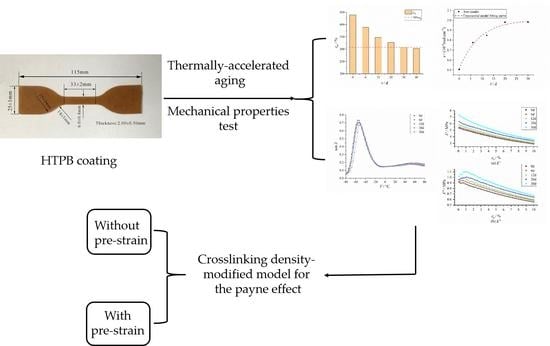

Influence of Thermally-Accelerated Aging on the Dynamic Mechanical Properties of HTPB Coating and Crosslinking Density-Modified Model for the Payne Effect

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thermal Accelerated Aging Test

2.3. Uniaxial Tensile Test

2.4. Low-field 1H NMR Crosslinking Density Test

2.5. Dynamic Mechanical Property Test

- (1)

- Dynamic temperature scanning. The temperature scanning range was −80 °C~80 °C. Liquid nitrogen was used for refrigeration. The heating rate was 3K/min, the strain amplitude was 0.1% and the loading frequency was 5 Hz;

- (2)

- Pre-strain dynamic strain scanning. The test temperature was set at 25 °C, and the loading frequency was 5Hz. The results of finite element analysis demonstrated that the maximum strain of the coating is about 9% [27] during long-term storage. Therefore, the pre-strains were selected as 0%, 3%, 6% and 9%, respectively, and the scanning range of the dynamic strain amplitude was 0.1%~10%.

3. Results

3.1. Correlation Analysis of Maximum Elongation and Crosslinking Density

3.1.1. Aging Results of Maximum Elongation

3.1.2. Aging Results of Crosslinking Density

3.1.3. Correlation Analysis

3.2. Analysis and Modeling of Dynamic Mechanical Properties

3.2.1. The Changing Regularity and Modeling Analysis of Loss Factor tanδ

3.2.2. Crosslinking Density Modified Model for Payne Effect

3.2.3. Pre-strain Crosslinking Density Modified Model for Payne Effect

4. Conclusions

- The changing mechanisms of the maximum elongation and crosslinking density of HTPB coating with aging time were analyzed, and the exponential function model of the crosslinking density was established. Through the correlation analysis, it was found that there was a good linear relationship between crosslinking density and maximum elongation, and the correlation coefficient R = 0.9539. The crosslinking density can be used as the aging evaluation parameter to analyze the performance of the HTPB coating.

- With the increase of aging time, the Tg of the HTPB coating gradually increased, while Tα, tanβ and tanα decreased. The exponential function model of the loss factor parameters (Tg, Tα, tanβ and tanα) with aging time was established. The correlation coefficients between the model fitting results and the test results were all greater than 0.9100. Furthermore, the functional relationships between the loss factor parameters and crosslinking density were constructed.

- The storage modulus and loss modulus of HTPB coating increased with aging time, and the aging enhanced the Payne effect of the HTPB coating. The crosslinking density was introduced into the Kraus model as the aging evaluation parameter, and the crosslinking density-modified model for the Payne effect was established. The proposed model can solve the problem that the Kraus model has a poor fitting effect under the condition of small strain and on loss modulus, and has improved the correlations between model fitting results and test results.

- The storage modulus and loss modulus of HTPB coating decreased with the increase of pre-strain, and the existence of pre-strain weakened the Payne effect of HTPB coating. Considering the effect of stress relaxation, a pre-strain crosslinking density modified model for the Payne effect was established. The correlation coefficients between the fitting results and the test results were all greater than 0.9960, which can be effectively used in the description of the Payne effect of an HTPB coating under pre-strain.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sekkar, V.; Alex, A.S.; Kumar, V.; Bandyopadhyay, G.G. Pot life extension of hydroxyl terminated polybutadiene based solid propellant binder system by tailoring the binder polymer microstructure. J. Macromol. Sci. A 2017, 54, 171–175. [Google Scholar] [CrossRef]

- Moon, B.; Jun, N.; Park, S.; Seok, C.S.; Hong, U. A study on the modified Arrhenius equation using the oxygen permeation block model of crosslink structure. Polymers 2019, 11, 136. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.H.; Yu, P.S.; Dong, S.H. The influence of crosslink density on the failure behavior in amorphous polymers by molecular dynamics simulations. Materials 2016, 9, 234. [Google Scholar] [CrossRef] [Green Version]

- Zhao, F.; Bi, W.N.; Zhao, S.G. Influence of crosslink density on mechanical properties of natural rubber vulcanizates. J. Macromol. Sci. B 2011, 50, 1460–1469. [Google Scholar] [CrossRef]

- Katarzyna, B.; Louis, R.; Jerzy, D.; Wilma, D.; Anke, B.; Dariusz, B. Influence of network structure on glass transition temperature of elastomers. Materials 2016, 9, 607. [Google Scholar]

- Fox, T.G.; Loshaek, S. Influence of molecular weight and degree of crosslinking on the specific volume and glass temperature of polymers. J. Polym. Sci. 1955, 15, 371–390. [Google Scholar] [CrossRef]

- Gillen, K.T.; Celina, M.; Bernstein, R. Validation of improved methods for predicting long-term elastomeric seal lifetimes from compression stress–relaxation and oxygen consumption techniques. Polym. Degrad. Stab. 2003, 82, 25–35. [Google Scholar] [CrossRef]

- Stan, F.; Fetecau, C. Study of stress relaxation in polytetrafluoroethylene composites by cylindrical macroindentation. Compos. Part B Eng. 2013, 47, 298–307. [Google Scholar] [CrossRef]

- Siouris, S.; Shaw, B.; Wilson, C. Method for the evaluation of elastomeric seals by compression stress relaxation. Polym. Test. 2013, 32, 1299–1305. [Google Scholar] [CrossRef]

- Celina, M.; Minier, L.; Assink, R. Development and application of tools to characterize the oxidative degradation of AP/HTPN/AL propellants in a propellant reliability study. Thermochim. Acta 2002, 384, 343–349. [Google Scholar] [CrossRef]

- Byungwoo, M.; Jongmin, L.; Soo, P.; Chang-Sung, S. Study on the aging behavior of natural rubber/butadiene rubber (NR/BR) blends using a parallel spring model. Polymers 2018, 10, 658. [Google Scholar]

- Baboo, M.; Sharma, K.; Saxena, N.S. Viscosity glass transition and activation energy of solid cis-polyisoprene and trans-polyisoprene blends. Phase Transit. 2011, 84, 901–907. [Google Scholar] [CrossRef]

- Fu, W.; Wang, L. Research on Payne effect of natural rubber reinforced by graft-modified silica. J. Appl. Polym. Sci. 2016, 133, 43891–43898. [Google Scholar] [CrossRef]

- Gan, S.; Wu, Z.L.; Xu, H.; Song, Y.H.; Zheng, Q. Viscoelastic behaviors of carbon black gel extracted from highly filled natural rubber compounds: Insights into the Payne effect. Macromolecules 2016, 49, 1454–1463. [Google Scholar] [CrossRef]

- Kraus, G.J. Mechanical losses in carbon-black-filled rubbers. Appl. Polym. Symp. 1984, 39, 75–92. [Google Scholar]

- Ulmer, J.D. Strain dependence of dynamic mechanical properties of carbon black-filled rubber compounds. Rubber Chem. Technol. 1996, 69, 15–47. [Google Scholar] [CrossRef]

- Cho, J.H.; Youn, S.K. A viscoelastic constitutive model of rubber under small oscillatory load superimposed on large static deformation considering the Payne effect. Arch. Appl. Mech. 2006, 75, 275–288. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Chen, L.; Su, B.L.; Wang, Y.S. Evolution of Payne effect of silica-filled natural rubber in curing process. J. Rubber Res. 2019, 22, 127–132. [Google Scholar] [CrossRef]

- Azoug, A.; Constantinescu, A.; Pradeilles-Duval, R.M.; Vallat, M.F.; Neviére, R. Effect of the sol fraction and hydrostatic deformation on the viscoelastic behavior of prestrained highly filled elastomers. J. Appl. Polym. Sci. 2013, 127, 1772–1780. [Google Scholar] [CrossRef]

- Thorin, A.; Azoug, A.; Constantinescu, A. Influence of prestrain on mechanical properties of highly-filled elastomers: Measurements and modeling. Polym. Test. 2012, 31, 978–986. [Google Scholar] [CrossRef] [Green Version]

- Kergourlay, G.; Balmès, E.; Legal, G. A characterization of frequency-temperature-prestress effects in viscoelastic films. J. Sound Vib. 2006, 297, 391–407. [Google Scholar] [CrossRef]

- Leu, L.J.; Mukherjee, S. Sensivity analysis of hyperelastic-viscoplastic solids undergoing large deformations. Comput. Mech. 1994, 15, 101–116. [Google Scholar]

- DeLuca, L.T.; Galfetti, L.; Maggi, F.; Colomb, G.; Merotto, L.; Boiocchi, M.; Paravan, C.; Reina, A.; Tadini, P.; Fanton, L. Characterization of HTPB-based solid fuel formulations: Performance, mechanical properties, and pollution. Acta Astronaut. 2013, 92, 150–162. [Google Scholar] [CrossRef]

- Reshmi, S.; Arunan, E.; Nair, C.P.R. Azide and alkyne terminated polybutadiene binders: Synthesis, cross-linking, and propellant studies. Ind. Eng. Chem. Res. 2014, 53, 16612–16620. [Google Scholar] [CrossRef]

- Bystritskaya, E.V.; Monakhova, T.V.; Ivanov, V.B. TGA application for optimizing the accelerated aging conditions and predictions of thermal aging of rubber. Polym. Test. 2013, 32, 197–201. [Google Scholar] [CrossRef]

- García-Moreno, I.; Caminero, M.Á.; Rodríguez, G.P.; López-Cela, J.J. Effect of thermal ageing on the impact and flexural damage behaviour of carbon fibre-reinforced epoxy laminates. Polymers 2019, 11, 160. [Google Scholar] [CrossRef] [Green Version]

- Zhou, D.M.; Liu, X.Y.; Sui, X.; Wei, Z.J.; Wang, N.F. Elongation aging model of HTPB propellant under constant strain. J. Propul. Technol. 2017, 38, 207–213. [Google Scholar]

- Zou, S.S.; Yan, C.C.; Ma, C.R.; Xia, X.H. The dualistic linear regression model of HTPB propellant’s elongation under constant strain. J. Proj. Rocket. Missiles Guid. 2013, 33, 131–133. [Google Scholar]

- Chen, H.J.; Teng, K.N.; Li, B.; Gu, J.Y. A research of solid rocket motor grain storage life forecast based on modified Arrhenius method. J. Proj. Rocket. Missiles Guid. 2011, 31, 232–235. [Google Scholar]

- Chi, X.H.; Pang, A.M.; Peng, S. Studies on the aging of HTPB liner for NEPE propellant (II)-A stress relaxation model with aging effects based on chemical parameters. J. Solid Rocket Technol. 2010, 33, 435–439. [Google Scholar]

- Pimolsiriphol, V.; Saeoui, P.; Sirisinha, C. Relationship among thermal ageing degradation, dynamic properties, cure systems and antioxidants in natural rubber vulcanisates. Polym. Plast. Technol. Eng. 2007, 46, 113–121. [Google Scholar] [CrossRef]

- Choi, S.S.; Kim, J.C.; Lee, S.G.; Joo, Y.L. Influence of the cure systems on long time thermal aging behaviors of NR composites. Macromol. Res. 2008, 16, 561–566. [Google Scholar] [CrossRef]

- Layton, L.H. Chemical Structural Aging Studies on HTPB Propellant; AD-A010731; National Technical Information Service: Springfield, WV, USA, 1975. [Google Scholar]

- COSTIND. The Method for Temperature Accelerated Aging of Composite Solid Propellant; QJ2328A-2005; COSTIND: Beijing, China, 2005. [Google Scholar]

- Azoug, A.; Constantinescu, A.; Nevière, R.; Jacob, G. Microstructure and deformation mechanisms of a solid propellant using 1H NMR spectroscopy. Fuel 2015, 148, 39–47. [Google Scholar] [CrossRef]

- Lucchelli, E.; Tomka, I.; Vancso, G.; Yeh, P.L. Numerical evaluation of the thermodynamic equation for the state of polymer melts from pressure-volume-temperature (pVT) data. Polym. Bull. 1988, 20, 569–576. [Google Scholar] [CrossRef]

- Mitra, S.; Ahire, A.; Mallik, B.P. Investigation of accelerated aging behaviour of high performance industrial coatings by dynamic mechanical analysis. Prog. Org. Coat. 2014, 77, 1816–1825. [Google Scholar] [CrossRef]

- Baboo, M.; Dixit, M.; Sharma, K.; Saxena, N.S. Effect of temperature on thermal transport and mechanical properties of trans-polyisoprene. A.I.P. Proc. 2010, 1249, 87–90. [Google Scholar]

- Wang, F.F.; Chang, H.; Zhang, L.J.; Wang, Q. Relationship between crosslinking density and mechanical properties in the aging process of casting polymer bonded explosive. Chin. J. Expl. Propell. 2017, 40, 69–74. [Google Scholar]

- Xiang, K.W.; Wang, X.A.; Huang, G.S.; Zheng, J.; Huang, J.Y.; Li, G.X. Thermal ageing behavior of styrene-butadiene random copolymer: A study on the ageing mechanism and relaxation properties. Polym. Degrad. Stab. 2012, 97, 1704–1715. [Google Scholar] [CrossRef]

- Hill, L.W. Calculation of crosslink density in short chain networks. Prog. Org. Coat. 1997, 31, 235–243. [Google Scholar] [CrossRef]

- Neogi, C.; Bhattacharya, A.K.; Bhowmick, A.K. Dynamic mechanical analysis of carbon black filled rubber compounds under swollen conditions. Rubber Chem. Technol. 1989, 62, 651–659. [Google Scholar]

- Heinrich, G.; Klüppel, M. Recent advances in the theory of filler networking in elastomers. In Filled Elastomers Drug Delivery Systems. Advances in Polymer Science; Lee, K.S., Ed.; Springer: Berlin/Heidelberg, Germany, 2002; Volume 160, pp. 1–44. [Google Scholar]

- Vieweg, S.; Unger, R.; Heinrich, G.; Donth, E. Comparison of dynamic shear properties of styrene-butadiene vulcanizates filled with carbon black or polymeric fillers. J. Appl. Polym. Sci. 1999, 73, 495–503. [Google Scholar] [CrossRef]

- Wang, Z.; Qiang, H.; Wang, G.; Huang, Q. Tensile mechanical properties and constitutive model for HTPB propellant at low temperature and high strain rate. J. Appl. Polym. Sci. 2015, 132, 42104. [Google Scholar] [CrossRef]

| Parameters | ν0 | k | α | R |

|---|---|---|---|---|

| Fitting Results | 2.0059 | 0.1151 | −0.4967 | 0.9864 |

| Paremeters | Fitting Equation | Correlation Coefficient R |

|---|---|---|

| Tβ | Tβ = 3.4927exp(0.0252t) − 58.4671 | 0.9728 |

| Tα | Tα = 10.7218exp(−0.0386t) + 45.9629 | 0.9183 |

| tanβ | tanβ = 0.0474exp(−0.0893t) + 0.6867 | 0.9368 |

| tanα | tanα = 0.0152exp(−0.1846t) + 0.1778 | 0.9480 |

| 0 | 8.1502 | 2.3803 | 0.5042 |

| 6 | 8.3056 | 2.5024 | 0.5043 |

| 12 | 8.3562 | 2.9747 | 0.9089 |

| 20 | 8.4099 | 2.0871 | 1.1104 |

| 30 | 6.3903 | 6.0678 | 1.1108 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Zheng, J.; Yu, G. Influence of Thermally-Accelerated Aging on the Dynamic Mechanical Properties of HTPB Coating and Crosslinking Density-Modified Model for the Payne Effect. Polymers 2020, 12, 403. https://doi.org/10.3390/polym12020403

Du Y, Zheng J, Yu G. Influence of Thermally-Accelerated Aging on the Dynamic Mechanical Properties of HTPB Coating and Crosslinking Density-Modified Model for the Payne Effect. Polymers. 2020; 12(2):403. https://doi.org/10.3390/polym12020403

Chicago/Turabian StyleDu, Yongqiang, Jian Zheng, and Guibo Yu. 2020. "Influence of Thermally-Accelerated Aging on the Dynamic Mechanical Properties of HTPB Coating and Crosslinking Density-Modified Model for the Payne Effect" Polymers 12, no. 2: 403. https://doi.org/10.3390/polym12020403

APA StyleDu, Y., Zheng, J., & Yu, G. (2020). Influence of Thermally-Accelerated Aging on the Dynamic Mechanical Properties of HTPB Coating and Crosslinking Density-Modified Model for the Payne Effect. Polymers, 12(2), 403. https://doi.org/10.3390/polym12020403