass transition temperature, Tg, evaluated with differential scanning calorimetry (DSC), of 5 °C and a melting temperature, Tm, of 175 °C.

- Wheat bran was received ground by Barilla (Parma, Italy) and sieved with 250 μm mesh. The starch content of the sample used varies between 10 and 18%, also in accordance with literature data [37]. Bran was dried in a ventilated oven at 110 °C for about 24 h.

- Acetyl tributyl citrate (ATBC), supplied by Tecnosintesi® (Bergamo, Italy), was used as plasticizer. It is a biobased, biodegradable, colorless, odorless, and organic liquid. It has a density of 1.05 g/cm3 and a molecular weight of 402.5 g/mol.

- Calcium carbonate, CaCO3, (OMYACARB 1-AV) purchased from Omya® (Avenza/Carrara, Italy) was used as inorganic filler (average particle diameter of 1.6 μm) for guaranteeing the sample removal from the mold in the injection molding.

- Aquacer T561 (non-ionic aqueous emulsion of beeswax) and Aquacer T581 (non-ionic aqueous emulsion of carnauba wax) purchased from BYK (Wesel, Germany) were used to wet bran fibers to improve their adhesion with the matrix and dispersion in the matrix.

2.2. Testing Methods

3. Results and Discussion

3.1. Thermogravimetric Analysis

3.2. Morphology Analysis

3.3. Melt Flow Analysis

3.4. Mechanical Properties

Predictive Models for the Mechanical Properties

3.5. DSC Analysis

3.6. DMTA Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Biber, E.; Kelsey, N.; Meckling, J. The political economy of decarbonization: A research agenda. Brook. Law Rev. 2016, 82, 605. [Google Scholar]

- Pouton, C.W.; Akhtar, S. Biosynthetic polyhydroxyalkanoates and their potential in drug delivery. Adv. Drug Deliv. Rev. 1996, 18, 133–162. [Google Scholar] [CrossRef]

- Rivera-Briso, A.L.; Serrano-Aroca, Á. Poly (3-Hydroxybutyrate-co-3-Hydroxyvalerate): Enhancement strategies for advanced applications. Polymers (Basel) 2018, 10, 732. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, L.; McDonald, A.G. Peroxide induced cross-linking by reactive melt processing of two biopolyesters: Poly(3-hydroxybutyrate) and poly(l-lactic acid) to improve their melting processability. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Keskin, G.; Klzll, G.; Bechelany, M.; Pochat-Bohatier, C.; Öner, M. Potential of polyhydroxyalkanoate (PHA) polymers family as substitutes of petroleum based polymers for packaging applications and solutions brought by their composites to form barrier materials. Pure Appl. Chem. 2017, 89, 1841–1848. [Google Scholar] [CrossRef]

- Avella, M.; Martuscelli, E.; Raimo, M. Properties of blends and composites based on poly(3-hydroxy)butyrate (PHB) and poly(3-hydroxybutyrate-hydroxyvalerate) (PHBV) copolymers. J. Mater. Sci. 2000, 35, 523–545. [Google Scholar] [CrossRef]

- Jost, V.; Langowski, H.C. Effect of different plasticisers on the mechanical and barrier properties of extruded cast PHBV films. Eur. Polym. J. 2015, 68, 302–312. [Google Scholar] [CrossRef]

- Chu, L.; Wang, J. Denitrification of groundwater using PHBV blends in packed bed reactors and the microbial diversity. Chemosphere 2016, 155, 463–470. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A.K.; Sugie, T.; Takai, Y.; Hamada, H. Renewable resource based biocomposites from natural fiber and polyhydroxybutyrate-co-valerate (PHBV) bioplastic. Compos. Part A Appl. Sci. Manuf. 2008, 39, 875–886. [Google Scholar] [CrossRef]

- Gigante, V.; Seggiani, M.; Cinelli, P.; Signori, F.; Vania, A.; Navarini, L.; Amato, G.; Lazzeri, A. Utilization of coffee silverskin in the production of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) biopolymer-based thermoplastic biocomposites for food contact applications. Compos. Part A Appl. Sci. Manuf. 2020, 10, 106172. [Google Scholar]

- Seggiani, M.; Cinelli, P.; Balestri, E.; Mallegni, N.; Stefanelli, E.; Rossi, A.; Lardicci, C.; Lazzeri, A. Novel Sustainable Composites Based on Poly(hydroxybutyrate-co-hydroxyvalerate) and Seagrass Beach-CAST Fibers: Performance and Degradability in Marine Environments. Materials (Basel) 2018, 11, 772. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cinelli, P.; Seggiani, M.; Mallegni, N.; Gigante, V.; Lazzeri, A. Processability and Degradability of PHA-Based Composites in Terrestrial Environments. Int. J. Mol. Sci. 2019, 20, 284. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cinelli, P.; Mallegni, N.; Gigante, V.; Montanari, A.; Seggiani, M.; Coltelli, M.B.; Bronco, S.; Lazzeri, A. Biocomposites based on polyhydroxyalkanoates and natural fibers from renewable byproducts. Appl. Food Biotechnol. 2019, 6, 35–43. [Google Scholar]

- Batista, K.C.; Silva, D.A.K.; Coelho, L.A.F.; Pezzin, S.H.; Pezzin, A.P.T. Soil biodegradation of PHBV/peach palm particles biocomposites. J. Polym. Environ. 2010, 18, 346–354. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibers—A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef] [Green Version]

- Righetti, M.C.; Cinelli, P.; Mallegni, N.; Massa, C.A.; Bronco, S.; Stäbler, A.; Lazzeri, A. Thermal, mechanical, and rheological properties of biocomposites made of poly(Lactic acid) and potato pulp powder. Int. J. Mol. Sci. 2019, 20, 675. [Google Scholar] [CrossRef] [Green Version]

- Elanchezhian, C.; Ramnath, B.V.; Ramakrishnan, G.; Rajendrakumar, M.; Naveenkumar, V.; Saravanakumar, M.K. Review on mechanical properties of natural fiber composites. Mater. Today Proc. 2018, 5, 1785–1790. [Google Scholar] [CrossRef]

- Rahman, A.; Ulven, C.A.; Johnson, M.A.; Durant, C.; Hossain, K.G. Pretreatment of wheat bran for suitable reinforcement in biocomposites. J. Renew. Mater. 2017, 5, 62–73. [Google Scholar] [CrossRef]

- Caprez, A.; Arrigoni, E.V.A.; Amadò, R.; Neukom, H. Influence of different types of thermal treatment on the chemical composition and physical properties of wheat bran. J. Cereal Sci. 1986, 4, 233–239. [Google Scholar] [CrossRef]

- Taj, S.; Munawar, M.A.; Khan, S. Natural fiber-reinforced polymer composites. Proc. Pak. Acad. Sci. 2007, 44, 129. [Google Scholar]

- Rahman, A.; Ulven, C.A.; Durant, C.; Johnson, M.A.; Fehrenbach, J.; Hossain, K.G. Selection, pretreatment, and use of wheat bran for making thermoplastic composite. In Proceedings of the 2017 ASABE Annual International Meeting, Spokane, DC, USA, 16–19 July 2017; American Society of Agricultural and Biological Engineers: St Joseph, MI, USA, 2017; p. 1. [Google Scholar]

- El-Wakil, A.E.-A.A.; Moustafa, H.; Youssef, A.M. Antimicrobial low-density polyethylene/low-density polyethylene-grafted acrylic acid biocomposites based on rice bran with tea tree oil for food packaging applications. J. Thermoplast. Compos. Mater. 2020, 0892705720925140. [Google Scholar] [CrossRef]

- Fu, Z.; Wu, H.; Wu, M.; Huang, Z.; Zhang, M. Effect of Wheat Bran Fiber on the Behaviors of Maize Starch Based Films. Starch Stärke 2020, 72, 1900319. [Google Scholar] [CrossRef]

- Seggiani, M.; Cinelli, P.; Mallegni, N.; Balestri, E.; Puccini, M.; Vitolo, S.; Lardicci, C.; Lazzeri, A. New Bio-Composites Based on Polyhydroxyalkanoates and Posidonia oceanica Fibers for Applications in a Marine Environment. Materials (Basel) 2017, 10, 326. [Google Scholar] [CrossRef] [Green Version]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Studies on mechanical, thermal, and morphological characteristics of biocomposites from biodegradable polymer blends and natural fibers. In Biocomposites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 93–140. ISBN 9781782423737. [Google Scholar]

- Pandey, J.K.; Nagarajan, V.; Mohanty, A.K.; Misra, M. Biocomposites; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9781782423737. [Google Scholar]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G. A review on grafting of biofibers for biocomposites. Materials (Basel) 2016, 9, 303. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G.; Stark, N.M. Grafting of Bacterial Polyhydroxybutyrate (PHB) onto Cellulose via In Situ Reactive Extrusion with Dicumyl Peroxide. Biomacromolecules 2015, 16, 1040–1049. [Google Scholar] [CrossRef]

- Alam, A.K.M.M.; Beg, M.D.H.; Prasad, D.M.R.; Khan, M.R.; Mina, M.F. Structures and performances of simultaneous ultrasound and alkali treated oil palm empty fruit bunch fiber reinforced poly (lactic acid) composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1921–1929. [Google Scholar] [CrossRef] [Green Version]

- Herrera-Franco, P.; Valadez-Gonzalez, A.; Cervantes-Uc, M. Development and characterization of a HDPE-sand-natural fiber composite. Compos. Part B Eng. 1997, 28, 331–343. [Google Scholar] [CrossRef]

- Vilay, V.; Mariatti, M.; Taib, R.M.; Todo, M. Effect of fiber surface treatment and fiber loading on the properties of bagasse fiber–reinforced unsaturated polyester composites. Compos. Sci. Technol. 2008, 68, 631–638. [Google Scholar] [CrossRef]

- Righetti, M.C.; Cinelli, P.; Mallegni, N.; Massa, C.A.; Aliotta, L.; Lazzeri, A. Thermal, mechanical, viscoelastic and morphological properties of poly (lactic acid) based biocomposites with potato pulp powder treated with waxes. Materials (Basel) 2019, 12, 990. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.P.; del Mar Castro-López, M.; Rayón, E.; Barral-Losada, L.F.; López-Vilariño, J.M.; López, J.; González-Rodríguez, M.V. Plasticized poly (lactic acid)–poly (hydroxybutyrate)(PLA–PHB) blends incorporated with catechin intended for active food-packaging applications. J. Agric. Food Chem. 2014, 62, 10170–10180. [Google Scholar] [CrossRef]

- Ren, K.; Fei, T.; Metzger, K.; Wang, T. Coating performance and rheological characteristics of novel soybean oil-based wax emulsions. Ind. Crops Prod. 2019, 140, 111654. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elaya Perumal, A.; Arunsundaranayagam, D. Fiber surface treatment and its effect on mechanical and visco-elastic behaviour of banana/epoxy composite. Mater. Des. 2013, 47, 151–159. [Google Scholar] [CrossRef]

- Babu, C.R.; Ketanapalli, H.; Beebi, S.K.; Kolluru, V.C. Wheat bran-composition and nutritional quality: A review. Adv. Biotechnol. Microbiol. 2018, 9, 1–7. [Google Scholar]

- Satyanarayana, K.G.; Sukumaran, K.; Mukherjee, P.S.; Pavithran, C.; Pillai, S.G.K. Natural fiber-polymer composites. Cem. Concr. Compos. 1990, 12, 117–136. [Google Scholar] [CrossRef]

- Shenoy, A. V Rheology of Filled Polymer Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 9401592136. [Google Scholar]

- Gasner, G.E.; Bigio, D.; Marks, C.; Magnus, F.; Kiehl, C. A new approach to analyzing residence time and mixing in a co-rotating twin screw extruder. Polym. Eng. Sci. 1999, 39, 286–298. [Google Scholar] [CrossRef]

- Scaffaro, R.; Lopresti, F.; Botta, L. PLA based biocomposites reinforced with Posidonia oceanica leaves. Compos. Part B Eng. 2018, 139, 1–11. [Google Scholar] [CrossRef]

- Fiore, V.; Botta, L.; Scaffaro, R.; Valenza, A.; Pirrotta, A. PLA based biocomposites reinforced with Arundo donax fillers. Compos. Sci. Technol. 2014, 105, 110–117. [Google Scholar] [CrossRef]

- Gigante, V.; Cinelli, P.; Righetti, M.C.; Sandroni, M.; Tognotti, L.; Seggiani, M.; Lazzeri, A. Evaluation of Mussel Shells Powder as Reinforcement for PLA-Based Biocomposites. Int. J. Mol. Sci. 2020, 21, 5364. [Google Scholar] [CrossRef] [PubMed]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Agro-residue reinforced high-density polyethylene composites: Fiber characterization and analysis of composite properties. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1445–1454. [Google Scholar]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Sustainable Green Composites: Value Addition to Agricultural Residues and Perennial Grasses. ACS Sustain. Chem. Eng. 2013, 1, 325–333. [Google Scholar]

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable biodegradable coffee grounds filler and its effect on the hydrophobicity, mechanical and thermal properties of biodegradable PBAT composites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Aliotta, L.; Lazzeri, A. A proposal to modify the Kelly-Tyson equation to calculate the interfacial shear strength (IFSS) of composites with low aspect ratio fibers. Compos. Sci. Technol. 2020, 186, 107920. [Google Scholar]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar]

- Nicolais, L.; Narkis, M. Stress-strain behavior of styrene-acrylonitrile/glass bead composites in the glassy region. Polym. Eng. Sci. 1971, 11, 194–199. [Google Scholar]

- Nicolais, L.; Nicodemo, L. The effect of particles shape on tensile properties of glassy thermoplastic composites. Int. J. Polym. Mater. 1974, 3, 229–243. [Google Scholar]

- Pukánszky, B. Influence of interface interaction on the ultimate tensile properties of polymer composites. Composites 1990, 21, 255–262. [Google Scholar]

- Czerniecka, A.; Magoń, A.; Schliesser, J.; Woodfield, B.F.; Pyda, M. Heat capacity of poly (3-hydroxybutyrate). J. Chem. Thermodyn. 2014, 73, 76–84. [Google Scholar]

- Di Lorenzo, M.L.; Gazzano, M.; Righetti, M.C. The role of the rigid amorphous fraction on cold crystallization of poly (3-hydroxybutyrate). Macromolecules 2012, 45, 5684–5691. [Google Scholar]

- Signori, F.; Pelagaggi, M.; Bronco, S.; Righetti, M.C. Amorphous/crystal and polymer/filler interphases in biocomposites from poly (butylene succinate). Thermochim. Acta 2012, 543, 74–81. [Google Scholar] [CrossRef]

- Righetti, M.C.; Tombari, E.; Di Lorenzo, M.L. The Role of the Crystallization Temperature on the Nanophase Structure Evolution of Poly[(R)-3-hydroxybutyrate]. J. Phys. Chem. B 2013, 117, 12303–12311. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fiber reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Gatenholm, P.; Kubát, J.; Mathiasson, A. Biodegradable natural composites. I. Processing and properties. J. Appl. Polym. Sci. 1992, 45, 1667–1677. [Google Scholar] [CrossRef]

- Kubat, J.; Rigdahl, M.; Welander, M. Characterization of interfacial interactions in high density polyethylene filled with glass spheres using dynamic-mechanical analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G.; Freitag, C.; Morrell, J.J. Effects of wood fiber esterification on properties, weatherability and biodurability of wood plastic composites. Polym. Degrad. Stab. 2013, 98, 1348–1361. [Google Scholar] [CrossRef]

- Correa, C.A.; Razzino, C.A.; Hage, E. Role of Maleated Coupling Agents on the Interface Adhesion of Polypropylene—Wood Composites. J. Thermoplast. Compos. Mater. 2007, 20, 323–339. [Google Scholar] [CrossRef]

| Sample | PHBV | CaCO3 | ATBC | Bran | T561 Wax | T581 Wax |

|---|---|---|---|---|---|---|

| Polymeric Matrix (M) | 85 | 5 | 10 | - | - | - |

| M + 5 bran (B5) | 80.75 | 4.75 | 9.5 | 5 | - | - |

| M + 10 bran (B10) | 76.5 | 4.5 | 9 | 10 | - | - |

| M + 15 bran (B15) | 72.25 | 4.25 | 8.5 | 15 | - | - |

| M + 5 bran T561 (B5_T561) | 80.75 | 4.75 | 9.5 | 4.75 | 0.25 | - |

| M + 10 bran T561 (B10_T561) | 76.5 | 4.5 | 9 | 9.5 | 0.5 | - |

| M + 15 bran T561 (B15_ T561) | 72.25 | 4.25 | 8.5 | 14.25 | 0.75 | - |

| M + 5 bran T581 (B5_T581) | 80.75 | 4.75 | 9.5 | 4.75 | - | 0.25 |

| M + 10 bran T581 (B10_T581) | 76.5 | 4.5 | 9 | 9.5 | - | 0.5 |

| M + 15 bran T581 (B15_T581) | 72.25 | 4.25 | 8.5 | 14.25 | - | 0.75 |

| Sample | Δhm (J/g) | wC |

|---|---|---|

| M | 94 | 0.66 |

| B10 | 91 | 0.64 |

| B10_T561 | 93 | 0.65 |

| B10_T581 | 91 | 0.64 |

| Sample | Tg (°C) | E’ (MPa) | A (-) |

|---|---|---|---|

| M | 4 | 1912 | 0 |

| B10 | 9 | 2190 | −0.257 |

| B10_T561 | 8 | 2101 | −0.374 |

| B10_T581 | 8 | 2020 | −0.095 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gigante, V.; Cinelli, P.; Righetti, M.C.; Sandroni, M.; Polacco, G.; Seggiani, M.; Lazzeri, A. On the Use of Biobased Waxes to Tune Thermal and Mechanical Properties of Polyhydroxyalkanoates–Bran Biocomposites. Polymers 2020, 12, 2615. https://doi.org/10.3390/polym12112615

Gigante V, Cinelli P, Righetti MC, Sandroni M, Polacco G, Seggiani M, Lazzeri A. On the Use of Biobased Waxes to Tune Thermal and Mechanical Properties of Polyhydroxyalkanoates–Bran Biocomposites. Polymers. 2020; 12(11):2615. https://doi.org/10.3390/polym12112615

Chicago/Turabian StyleGigante, Vito, Patrizia Cinelli, Maria Cristina Righetti, Marco Sandroni, Giovanni Polacco, Maurizia Seggiani, and Andrea Lazzeri. 2020. "On the Use of Biobased Waxes to Tune Thermal and Mechanical Properties of Polyhydroxyalkanoates–Bran Biocomposites" Polymers 12, no. 11: 2615. https://doi.org/10.3390/polym12112615

APA StyleGigante, V., Cinelli, P., Righetti, M. C., Sandroni, M., Polacco, G., Seggiani, M., & Lazzeri, A. (2020). On the Use of Biobased Waxes to Tune Thermal and Mechanical Properties of Polyhydroxyalkanoates–Bran Biocomposites. Polymers, 12(11), 2615. https://doi.org/10.3390/polym12112615